SATEL CA-64 PTSA 7

5. Connecting power supply

Never connect two devices with a power supply unit to one transformer.

Prior to connecting transformer to the circuit from which it will be supplied, the circuit

must be deenergized.

It is not permissible to connect a fully discharged battery to the mimic board (when the

voltage across battery terminals with no load connected drops below 11 V). To avoid

damage to the equipment, the battery, if deeply discharged or not used for a long time,

must be pre-charged with a suitable charger.

The mimic board requires 18 V AC (±10%) supply. It is recommended that at least 40 VA capacity

transformer be used. The transformer should be permanently connected to the 230 V AC mains.

Before you proceed to making cable connections, familiarize yourself with the electrical system in the

facility. To supply the device, you should choose a circuit which is always alive and properly

protected. Instruct the user of the device on how the transformer should be disconnected from the

mains (e.g. by showing him/her the fuse protecting the supply circuit).

For a backup power supply, use a 12 V sealed lead-acid battery.

Note: If the battery voltage drops below 11 V for more than 12 minutes (3 battery tests), the mimic

board will signal a battery trouble alarm. After the voltage goes down to abt. 9,5 V, the battery

will be disconnected.

5.1 Power connection procedure

1. Deenergize the 230 V AC circuit to which the transformer is to be connected.

2. Connect the 230 V AC cables to the terminals of transformer primary winding.

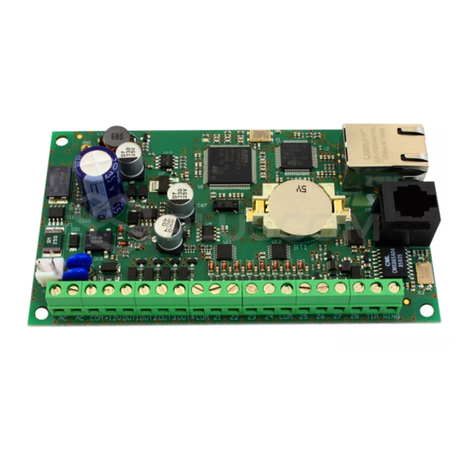

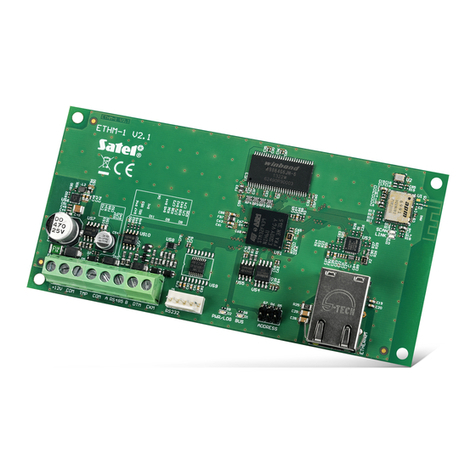

3. Connect the terminals of transformer secondary winding to the AC terminals on the electronics

board of CA-64 PTSA device.

4. Connect the battery to the dedicated leads (the red one to battery plus, the black one to minus).

The mimic board will not start when the battery alone is connected. Do not cut off the

terminals of battery cables.

5. To start the mimic board, turn on 230 V AC power supply in the circuit to which the transformer is

connected.

The above power-up sequence (first the battery, then 230 V AC) will enable proper operation of the

power supply unit and electronic protection circuits of the mimic board.

Note: If it is necessary to disconnect power supply from the mimic board, disconnect the mains first

and the battery after that. To re-connect power supply, follow the procedure described above.

6. Specifications

Supply voltage ................................................................................................ 18 V AC ±10%, 50–60 Hz

Standby current consumption*.......................................................................................................25 mA

Maximum current consumption* ....................................................................................................40 mA

* without battery charging current and connected LEDs

Type of power supply unit ......................................................................................................................A

Power supply output current ............................................................................................................1,3 A

Battery trouble reporting voltage.............................................................................................11 V ±10%

Battery cut-off voltage ............................................................................................................9.5 V ±10%

Battery charging current...............................................................................................................350 mA

Environmental class............................................................................................................................... II

Working temperature range ............................................................................................ -10 °C…+55 °C

Maximum humidity ........................................................................................................................ 93±3%

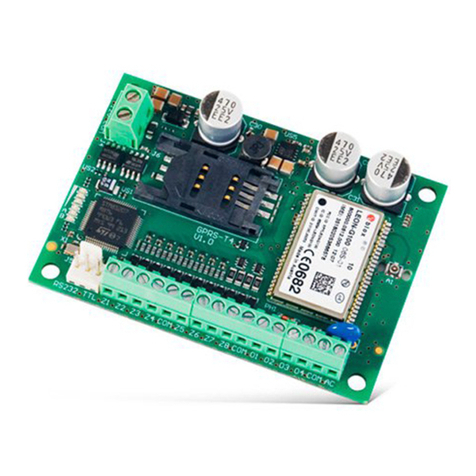

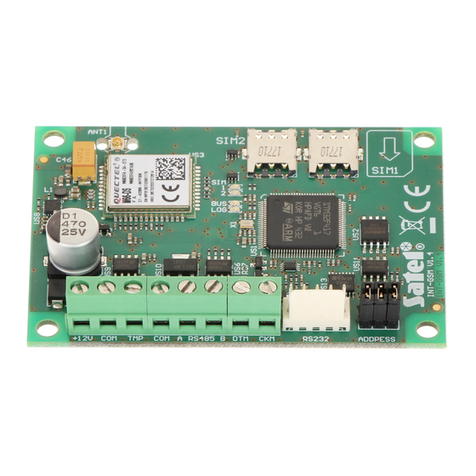

Electronics board dimensions ........................................................................................173x102x37 mm

Weight............................................................................................................................................. 202 g