Tecnoma VECTIS 800e User guide

VECTIS 800e - 1000e

1000 - 1200

Adjustments, Use and Maintenance

Read carefully before to use the sprayer

990241F Appril 2015

MAY-2015 3

990241

INDEX

1 - MACHINE IDENTIFICATION

1.1 - SEAL OF THE AUTHORIZED DEALER....................................................................................................................................................................................... 7

1.2 - BRAND PLATE............................................................................................................................................................................................................................. 7

2 - GENERAL INFORMATION

2.1 - FOREWORD ................................................................................................................................................................................................................................ 9

2.2 -THE USER INSTRUCTIONS ....................................................................................................................................................................................................... 9

2.2.1- Product improvements ...............................................................................................................................9

2.2.2- User warning..............................................................................................................................................9

2.3 - GENERAL COMMUNICATIONS .................................................................................................................................................................................................. 9

2.3.1 - Denitions ..................................................................................................................................................9

2.3.2- Conventions used ....................................................................................................................................10

2.4 - EXPECTED USAGE CONDITIONS.......................................................................................................................................................................................... 10

2.4.1- Machine functions ...................................................................................................................................10

2.4.2 - Operator qualications .............................................................................................................................11

2.4.3- Working conditions...................................................................................................................................11

2.5 - INFORMATION FROM AUTHORISED DEALER ........................................................................................................................................................................11

2.5.1- Commissioning ........................................................................................................................................11

2.6 - INFORMATION ON OWNER ......................................................................................................................................................................................................11

2.7 -APPENDIX ................................................................................................................................................................................................................................. 12

3 - GENERAL SAFETY

3.1 - FOREWORD .............................................................................................................................................................................................................................. 13

3.2 - USE OF AN AGRICULTURAL MACHINE. ................................................................................................................................................................................. 13

3.3 - USING CROP TREATMENT PRODUCTS ................................................................................................................................................................................. 14

3.4 - CONVENTIONS RELATING TO SAFETY SYMBOLS ............................................................................................................................................................... 15

3.5 - RECOMMENDATIONS PRIOR TO USE.................................................................................................................................................................................... 15

3.5.1- User manual.............................................................................................................................................15

3.5.2 -Protection of persons ...............................................................................................................................16

3.5.3- Safety and protection systems.................................................................................................................16

3.6 - RISKS RELATED TO THE USE OF THE MACHINE ................................................................................................................................................................. 16

3.6.1- Hitching the machine ...............................................................................................................................17

3.6.2- Power take-off and drive shafts................................................................................................................18

3.6.3-Tyres ........................................................................................................................................................18

3.6.4- Braking systems......................................................................................................................................19

3.6.5- Driving onroads........................................................................................................................................19

3.6.6-Transport on a truck.................................................................................................................................20

3.6.7- Before getting off the tractor.....................................................................................................................20

3.6.8- Other risks ...............................................................................................................................................20

3.6.9- Risks incurred if the safety recommendations are not followed...............................................................22

3.7 - CLEANING, MAINTENANCE AND REPAIR .............................................................................................................................................................................. 22

3.7.1- Cleaning your machine ............................................................................................................................22

3.7.2- Maintenance and repair ...........................................................................................................................22

3.8 - MODIFICATIONS TO THE MACHINE........................................................................................................................................................................................ 24

3.9 - ENVIRONMENTAL PROTECTION ............................................................................................................................................................................................ 24

3.10 - WARNING PICTOGRAMS AND OTHER MARKINGS............................................................................................................................................................. 24

3.10.1- Description of warning pictograms ........................................................................................................24

4 - DECRIPTION OF THE MACHINE

4.1 - GENERAL CHARACTERISTICS ............................................................................................................................................................................................... 25

4.1.1-Tanks .......................................................................................................................................................25

4.1.2- Chassis ....................................................................................................................................................25

4.1.3 -Hitching boom ..........................................................................................................................................25

4.1.4-Axle ..........................................................................................................................................................25

MAY-2015 4

4.1.5- Pump........................................................................................................................................................25

4.1.6- Filtration ..................................................................................................................................................25

4.1.7- REGULAIR adjustment ...........................................................................................................................26

4.1.8- VENTILATION..........................................................................................................................................26

4.1.9 -Compatible booms ...................................................................................................................................26

4.1.10- Options With pneumatic equipment .......................................................................................................27

4.1.11 - Options With PRECIJET equipment.......................................................................................................28

4.2 - CONFORMITY ........................................................................................................................................................................................................................... 29

4.3 - NOISE MEASUREMENTS ......................................................................................................................................................................................................... 30

4.3.1- Values .....................................................................................................................................................30

4.3.2- reference Measurement appliance ..........................................................................................................30

4.4 - TECHNICAL CHARACTERISTICS ............................................................................................................................................................................................ 31

4.4.1- BRAKING.................................................................................................................................................31

4.4.2- Sprayer weight .........................................................................................................................................31

4.4.3- Sprayer dimensions .................................................................................................................................33

4.4.4-Tank characteristics .................................................................................................................................34

4.4.5- Equipment for road travel.........................................................................................................................35

4.4.6- Characteristics of the pumps and other components...............................................................................35

4.5 - PRESENTATION OF ASSEMBLIES .......................................................................................................................................................................................... 36

4.6 - PRINCIPLE DIAGRAMS OF THE SPRAYING CIRCUIT ........................................................................................................................................................... 37

4.7 - SAFETY PICTOGRAMS ............................................................................................................................................................................................................ 37

4.7.1- Position of the pictograms........................................................................................................................38

4.7.2- Explanation of the pictograms..................................................................................................................38

4 - COMMISSIONING THE MACHINE

4.1 - RECEPTION OF THE MACHINE............................................................................................................................................................................................... 41

4.1.1- Introduction ..............................................................................................................................................41

4.1.2 -Unloading - loading ..................................................................................................................................41

4.1.3- Receipt check ..........................................................................................................................................42

4.2 - COMMISSIONING ..................................................................................................................................................................................................................... 42

4.2.1- Environment.............................................................................................................................................42

4.2.2- Checking the required characteristics of the tractor.................................................................................42

4.2.3 - Qualication of the operator.....................................................................................................................43

4.2.4 -Preparation for assembly .........................................................................................................................43

4.2.5-Tyres ........................................................................................................................................................44

4.2.6-Axles ........................................................................................................................................................45

4.2.7- Hitching - Uncoupling the machine .........................................................................................................47

4.2.8- Installation of the drive shaft transmission ...............................................................................................49

4.2.9- Electrical connections ..............................................................................................................................52

4.2.10- Hydraulic assemblies .............................................................................................................................53

4.2.11 - Connecting the hydraulic functions (SC type connection)......................................................................53

4.2.12- Connecting the hydraulic functions (ED type connection) .....................................................................54

4.2.13- Hydraulic unit centre open / centre closed / LS option...........................................................................54

4.2.14- Immobilising the tractor - machine combination.....................................................................................55

4.3 -ADDITIONAL DOCUMENTS ...................................................................................................................................................................................................... 55

4.4 - RINSING / SPRAY TEST ........................................................................................................................................................................................................... 56

5 - USING THE MACHINE

5.1 - RECOMMENDATIONS BEFORE USE ...................................................................................................................................................................................... 57

5.1.1 -General checks ........................................................................................................................................59

5.2 - COUPLING AND UNCOUPLING ............................................................................................................................................................................................... 60

5.3 - DRIVE SHAFT............................................................................................................................................................................................................................ 60

5.3.1-Assembling the drive shaft onto the machine. .........................................................................................60

5.3.2- Coupling the drive shaft ...........................................................................................................................60

5.3.3- Uncoupling the drive shaft .......................................................................................................................61

5.4 - OPERATING PRINCIPLE OF THE SPRAYER .......................................................................................................................................................................... 61

5.5 - WORKSTATIONS....................................................................................................................................................................................................................... 63

MAY-2015 5

5.6 - USING THE VALVES ................................................................................................................................................................................................................. 64

5.6.1- Suction valve............................................................................................................................................64

5.6.2- Valve for output to LAV'TON, Eductor or Accessory ................................................................................64

5.6.3-Accessory valve / Regulation activation...................................................................................................64

5.6.4- Valve controlling tank returns from decompressions................................................................................64

5.6.5-Agitator valves..........................................................................................................................................65

5.6.6- Eductor accessories valve .......................................................................................................................65

5.6.7- Valves for LAV'BOX and eductor rinsing..................................................................................................66

5.7 - MAIN FUNCTIONS THAT ARE POSSIBLE ............................................................................................................................................................................... 66

5.8 - USING THE FUNCTIONS.......................................................................................................................................................................................................... 67

5.8.1- Filling the tanks .......................................................................................................................................67

5.8.2- Incorporating plant treatment products ....................................................................................................68

5.8.3 -adjusting spraying ....................................................................................................................................70

5.8.4- Spraying...................................................................................................................................................70

5.8.5- Rinsing the spray mixture tank using the LAV'TON washers...................................................................73

5.8.6- Cleaning the outside of the sprayer. ........................................................................................................74

5.8.7- Rinsing the hopper and the packaging (Lav'box).....................................................................................74

5.8.8- Rinsing just the boom with the rinsing tank. ............................................................................................75

5.8.9-Agitation of the spray mixture tank ..........................................................................................................76

5.8.10- Connecting an accessory.......................................................................................................................77

5.8.11 - Cleaning the spraying lters and working on the circuits .......................................................................77

5.8.12- Fast stop ................................................................................................................................................78

5.8.13- Rinsing with a cleaning product .............................................................................................................78

5.8.14- Rinsing and protecting from frost ...........................................................................................................79

5.9 - PREPARING THE SPRAY MIXTURE ........................................................................................................................................................................................ 80

5.9.1- Pesticides used........................................................................................................................................81

5.10 - SPRAYER PARTS.................................................................................................................................................................................................................... 81

5.10.1- Main tank (spray mixture) ....................................................................................................................81

5.10.2- Rinsing tank ...........................................................................................................................................87

5.10.3- Hand wash tank (15 litres) .....................................................................................................................87

5.10.4- Spray pump............................................................................................................................................88

5.10.5-AUTONET integrated .............................................................................................................................89

5.10.6- Electric compressor for pneumatic assistance (Regulair regulation) .....................................................92

5.10.7- Solenoid valves......................................................................................................................................93

5.10.8- MANUAL CONNECTION AND REPAIRS ...........................................................................................94

5.10.9-Axles .....................................................................................................................................................94

5.10.10- Step......................................................................................................................................................95

5.10.11 -The safety of the automatic coupling....................................................................................................95

5.10.12- BRAKING.............................................................................................................................................95

5.10.13- Draw bars.............................................................................................................................................96

5.10.14- Stand....................................................................................................................................................97

5.10.15-Tyres ....................................................................................................................................................97

5.10.16- Hydraulic assemblies ...........................................................................................................................98

5.10.17- VENTILATION COLUMN .....................................................................................................................98

5.10.18- EQUIPMENT OPERATION................................................................................................................100

5.11 - HIGHWAY TRAVEL ................................................................................................................................................................................................................ 101

5.12 - STOPPING THE MACHINE .................................................................................................................................................................................................. 101

5.13 - TROUBLESHOOTING ........................................................................................................................................................................................................... 102

6 - MACHINE MAINTENANCE

6.1 - SPRAYER GENERAL MAINTENANCE ................................................................................................................................................................................... 105

6.1.1- Regular checks of sprayers ...................................................................................................................109

6.2 - REPAIRS.................................................................................................................................................................................................................................. 109

6.3 - SPRAYER SCRAPPING ...........................................................................................................................................................................................................110

6.4 - CLEANING ................................................................................................................................................................................................................................110

6.4.1- Internal cleaning of the sprayer..............................................................................................................110

6.4.2- External cleaning of the sprayer ............................................................................................................ 111

MAY-2015 6

6.5 - SERVICING VECTIS.................................................................................................................................................................................................................113

6.5.1- Periodic towed sprayer inspections .......................................................................................................113

6.5.2- Greasing VECTIS ..................................................................................................................................113

6.5.3- Ventilation column..................................................................................................................................114

6.5.4- Hydraulic and spray circuits ...................................................................................................................116

6.5.5-Axles .....................................................................................................................................................117

6.5.6-Tyres ......................................................................................................................................................117

6.5.7- Filtering .................................................................................................................................................118

6.5.8- Servicing the solenoid valves.................................................................................................................119

6.5.9- Servicing the spray pump ......................................................................................................................119

7 - ENVIRONMENTAL PROTECTION

7.1 - PREVENTIVE MEASURE ........................................................................................................................................................................................................ 121

7.1.1- Foreword................................................................................................................................................121

7.1.2 - Tanks lling.............................................................................................................................................121

7.1.3- Spraying preparation..............................................................................................................................121

7.1.4- Spraying.................................................................................................................................................122

7.1.5-Transportation ........................................................................................................................................122

7.1.6- Handling of residues ..............................................................................................................................122

7.1.7- External cleaning of the sprayer ............................................................................................................123

7.1.8- Handling of waste products....................................................................................................................123

7.1.9-Air Pollution ............................................................................................................................................123

7.1.10- Rejection .............................................................................................................................................123

7.2 - OPERATING CONDITIONS..................................................................................................................................................................................................... 124

7.3 - COMPATIBLE NOZZLES AND FILTERS ................................................................................................................................................................................ 124

7.3.1- Nozzle types and sizes ..........................................................................................................................124

7.3.2- Filtering component types and sizes......................................................................................................125

7.4 - INSTRUCTIONS FOR MAINTENANCE .................................................................................................................................................................................. 125

7.5 -TYPES OF PESTICIDES LIKELY TO AFFECT SPRAYER EFFICIENCY................................................................................................................................ 125

7.5.1- Products that may cause failure of the sprayer.....................................................................................125

7.6 - PESTICIDES USED ................................................................................................................................................................................................................. 126

7.7 - CONNECTION AND USE OF EQUIPMENT ............................................................................................................................................................................ 126

7.8 - NATIONAL REGULATIONS ..................................................................................................................................................................................................... 126

7.9 - CHARACTERISTICS TO BE MONITORED TO ENSURE CORRECT OPERATION OF THE SPRAYER .............................................................................. 127

7.9.1- Pressure measurement on boom sections. ...........................................................................................127

7.9.2- Pressure measurement in hydraulic oil system.(depend of your machine) ...........................................127

8 - PERSONAL NOTES

9 - INDEX

May-2015 7

Chapter 1

1 - MACHINE IDENTIFICATION

1.1- SEAL OF THE AUTHORIZED DEALER

1.2- BRAND PLATE

NAME of the DEVICE: .....................................

..........................................................................

NAME of the EQUIPMENT: .............................

..........................................................................

Frame Number: ................................................

..........................................................................

Do not remove the constructor

and brand plates from the

machine.

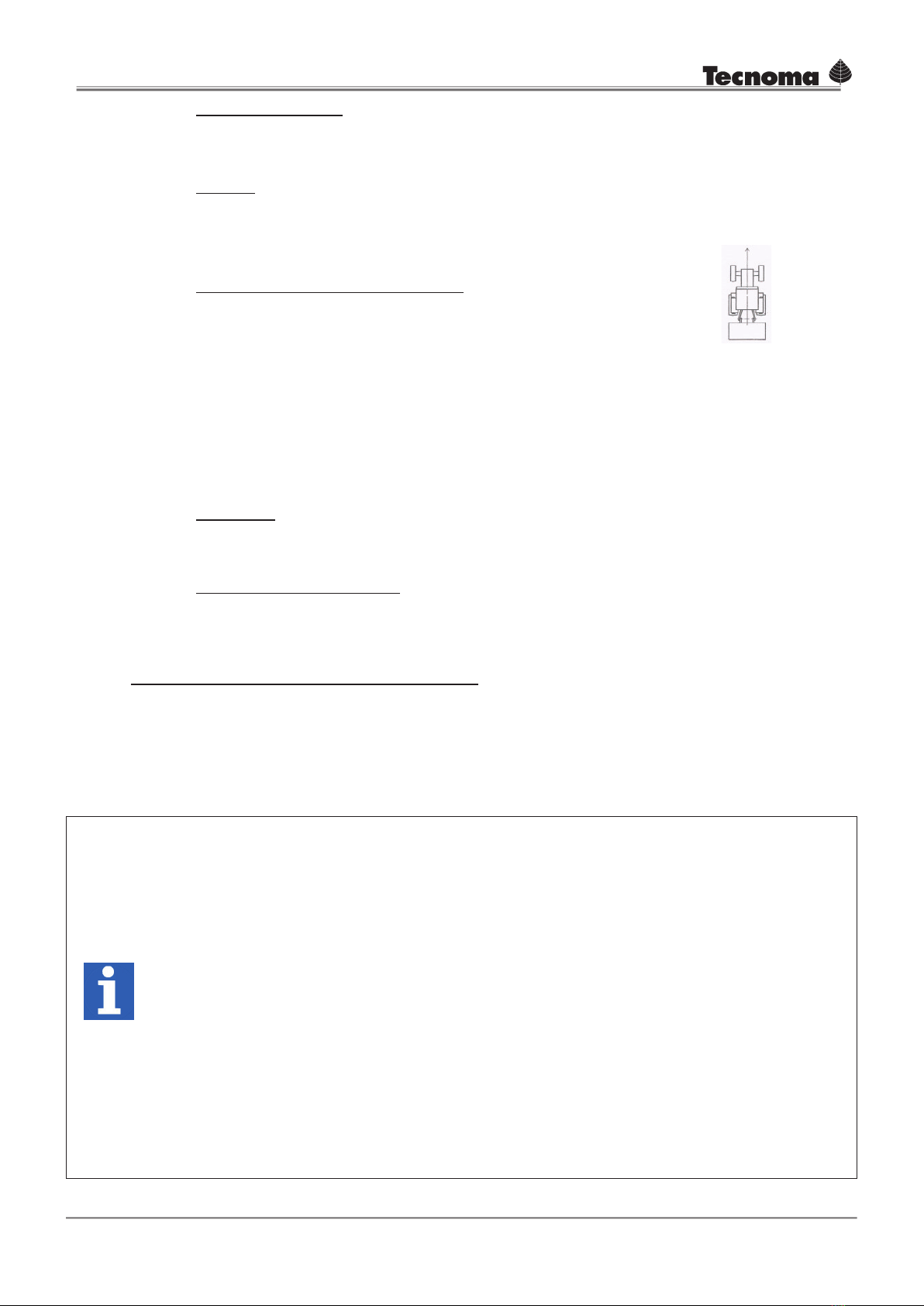

To visualise the positioning of the plate on the

equipment and the information concerning

the different marking areas, refer to chapter

MACHINE DESCRIPTION

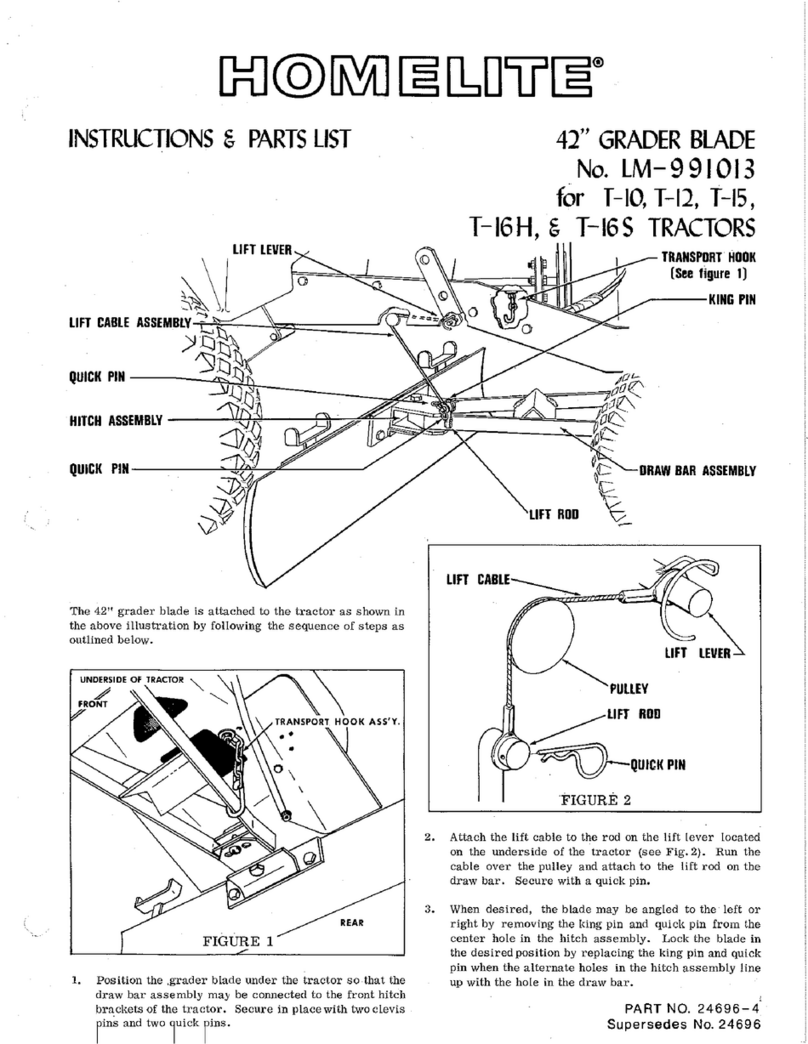

Fig.1

May-2015 8

– MACHINE IDENTIFICATION –

9May-2015

CHAPTER 2

2.1- FOREWORD

We recommend that the dealers of this new or used machine and/or equipment keep a written proof that this

sheet was indeed supplied with this machine and/or equipment (Phytomieux Chart).

2.2- THE USER INSTRUCTIONS

The original user manual is written and published in French. All foreign language versions are translations of

the original. In the event of contradiction, inaccuracy or digression between the original version in French and

versions in other languages, the original in French shall prevail.

•Description of machine or equipment operation and maintenance methods

•Provides instructions for a perfectly safe use of the machinery

•It is an integral part of the machine.

•Should be kept in the tractor cabin

•Must be thoroughly read by all machine users

If, in spite of the information provided in this manual, some points remain unclear, contact your Authorized

Tecnoma Dealer or, if not possible, contact Tecnoma see chapter MACHINE IDENTIFICATION

. Tecnoma

has paid due diligence to the writing of this manual in order to make it as complete and precise as possible, and

shall not be held liable for any possible omissions or imprecision.

2.2.1 - PRODUCT IMPROVEMENTS

Tecnoma continuously strives to improve its products and therefore reserves the right to perform the

modications deemed necessary for improvement without prior warning and without being required to perform

modications or improvements on machines or equipment that has already been sold.

Any modication on Tecnoma machines and/or equipment is prohibited , except for modications expressly

authorized in writing by After Sales Services or Tecnoma Technical Department.

2.2.2 - USER WARNING

We regularly updated our instructions and are open to your suggestions for improvements of our documents.

2.3- GENERAL COMMUNICATIONS

2.3.1 - DEFINITIONS

2.3.1.1 Hazardous area

All areas inside and/or in the vicinity of a machine in which there is a risk for the safety or health of an exposed

individual.

2.3.1.2 Exposed person

Any individual partially or completely present in the dangerous zone.

2.3.1.3 Operator - Driver

The individual or individuals responsible for the installation, operation, adjustments, cleaning, repair of breakdowns

and transportation of a machine.

2.3.1.4 Authorised dealer

Any individual who has benetted from an agreement with Tecnoma regarding the specic training that has

been provided by Tecnoma.

2 - GENERAL INFORMATION

10May-2015

– GENERAL INFORMATION –

2.3.1.5 Right Side - Left Side

All indications of direction in the instruction manual are provided in relation to the direction of travel

2.3.1.6 Machine

Generic term to refer to the sprayer

2.3.2 - CONVENTIONS USED

2.3.2.1 Operation recommendations, reactions

The operations are shown in the form of a numbered list which it is advisable

to comply with, the precise operator action can be described (►), the

resulting reaction resulting from the application of the operation or of the

action is shown, where necessary, by an arrow ( → ) for example :

1. Operation 1

1► Action 1 of the operator

→ Result

2. Operation 2

→ Result

2.3.2.2 Illustrations

As Tecnoma is constantly developing its machines, the assembly variations are numerous, the diagrams,

sketches and photos which illustrate these instructions are not contractually binding.

2.3.2.3 References in the illustrations

The bracketed numbers show positions in the illustration, for example (1)

or even (1/g2) refer 1 to illustration 2 of the chapter in question.

2.4- EXPECTED USAGE CONDITIONS

2.4.1 - MACHINE FUNCTIONS

This machine is exclusively intended to be used for current agricultural, forestry or wine making activities, namely

the spreading of phytosanitary products in accordance with environmental regulations

Any other use is considered contrary to normal use and is therefore prohibited.

The consequences of the use of certain phytosanitary products

Beware, certain products can be damaging due to their action on the materials used in the

manufacture of the sprayer. In order to limit the action of these products on the integrity of your

machine it is advisable to :

•Avoid prolonged contacts (approx. 20 hours)

•Never used unauthorised mixtures obtained starting from different phytosanitary products

•Do not use products that have a tendency to solidify or gum up.

•Empty and rinse the equipment immediately after treatment

Your machine is compatible with the use of liquid fertilizers

The sprayer's pump membranes have been designed by Tecnoma, and are resistant to a wide

range of products.

If you have doubts, please contact your Authorized Dealer.

Direction of movement

Left side Right side

Fig.2

11May-2015

– GENERAL INFORMATION –

2.4.2 - OPERATOR QUALIFICATIONS

• The machine can only be used, serviced and repaired by individuals fully conversant

with its mode of operation and safety procedures.

• Before using your machine, insure that you are familiar with all its controls and correct

use.

2.4.3 - WORKING CONDITIONS

CONTROL STATION

The operator must not leave the work station while the machine is moving

unless for a particular maintenance operation (i.e. : lling).

DRIVING

Adapt your speed and driving to the terrain, roads and paths.

Turning angle

It is limited by the transmission characteristics. Exceeding this angle can be damaging to the

machine and void any machine guarantee.

Work speed

Move forward steadily and smoothly.

Working by night

Operate your machine with sufcient lighting, otherwise use articial lighting. Contact your

Authorized Dealer or manufacturer for more information.

2.5- INFORMATION FROM AUTHORISED DEALER

The Authorized Dealer must perform certain procedures when supplying a new Tecnoma machine and/or

equipment.

The machines are made roadworthy under the responsibility of the Authorised Tecnoma. Dealer.

•Check that the machine delivered is compliant with the purchase order.

•Read the Operation and Servicing Manual and all Safety Instructions for the machines.

•Insure that the information indicated on the control lists before delivery and upon delivery are thoroughly

checked and are compliant before delivering Tecnoma Technologies machines to their owners.

•The Authorized Dealer must give his customer complete instructions of the basic principles, operation and

servicing of the machine and the operating limits beyond which safety conditions would be hazardous and

inevitably become a danger to the user.

•The Dealer must give the customer the manuals of the machine.

2.5.1 - COMMISSIONING

Refer to chapter MACHINE COMMISSIONING

(into the manual of the machine)

2.6- INFORMATION ON OWNER

Tecnoma thanks you for purchasing one of its sprayers

The machine is designed and constructed to offer several years of satisfactory operations. However, its operation

and life cycle depend in part on the manner in which it is used and serviced.

•Comply with the recommended safety requirements indicated throughout the manual. Refer to chapter

GENERAL SAFETY

(into the manual of the machine)

12May-2015

– GENERAL INFORMATION –

•Use the equipment as instructed in this manual.

Refer to chapter MACHINE USE

•Maintain this equipment on a daily basis and as instructed in this manual

Refer to chapter MACHINE MAINTENANCE

Use only Tecnoma original parts if you wish to maintain the

validity of the warranty.

•Do not modify the machine.

•Do not use the machine with protection or safety systems that are faulty, poorly installed or not certied by

Tecnoma.

•Do not install optional equipment that is not allowed or out of production.

•Check that the details of your machine or equipment appear in the "MACHINE MAINTENANCE" chapter.

This information will be useful when ordering spare parts from your approved reseller.

CAUTION

•Failure to comply with these rules :

•Can make your machine dangerous

It frees the manufacturer of all responsibility in case of damages or injuries.

•If you have doubts, please contact your Authorized Dealer.

Only Authorized Dealers can provide original parts. They can assemble the parts and offer advice regarding the

assembly and use of these spare parts.

WARRANTY

The start of the guarantee comes into effect on the day of commissioning, providing the

documents are received within 15 days at most.

In the event that these operation and maintenance precautions are not followed, Tecnoma will be

forced to waiver all guarantees or nancial consequences due to the failure to comply with these

recommendations.

2.7- APPENDIX

IMPORTANT

Please see the "APPENDIX" chapter at the end of this manual. Except where indicated to the

contrary, apply the recommendations indicated in this chapter, such as the type of grease to use,

torques to be applied. etc

MAY-2015 13

CHAPTER 3

3 - GENERAL SAFETY

3.1- FOREWORD

For safe usage, follow the instructions in this chapter and in the rest of this manual. You must also obey the

legislation applying to safety precautions, accident prevention, the labour code and the highway code.

Thorough knowledge and a good understanding of the safety rules are also necessary to use the machine safely

and properly.

3.2- USE OF AN AGRICULTURAL MACHINE.

Using an agricultural machine can incur risks for the user, third parties, the machine and even its environment.

To minimise these risks :

•Only use the machine for its intended purpose as stated in GENERAL INFORMATION .

•Always keep the machine in perfect working order and a safe condition.

•Regularly check the tightening torques.

•Regularly inspect the hydraulic circuit and check all connections.

•Before use, always activate the safety and protection systems that must be installed and operational.

•Always call on qualied personnel for the upkeep and maintenance of the machine.

•Clean the machine after use so that the safety labels remain legible and before any maintenance

operations.

•The use of a tractor with a safety cabin is recommended.

•Make sure that your tractor is compatible with your machine :

◊ hitching system

◊ maximum admissible hitching load of the tractor

◊ sufcient turning angle

•If your machine is equipped with a steering axle, do not exceed its steering angle

•Only use the machine in forward gears.

•The machine should be driven by just one person, sitting in the tractor driver's seat.

•Do not walk on the covers or on any other parts of the machine, besides the parts intended for this purpose.

•It is forbidden to transport people, animals or tools on the machine.

•Do not eat, drink or smoke when using or working on contaminated equipment.

•Always keep children well clear of the machine.

•Leave remote controls in the places provided by the manufacturer.

•The fast-coupling release mechanisms must be loosely connected so that they are not only released in the

low position.

•Stay well clear of moving parts.

•Do not wear loose clothing, jewellery or long hair which can be trapped or caught by moving parts.

•Make sure that no persons, animals or obstacles are close to the machine before starting up.

•During boom manoeuvres: WATCH OUT for telephone and electricity lines.

•Do not loiter close to the machine or the boom when it is moving.

•If you hear an unexpected noise or vibration, stop the machine and try to correct the cause of the noise

before resuming. Call your dealer if necessary.

MAY-2015 14

– GENERAL SAFETY –

•Be extremely careful when hitching and unhitching the machine.

•When unhitched, the machine must be parked on a level surface with the hand brake engaged (use chocks

if necessary).

Remember that caution and care are the required to work in safety.

3.3- USING CROP TREATMENT PRODUCTS

This crop sprayer was designed and built by our company to be used with the treatment products of your choosing.

To make sure that the sprayer functions correctly, please strictly follow the recommendations in the User Manual

provided .

As the user, you alone are responsible for following the recommendations given by the manufacturers of the

treatment products you use. The operator must also obtain an approved applicator's certicate and obey the

applicable legislation.

In particular, each user is advised to:

•check the pressure with clear water before incorporating products in the tank.

•Read carefully the treatment product manufacturer's label(s) and follow the instructions therein (dosage,

PPE, etc.);

•Avoid mixing the products unless their compatibility is specically recognised by the manufacturer of the

phytosanitary products;

•Prevent air from entering the sprayer tank when lling to avoid the formation of foam and problems due to

overow;

•Follow the precautions and warnings given by the manufacturer of the phytosanitary products, especially

for the storage of the treatment products, which should be kept in a locked room out of reach of children and

animals;

•Follow the precautions for recycling the packaging, in accordance with the recommendations of the

manufacturers of the phytosanitary products;

•Protect untreated areas;

•Contact the manufacturer of the phytosanitary product (or their representative) if you are in doubt, or if

information is missing.

After treatment, wash and change your clothes. Wash the tools that may have been contaminated.

MAY-2015 15

– GENERAL SAFETY –

3.4- CONVENTIONS RELATING TO SAFETY SYMBOLS

The terms DANGER, WARNING and CAUTION are used with the triangular safety symbol. This symbol

refers to the scale of the risk incurred.

DANGER:

Indicates an immediate and serious danger

Failure to follow the recommendations could lead to death or extremely serious injury (long-term injury,

memory loss).

WARNING

Indicates a potential moderate danger

Failure to follow the recommendations could, under certain conditions, lead to death or extremely serious

injury.

CAUTION

Indicates a low level danger

Failure to follow the recommendations could lead to bodily injury and material damage on a reduced or

moderate scale.

IMPORTANT

Indicates an obligation

Failure to behave properly or to perform the actions described in the recommendations could lead to

accidents or malfunction.

REMARK

Indicates information or advice on use

This advice will enable you to operate your machine to the full.

3.5- RECOMMENDATIONS PRIOR TO USE

3.5.1 - USER MANUAL

IMPORTANT

The manual

Must always be accessible to users and maintenance personnel and should be kept where the

machine is used. It must also be understood.

MAY-2015 16

– GENERAL SAFETY –

3.5.2 - PROTECTION OF PERSONS

Always keep a rst aid kit on hand.

WARNING

Phytosanitary products, oils, antifreeze, solvents

and fuels.

Follow the manufacturers' instructions in order to use

these products in safety.

To avoid any contact with the skin, eyes and mouth,

provide the user with protective gear bearing

the label .

Example of individual protective equipment :

•Gloves and overalls that are resistant to

chemicals

•Waterproof safety footwear

•face protection

•protective goggles

•respiratory protection

•etc...

In the event of an incident, consult a doctor and bring

the label of the product.

Via the mucosa (eyes)

• Splashes

• rubbing eyes with contaminated

hands

via the respiratory system

• dust

• spray mist

• vapour

via the digestive system

• Eating, drinking and smoking during

application or after treatment with

unwashed hands

• accidental ingestion

via the skin

• Splashes

• contact with the treated crops

Main channels of contamination

3.5.3 - SAFETY AND PROTECTION SYSTEMS

•Before use, always activate the safety and and protection systems that must be installed and operational.

•Visually check that these systems are in proper condition on a daily basis.

•It is forbidden to dismantle or to open the protection systems while the sprayer, its equipment or its

elements are working.

WARNING

A faulty guard or device can be the source of serious danger

CAUTION

Never use the sprayer without the screens and protective shields.

3.6- RISKS RELATED TO THE USE OF THE MACHINE

The risks that relate to the specic functions of your machine are addressed in all the chapters of this manual.

WARNING

Beware of the danger of accidents due to electrocution, crushing, cutting, tearing and dragging

by moving mechanisms that may occur if the required safety measures are not taken or due to

insufcient care

If your equipment is provided with a hydraulic ramp, an alarm sounds when the boom is in motion.

The safety pictograms and other markings on the machine indicate the potential risks and provide important

recommendations on the safe use of the machine.

MAY-2015 17

– GENERAL SAFETY –

3.6.1 - HITCHING THE MACHINE

3.6.1.1 General

For assembly, refer to chapter COMMISSIONING THE MACHINE .

•Make sure that the machine is compatible with the tractor

•When hitching the machine to the tractor or when unhitching, place the control lever of the tractor's

hydraulic circuit in the position that prevents any risk of accidental lifting or lowering.

•The machine must be hitched to the tractor using the hitch points provided.

•When hitching or removing the machine, store all support and balance equipment in its proper place (when

provided).

•When manoeuvring, select the slowest forward gear of the tractor.

•Do not stand between the tractor and the machine during three-point lifting manoeuvres by the tractor

(onlookers must stay well clear of the machine in order to guide the driver and wait for the the tractor to stop

completely before proceeding with the nal hitching operation).

•As soon as the machine is hitched, lock the hitching device. Before setting off, check the hitch and make

sure that it is properly locked.

ÖChecks

Once the machine is hitched at the front or the back, make sure that the hitch does not carry any additional loads,

and that the weight is properly distributed on the tractor, so that it remains stable. Make sure the following values

are never exceeded:

•total authorised tractor weight

•authorised tractor axle load

•admissible loads for the tyres

•Do not exceed the maximum permissible load on the tow bars.

•If required, install ballast on the supports on the tractor.

3.6.1.2 Specic case of a machine towed using the lower arms of the lifting system: two hitching points

•Hitch the machine to a tractor equipped with lifting equipment with lateral and vertical locks.

•When driving on roads, comply with the specied height in the instruction manual and block the lifting

system.

3.6.1.3 Detachable drawbar with hitching rings

IMPORTANT

TOWED MACHINES

Refer to chapter MACHINE USE

.

•When detaching / installing the ring, make sure that it is installed the right way round.

•Regularly check the tightening torque of the screws attaching the rings.

MAY-2015 18

– GENERAL SAFETY –

3.6.2 - POWER TAKE-OFF AND DRIVE SHAFTS

For assembly, refer to chapter COMMISSIONING THE MACHINE

DANGER:

It is imperative that the transmission shaft covers be installed and in good condition. Change them

immediately if they are damaged.

3.6.2.1 Safety measures for the tractor's power take-off and the machine's input shaft.

•Before use, check that the speed and direction of rotation of the power take-off on the tractor are

compatible with the intended use of the machine.

•Before use, make sure the power take-off guards are in position and in good condition. Replace them

immediately if they are damaged.

•Do not engage the power take-off clutch of the tractor when the engine is stopped.

•Disengage the power take-off when the angular limit of the transmission shaft is approached, especially

when turning, climbing or descending.

•Any contact between the universal joint shaft and the tractor or machine can cause damage.

•Before working on the transmission or power take-off, disengage the clutch, stop the engine, remove the

key from the ignition and wait until all moving parts have completely stopped.

3.6.2.2 Safety measures for the universal joint shaft:

•Always use the drive shaft provided with the machine or recommended by the manufacturer.

•Make sure that the universal joint shaft tubes are properly covered when in the work or transport positions.

•Follow the safety instructions of the manufacturer of the universal joint drive shaft.

•Before use, check that the transmission shafts are in good working order and that they are correctly

assembled and locked. Always call on a specialist to solve any problems with the transmission.

•Before connecting or disconnecting a universal joint shaft, disengage the power take-off, stop the engine

and remove the key from the ignition

•Before use, make sure the docking chains of the guards are in place

•After disconnecting the universal joint shaft from the tractor's power take-off, install the protective cover.

•Place the uncoupled universal joint shaft on the support provided.

3.6.3 - TYRES

IMPORTANT

TOWED MACHINES

•Work on the tyres and the wheels must be carried out by specialists with the appropriate tools.

•Regularly check and adjust the tyre pressure to the recommended value.

•Regularly check and adjust the tightening torque of the wheel nuts.

•(label on rim) refer to chapter COMMISSIONING THE MACHINE .

•Only mount the sizes that are recommended for your machine, particularly for 40 kph machines certied by

UTAC with a compressed air braking system.

•Comply with the "OVERHANG", which is the distance between the end of the axle frame and the axis of the

tyres, as detailed in chapter COMMISSIONING THE MACHINE .

MAY-2015 19

– GENERAL SAFETY –

3.6.4 - BRAKING SYSTEMS

IMPORTANT

TOWED MACHINES

CAUTION

If the brake system malfunctions:

• Stop the tractor immediately

• Call a specialist outt authorised to work on brake systems.

3.6.4.1 Hydraulic brake system

•When topping up or changing the oil, use the prescribed oils and follow the recommendations

3.6.4.2 Compressed air brakes.

•Bleed the tank of air on a daily basis

•Check that the seal rings on the coupling heads are clean.

•A pressure of 0.5 bar is required before starting to move the machine.

•Never change the factory settings

•Replace the air tank

◊ if it is no longer attached to its support

◊ or it is damaged

3.6.5 - DRIVING ONROADS

In addition to obeying the currently valid highway code, always follow the recommendations below

•Before driving on the road

◊ Check the brake system

◊ Check the compulsory transport systems (lights, indicators, guards)

◊ Visually check that all the safety devices are in place, particularly those of the towing system.

◊ Check that the lower hitching arms of the tractor are properly locked.

◊ Place the machine's pivoting parts in the transport position, and lock them with the safety devices

provided.

◊ Lock the 3-point hitching control lever, in order to avoid accidental lowering or raising of the machine.

•Use the front ballast if necessary

◊ The front tractor axle must support at least 20% of the tractor's unladen weight.

◊ Secure the ballast to the points provided in accordance with the regulations.

•Do not exceed the maximum working load of the machine and the permissible tractor axle and drawbar

loads

•Check that the tractor's deceleration power meets the regulations.

•Adapt your driving style. Towed or carried machines inuence the behaviour of the tractor

•Do not exceed the speed limit

•Beware of overhead power lines

MAY-2015 20

– GENERAL SAFETY –

IMPORTANT

TOWED MACHINES

•If your machine is equipped with an articulated drawbar or a steering/levelling axle, make sure it is locked in

the road position. Refer to chapter MACHINE USE

•If your machine is equipped with AXAIR suspension, do not drive the sprayer with deated bellows. Refer to

chapter COMMISSIONING THE MACHINE for the bellow ination procedure

•Completely release the parking brake

3.6.6 - TRANSPORT ON A TRUCK

IMPORTANT

TOWED MACHINES

•To ensure the stability of a sprayer equipped with AXIAR suspensions when being transported

on a truck or low loader, deate the two bellows using the procedure described in chapter

COMMISSIONING THE MACHINE

3.6.7 - BEFORE GETTING OFF THE TRACTOR

Take all precautionary measures to avoid accidental starting and/or movement of the tractor:

1. Immobilise the machine on a at surface

2. Lower the machine to the ground

3. Put the parking brake on

4. Stop the engine and remove the key from the ignition

5. Use chocks when parked on a slope

3.6.8 - OTHER RISKS

3.6.8.1 Overhead power lines

•Make sure that the clearance in relation to the machine is sufcient whenever the machine is operated (for

example the maximum boom height with the back hatch open)

•Also remember the radio aerial and all other original or other installed accessories

•If the machine comes into contact with a power line, stop the machine and the tractor's engine immediately

and apply the parking brake

•Check whether you can leave your current position without touching the electric lines, then jump from your

position so that there is no simultaneous contact between your body and the machine and the ground while

dismounting.

•Stay well clear of the machine until the power lines are powered down.

•Warn all persons near the machine of the danger.

•Ask for the line to be powered down

3.6.8.2 Electric batteries

The batteries contain sulphuric acid. In the event of contact with the skin, rinse thoroughly with clean water and

consult a doctor.

3.6.8.3 Hydraulic circuits

•Regularly check that the hydraulic circuits are in good working order.

•In the event of injury caused by the hydraulic oil, immediately consult a doctor.

•For machines without a hydraulic control unit

This manual suits for next models

3

Table of contents

Popular Tractor Accessories manuals by other brands

Bradco

Bradco 330 Operator and parts manual

Cub Cadet

Cub Cadet 19B70054 Series Operator's manual

Ventrac

Ventrac KH500 Versa-Loader Owner/operator's manual & parts list

GreenTec

GreenTec HXF 2302 Handbook

Curtis

Curtis 1KB17AS1 Installation & owner's manual

matev

matev FPS-PTO JD 4020 Original operating manual