7

Before installation/maintenance, the tractor and attachment should

be stationary with the hydraulic lift system in a neutral position and

the ignition key removed.

On a at area of ground lower the three point linkage on the tractor to its

lowest position. Attach the attachment to the tractor using the three point

linkage pins and linch pins:

Installation Overview

1. With the attachment on the ground, adjust the length of the top link

arm so that the attachment is level.

2. Check the clearance between the attachment skids and the blades for

the tilling depth.

3. Raise the tilling depth for drier patches of ground or heavier soil

types. To do this, raise the tractor’s hydraulic lift arms and adjust the

skids on the attachment to increase the blade tilling depth. A lower

pass can be made when the top layer of soil is broken up.

4. The working speed of the attachment should be at a walking pace of 1

to 4 mph. Heavier soil should be cultivated at a slow pace for the best

nish and to avoid any damage to the attachment.

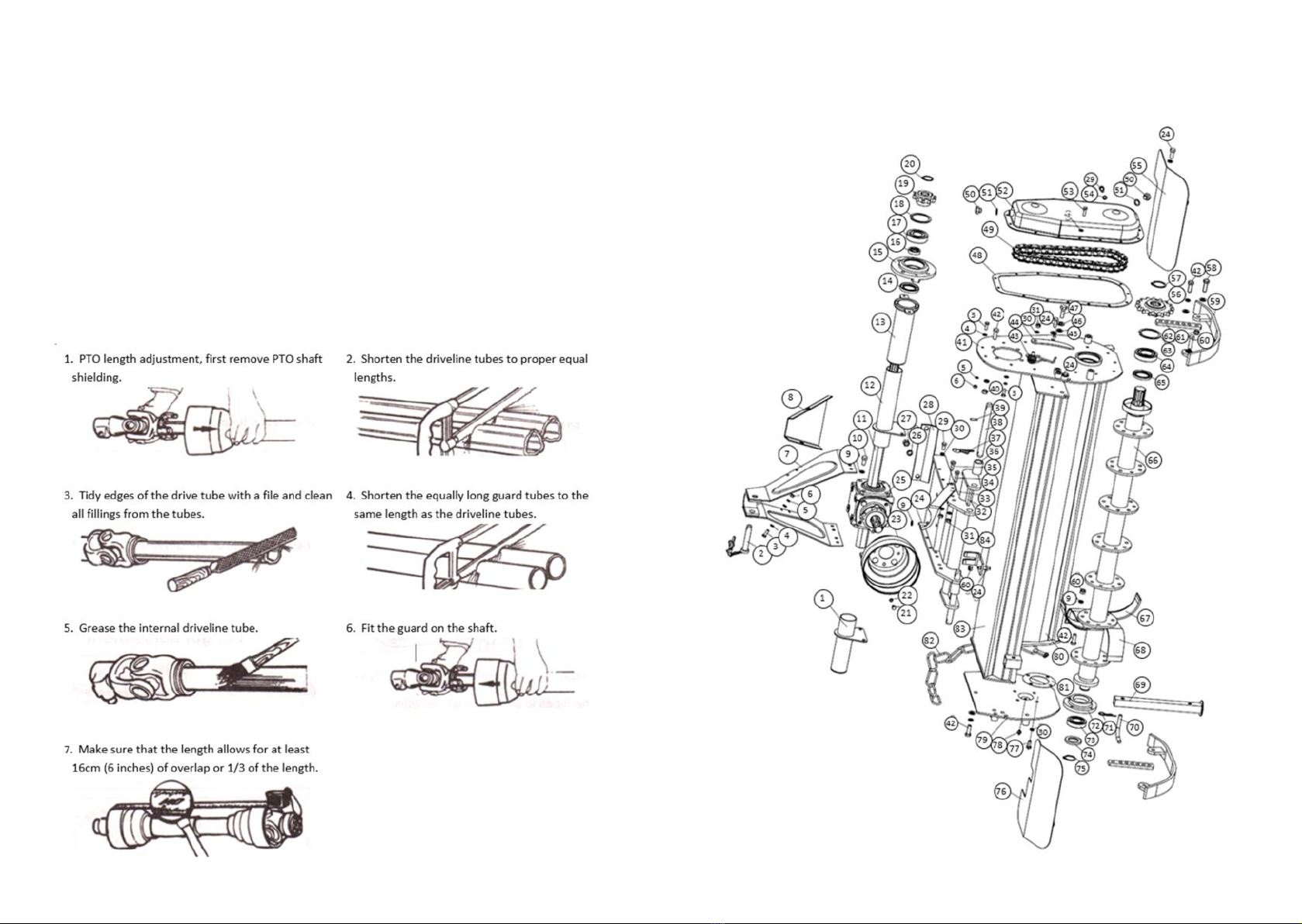

5. Lubricate all grease points including PTO drive shaft. Attach the PTO

drive shaft and ensure locking pin is secure on both the tractor and

attachment sides. Attach the chain to a secure point on the tractor/

attachment.

6. Ensure all safety guards are in place. Always replace worn or

damaged PTO drive shafts. Operate the attachment with tractor in a

low gear range, keep the PTO output from the tractor at 540 rpm.

8

Installation Overview (Continued)

• Check the tractor's 3-point hydraulic lift system. It should operate up

and down smoothly and hold its position when set.

• The tractor should be equipped with stabiliser bars, and adjustable

sway chains or sway blocks to keep the attachment from swinging

side to side.

• Small tractors may require front counter weights to counter-balance

the weight of the attachment. We recommend the tractor has a

Rollover Protection System (ROPS) and a seat belt is used.

Operating Advice

1. Take extreme care when travelling, slow down on turns and watch out

for uneven land. Always reduce speed on slopes/corners to avoid

tipping.

2. Check the soil type and moisture level. If the ground is too dry, the

blades will struggle to cut in, and if too wet the soil will ‘ball up’ in the

rotor and blades. Typically, sandy soils can be worked better than

heavy clay or loam soil types.

3. Before starting any work, check for/remove any obstructions such as

buried pipes, rocks and stumps.

4. Set correct working depth, check the drive chain, belts and blade

condition and the tightness of all bolts, buts and screws.

5. Check the oil level in the gearbox and chain case.

6. Begin by slowly easing the rotovator into the soil: Lower the

rotovator so the blades are just o the ground, then start the PTO

drive from the tractor, slowly increasing to 540 rpm to engage the

blades. Lower the linkage slowly, to allow the blades to cut into the

soil. Move forward in a low gear, and increase speed to suit the

ground conditions. If the tractor/attachment appears to struggle, slow

the speed.

7. We recommend using two passes when tilling hard or compacted

soils. For consistency and to minimise compaction, make a second

pass at an angle to the rst.

8. Use the rear ap to maintain a level seedbed. Adjust the angle of the

ap if necessary using the chain and brackets.