KUBOTA B SERIES PHASE II HARD & SOFT SIDE CABS

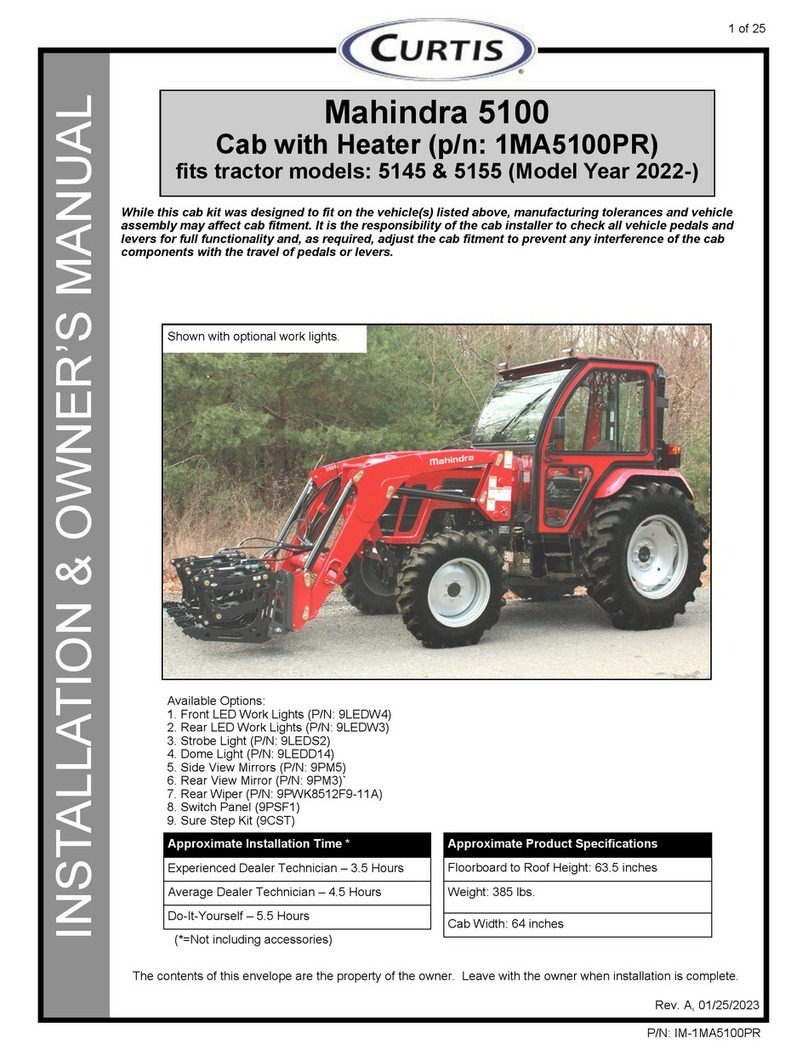

1. VEHICLE PREP. (see Fig. 1)

1.1 Remove grab handles and rear lights from left and right fenders.

1.2 Remove SMV sign and mounting bracket from roll bar.

NOTE: Leave roll bar bolt temporarily uninstalled.

1.3 For the following nine models only: 1700, 2100, 2400, 2410,

7300, 7500, 7410, 7510, and 7610, remove plastic plugs hold-

ing floor mat down in the rear corners. Also see Fig. 18 on page

6 which shows that 5/16” carriage bolts will eventually be in-

stalled in location B. Drill these two small plug holes out to

11/32” diameter at this time.

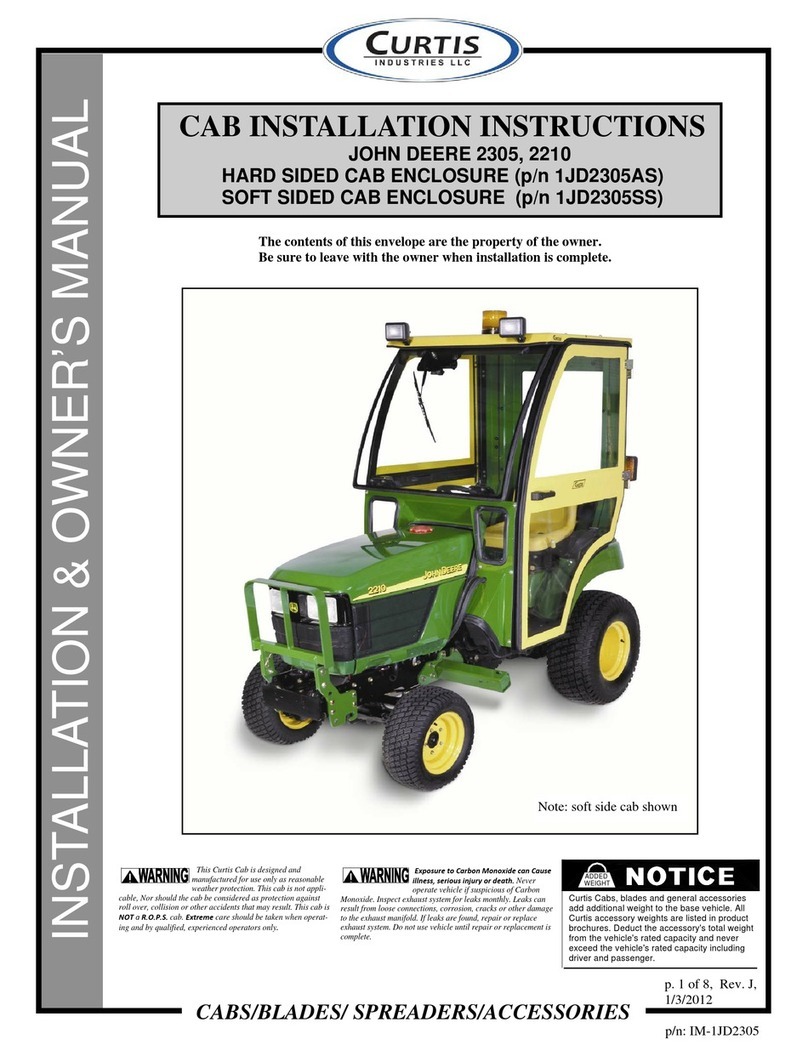

2. COWL

2.1 Per Fig. 2, transfer the hole up through the sheetmetal of the

floorboard pan using the existing hole in the front mount brack-

et as a guide. NOTE: this front mount bracket is underneath the

sheetmetal that is shown in Fig. 2. Drill a 7/16” hole from the

bottom of the vehicle upwards. Repeat for right side.

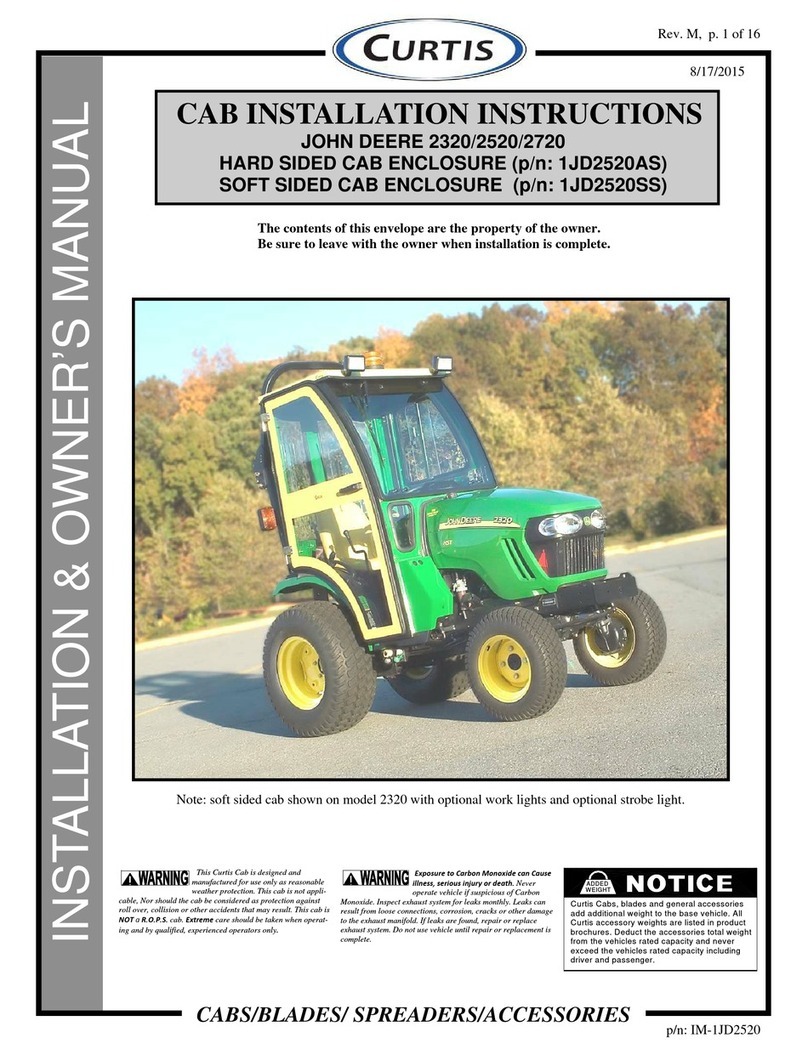

2.2 Position the cowl over the hood of the vehicle. See Fig. 3.

2.3 Loosely install 3/8” x 1-1/4” hex head bolts, steel washers, and

locknuts through the flange on the bottom of the cowl and into

the floorboard holes drilled in step 2.1.

3. FRAME PREPARATION

3.1 Remove doors from side frames by opening and lifting up off

of pin hinges.

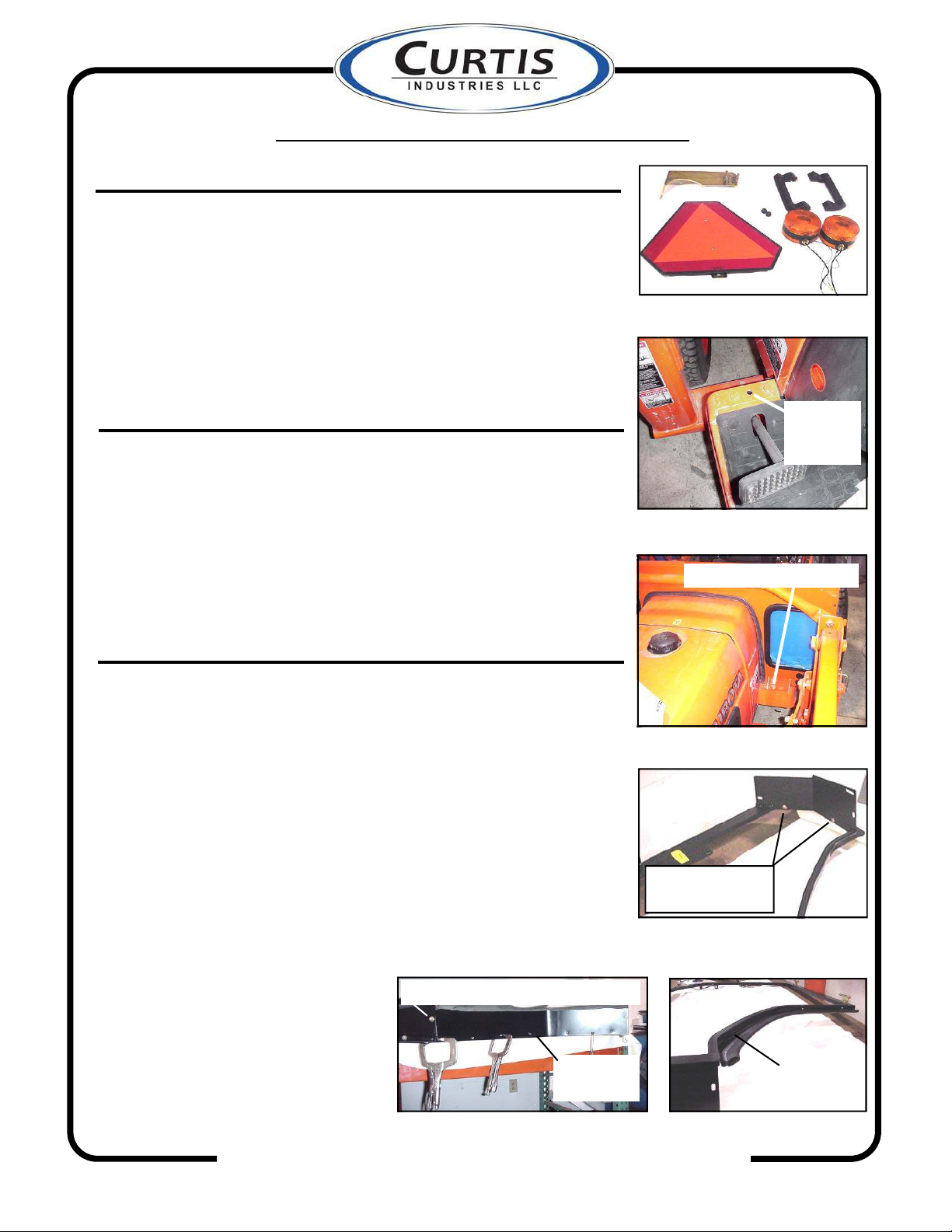

3.2 Place the left side frame on a soft, clean surface. Install the left

floorboard extension (as shown in Fig. 4) using two 5/16-18 x

3/4” carriage bolts.

3.3 The following models use contour (A) shown in Fig. 5: B1700,

B2100, B2400, B2410, B7300, B7500, B7410, B7510, and

B7610. See page 9 for a picture of (A) & (B). Fig 6 shows con-

tour (B) required for use on the following three models: 2710,

2910, and 7800. Apply 39” long pieces of 1/2” weatherseal to

the frame tube surfaces that the contours will be fastened to.

NOTE: self adhesive backed weatherseal should be applied

to a clean, dry surface at room temperature. Clamp the ap-

propriate contour to the side frame and fasten with the supplied

self-tapping screws. On tractors

using contour (A) shown in Fig.

5, attach the contour to the floor-

board extension with a 3/4”

long carriage bolt.

3.4 Repeat steps 3.2 and 3.3 for

right side frame.

CABS/BLADES/ SPREADERS/ACCESSORIES

p. 3 of 10

Fig. 1

Fig. 4

Fig. 3

head of 3/8” hex head bolt

Fig. 2

transfer

from

bottom up

carriage bolt heads

on this upper side

Fig. 6

Fig. 5

5/16” locknut underneath floorboard

fender

contour (B)

fender

contour (A)