D

4.3.1 MAIN FRAME WITH SWING-ARM ............................................................................................................................................ 16

4.3.2 AUTOMATIC HYDRAULIC BREAK-BACK SYSTEM (AHS).......................................................................................................... 17

4.3.3 FLOW REGULATOR FOR OIL QUANTITY ASSURANCE............................................................................................................. 18

4.3.4 WORKING ANGLE ADJUSTMENT ............................................................................................................................................ 19

4.3.5 SUPPORT LEGS FOR MOUNTING............................................................................................................................................ 20

4.3.6 EURO-BRACKET / ADAPTER FOR MOUNTING ON VEHICLES................................................................................................. 20

4.3.7 ADJUSTABLE FOOT FOR VERTICAL MOUNTING (ONLY HXF 2302 & HXF 2802) .................................................................. 21

4.3.8 MECHANICAL QUICK RELEASE & QUICK COUPLINGS (ONLY HXF 2302) ............................................................................. 22

4.4 APPROVED ATTACHMENT TOOLS (n)............................................................................................................................................23

4.5 ACCESSORIES................................................................................................................................................................................24

4.5.1 HYDRAULIC WORK ANGLE ADJUSTMENT .............................................................................................................................. 24

4.5.2 ELECTRICAL OPERATION OF WORKING ANGLE W. CONTROL PANEL................................................................................... 24

4.5.3 HYDRAULIC HOSE SET, 8.5 M ............................................................................................................................................... 25

4.5.4 COUNTERWEIGHTS................................................................................................................................................................. 25

4.5.5 OTHER BRACKETS / ADAPTERS FOR VEHICLES.................................................................................................................... 26

4.6 SPECIFICATIONS............................................................................................................................................................................27

4.7 NOISE MEASUREMENT OF AIRBORNE NOISE (u).........................................................................................................................28

5. INSTRUCTIONS FOR USE OF THE MASCHINE (k) ................................................................................................................................... 29

5.1 INSTRUCTIONS FOR DELIVERY OF THE MACHINE .......................................................................................................................29

5.2 INSTRUCTIONS FOR ASSEMBLY, CONNECTION AND DISCONNECTION (j)..................................................................................30

5.2.1 PREPARATION OF VEHICLE..................................................................................................................................................... 30

5.2.2 MOUNTING AND CONNECTION OF THE MACHINE (i)............................................................................................................. 31

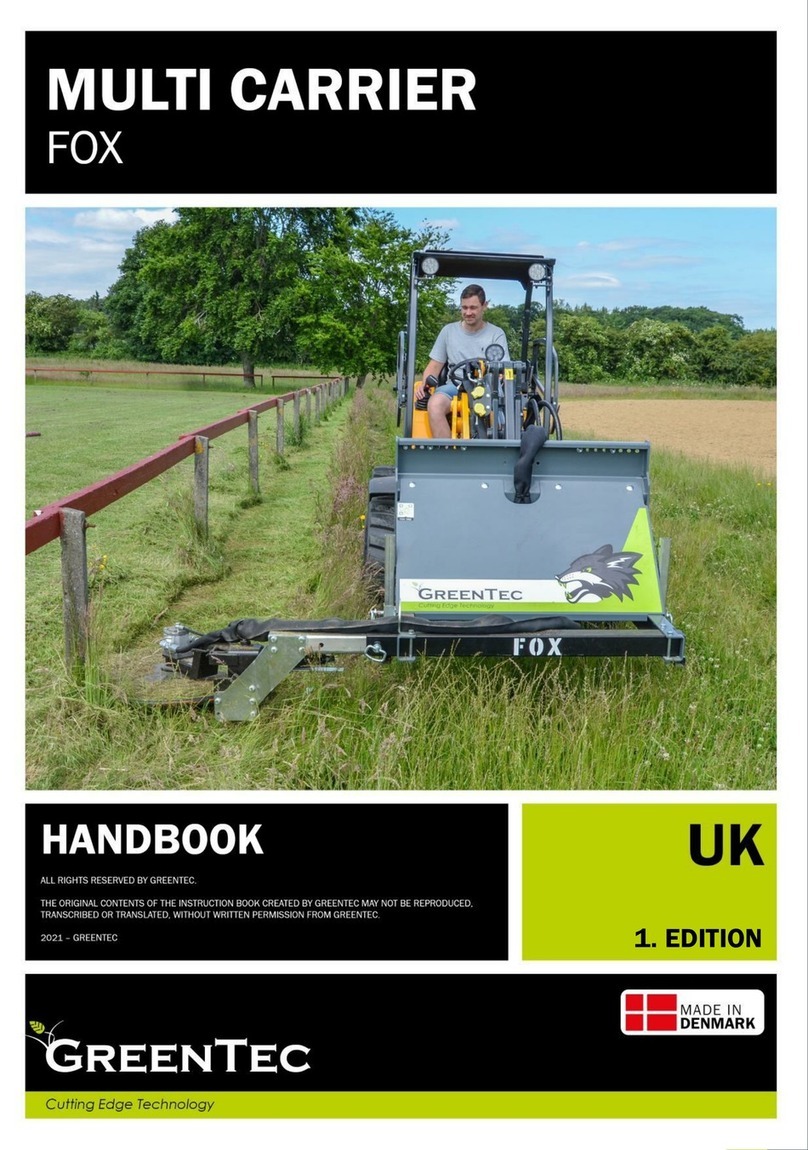

5.2.3 MOUNTING OF HXF MULTI CARRIER ON FRONT LOADER ..................................................................................................... 31

5.2.4 INSTALLATION AND MOUNTING OF ELECTRICAL CONTROL FOR WORKING ANGLE ADJUSTMENT..................................... 35

5.2.5 DE-MOUNTING OF HXF MULTI CARRIER ON FRONTLOADER................................................................................................. 35

5.2.6 MOUNTING OF ATTACHTMENT TOOL ON A HXF MULTI CARRIER.......................................................................................... 36

5.2.6.1 SETTING THE HXF MULTI CARRIER IN WORKING POSITION....................................................................................... 36

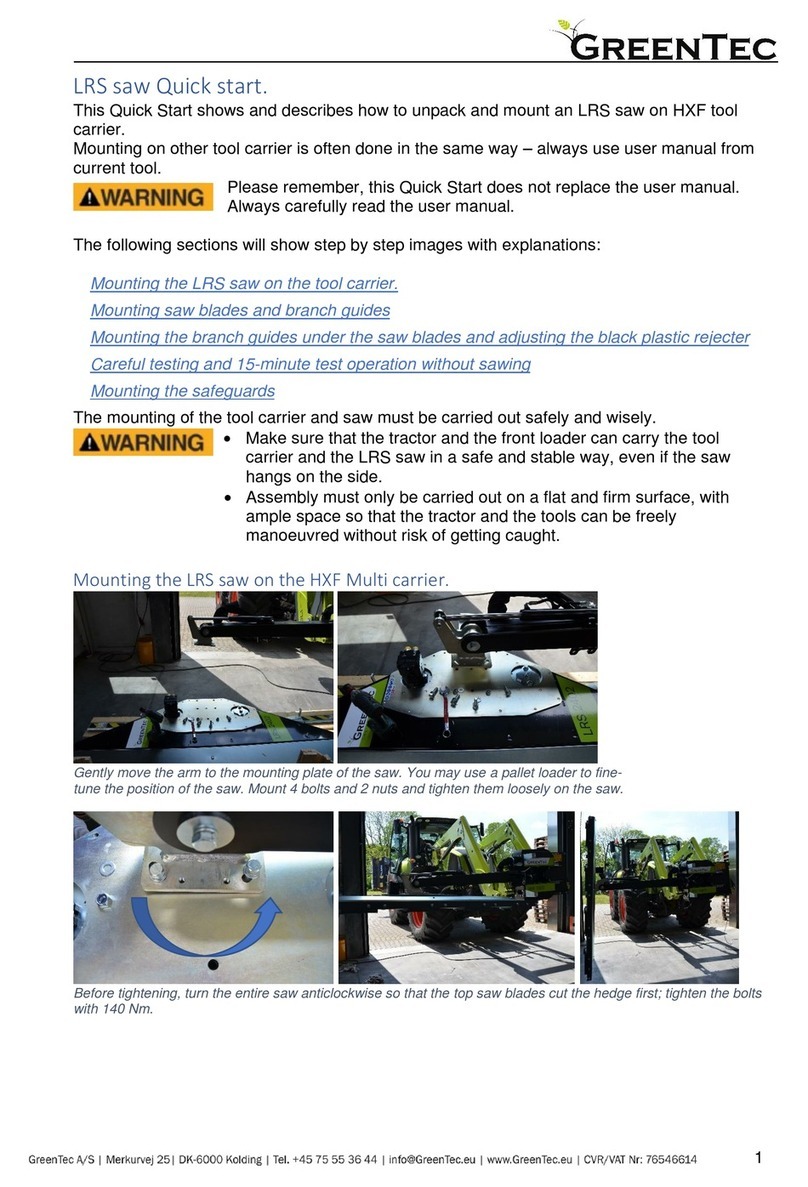

5.2.6.2 MOUNTING EXAMPLE OF ATTACHMENT TOOL: GREENTEC LRS QUADSAW.............................................................. 36

5.2.7 STABILITY (o)........................................................................................................................................................................... 38

5.2.7.1 CONTROL OF STABILITY:.............................................................................................................................................. 38

5.2.7.2 STABILITY CAN BE INCREASED BY: ............................................................................................................................. 39

5.2.7.3 FACTORS INFLUENCING THE STABILITY:..................................................................................................................... 39

5.3 PREPARING THE MACHINE FOR USE............................................................................................................................................40

5.3.1 INITIAL START UP AND FIRST USE OF THE MACHINE............................................................................................................ 40

5.3.2 PROCEDURES BEFORE USING THE MACHINE....................................................................................................................... 40

5.4 OPERATING THE MACHINE (e) ......................................................................................................................................................40

5.4.1 TRAINING OF MACHINE OPERATOR BEFORE USE ................................................................................................................. 40

5.4.2 OPERATOR’S WORKPLACE (f)................................................................................................................................................. 41