Ignite Blade Box 48 Manual

7495908enUS (A)

October 2022

Printed in USA

Original Instructions

© 2022 Ignite Attachments.

All Rights Reserved.

Operation & Maintenance Manual

Three-Point Box Blade

Blade Box 48 S/N: B63Y00101 & Above

Blade Box 60 S/N: B63Z00101 & Above

Blade Box 72 S/N: B64100101 & Above

1

FOREWORD............................................................................................................................................................3

MANUFACTURER.............................................................................................................................................3

North America ...............................................................................................................................................3

SERIAL NUMBER LOCATION ...........................................................................................................................3

Implement Serial Number ................................................................................................................................3

IMPLEMENT IDENTIFICATION ..........................................................................................................................4

Rear O Implement..........................................................................................................................................4

Front Of Implement ........................................................................................................................................4

STANDARD ITEMS ...........................................................................................................................................5

SAFETY AND TRAINING RESOURCES....................................................................................................................6

SAFETY INSTRUCTIONS..................................................................................................................................6

Safe Operation Is The Operator’s Responsibility (Implement) ..................................................................................6

Use Safety Rules ...........................................................................................................................................6

Call Before You Dig ........................................................................................................................................6

Silica Dust Exposure.......................................................................................................................................6

FIRE PREVENTION...........................................................................................................................................7

Maintenance.................................................................................................................................................7

Operation.....................................................................................................................................................7

Electrical......................................................................................................................................................7

Hydraulic System...........................................................................................................................................7

Fueling ........................................................................................................................................................8

Starting........................................................................................................................................................8

Spark Arrester Exhaust System......................................................................................................................... 8

Welding And Grinding .....................................................................................................................................8

Fire Extinguishers ..........................................................................................................................................8

PUBLICATIONS AND TRAINING RESOURCES .................................................................................................9

IMPLEMENT SIGNS (DECALS) .........................................................................................................................9

OPERATING INSTRUCTIONS ................................................................................................................................ 10

DAILY INSPECTION........................................................................................................................................ 10

Implement Mounting Frame............................................................................................................................ 10

Three-Point Hitch......................................................................................................................................... 10

OPERATING PROCEDURE WITH COMPACT TRACTORS ............................................................................... 11

Approved Compact Tractor Models And Requirements ........................................................................................ 11

Setting Up The Ballast................................................................................................................................... 11

Entering And Exiting The Compact Tractor ........................................................................................................ 11

Installing The Three-Point Implement ............................................................................................................... 11

Control Functions Three-Point Hitch (Implement) ................................................................................................ 14

Driving The Implement And Tractor To Worksite.................................................................................................. 14

Operating The Scraper Blade ......................................................................................................................... 15

Operating The Backfill Blade .......................................................................................................................... 15

Adjusting The Scarifier Teeth .......................................................................................................................... 16

Removing The Three-Point Implement.............................................................................................................. 16

LIFTING THE IMPLEMENT.............................................................................................................................. 17

TRANSPORTING THE IMPLEMENT ON A TRAILER ........................................................................................ 18

Fastening The Implement On A Trailer.............................................................................................................. 18

TRANSPORTING THE IMPLEMENT AND MACHINE ON A TRAILER................................................................ 18

Transporting The Attachment And Machine On A Trailer ....................................................................................... 18

PREVENTIVE MAINTENANCE............................................................................................................................... 20

TABLE OF CONTENTS

2

MAINTENANCE SAFETY WARNINGS ............................................................................................................. 20

TROUBLESHOOTING ..................................................................................................................................... 21

Troubleshooting The Implement ...................................................................................................................... 21

SERVICE SCHEDULE ..................................................................................................................................... 22

Maintenance Intervals................................................................................................................................... 22

CUTTING EDGE.............................................................................................................................................. 22

Removing And Installing The Cutting Edge ........................................................................................................ 22

SCARIFIER TEETH ......................................................................................................................................... 23

Removing And Installing Scarifier Teeth ............................................................................................................ 23

STORAGE AND RETURN TO SERVICE........................................................................................................... 24

Implement Storage....................................................................................................................................... 24

Return To Service ........................................................................................................................................ 24

SPECIFICATIONS.................................................................................................................................................. 25

IMPLEMENT DIMENSIONS ............................................................................................................................. 25

PERFORMANCE SPECIFICATIONS ................................................................................................................ 26

WARRANTY .......................................................................................................................................................... 27

IMPLEMENT WARRANTY ............................................................................................................................... 27

TABLE OF CONTENTS

3

MANUFACTURER

North America

Ignite Attachments

2741 20th Avenue South

Moorhead, MN 56560

SERIAL NUMBER LOCATION

Implement Serial Number

Figure 1

P142002f

Always use the serial number of the three-point box blade

when requesting service information or when ordering

parts. Earlier or later models (identification made by serial

number) may use different parts, or it may be necessary

to use a different procedure in doing a specific service

operation [Figure 1].

FOREWORD

6

SAFETY INSTRUCTIONS

Safe Operation Is The Operator’s

Responsibility (Implement)

Safety Alert Symbol

This symbol with a warning statement means:

“Warning, be alert! Your safety is involved!” Carefully

read the message that follows.

DANGER

The signal word DANGER on machine signs and in

the manuals indicates a hazardous situation which, if

not avoided, will result in serious injury or death.◂

D-1002

WARNING

The signal word WARNING on the machine and in the

manuals indicates a potentially hazardous situation

which, if not avoided, could result in serious injury or

death.◂

W-2044

IMPORTANT

This notice identifies procedures which must be

followed to avoid damage to the machine.◂

I-2019

The machine and implement must be in good operating

condition before use.

Check all of the items on the Service Schedule decal (if

equipped) in the Every 10 Hours section or as shown in

the Operation & Maintenance Manual.

Use Safety Rules

• Read and follow instructions in the machine and the

implement’s Operation & Maintenance Manual

before operating.

• Check for underground lines before operating

implement (if applicable).

• In addition to the design and configuration of

equipment, hazard control, and accident prevention

are dependent upon the awareness, concern,

prudence, and proper training of personnel involved

in the operation, transport, maintenance, and

storage of equipment.

• Check that the implement is securely fastened to the

machine.

• Make sure all the machine controls are in the neutral

position before starting the machine.

• Operate the implement only from the operator’s

position.

• Operate the implement according to the Operation &

Maintenance Manual.

• When learning to operate the implement, do it at a

slow rate in an area clear of bystanders.

• DO NOT permit personnel to be in the work area

when operating the machine and implement.

• The implement must be used ONLY on approved

machines. Visit [Missing external cross reference

text] for an updated list of approved implements for

each machine model.

• DO NOT modify equipment or add implements that

are not approved by the manufacturer.

• DO NOT make any adjustments or repairs on the

machine or implement while the engine is running.

• Keep shields and guards in place. Replace if

damaged.

Call Before You Dig

P200081

Dial 811 (USA Only)

Dial 1-888-258-0808 (USA & Canada)

When you call, you will be directed to a location in your

state / province / city for information about buried lines

(telephone, cable TV, water, sewer, gas, etc.).

Silica Dust Exposure

NA3504

SAFETY AND TRAINING RESOURCES

7

Silica dust can cause lung disease and is known to the

state of California to cause cancer.

Cutting or drilling concrete containing sand or rock

containing quartz may result in exposure to silica dust.

Do not exceed Permissible Exposure Limits (PEL) to

silica dust as determined by OSHA or other job site Rules

and Regulations. Use a respirator, water spray, or other

means to control dust.

FIRE PREVENTION

NA3505

Maintenance

The machine and some attachments have components

that are at high temperatures under normal operating

conditions. The primary source of high temperatures is

the engine and exhaust system. The electrical system, if

damaged or incorrectly maintained, can be a source of

arcs or sparks.

Flammable debris (leaves, straw, etc.) must be removed

regularly. If flammable debris is allowed to accumulate, it

can cause a fire hazard. Clean often to avoid this

accumulation. Flammable debris in the engine

compartment is a potential fire hazard.

The operator’s area, engine compartment, and engine

cooling system must be inspected every day and cleaned

if necessary to prevent fire hazards and overheating.

All fuels, most lubricants, and some coolants mixtures are

flammable. Flammable fluids that are leaking or spilled

onto hot surfaces or onto electrical components can

cause a fire.

Operation

Do not use the machine where exhaust, arcs, sparks, or

hot components can contact flammable material,

explosive dust, or gases.

Electrical

P200082

Check all electrical wiring and connections for damage.

Keep the battery terminals clean and tight. Repair or

replace any damaged part or wires that are loose or

frayed.

Battery gas can explode and cause serious injury. Use

the procedure in the Operation & Maintenance Manual for

connecting the battery and for jump starting. Do not jump

start or charge a frozen or damaged battery. Keep any

open flames or sparks away from batteries. Do not

smoke in battery charging area.

Hydraulic System

Check hydraulic tubes, hoses and fittings for damage and

leakage. Never use open flame or bare skin to check for

SAFETY AND TRAINING RESOURCES

8

leaks. Hydraulic tubes and hoses must be properly routed

and have adequate support and secure clamps. Tighten

or replace any parts that show leakage.

Always clean fluid spills. Do not use gasoline or diesel

fuel for cleaning parts. Use commercial nonflammable

solvents.

Fueling

P200084

Stop the engine and let it cool before adding fuel. No

smoking! Do not refuel a machine near open flames or

sparks. Fill the fuel tank outdoors.

Ultra Low Sulfur Diesel (ULSD) poses a greater static

ignition hazard than earlier diesel formulations with

higher sulfur content. Avoid death or serious injury from

fire or explosion. Consult with your fuel or fuel system

supplier to ensure the delivery system is in compliance

with fueling standards for proper grounding and bonding

practices.

Starting

Do not use ether or starting fluids on any engine that has

glow plugs or an air intake heater. These starting aids

can cause explosion and injure you or bystanders.

Use the procedure in the Operation & Maintenance

Manual for connecting the battery and for jump starting.

Spark Arrester Exhaust System

The spark arrester exhaust system is designed to control

the emission of hot particles from the engine and exhaust

system, but the muffler and the exhaust gases are still

hot.

Check the spark arrester exhaust system regularly to

make sure it is maintained and working properly. Use the

procedure in the Operation & Maintenance Manual for

cleaning the spark arrester muffler (if equipped).

Welding And Grinding

Always clean the machine and implement, disconnect the

battery, and disconnect the wiring from the Ignite

Attachments controllers before welding. Cover rubber

hoses, battery, and all other flammable parts. Keep a fire

extinguisher near the machine when welding.

Have good ventilation when grinding or welding painted

parts. Wear a dust mask when grinding painted parts.

Toxic dust or gas can be produced.

Dust generated from repairing nonmetallic parts such as

hoods, fenders, or covers can be flammable or explosive.

Repair such components in a well-ventilated area away

from open flames or sparks.

Fire Extinguishers

P200083

Know where fire extinguishers and first aid kits are

located and how to use them. Inspect the fire

extinguisher and service the fire extinguisher regularly.

Obey the recommendations on the instructions plate.

SAFETY AND TRAINING RESOURCES

9

PUBLICATIONS AND TRAINING

RESOURCES

The following publications are also available for your

Ignite Attachments machine. Access them online at

Igniteattachments.com.

P217312

Operation & Maintenance

Manual

Complete instructions on

the correct operation and

the routine maintenance

of your attachment.

7495908

For the latest information on Ignite Attachments products

and the Ignite Attachments Company, visit our website at

Igniteattachments.com

IMPLEMENT SIGNS (DECALS)

Figure 4

P142002d

REF. DECAL

1 Crush Warning

Located near 3 point hitch, both sides

71892000IG

SAFETY AND TRAINING RESOURCES

10

DAILY INSPECTION

Implement Mounting Frame

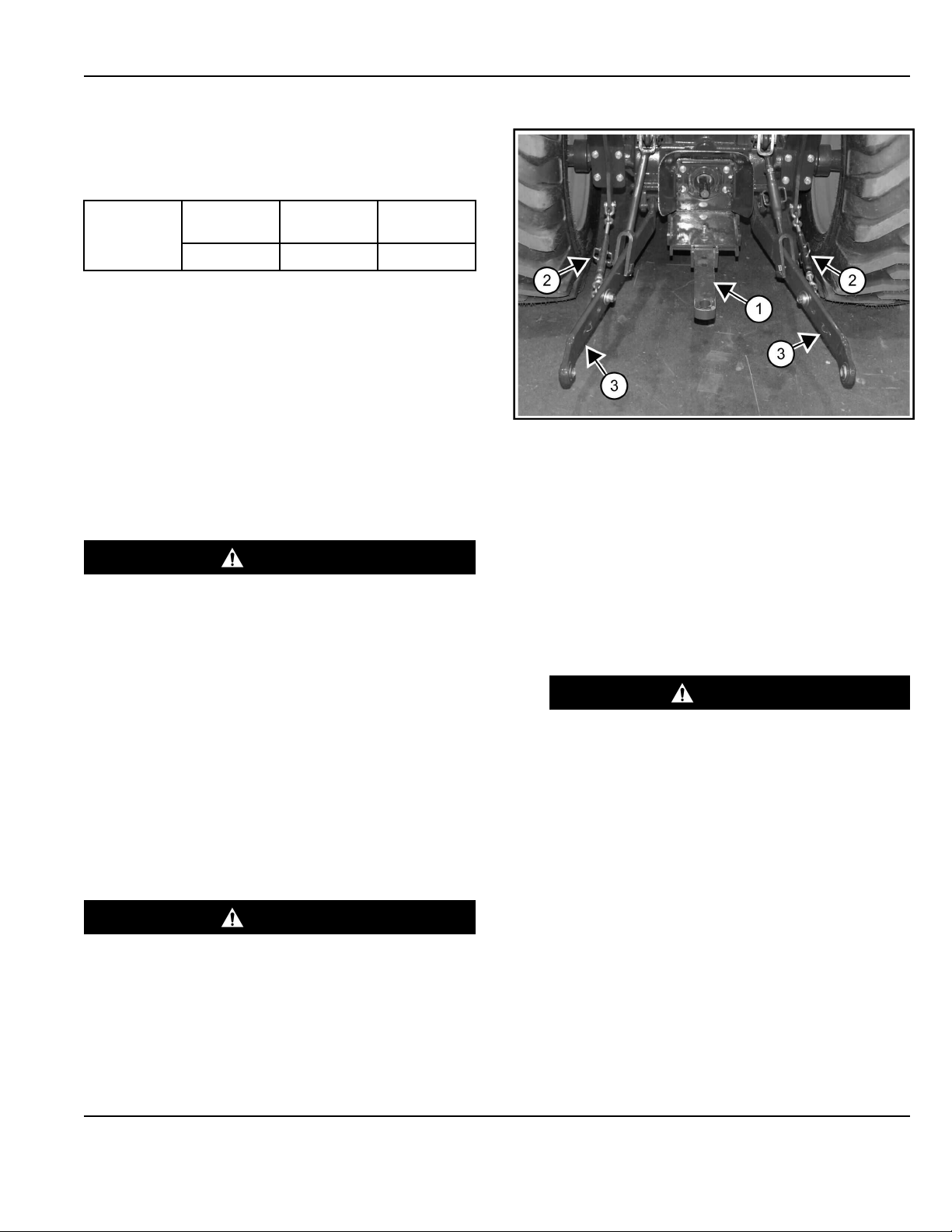

Figure 5

P142002e

Inspect the lower implement mounts (Item 1) and upper

mount (Item 2) [Figure 5] and all welds for wear and

damage each time the implement is removed from the

machine.

Check the following items at the start of a work day:

• Check for damaged or missing decals. Replace if

necessary.

• Replace any worn or damaged parts immediately.

Three-Point Hitch

WARNING

UNINTENDED MOVEMENT HAZARD

Failure to follow instructions can cause serious

injury or death.

The parking brake must be engaged before leaving

the operator’s seat. Rollaway can occur because the

transmission may not prevent machine movement.

Lock the brake pedals together (if equipped) before

activating the parking brake.◂

W-2656

Figure 6

c138256

• Inspect the three-point hitch linkage, PTO shaft

splines, guards, and shields. Replace if damaged or

missing [Figure 6].

Repair broken or loose parts.

See your machine Operation & Maintenance Manual

for detailed information on inspecting three-point

hitch.

OPERATING INSTRUCTIONS

11

OPERATING PROCEDURE WITH COMPACT

TRACTORS

Approved Compact Tractor Models And

Requirements

Box Blade

48

Box Blade

60

Box Blade

72

Tractor HP 18–30 26–65 35–65

The chart shows the approved box blade models for

compact tractors based on horsepower.

Warranty on this implement is void if used on a non-

approved carrier. Contact your Ignite Attachments

representative for a current list of compatible carriers.

Setting Up The Ballast

Install the correct ballast on the compact tractor before

installing the three-point box blade. See the compact

tractor Operation & Maintenance Manual for ballast

information.

Entering And Exiting The Compact Tractor

WARNING

INSTABILITY HAZARD

Failure to obey warnings can cause the machine to

rollover.

• Use Roll-Over Protective Structure (ROPS) and

fasten the seat belt.

• Install the correct rear ballast.

• Do NOT exceed the Loader lift capacity.

• Check tire condition and proper air pressure.

• Use tires with the correct load rating.◂

W-3043

See your compact tractor Operation & Maintenance

Manual for detailed instructions on entering and exiting

the machine.

Installing The Three-Point Implement

Always inspect the compact tractor three-point hitch and

implement three-point mounting before installation.

(See Daily Inspection on Page 10) .

WARNING

GENERAL HAZARD

Failure to obey warnings can cause serious injury or

death.

Obey all warnings on the machine and in the

manuals.◂

W-2744

Figure 7

c138256a

1. Move the drawbar (Item 1) [Figure 7] to the storage

position or remove (if necessary). See the compact

tractor Operation & Maintenance Manual for detailed

information.

The three-point hitch lower links must be set wide

enough to clear the implement mounting pins.

2. Adjust the sway bars (Item 2) (both sides) to move

the lower links (Item 3) [Figure 7] as needed.

See the compact tractor Operation & Maintenance

Manual for detailed information on adjusting sway

bars.

WARNING

CRUSHING HAZARD

Contact with the machine can cause serious

injury or death.

Before backing the machine, look in all

directions and make sure no bystanders are in

the work area. Do not allow anyone between the

machine and the implement when backing up to

the implement for installation. ◂

W-2734

3. Enter the compact tractor

(See Entering And Exiting The Compact Tractor on

Page 11) .

4. Start the engine and release the parking brake.

OPERATING INSTRUCTIONS

12

Figure 8

P142006a

5. Drive the compact tractor to the implement and align

the lower links (Item 1) with the implement lower

mounts (Item 2) [Figure 8] (both sides).

6. Lower or raise the compact tractor three-point hitch

lower links (Item 1) until they are even with the lower

mounts (Item 2) [Figure 8] (both sides) of the three-

point implement.

See the compact tractor Operation & Maintenance

Manual for detailed information on operating the

compact tractor.

7. Stop the engine and exit the compact tractor.

(See Entering And Exiting The Compact Tractor on

Page 11)

WARNING

PINCHING HAZARD

Failure to follow instructions can cause serious

injury.

Keep fingers and hands out of pinch points when

installing and removing implement or

attachments.◂

W-2571

Figure 9

P142005a

8. Install the lower implement pin (Item 1) through the

lower mounts and lower link (Item 2) [Figure 9] (both

sides) and secure with retaining clip.

Figure 10

c138244a

9. Remove the top link (Item 1) from the storage

position bracket (Item 2) [Figure 10].

OPERATING INSTRUCTIONS

13

Figure 11

c138245a

10. Lower the top link (Item 1) [Figure 11] until it aligns

with the implement upper mounting hole.

11. Install the pin (Item 2) and retainer pin (Item 3)

[Figure 11].

NOTE: It may be necessary to lengthen or shorten

the top link to align it with the implement

mounting hold [Figure 11].

(See Adjusting The Top Link on Page 13)

12. The implement can be leveled front to back by

adjusting the top link.

(See Adjusting The Top Link on Page 13)

13. The implement side to side sway will need to be

adjusted. (See Adjusting The Sway Bar on Page 14)

Adjusting The Lift Link

Figure 12

p138247b

The lift link (Item 1) [Figure 12] is used to adjust the side

to side level of the implement.

See the compact tractor Operation & Maintenance

Manual for detailed information on adjusting the lift link.

Adjusting The Top Link

Figure 13

c138246a

The top link (Item 1) [Figure 13] is used to adjust the front

to back level of the implement.

1. Loosen the locknut (Item 2) and use the adjuster

(Item 3) [Figure 13] to lengthen or shorten the top

link.

2. Turn clockwise to lengthen the top link, turn

counterclockwise to shorten top link.

3. After the implement has been leveled, tighten the

locknut (Item 2) [Figure 13].

OPERATING INSTRUCTIONS

14

Adjusting The Sway Bar

Figure 14

c138248a

The sway bar (Item 1) [Figure 14] (both sides) are used to

center the implement between the tires and limits the

implements side to side movement.

Adjust the sway bars to center the implement between

the tires. See the compact tractor Operation &

Maintenance Manual for detailed information on adjusting

sway bars.

When adjusting the sway bars with implement installed,

the implement will need to be raised slightly off the

ground.

Control Functions Three-Point Hitch

(Implement)

The three-point hitch will be used to raise or lower the

implement. (See the compact tractor Operation &

Maintenance Manual for detailed information on

operating the three-point hitch).

Driving The Implement And Tractor To

Worksite

WARNING

GENERAL HAZARD

Steering and braking can be affected by the loader

attachment, implements, front wheel assist and the

rear differential lock.

Always install the correct ballast. Do not exceed the

Loader or Three-Point Hitch lift capacities.

Always carry loads low. Slow down when turning.

Always lock the brake pedals together (if equipped)

for road travel.

Unlock the brake pedals (if equipped) only when

using brake pedals to assist in slow speed turns in

work applications.

Make sure that the brakes are adjusted correctly so

the compact tractor does not pull to one side when

braking.◂

W-2738

WARNING

INSTABILITY HAZARD

Failure to obey warnings can cause the machine to

rollover.

• Use ROPS and fasten the seat belt.

• Install the correct rear ballast.

• Do NOT exceed the Loader lift capacity.

• Check tire condition and proper air pressure.

• Use tires with the correct load rating.◂

W-3043

1. Enter the compact tractor.

(See Entering And Exiting The Compact Tractor on

Page 11) .

2. Start the engine.

Figure 15

P142007g

OPERATING INSTRUCTIONS

15

3. Raise the three-point box blade to the travel position

[Figure 15]. See the compact tractor Operation &

Maintenance Manual for detailed information on

operating the three-point hitch.)

4. Drive the compact tractor and implement to the work

area.

5. When operating on public road or highway, always

follow local regulations. For example; Slow Moving

Vehicle (SMV) emblem or directional signals and

hazard / flasher lights may be required.

6. Park on flat level ground.

7. Lower the three-point box blade slightly above the

ground. (See the compact tractor Operation &

Maintenance Manual for detailed information on

operating the three-point hitch.)

8. Stop the engine and exit the compact tractor.

(See Entering And Exiting The Compact Tractor on

Page 11)

WARNING

UNINTENDED MOVEMENT HAZARD

Failure to follow instructions can cause serious

injury or death.

Before you leave the operator’s seat:

Fully lower the loader arms, put the attachment

flat on the ground (if equipped).

Fully lower the implement(s) to the ground (if

equipped).

Lock brake pedals together (if equipped) and

engage the parking brake.

Place all controls in neutral.

Stop the engine, unfasten the seat belt, and

remove the key.◂

W-3178

Operating The Scraper Blade

1. When at the area to be scraped, stop the tractor,

lower the box blade from the travel position to the

ground.

2. Exit the compact tractor.

(See Entering And Exiting The Compact Tractor on

Page 11)

3. Adjust the top link to set the cutting edge at the

correct angle.

(See Adjusting The Top Link on Page 13)

4. Enter the compact tractor.

(See Entering And Exiting The Compact Tractor on

Page 11)

5. Slowly drive the tractor forward scraping the box

blade across the ground with the three-point lift

control in the float position.

6. Watch for and avoid obstructions and obstacles that

may cause damage to the box blade and compact

tractor.

7. When done with the pass, lift the box blade, turn the

tractor around, lower the box blade to the ground,

and continue until the area is finished.

Operating The Backfill Blade

The top link is critical in all backfilling operations. Adjust

the top link so the blade is tilted down at the rear, causing

the blade to move across the ground and not digging into

the ground. (See Adjusting The Top Link on Page 13)

• Use a slow speed and caution to prevent damage to

the box blade while using the backfill blade.

• The backfilling operation should be performed with

the load in the center of the blade. Avoids loads at

the ends of the blades.

• Do not ram into a load, this may cause damage to

the box blade and compact tractor.

• Perform all backfilling operations at slow speeds to

prevent damage if the blade hits an object.

• Moving snow with the backfilling blade is a delicate

operation and should be done at a slower speed and

with caution.

NOTE: Damage to the box blade and compact

tractor may occur by hitting hidden objects.

• Damage to the box blade may occur by hitting

objects that can be hidden easily in the snow, or a

snow bank that is too much material to move.

• Use caution when using the box blade for snow

removal because the compact tractor may suddenly

lose and regain traction causing a sudden surge of

ground speed.

OPERATING INSTRUCTIONS

16

Adjusting The Scarifier Teeth

Figure 16

P142022b

1. Remove the retaining pin (Item 1), locking pin (Item

2), and adjust the scarifier (Item 3) [Figure 16] to the

desired position.

2. Insert locking pin and retaining pin.

Removing The Three-Point Implement

Figure 17

C138245a

1. Remove the retainer pin (Item 1) and pin (Item 2)

[Figure 17].

It may be necessary to lengthen or shorten the top

link when remove the implement from the compact

tractor. (See Adjusting The Top Link on Page 13)

2. Remove the top link (Item 3) [Figure 17] from the

implement.

Figure 18

138244a

3. Place the top link (Item 1) into the storage position

bracket (Item 2) [Figure 18].

Figure 19

P142005a

4. Remove the lower implement pin (Item 1) from the

lower mounts and lower link (Item 2) [Figure 19]

5. Enter the compact tractor.

(See Entering And Exiting The Compact Tractor on

Page 11)

6. Start the engine and release the parking brake.

OPERATING INSTRUCTIONS

17

Figure 20

P142006c

7. Slowly drive the compact tractor away from the

implement [Figure 20]

8. Remove the front ballast from the compact tractor (if

equipped).

LIFTING THE IMPLEMENT

Use chains that are in good condition and of adequate

size to lift the implement.

Figure 21

C141660a

• Fasten the chains to the three-point box blade (Item

1) [Figure 21].

OPERATING INSTRUCTIONS

18

TRANSPORTING THE IMPLEMENT ON A

TRAILER

Fastening The Implement On A Trailer

Figure 22

C141661a

Figure 23

C141662a

• Fasten the chains to the implement (Item 1)

[Figure 22] and [Figure 23] and fasten each end of

the chain to the transport vehicle.

• Use chain binders to prevent the implement from

moving during transport.

TRANSPORTING THE IMPLEMENT AND

MACHINE ON A TRAILER

Transporting The Attachment And Machine

On A Trailer

WARNING

INSTABILITY HAZARD

Wood ramps can break and cause personal injury.

Use adequately designed ramps of sufficient

strength to support the weight of the machine

loading onto a transport vehicle.◂

W-2058

Be sure the transport and towing vehicles are of

adequate size and capacity for weight of machine and

attachment combination. (See machine and attachment

Operation & Maintenance Manuals for specifications)

Loading

• The rear of the trailer must be blocked or supported

when loading and unloading to prevent the front of

the trailer from raising.

• Load the heaviest end of the machine and

attachment combination first.

• Lower the attachment to the floor.

• Turn the machine off.

• Engage the parking brake (if equipped).

• Exit the machine. (See the machine’s Operation

& Maintenance Manual for the correct

procedure.)

Fastening

• Install the chains at the front and rear tie-down

positions on the machine. (See the machine’s

Operation & Maintenance Manual to properly chain

the machine to the transport vehicle.)

• Install chains on the attachment (if required).

• Fasten each end of the chain to the transport

vehicle.

NOTE: Use chain binders to prevent the attachment

and machine from moving during transport.

OPERATING INSTRUCTIONS

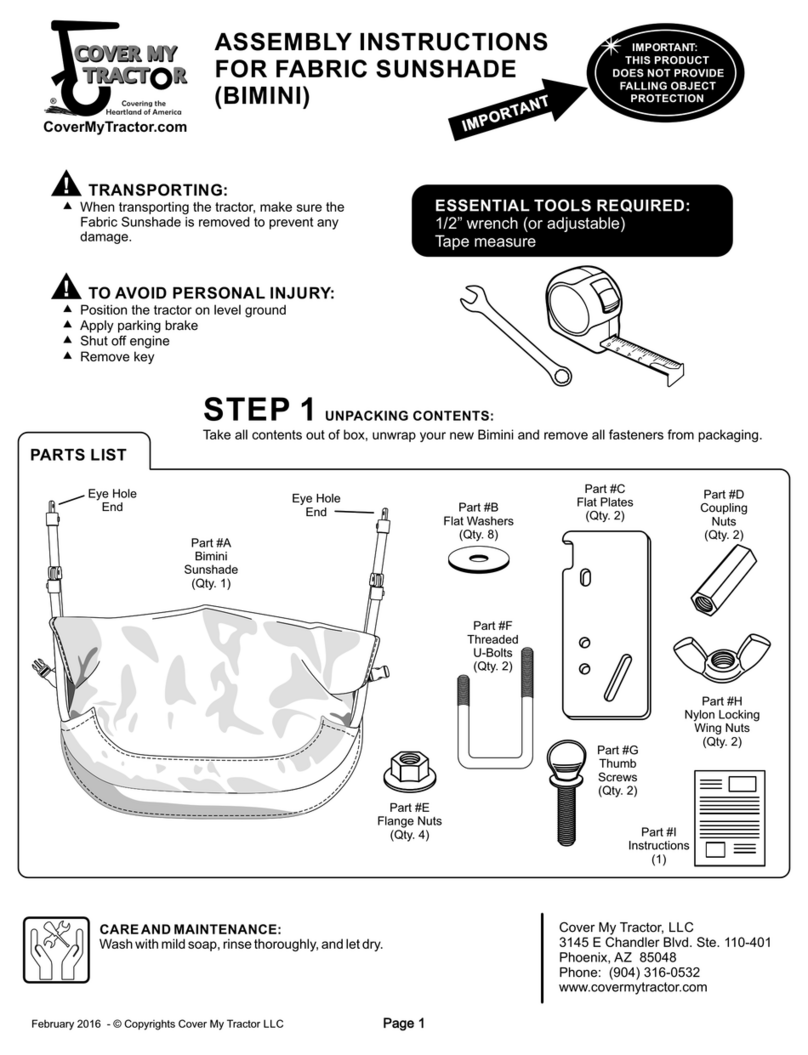

This manual suits for next models

2

Table of contents

Other Ignite Tractor Accessories manuals

Popular Tractor Accessories manuals by other brands

Cover My Tractor

Cover My Tractor Bimini Assembly instructions

Tiger

Tiger BENGAL 5085M Series Mounting and operating instructions

Swisher

Swisher 20020 owner's manual

HE-VA

HE-VA Top-Cutter Solo operating instructions

Original Tractor Cabs

Original Tractor Cabs CAB 12152 Assembly instructions

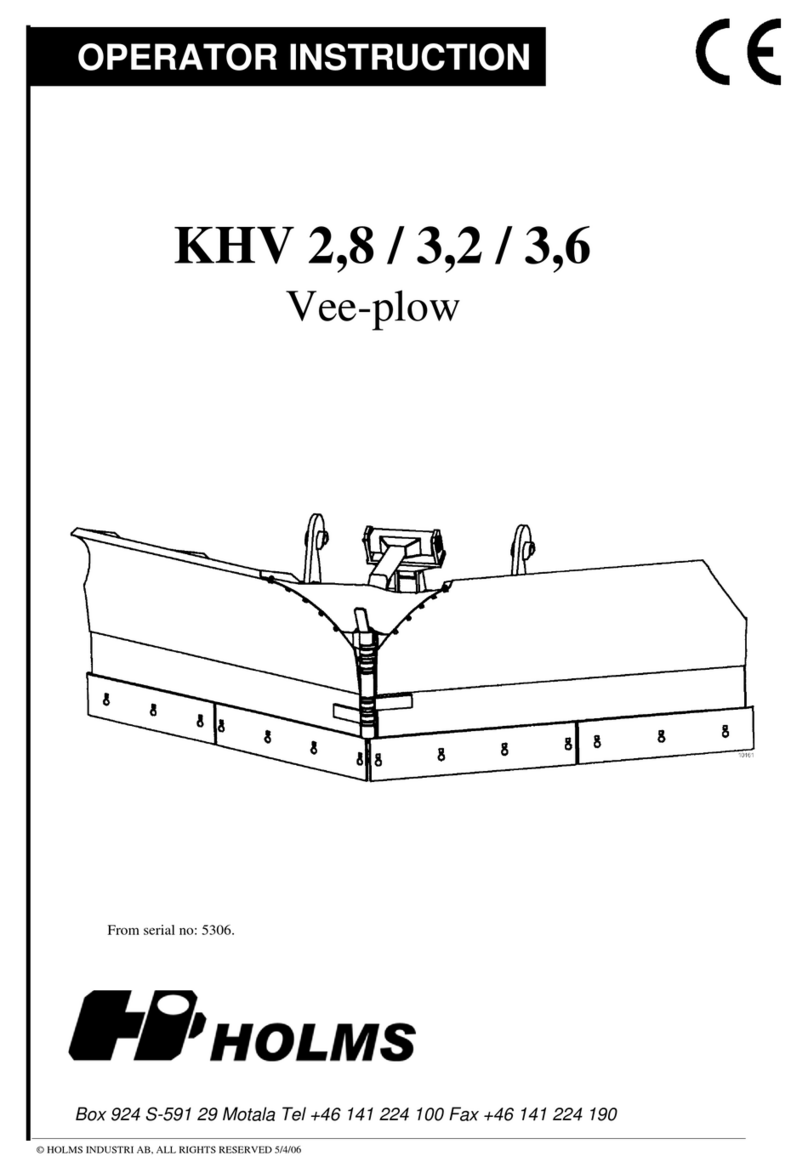

HOLMS

HOLMS KHV 280 SMS bracket Operator instructions