TECNOVAP Steam Box Professional Installation instructions

STEAM BOX PRO

USER INSTRUCTION

With integrated industrial vacuum cleaner

Standard

Bacchus

With vacuum cleaner

STEAM BOX PROFESSIONAL

Pag. 2 TECNOVAP 06/15

STEAM BOX PROFESSIONAL

Pag. 3 TECNOVAP 06/15

Interpretation of the symbols placed on the unit

BURNING DANGER!!

IT IS COMPULSORY TO USE PROTECTIVE GLOVES.

EQUIPMENT WITH SOUND PRESSURE LEVEL > 85db

IT IS COMPULSORY TO USE EARS PROTECTIVE SHROUDS.

BEFORE USING THE STEAM GENERATOR, READ AND FOLLOW THIS INSTRUCTION MANUAL.

IT IS RECOMMENDED TO KEEP THIS INSTRUCTION MANUAL TO CONSULT IT LATER OR TO GIVE IT TO THE

FOLLOWING OWNERS.

PLEASE READ THE SAFETY INSTRUCTIONS ON THIS HANDBOOK BEFORE PROCEEDING WITH THE FIRST USE.

EVENTUAL DAMAGES DUE TO THE CARRIAGE MUST BE COMMUNICATED AS SOON AS POSSIBLE TO YOUR

OWN RETAILER.

ATTENTION!!

STEAM…. BURNING DANGER

ATTENTION!!

READ THE OPERATING MANUAL

OPERATING MANUAL;

OPERATING INSTRUCTIONS

STEAM BOX PROFESSIONAL

Pag. 4 TECNOVAP 06/15

Environment protection

ALL THE PACKINGS ARE RECYCLABLE, PACKINGS DO NOT HAVE

TO BE THROWN IN THE DOMESTIC WASTE BUT THEY HAVE TO BE

DELIVERED TO THE CENTERS SPECIALIZED FOR THE DISPOSING

OF THE WASTE.

ALL DEVICES NOT USED ANYMORE CONTAIN PRECIOUS

RECYCLABLE MATERIALS THAT SHOULD BE DELIVERED TO THE

CENTERS SUITABLE FOR THE DISPOSING OF THE WASTE.

ELECTRIC AND ELECTRONIC EQUIPMENT, BATTERIES, OIL AND

SIMILAR SUBSTANCES MUST BE RECYCLED IN THE PROPER

RECYCLING CENTERS AND MUST NOT BE LEFT IN THE

ENVIRONMENT.

SUBSTANCES SUCH AS OIL FOR MOTORS, DIESEL OIL, PETROL

MUST NOT BE LEFT IN THE ENVIRONMENT AND MUST BE

RECYCLED IN THE PROPER RECYCLING CENTERS ACCORDING

TO THE ENVIRONMENTAL REGULATIONS.

The user might return the unit for disposal also to the retailer when purchasing a new equivalent device on a

one to one ratio.

STEAM BOX PROFESSIONAL

Pag. 5 TECNOVAP 06/15

1. SUMMARY

1. SUMMARY

2. SAFETY REGULATIONS

3. CONNECTION TO THE WATER NET

4. PREFACE

5. TECHNICAL CHARACTERISTICS

6. NOMENCLATURE

7. TECHNICAL DRAWINGS

8. OPERATING INSTRUCTIONS

9. MAINTENANCE

10. BEFORE REFERRING TO THE TECHNICAL SERVICE

11. DECLARATION OF CONFORMITY

2. SAFETY REGULATIONS

▪The electrical connection shall be made by a qualified electrician and comply with IEC 60364-1.

▪If the power cable is damaged, it has to be replaced by the manufacturer or by an authorized

technical service or by a qualified person in order to prevent any risk.

▪It is recommended that the electric supply to this machine should include either a residual current

device that will interrupt the supply if the leakage current to earth exceeds 30ma for 30ms or a device

which will prove the earth circuit.

▪SAFETY VALVE This machine is equipped with two safety valves, able to ensure the safety of the

machine itself in case other primary control devices are inefficient (due to a failure). Due to the extreme

importance of these components and as not to compromise the safety of the machine, it is

recommended to provide to check them and to substitute them through an authorized service center

every 2 years starting from the purchasing date.

▪PRESSURE SWITCH This machine is equipped with a pressure switch able to check and to maintain

the pressure under certain preset limits (ref. “rated pressure” on the technical label underneath the

machine). In case there would be a steam leakage on the lower side of the machine, it means that the

functioning of this device has been compromised and the safety valve has been involved as to limit the

boiler’s internal pressure. It is recommended not to use the machine, immediately unplug the

machine from the power feeding and call the service center.

▪MUD DRAIN FROM THE BOILER The unit automatically indicates the necessity to proceed with the

mud drain; the notice C A L C will be displayed alternatively to the current visualization on the panel.

STEAM BOX PROFESSIONAL

Pag. 6 TECNOVAP 06/15

▪ATTENTION. Use a new set of fittings, tubes and sealing gaskets every time the appliance is

connected to the water net.

▪ATTENTION. This appliance has been projected for being used with cleaning agents supplied or

recommended by the manufacturer. The usage of other detergents and chemicals may adversely affect

the safety of the user and of the appliance itself.

▪ATTENTION. Risk of explosion. Do not spray flammable liquids.

▪ATTENTION. Do not use the appliance within the range of persons unless they wear protective

clothing.

▪ATTENTION. The high pressure jets can be dangerous if not used properly. The jet does not have to

be directed against persons, electrical devices under tension or the unit itself.

▪ATTENTION. Do not direct the jet against yourself or others in order to clean clothes or footwear.

▪ATTENTION. Water flowed through the anti-reflux devices is not potable water approved.

▪Disconnect the power supply by unplugging the power cable before proceeding with the maintenance

effected by the user.

▪ATTENTION. This unit is not intended to be used by children or by unqualified persons.

▪Monitor the children so they cannot play with the machine.

▪ATTENTION. To ensure the machine’s safety, use only original spare parts from the manufacturer or

spare parts approved by the manufacturer.

▪ATTENTION. Pressure hoses, fittings and couplings are important for the safety of the machine. Use

only hoses, fittings and couplings recommended by the manufacturer.

▪ATTENTION. Do not use the machine if the power cord or other important parts of the machine are

damaged, i.e. safety devices, pressure hoses and trigger gun.

▪ATTENTION. If an extension cord is used, the plug and the socket must be of a watertight

construction.

▪ATTENTION. Inadequate extension cords can be dangerous.

▪The hand-arm vibration data referred to this device are not mentioned as they are below 2,5 m/s².

▪ATTENTION. The detergent injection of this appliance can’t be used continuously but intermittently

(20 seconds ON - 20 seconds OFF). The detergent can be continuously used for no longer than two

minutes.

▪When using detergent (make sure it’s non-foaming) please follow the specific instructions: 1 liter of

detergent for every 10 liters of water (detergent percentage about 10%), making sure to fill in first the

detergent to obtain a better mixing.

STEAM BOX PROFESSIONAL

Pag. 7 TECNOVAP 06/15

Please be careful with the detergent to be used as some available in commerce will emanate

highly toxic gases when heated above 100°C. Always consult the MSDS datasheet from the

manufacturer.

▪ATTENTION. In case of accidental contact with the detergent, strictly follow the instructions indicated

on its packaging or in its MSDS.

▪Use ear protections and gloves while using the machine.

3. CONNECTION TO THE WATER NET

The connection to the water net shall be made by qualified personnel. It

is recommended to use a new set of food grade fittings and food grade

hoses; it is not possible to use again the same set (fittings, tubes,

gaskets, reductions etc.) for a new connection.

Being a movable device, the connection hose to the water net is not

supplied due to the unknown distance from the water connection point.

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

6 bar max

2 bar min

STEAM BOX PROFESSIONAL

Pag. 8 TECNOVAP 06/15

4. PREFACE

Dear Client,

We would like to congratulate you on your choice.

With the goal of improving and continually updating production by always offering innovative products,

TECNOVAP has studied, designed and created STEAM BOX PRFESSIONAL, a combined model for

cleaning which brings together the power of steam and the force of vacuuming (optional).

This product is equipped with a dependable stainless steel boiler with automatic refilling system which

allows it to produce a powerful and continuous supply of steam (24/24 hours).

STEAM BOX PROFESSIONAL offers the overheated water function and is also equipped with a

separate detergent tank which allows the injection of detergent up to 90-160°C.

With the power of steam, meaning ecological cleaning power, Tecnovap has combined a powerful

vacuum (optional) able to pick up solids and liquids.

STEAM BOX PROFESSIONALL is the ideal solution when it comes to cleaning and disinfecting.

STEAM BOX PROFESSIONAL

Pag. 9 TECNOVAP 06/15

5. TECHNICAL CHARACTERISTICS

FACTORY: TECNOVAP SRL VIA DEI SASSI 1A 37026 PESCANTINA VERONA ITALY

Model

Steam Box Professional

Code

4W07010 - 4W06010 - 4W05010 - 4W04010 - 4W0401M

4W07A10 - 4W06A10 - 4W05A10 - 4W04A10 - 4W04A1M

4W07T10 - 4W06T10 - 4W05T10 - 4W04T10 - 4W04T1M

Rated Voltage

V

230/400

Current type

Hz

50/60 3~

Rated Power Boiler

kW

10,8 –14,4 –21,6 –28,8 –36,0

10,8 –14,4 –21,6 –28,8 –36,0

10,0 –14,4 –20,75

Rated Power vacuum

kW

1,0 –1,2 –3,0

Max Rated Power

kW

11,0 –14,8 –22,0 –29,2 –36,4

11,0 –17,8 –22,0 –32,2 –39,4

11,1 –15,8 –22,15

Rated Steam Pressure

kPa

bar

1000

10

Permissible Steam Pressure

kPa

bar

1200

12

Max. Steam Rated Flow

g/min

291 –388 –582 –776 –970

291 –388 –582 –776 –970

291 –388 –564

Max. Steam Rated Flow

Kg/h

17,5 –23,0 –35,0 –46,5 –58,0

17,5 –23,0 –35,0 –46,5 –58,0

17,5 –23,0 –33,8

Max temperature

°C

180

Max. inlet water pressure

KPa

bar

600

6

Min. inlet water pressure

KPa

bar

50

0,5

Kickback forces

N

< 20

Vibration hand-arm

m/s²

< 2,5

Sound pressure level LPa

dB

98,7

Sound power level Lwa

dB

111,4

Mass

kg

106

STEAM BOX PROFESSIONAL

Pag. 10 TECNOVAP 06/15

Model

Steam Box Professional Bacchus

Code

4007060 –4006060 –4005060 –4004060 –400406M

Rated Voltage

V

230/400

Current type

Hz

50/60 3~

Rated Power Boiler

kW

10,8 –14,4 –21,6 –28,8 –36,0

Max Rated Power

kW

11,0 –14,8 –22,0 –29,2 –36,4

Rated Steam Pressure

kPa

bar

600

6

Permissible Steam Pressure

kPa

bar

1200

12

Max. Steam Rated Flow

g/min

291 –388 –582 –776 –970

Max. Steam Rated Flow

Kg/h

17,5 –23,0 –35,0 –46,5 –58,0

Max temperature

°C

165

Max. inlet water pressure

KPa

bar

600

6

Min. inlet water pressure

KPa

bar

50

0,5

Kickback forces

N

< 20

Vibration hand-arm

m/s²

< 2,5

Sound pressure level LPa

dB

98,7

Sound power level Lwa

dB

111,4

Mass

kg

106

STEAM BOX PROFESSIONAL

Pag. 11 TECNOVAP 06/15

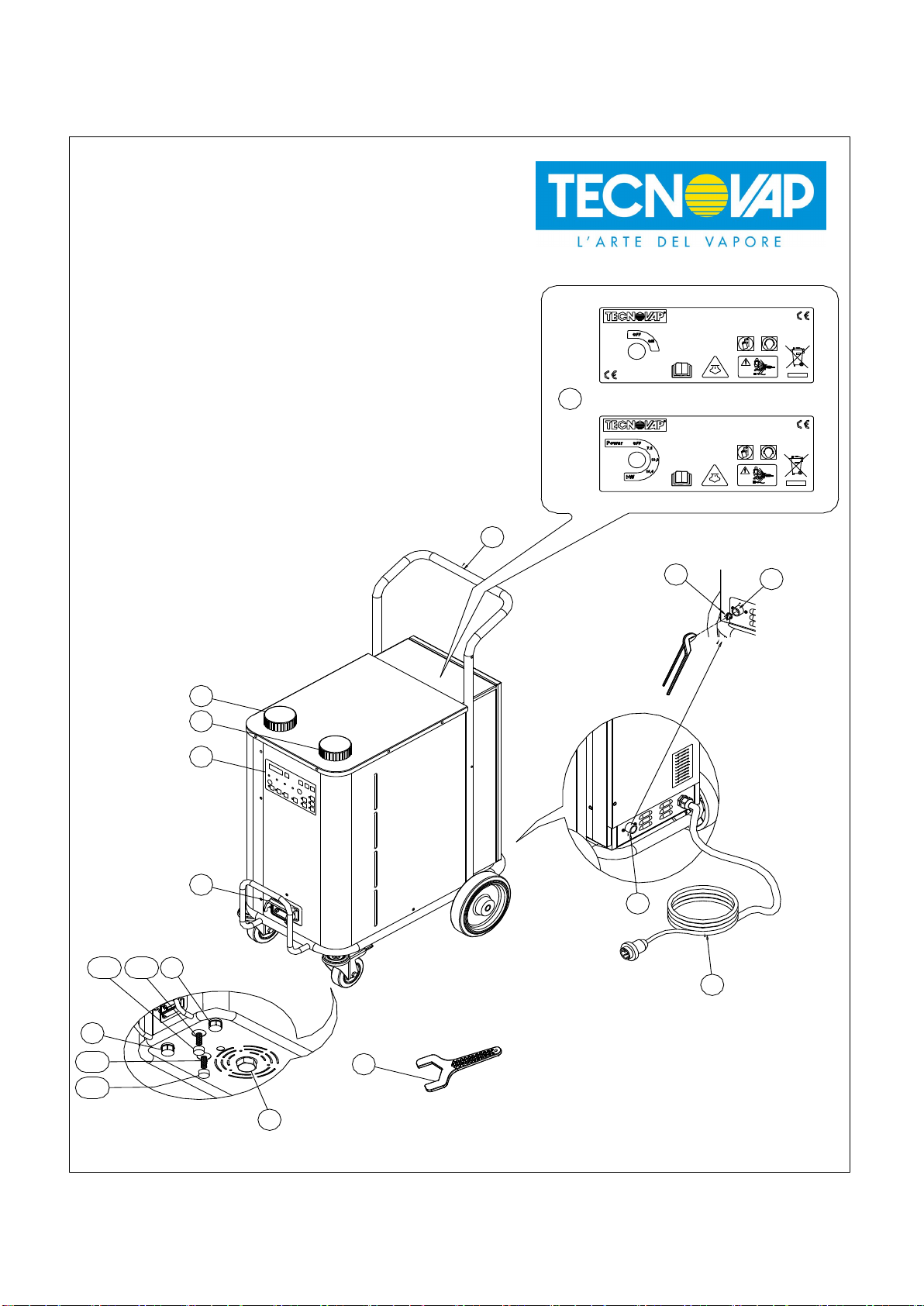

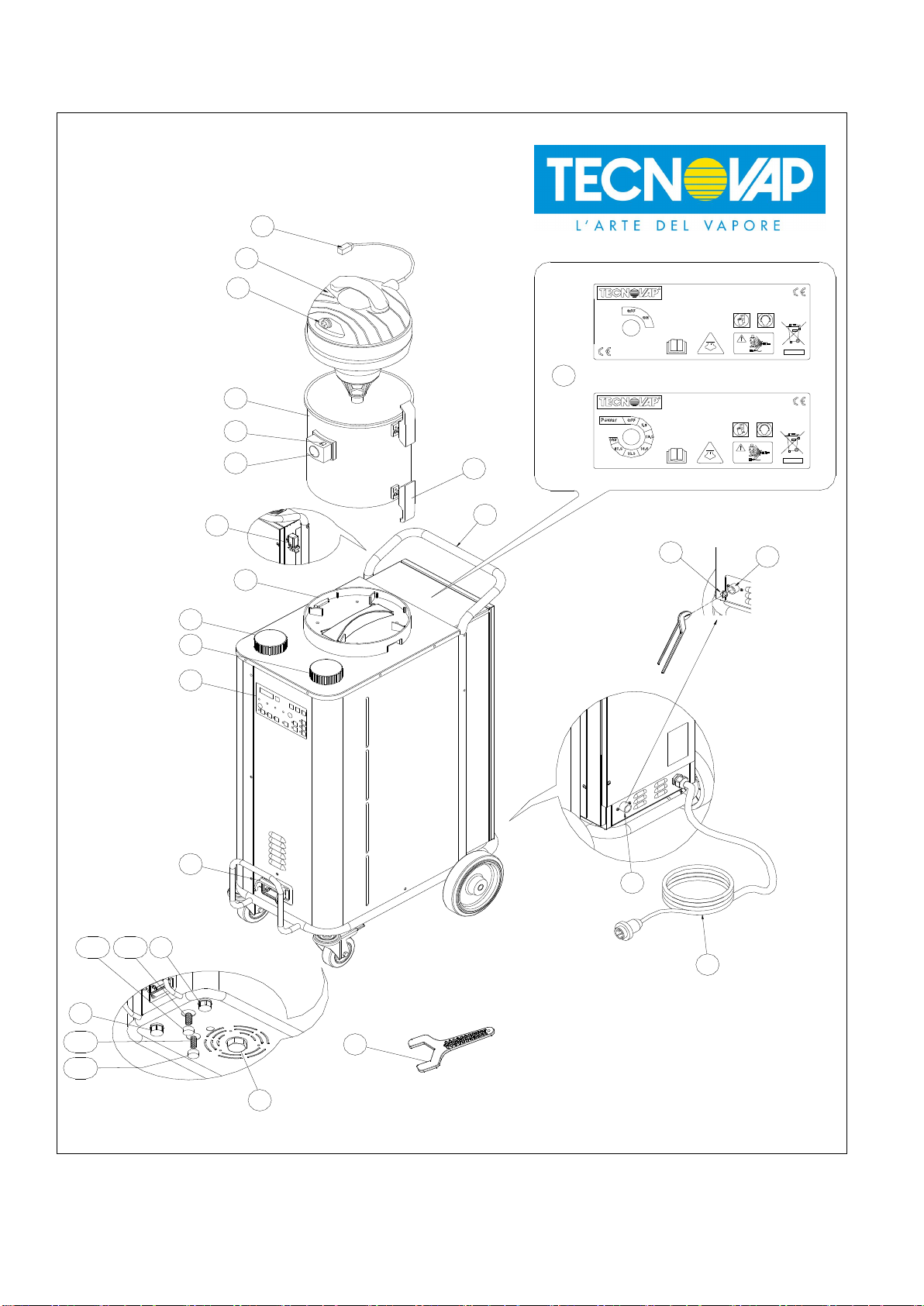

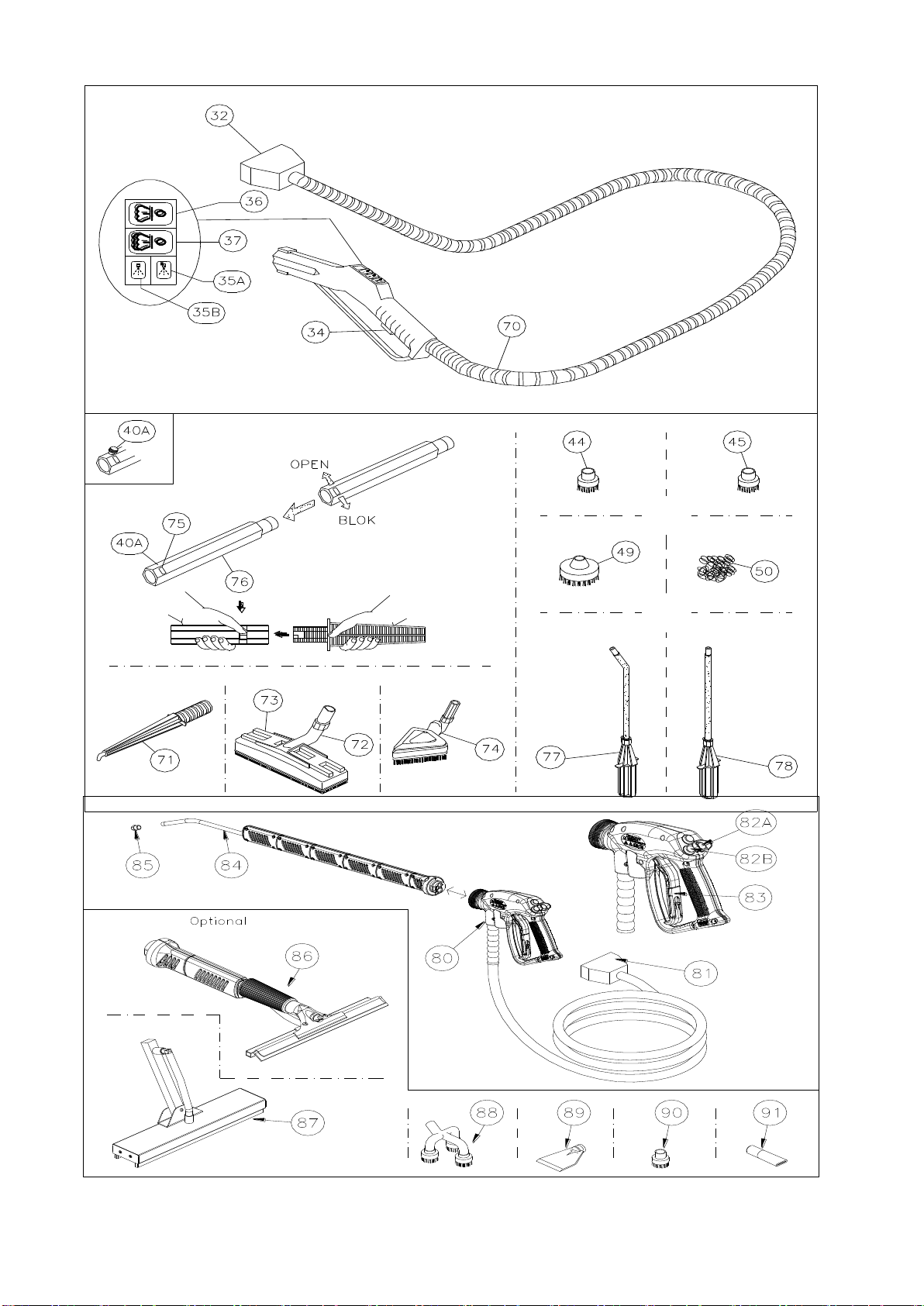

6. NOMENCLATURE

Steam Box Professional

01) Power cord

35B) Hot water switch

02) Water inlet for direct water feed

36) 37) Steam regulation switches

03) Water inlet valve filter

38) Vacuum switch

04) General power switch

40) Locking latches for accessories

05) Handle bar

40A) Handwheel screw

06) Detergent tank

07) Water tank

41) Steam / vac extension tubes

08) Control panel

42) Steam / vac turbo lance

08A) Bacchus control panel

44) Brass brush (Ø 28mm)

09) Steam outlet

45) St. steel brush (Ø 28mm)

10) Drain cap –detergent tank

49) St. steel brush (Ø 60mm)

10A) Detergent filter cap

50) St. steel wool pad

10B) Detergent filter

51) Floor tool for inserts

11) Drain cap –water tank

52) Locking latches for inserts

11A) Water filter cap

53) Insert squeegee / brush

11B) Water filter

54) Insert squeegee / squeegee (L. 375mm)

12) Boiler drain cap

55) Steam & vac industrial brush L.530

13) Key for boiler drain cap

56) St. steel upholstery tool

14) Electric socket for vacuum cleaner

15) Vacuum hose outlet

70) Steam hose w/ handgrip

16) Locking latch vacuum outlet

71) Steam lance

17) Base for vacuum drum

72) Rectangular brush

18) Vacuum drum

73) Cloth holder

19) Clamping hooks for vacuum motor

74) Triangular brush

20) Locking latch vacuum outlet

75) Locking latches for accessories

21) Vacuum hose outlet

76) Extension tube

22) Vacuum head

77) Curved bayonet lance 45°

23) Vacuum cleaner power cord

78) Bayonet lance

24) Vacuum cleaner main switch

25) Connection tube vacuum drum –turbine

80) Geyser hose with handgrip

26) Steam hose

81) Steam plug

26A) Hose - bottling line rapid coupling

82A) Hot water injection button (red)

27) Garolla connection steam hose coupling

82B) Detergent button (yellow)

27A) Bottling line overpressure safety valve

83) Steam outlet lever

27B) Garolla connection

84) Lances 100 / 400 / 800 / 1200 mm

28) Safety pressure switch (optional)

85) Round nozzle

86) Window cleaner with diffuser 250 / 350 / 450 mm

30) Vacuum hose

87) Steam brush with bristles 250 / 350 / 450 mm

32) Steam plug

88) St. steel floor scrubber with 3 brushes

33) Steam & vac hose w/ handgrip

89) Flat nozzle 4 cm with scraper

34) Steam command switch

90) St. steel brush

35A) Detergent switch (intermittent)

91) Flat nozzle 1 cm

STEAM BOX PROFESSIONAL

Pag. 12 TECNOVAP 06/15

7. TECHNICAL DRAWINGS

6

7

8

9

10

11

10B

11B

12

13

10A

11A

4

2

1

5

3

SteamBox Professional

2

SINGLE POWER

MULTI POWER

STEAM BOX PROFESSIONAL

SteamBox Professional

AD4401M

AD40010

STEAM BOX PROFESSIONAL

Pag. 13 TECNOVAP 06/15

6

7

8

9

10

11

10B

11B

12

13

20

10A

11A

4

2

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

1

5

19

17

18

21

3

Steam Box Industrial

Steam Box Industrial

2

SINGLE POWER

MULTI POWER

24

23

22

14

STEAM BOX PROFESSIONAL

WITH VACUUM CLEANER

AD5301M

AD50010

STEAM BOX PROFESSIONAL

Pag. 14 TECNOVAP 06/15

6

7

8

9

10

11

10B

11B

12

13

20

22

25

10A

11A

4

2

1

5

19

17

18

21

16

15

32

SINGLE POWER

MULTI POWER

STEAM BOX PROFESSIONAL

CON ASPIRATORE INTEGRATO

SteamBox Professional

SteamBox Professional

AD4401M

AD40010

STEAM BOX PROFESSIONAL WITH

INTERGRATED VACUUM CLEANER

STEAM BOX PROFESSIONAL

Pag. 15 TECNOVAP 06/15

7

9

1111B

12

13

11A

4

2

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

kvglircismlòerga

1

5

3

SteamBoxBacchus

2

SINGLE POWER

MULTI POWER

STEAM BOX PROFESSIONAL

BACCHUS

SteamBoxBacchus

AD4406M

AD40060

8A

26A

26

28 27A

27B

27

26

STEAM BOX PROFESSIONAL

Pag. 16 TECNOVAP 06/15

STEAM BOX PROFESSIONAL

Pag. 17 TECNOVAP 06/15

KIT GEYSER 10 bar

JULY 10bar ACCESSORIES

ONLY FOR MODELS 10.8 kW e 14.4 kW

STEAM BOX PROFESSIONAL

Pag. 18 TECNOVAP 06/15

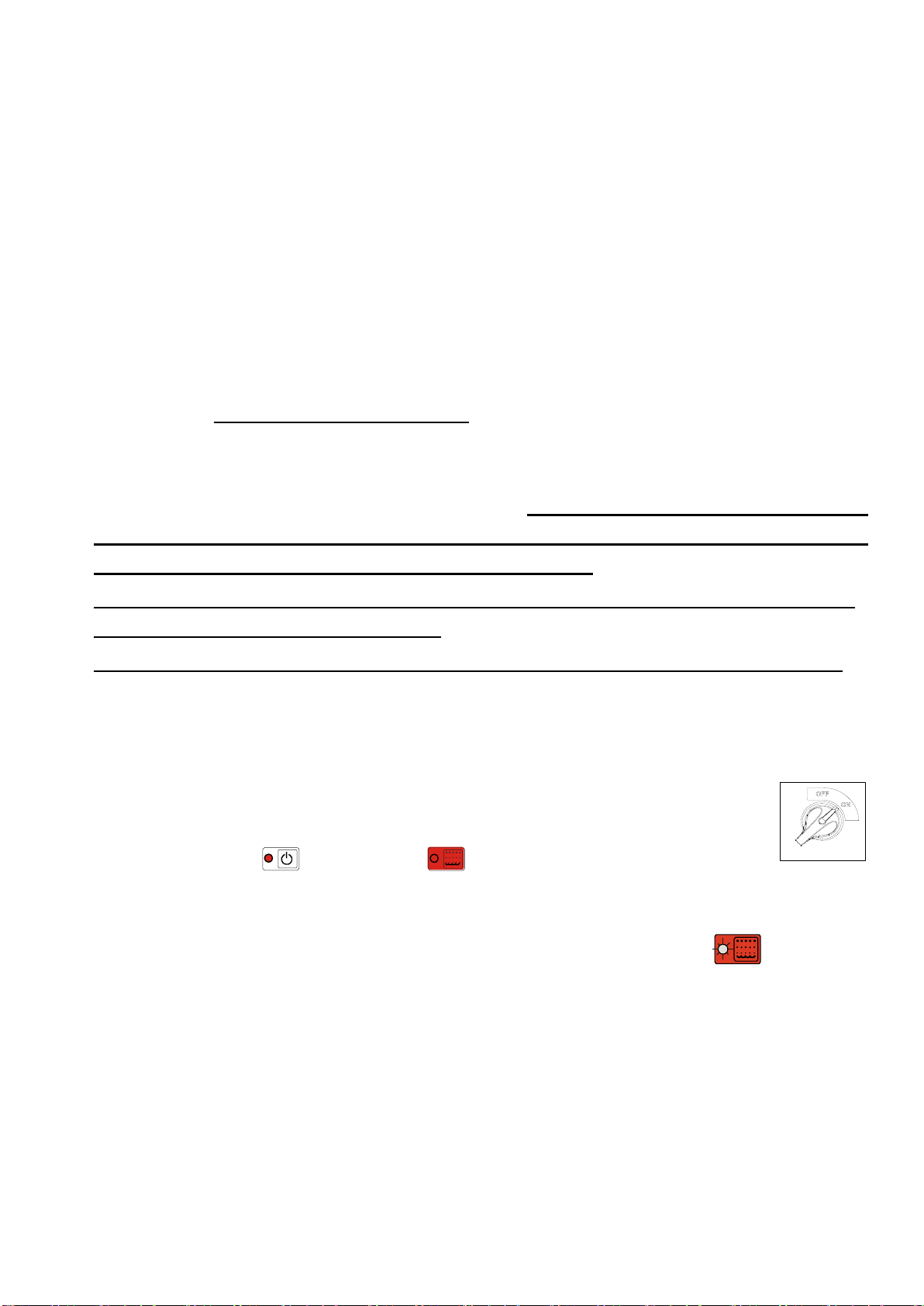

CONTROL PANEL (POS. 8)

Presence of tension

Informs the user that the

appliance is connected to the

power source.

Steam ready indicator

If this indicator is lit up, the

generator is ready to use.

“Low water” indicator

Indicates the lack of water in the tank, the indication is accompanied by an intermittent buzzer.

If lit, the overheated water injection cannot be used and steam production will be interrupted.

“Low detergent” indicator

Indicates the lack of detergent in the tank, the indication is accompanied by a continuous

buzzer. Attention! The continuous acoustic signal must have priority on the water intermittent

acoustic signal. For security reasons, please check the activation of both warning lights.

Power button

Powers the electronic components, steam solenoid valves and boiler refilling pump.

Boiler activation button

Activates the heating elements, the detergent pump and the overheated water injection valve.

If there is no water inside the boiler, the LED light will blink and the heating elements will not

be activated as long as the default level of liquid into the boiler will not be achieved. After

achieving the correct water level, the light will be fixed.

Direct water intake button

Activation of water supply from the water net; the LED light will show the status with a steady

light.

Steam regulation indicators: minimum –medium –maximum.

Detergent discharging switch and temperature / pressure display.

Total working hours (C1) (hour counter / totalizer).

Partial working hours; this hour counter is resettable by the user.

Clock set-up switch (the current time is displayed only when the machine is in stand-by mode).

STEAM BOX PROFESSIONAL

Pag. 19 TECNOVAP 06/15

BACCHUS CONTROL PANEL (POS. 8A)

Presence of tension

Informs the user that the

appliance is connected to the

power source.

Steam ready indicator

If this indicator is lit up, the

generator is ready to use.

“Low water” indicator

Indicates the lack of water in the tank, the indication is accompanied by an intermittent buzzer.

If lit, the overheated water injection (optional) cannot be used and steam production will be

interrupted.

“Low detergent” indicator

Function not enabled.

Power button

Powers the electronic components, steam solenoid valves and boiler refilling pump.

Boiler activation button

The unit automatically recognizes the inserted Bacchus hose and activates steam activation

buttons on the control panel and the heating elements. If there is no water inside the boiler, the

LED light will blink and the heating elements will not be activated as long as the default level of

liquid into the boiler will not be achieved. After achieving the correct water level, the light will

be fixed.

Direct water intake button

Activation of water supply from the water net; the LED light will show the status with a steady

light.

Steam activation buttons/indicators: minimum –medium –maximum.

Temperature / pressure display.

Total working hours (C1) (hour counter / totalizer).

Partial working hours; this hour counter is resettable by the user.

Clock set-up switch (the current time is displayed only when the machine is in stand-by mode).

STEAM BOX PROFESSIONAL

Pag. 20 TECNOVAP 06/15

8. OPERATING INSTRUCTIONS

(a) Fix the vacuum drum (18) on the round black base (17) by operating on the hooks (19).

(b) Insert the plug of the vacuum cleaner (23) into the outlet located on the right side of the steam

generator (14) (only for models with external vacuum cleaner).

(c) Insert one end of the hose (25) into the vacuum head (22) and the other end into the vacuum hose

outlet (15), activating the locking latch (16) (only for models with integrated vacuum cleaner).

(d) Remove the tanks caps (6 and 7) and fill in water and detergent in the relevant tanks, water inside

the blue funnel and detergent into the yellow funnel. It is recommended to be very careful

during this process because an inverted filling up (detergent into the water tank or water into

detergent tank) causes a steam generator fault.

(e) When using detergent (not foamy for extractions machines), please follow the specific instructions:

normally 1 liter of detergent for every 10 liters of water (detergent percentage about 10%), making

sure to fill in first the detergent to obtain a better mixing. Please be careful with the detergent to be

used as some available in commerce will emanate highly toxic gases when heated above

100°C. Always consult the MSDS datasheet from the supplier.

The detergent tank has to be filled only with detergent diluted with water, not with water only,

unless you are not using demineralized water.

The usage of water only (not demineralized) instead of detergent causes faults to the mixing circuit.

(f) Insert the plug (1) into the electrical outlet, making sure that the voltage and the amperage correspond

with the data printed on the plate located on the rear side of the unit.

(g) Switch the unit on by rotating the main switch onto position ON or onto the desired

power (only for models with power regulation).

Activate the standby and the boiler switches.

(h) The machine is equipped with a protective system against thermal shock. Therefore, in case of water

lacking inside the boiler, the system automatically disconnects the heating elements supply. This

situation is recognizable thanks to the blinking LED light on the “boiler switch” . The system

can intervene also after the boiler refilling once performed the mud drain during the maintenance

process.

Other manuals for Steam Box Professional

1

This manual suits for next models

14

Table of contents

Other TECNOVAP Kitchen Appliance manuals