TECNOVAP Evo 304 Base Installation instructions

EVO 304 BASE / EVO BLU BASE

Pag. 1 29/16

This manual is available in digital format on request;

kindly contact Info@tecnovap.it

EVO 304 BASE – EVO BLU BASE

USER INSTRUCTION

EVO 304 BASE / EVO BLU BASE

Pag. 2 29/16

EVO 304 BASE / EVO BLU BASE

Pag. 3 29/16

Interpretation of the symbols placed on the unit

BEFORE USING THE STEAM GENERATOR, READ AND FOLLOW THIS INSTRUCTION MANUAL.

IT IS RECOMMENDED TO KEEP THIS INSTRUCTION MANUAL TO CONSULT IT LATER OR TO GIVE IT TO THE

FOLLOWING OWNERS.

PLEASE READ THE SAFETY INSTRUCTIONS ON THIS HANDBOOK BEFORE PROCEEDING WITH THE FIRST USE.

EVENTUAL DAMAGES DUE TO THE TRANSPORT MUST BE COMUNICATED AS SOON AS POSSIBLE TO YOUR

OWN RETAILER.

ATTENTION!!

STEAM…. RISK OF BURNS

ATTENTION!!

READ THE OPERATING MANUAL

DO NO DIRECT THE STEAM JET AGAINST PEOPLE, ANIMALS,

ELECTRICAL DEVICES UNDER TENSION OR THE UNIT ITSELF.

EVO 304 BASE / EVO BLU BASE

Pag. 4 29/16

ENVIRONMENT PROTECTION

ALL PACKAGING ARE RECYCLABLE, PACKINGS DO NOT HAVE TO

BE THROWN IN THE DOMESTIC WASTE BUT THEY HAVE TO BE

DELIVERED TO THE CENTERS SPECIALIZED FOR THE DISPOSING

OF THE WASTE.

ALL DEVICES NOT USED ANYMORE CONTAIN PRECIOUS

RECYCLABLE MATERIALS THAT SHOULD BE DELIVERED TO THE

CENTERS SUITABLE FOR THE DISPOSING OF THE WASTE.

ELECTRIC AND ELECTRONIC EQUIPMENT, BATTERIES, OIL AND

SIMILAR SUBSTANCES MUST BE RECYCLED IN THE PROPER

RECYCLING CENTERS AND MUST NOT BE LEFT IN THE

ENVIRONMENT.

SUBSTANCES SUCH AS OIL FOR MOTORS, DIESEL OIL, PETROL

MUST NOT BE LEFT IN THE ENVIRONMENT AND MUST BE

RECYCLED IN THE PROPER RECYCLING CENTERS ACCORDING

TO THE ENVIRONMENTAL REGULATIONS.

The user might return the unit for disposal also to the retailer when purchasing a new equivalent device on a

one to one ratio.

EVO 304 BASE / EVO BLU BASE

Pag. 5 29/16

1. SUMMARY

1. SUMMARY

2. SAFETY REGULATIONS

3. TECHNICAL CHARACTERISTICS

4. PREFACE

5. NOMENCLATURE

6. TECHNICAL DRAWINGS

7. OPERATING INSTRUCTIONS

8. MAINTENANCE

9. BEFORE REFERRING TO THE TECHNICAL SERVICE

10. DECLARATION OF CONFORMITY

2. SAFETY REGULATIONS

§It is recommended not to open or remove any machine part for any reason; in case the unit should

present an abnormal functioning or a failure, disconnect the power plug and contact an authorized

service center or the dealer where the product has been purchased.

§If the power cable is damaged, it has to be replaced by the manufacturer or by an authorized

technical service or by a qualified person in order to prevent any risk.

§It is recommended that the electric supply to this machine should include either a residual current

device that will interrupt the supply if the leakage current to earth exceeds 30ma for 30ms or a device

which will prove the earth circuit.

§SAFETY VALVE This machine is equipped with one safety valve, able to ensure the safety of the

machine itself in case other primary control devices are inefficient (due to a failure). Due to the

extreme importance of this component and as not to compromise the safety of the machine, it is

recommended to provide to check the valve and to substitute it through an authorized service center

every 2 years starting from the purchasing date.

§PRESSURE SWITCH This machine is equipped with a pressure switch able to check and to maintain

the pressure under certain preset limits (ref. “rated pressure” on the technical label underneath the

machine). In case there would be a steam leakage on the lower side of the machine, it means that

the functioning of this device has been compromised and the safety valve has been involved as to

limit the boiler’s internal pressure. It is recommended not to use the machine, immediately

unplug the machine from the power feeding and call the service center.

§THERMOSTATS. The unit is equipped with 2 thermostats able to control the over temperature. In

case the main control system becomes inefficient, TR1 and TR4 would intervene permanently by

deactivating the boiler heating. If this occurs, disconnect the power plug and contact a service center.

EVO 304 BASE / EVO BLU BASE

Pag. 6 29/16

§MUD DRAIN FROM THE BOILER The machine is equipped with a warning system “mud drain”. The

writing CALC will appear on the display to indicate that it is necessary to proceed with the boiler

cleaning (see chapter 8 maintenance).

The opening of the drain cap has to be strictly carried out when the machine has been

switched off (plug not inserted) for at least 5 hours.

§ATTENTION. Do not use the appliance within the range of persons.

§ATTENTION. The steam jets can be dangerous if not used properly. The jet does not have to be

directed against persons, electrical devices under tension or the unit itself.

§ATTENTION. Do not direct the jet against yourself or others in order to clean clothes or footwear.

§Disconnect the power, by removing the plug from the electrical socket, before effectuating the

maintenance on user’s responsibility.

§ATTENTION. Risk of explosion. Do not spray flammable liquids.

§This device is not intended to be used by children. Monitor the children so they cannot play with the

machine.

§This device is not intended to be used by persons (including children) with a reduced physical,

mental or sensorial ability or with insufficient experience and/or competence.

§This unit is not designed to operate at over 2000m above sea level.

§ATTENTION. To ensure the machine’s safety, use only original spare parts from the manufacturer or

spare parts approved by the manufacturer.

§ATTENTION. Pressure hoses, accessories and couplings are important for the safety of the

machine. Use only those recommended by the manufacturer.

§ATTENTION. Do not use the machine if the power cord or other important parts of the machine are

damaged, i.e. safety devices, pressure hoses and trigger gun.

§ATTENTION. Always switch off the general power switch when leaving the unit unattended.

§ATTENTION. Inadequate extension cords can be dangerous. If an extension cord is used it must be

suitable for outdoor use and the connections must be dry and distant from the ground. It is

recommended to use a reel able to keep the plug at a minimum distance of 60mm from the ground.

§ATTENTION. The user must not leave the iron (optional) unattended when it is connected to the

power supply.

§The hand-arm vibration data, referred to this device, are not mentioned as they are below 2.5 m / s ².

EVO 304 BASE / EVO BLU BASE

Pag. 7 29/16

3. TECHNICAL CHARACTERISTICS

FACTORY:TECNOVAP SRL VIA DEI SASSI 1A 37026 PESCANTINA VERONA ITALY

Model

Evo Base

Standard code

304

ER3206I

Blu

ER32060

Boiler volume

L

4.0

Water capacity

L

3.0

Rated Voltage

V

230

Current type

Hz

50 / 60

Rated Power Boiler

kW

2.40

Max Rated Power

kW

2.40

Rated Steam Pressure

kPa

bar

600

6

Permissible Steam Pressure

kPa

bar

650

6.5

Max. Steam Rated Flow

L/min

0.064

Max. Steam Rated Flow

Kg/h

3.8

Max temperature

°C

165

Mass

Kg

14

Sound pressure level

LpA

< 70 dB(A)

EVO 304 BASE / EVO BLU BASE

Pag. 8 29/16

4. PREFACE

Dear Client,

We would like to congratulate you on your choice.

This appliance, together with its accessories, is designed to clean and sanitize surfaces and can be used

in both domestic and commercial sector.

Please consider that the machine before leaving our factory has been tested and tweaked by qualified

and specialized personnel in order to have the best performing results.

This model has a reliable stainless steel boiler which allows to obtain a powerful and steady steam flow.

Evo 304 Base / Evo Blu Base is the ideal solution with regards to cleaning and disinfection. With the

various available accessories it cleans, disinfects and removes dirt by also completely eliminating the

bacterial flora hidden in the most concealed places.

Read carefully this instructions manual as to be able to fully exploit the specifications of your

TECNOVAP steam generator and keep it with you in case of future clarifications.

EVO 304 BASE / EVO BLU BASE

Pag. 9 29/16

5. NOMENCLATURE

01) Boiler cap with safety valve

30) Extension tubes

03) General power switch

31) Blocking hook

04) Power cord with plug

33) Rectangular brush

05) Boiler drain cap

34) Cloth holder

06) Steam outlet / accessory connection

35) Triangular brush

07) Power button

36) Window cleaner

08) Boiler switch

37) Steam lance

09) Digital display

38) Nylon brush Ø 60

10) “Steam ready” indicator light

39) Small nylon brush Ø 28

11) “Low water” indicator light

40) Small brass brush Ø 28

41) Small st. steel brush Ø 28

12) Steam hose

42) Small triangular brush

13) Safety switch - steam outlet

43) Steam plunger

14) Locking lever for steam outlet

44) Steam scraper

15) Steam plug / remote control

45) Steel wool pad

16) Steam plug blocking hook

46) Filling bottle

17) Steam hose control panel

47) Rectangular steam buffer (optional)

17A) Steam selector (min-med-max)

48) Triangular steam buffer (optional)

17B) “Minimum steam” light

49) Microfiber cloth

17C) “Medium steam” light

17D) “Maximum steam” light

60) Steam iron (optional)

17E) “Low water” indicator light

61) Thermostat

62) Steam command switch

63) Rubber rest pad for iron (optional)

EVO 304 BASE / EVO BLU BASE

Pag. 10 29/16

6. TECHNICAL DRAWINGS

EVO 304 BASE / EVO BLU BASE

Pag. 11 29/16

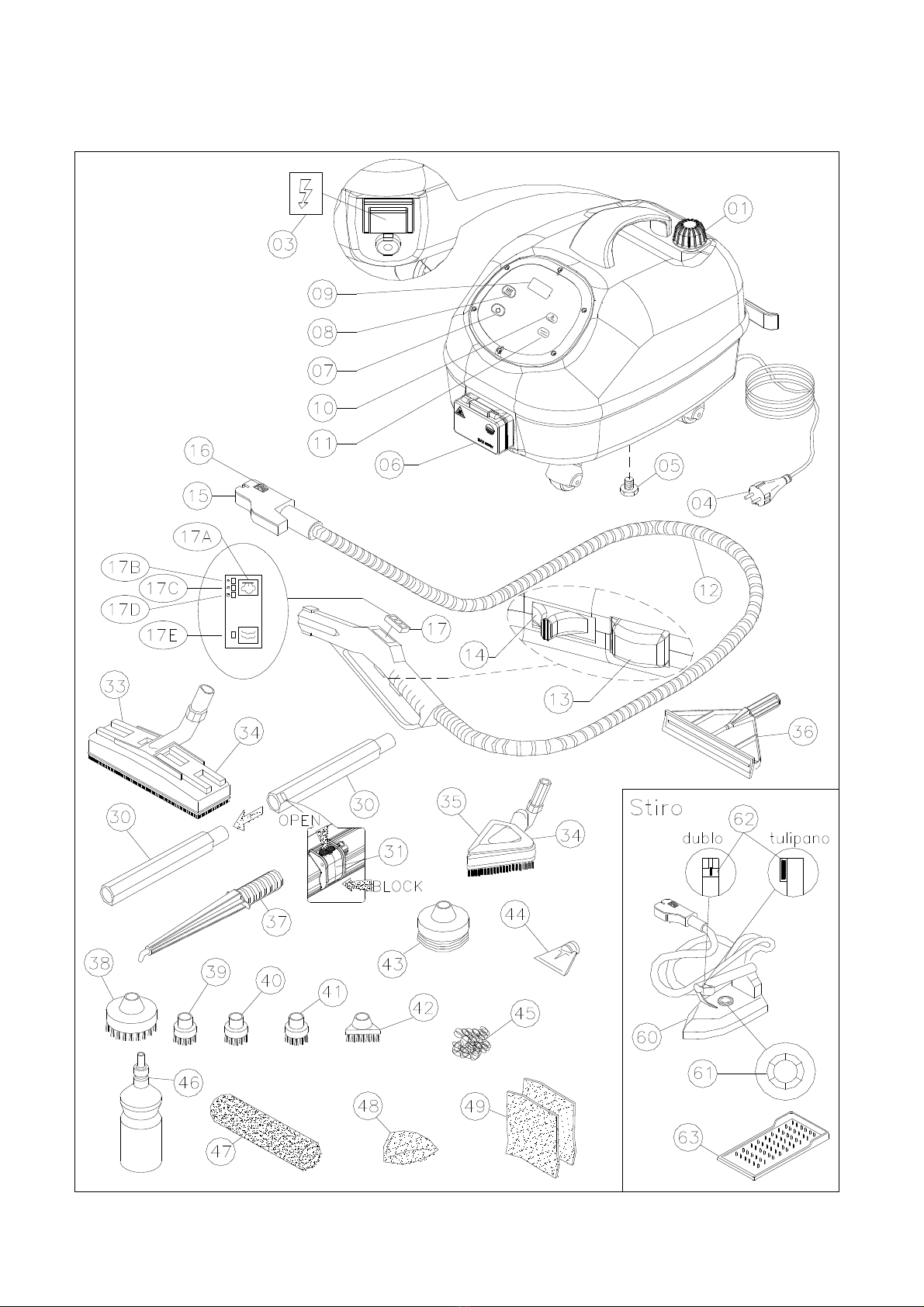

FUNCTIONS CONTROL PANEL

7. OPERATING INSTRUCTIONS

(a) Open the box and eventually block the unit on its cart (optional).

(b) Open the boiler safety cap (01) and add maximum 3 liters of water, it is recommended to use

only softened water, all other liquids can damage the generator or make it unsafe.

ATTENTION!! BURNING DANGER!!

(c) Screw on the safety cap (1) until it completely closes. NEVER unscrew it during usage.

(d) Check that there is an earthing system in the electric socket of your home. Insert the plug (04)

into an electrical outlet, making sure that the voltage and the amperage correspond to those

printed on the plate located under the machine.

(e) Refilling of water:

Add water only when the machine has cooled down (switched off for at least 5 hours), or when

the “Low water” indicators light on, as follow:

- Remove the plug from the power supply, unscrew the cap a turn and wait until the steam

generator has no pressure (all the steam has to come out).

- Only after having verified the absence of pressure it is possible to completely unscrew it.

- Do NEVER completely unscrew the cap without having read the instructions, it may

cause serious burns.

Presenza vapore

Mancanza acqua

Pulsante a!vazione caldaia

Pulsante accensione

Display mul"funzione

Multifunction display

Boiler activation switch

Power button

Steam ready indicator

Low water indicator

EVO 304 BASE / EVO BLU BASE

Pag. 12 29/16

- In case the refilling of water should be wrongly made without removing the plug from the

power supply, confirm the occurred refilling by pressing the “boiler switch” (8).

Power save mode

The power save mode permits to reduce the unit’s consumption after 1 hour of inactivity. For

activating or deactivating such mode it is enough to switch the generator off by pressing the switch

(07), then press and hold for some seconds the “boiler switch” (08). The display will show

alternatively T.ON or T.OFF depending on the previously selected setting.

7.1 USAGE OF TOOLS

Insert the steam plug (15) in the steam outlet (06) placed on the machine.

Press well as the blocking hook (16) has to guarantee the fixing of the tool. Activate the general

power switch (03), the switches (07) and (08), wait for about 5 minutes until the indicator light (10)

switches on which indicates the presence of steam inside the boiler.

Once the indicator (10) lights up select the desired steam flow through the switch (17A) on the

steam hose, (at each switching on of the unit, the steam selection is always deactivated; the led

lights on the hose will blink alternatively to indicate the necessity to select the desired steam flow).

Once the steam flow will be set, the relevant led light (17B, 17C, 17D) will remain on permanently (1

= minimum; 2 = medium; 3 = maximum); press the safety switch (13) to activate the steam flow.

It is possible to lock the safety switch through the lever (14).

To steam clean choose the appropriate accessory (rectangular (33) or triangular (35) brush, window

cleaner (36), steam lance (37), etc.). Connect the extension tubes (30) and secure them in place by

displacing the blocking hooks (31) to position “BLOCK”.

Wrap a cloth around the rectangular (33) or the triangular (35) brush and fix it with the respective

cloth holders (34).

Attach the brush (or any other accessory) to the extension tube (30) and secure it in place by

displacing the blocking hooks (31) to position “BLOCK”. If you want to use the small nylon brush (39)

remember to first attach the steam lance (37). The steam lance may also be used without the small

round brush especially to reach difficult areas.

EVO 304 BASE / EVO BLU BASE

Pag. 13 29/16

7.2 PRACTICAL TIPS

STEAM LANCE

Direct the strong steam flow toward cracks, hidden areas, greasy objects, kitchen tops, carpets,

carpeted floors, armchairs, sofas, tapestries etc. you will be able to remove easily and completely

grime, grease and dirt in general. After this operation it will be indispensable to pass over the treated

surfaces with a dry cloth.

IN THE KITCHEN

We suggest the use of the steam lance (37) with the various small brushes. These brushes help

remove the most obstinate dirt from kitchen tops, hoods, fryers, etc.

It is possible to clean the dishwasher by spraying steam with the turbo lance (37). In case of heavy

incrustation, we suggest to use the small nylon brush (39).

IN THE BATHROOM

For all areas which are difficult to reach we suggest applying to the steam hose (12) the steam

lance (37) and a small brush (39). This accessory allows cleaning radiator crevices and all difficult

points. In case of washbasin clogging, attach the steam plunger (43) to the steam lance (37) and

direct the steam into the drain.

WARNING

WHEN USING THE SMALL BRUSHES ON PORCELAIN EXERT THE LEAST POSSIBLE

PRESSURE.

WINDOW CLEANER (on glass or plastic surfaces)

We suggest using the window cleaner (36) by inserting it directly on the steam hose handgrip (12)

and applying steam on the surface to be cleaned. Then use the squeegee blade mounted on the

window cleaner to remove the humidity by using vertical movements to bring the dirt to the bottom of

the surface. Use a cotton or microfiber cloth to remove the dirt from the bottom of the treated surface.

TRIANGULAR BRUSH

Suitable for the cleaning of armchairs, sofas and mattresses, we suggest to use the triangular brush

with a cloth fastened with the respective clamps.

RECTANGULAR BRUSH (For tiled floors)

To carry out specific grout cleaning we suggest to use the steam lance (37) with a small brush (39 or

40 according to the need). This way it will be possible to get rid of the most difficult dirt and remove it

from the grouts thanks to the pressure applied. To remove the dirt from the floor use the rectangular

EVO 304 BASE / EVO BLU BASE

Pag. 14 29/16

brush (33) wrapped in a cloth, which will work as an “extractor” when fastened with the special

clamps. We suggest applying steam also while picking up the dirt. To get a good result, work with

surface areas not larger than 5sm at a time thus preventing dirt from drying and adhering on the floor

again.

We suggest that you use the brush without the cloth when the dirt to be removed is considerable

and when the dirt is not considerable, it is enough to work with the brush wrapped in a cloth.

When confronted with solid objects while cleaning the floor (i.e. chewing-gum) use the special scraper

(44) which can be attached to the steam lance (37) and is able to remove stubborn objects without

scratching the treated surface.

To remove wax from the floor use a cloth fastened to the rectangular brush (33). The steam helps

loosen the wax so that its removal will be easier. To spread the wax on the floor use as mentioned

above a clean cloth fastened onto the brush. Put the wax on the cloth, the heat of the steam will help

spread the wax evenly so that its penetration will be easier. When the wax is dry proceed with normal

polishing methods.

The power of steam substitutes any type of detergent.

WARNING

THE GENERATOR PRODUCES STEAM WITH A TEMPERATURE OVER 100°C. BEFORE

STARTING THE CLEANING TASK WE SUGGEST TO TRY ON A SMALL AREA TO AVOID

DAMAGES.

Marble and parquet floors

We suggest adding a steam buffer (47) to the rectangular brush (33) and then wrap it with a cotton

cloth to avoid scratching the surface. To continue the cleaning it is necessary to change the cloth

according to the quantity of dirt to be collected on the floor.

WARNING

THE STEAM SHOULD NOT BE IN DIRECT CONTACT WITH THIS KIND OF FLOOR FOR AN

EXTENDED PERIOD OF TIME! SUCH SURFACES MAY BE DAMAGED IN CASE OF

COMBINED USE OF EXCESSIVE HEAT, HUMIDITY AND BRISTLES. THEREFORE CARRY

OUT THE CLEANING TASK IN THE SHORTEST POSSIBLE TIME.

EVO 304 BASE / EVO BLU BASE

Pag. 15 29/16

Carpeted floors

Before carrying out the steam cleaning we suggest that you clean the carpeted area with a vacuum

cleaner. Then use the rectangular (33) or the triangular (35) brush with a cloth wrapped around it. To

continue with the cleaning the cloth should be replaced according to the quantity of dirt on the floor.

Car interiors

To clean car interiors (upholstery, carpets and seats) follow the cleaning instructions for the

carpeted floors.

Steam iron

Mod. Tulipano:

To iron with steam the iron thermostat (61) should be positioned between the symbol “••” (wool) and

the symbol “•••” (cotton). Wait a few minutes as to allow the iron to reach its ideal temperature. The

steam flow from the iron is obtained by activating at short intervals the red switch (62) on the

handgrip of the iron.

For dry ironing do not press the red switch (62) and switch off the button (08) on the control panel. In

this case position the thermostat according to the type of cloth being ironed. If the power save mode

is activated (chapter 7) the device will switch off after 1 hour independently form the usage of the

iron.

Mod. Dublo:

To iron with steam the iron thermosta (61) should be positioned between the symbol “••” (wool) and

the symbol “•••” (cotton) indipendently from the type of cloth being ironed. Wait a few minutes to allow

the iron to reach its ideal temperature then press the red button (62) on the handgrip of the iron to

activate the steam flow. To have a constant steam flow press and move the blocking switch on the

handgrip of the iron. To release the blocking move the button up.

For dry ironing switch the “boiler switch” off (08) and position the thermostat according to the type of

cloth being ironed. If the power save mode is activated (chapter 7) the device will switch off after 1

hour independently form the usage of the iron.

To remove the shine from clothes, brighten up wool tissue, curtains etc. use the iron vertically,

directing the steam flow onto the object.

EVO 304 BASE / EVO BLU BASE

Pag. 16 29/16

8. MAINTENANCE

WARNING

SWITCH OFF THE ELECTRIC SUPPLY (04) BEFORE PROCEEDING WITH THE USER'S

MAINTENANCE. IT IS RECOMMENDED TO CLEAN THE BOILER ONLY WHEN THE MACHINE

HAS COOLED DOWN (SWITCHED OFF FOR AT LEAST 5 HOURS).

8.1 MAINTENANCE OF THE STEAM GENERATOR

ELIMINATION OF SCALE DEPOSITS FROM THE BOILER

The unit is equipped with a maintenance warning which is working by writing CALC on the display

alternatively with the visualized temperature.

When the sign lights up it is possible to finish the cleaning task, then disconnect the power plug and

let the appliance cool down for at least 5 hours.

It is essential to follow the above procedure to make sure that steam under pressure is no

longer present inside the machine. (we suggest to proceed with the boiler cleaning prior to the

next usage of the machine provided that minimum 5 hours have been passed after having

disconnected the power plug.)

Put a basin under the unit and remove the underlying boiler drain cap (05), wait until the boiler is

completely emptied and insert the cap again only once you have removed eventual deposits from it

with running water as they may cause water leakages during the usage.

The cleaning process is finalized, insert again the power cord (04) into the electric power outlet and

switch the unit on by activating the general switch (03) and the buttons (07) and (08). We

recommend to activate also the switch (17A) on the steam hose and to press the safety switch (13)

to let out the air from the empty boiler.

Restore maintenance intervals CALC

Turn on the appliance by activating the switch (03) and the button (07), then again press the button

(07) and keep it pressed for approx. 10 seconds, the writing CALC will disappear from the display

and will only appear again for the next maintenance intervention.

The maintenance of the boiler is finished, proceed following the instruction described in chapter 7.

EVO 304 BASE / EVO BLU BASE

Pag. 17 29/16

8.2. HOUR METERS

The device is equipped with two hour meters, one resettable by the user and one non resettable. To

visualize the hours, turn off the unit by pressing the button (07) and subsequently press the button

(08); every time you press this button you can read the respective hour meter 1 and hour meter 2.

Resetting of the hour meter 2

Turn off the unit with the general power switch (03).

Press and keep pressed the buttons (07) and (08), while you keep them pressed switch on the

machine again by activating the general power switch (03).

8.3. PRESSURE GAUGE

With the unit being turned on press and keep pressed the button (07), after some seconds the

display will show the value in bar of the pressure inside the boiler; this data will remain visible on

the display for 10 seconds. Afterwards the value of the temperature in °C will appear again.

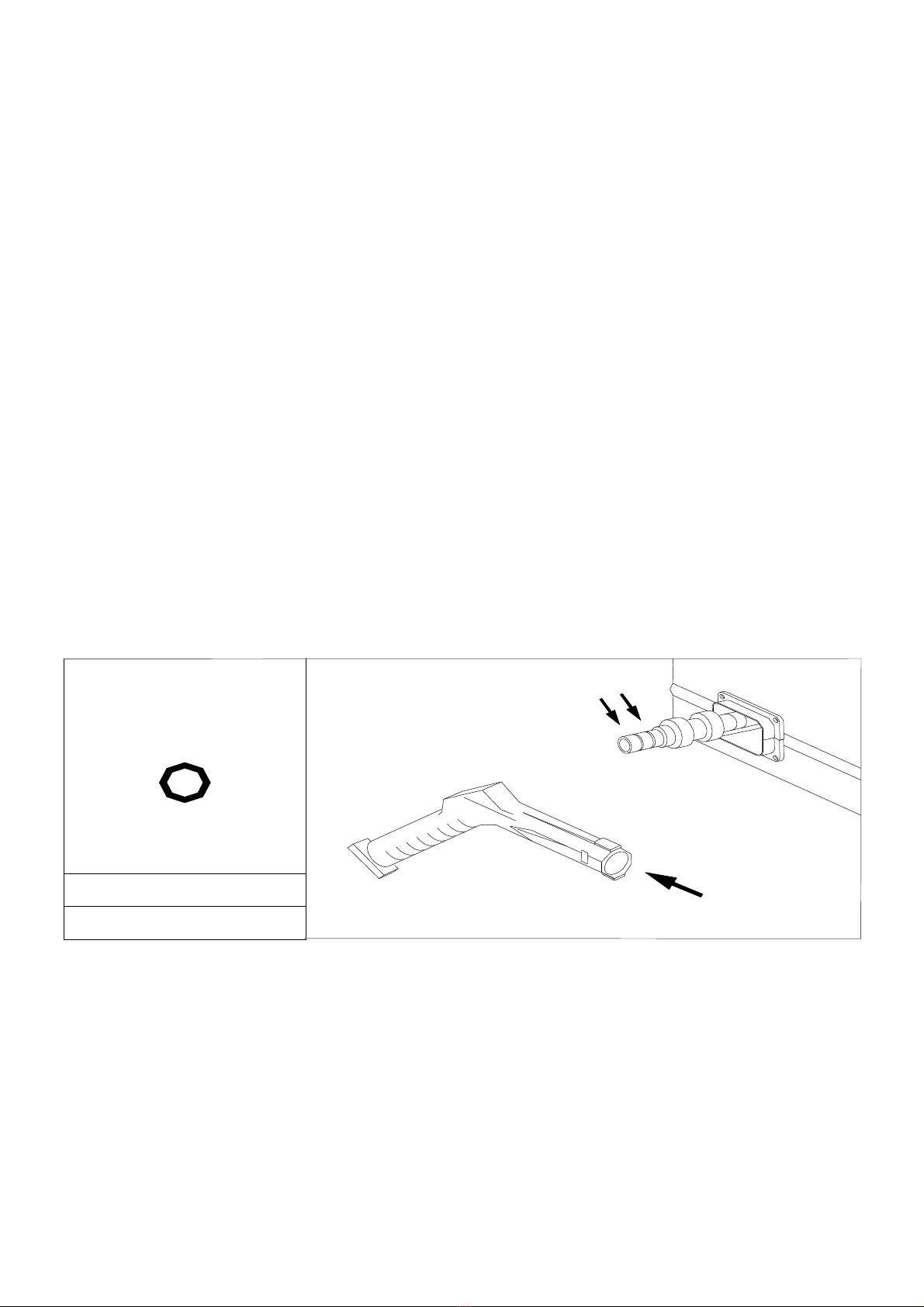

8.4. MAINTENANCE OF THE ACCESSORIES

Grease occasionally joints on the accessories and hose extensions.

PG5106

OR 9.25x1.78

EVO 304 BASE / EVO BLU BASE

Pag. 18 29/16

9. BEFORE REFERRING TO THE TECHNICAL SERVICE

PROBLEM

POSSIBLE CAUSE

REMEDY

The machine does not produce

steam.

Lack of power.

Make sure that the plug (04) is well inserted and

that the main switch of the building is activated.

The red “low water” indicator (11)

lights up.

All the water from the boiler (01) has been

consumed.

Refill the boiler (01) with clean water.

Water leaks through the

connections of the accessories.

Check the wear of the o-rings.

Clean and lubricate the o-rings with grease.

If necessary, replace with the spares supplied.

Steam does not come out.

A) Boiler has not reached yet the operational

pressure (green light (10) is off).

B) Boiler switch (08) has not been activated.

C) Safety switch (13) has not been activated.

A) Wait a few minutes.

B) Activate the “boiler switch” (08).

C) Press the safety switch (13) to activate the

steam flow.

Drops of water come out of the

accessories.

At beginning of work water condenses in the

tubes and accessories due to the difference in

temperature.

After a few minutes of use this problem will

disappear. If it continues, proceed with the boiler

cleaning.

Noise inside the generator.

The boiler getting cold, after about 6-7 hours

creates an internal depression which, at each

ignition, provokes some vibrations.

Wait until the pressure stabilizes (about 2-3

minutes), the noise will disappear.

Steam leaks from the valve cap

(01).

The valve cap (01) is not correctly screwed.

The rubber seal on the valve cap is damaged.

Screw on the safety cap correctly.

Substitute the seal.

Accessories do not fit perfectly.

There is dirt build up in the joints and the

connections.

Clean and lubricate the joints of the accessories.

EVO 304 BASE / EVO BLU BASE

Pag. 19 29/16

10. DECLARATION OF CONFORMITY

DICHIARAZIONE DI CONFORMITA’ CE

(EC DECLARATION OF CONFORMITY)

TECNOVAP S.R.L. con la presente dichiara che:

le macchine per pulizia a vapore modello:

(Certifies that the steam cleaning machine model:)

Evo Cod: ER3206I, ER32060

Risulta conforme alle specifiche delle direttive

(conforms to the specifications of directives)

2006/95/CE 2004/108/CE 2006/42/CE 2002/95/CE

Per il controllo della conformità alle sopraindicate direttive, sono stati seguiti i seguenti standard :

(For the checking of conformity to the above directives, the following standards have been used):

Riferimento alle norme armonizzate:

(Reference to harmonized standards):

EN 60335-1

EN 60335-2-79

EN 60335-2-3

EN 55014-1

EN55014-2

EN 61000-3-2

EN 61000-3-3

PESCANTINA – VERONA (ITALY) 01-08-2016

EVO 304 BASE / EVO BLU BASE

Pag. 20 29/16

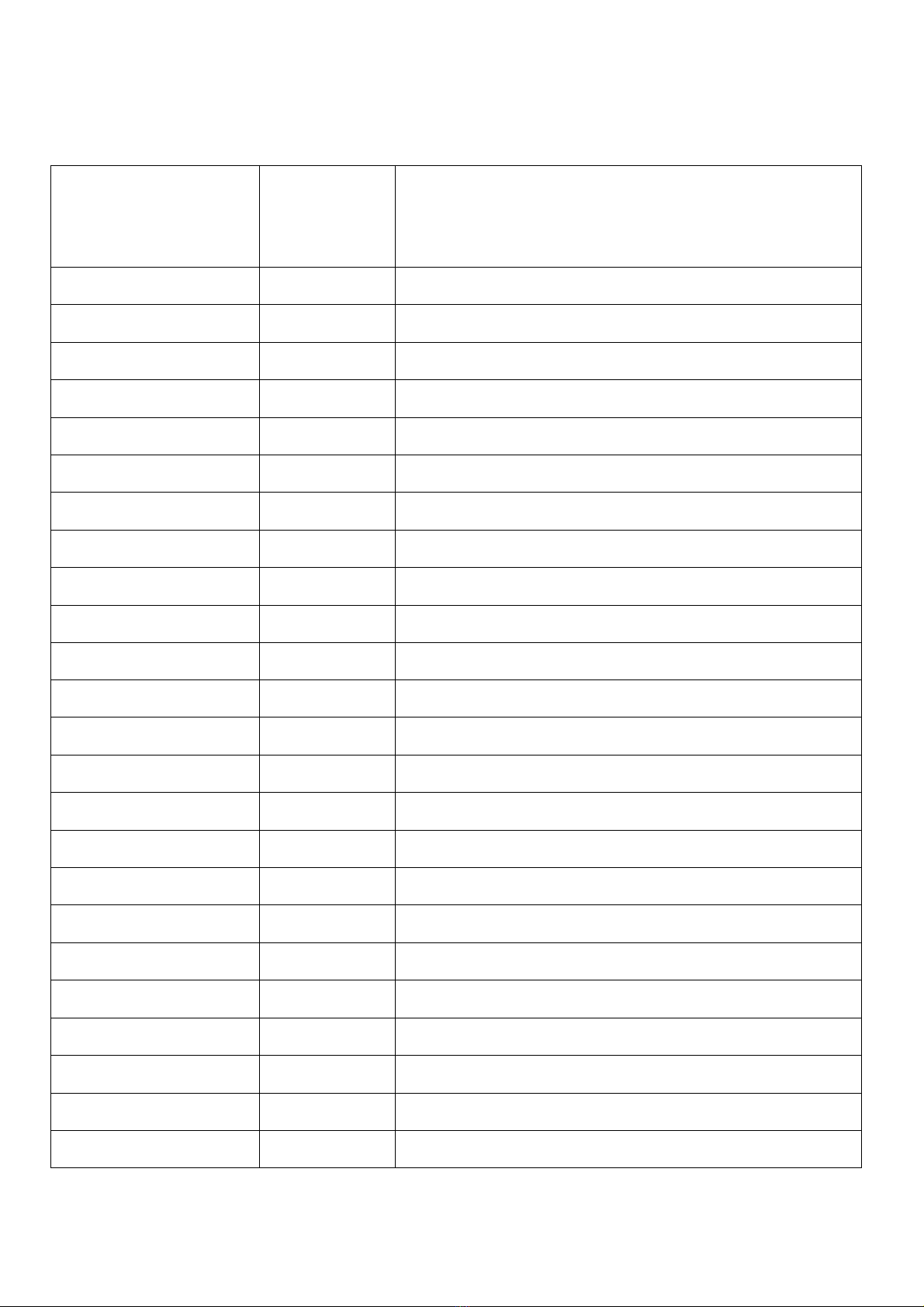

Ordinary maintenance procedures

Generator working

hours

Frequency

of

intervention

Notes

This manual suits for next models

3

Table of contents

Other TECNOVAP Kitchen Appliance manuals