TECO-Westinghouse Motor Anab EQ5 User manual

EQ5 AC Drive Operations Manual

Document: TWMC-EQ5OM

Revision: 001P0

EQ5 AC Drive Operations Manual

_______________________________________________________________________

TECO – Westinghouse Motor Company Compliance with UL

Preface

Thank you for purchasing our EQ5 series inverter. This product is used to drive a 3-phase electric motor at

variable speed. As incorrect use of this product may result in personal injury and/or property damage,

please read all safety and operating instructions before using.

Safety Instructions

Please read this manual carefully before installing, connecting (wiring), operating, servicing, or inspecting the

inverter. Also please familiarize yourself with all safety features before using the inverter.

In this manual, safety messages are classified as follows:

Danger Improper operation may result in serious personal injury or death.

Caution Improper operation may result in slight to medium personal injury or property

damage.

Situations more serious than those covered by CAUTION will depend on prevailing circumstances.

Always follow instructions.

Instructions on use:

Danger

•This inverter is designed to drive a 3-phase induction motor and is not suitable for a single-phase motor or

any other types, as fire may result.

•This inverter may not be used (as is) as a component of a life-support system or other medical device

directly affecting the personal welfare of the user.

•This inverter is manufactured under strict quality control standards. However, safety equipment must be

installed if the failure of this device may result in personal injury and/or property damage.

•There is a risk of accident.

Instructions on installation:

Danger

•Mount this inverter on an incombustible material such as metal. There is a risk of fire.

•Do not place combustible or flammable material near this inverter, as fire may result.

Caution

•Do not hold or carry this inverter by the surface cover. Inverter may be dropped causing injury.

•Ensure that the inverter and heat sink surfaces are kept free of foreign matter (lint, paper dust, small chips

of wood or metal, and dust), as fire or accident may result.

•Do not install or operate a damaged inverter or an inverter with missing parts, as injury may result.

EQ5 AC Drive Operations Manual

_______________________________________________________________________

TECO – Westinghouse Motor Company Compliance with UL

Instructions on wiring:

Danger

•Connect the inverter to power via a line-protection molded-case circuit breaker or fuse, otherwise fire may

result.

•Always connect a ground wire, otherwise electric shock or fire may result.

•A licensed specialist must perform the wiring, otherwise electric shock may result.

•Turn off the power before starting the wiring, otherwise electric shock may result.

•Wire the inverter after installation is complete, otherwise electric shock or injury may occur.

Caution

•Confirm that the phases and rated voltage of this product match those of the AC power supply, otherwise

injury may result.

•Do not connect the AC power supply to the output terminals (U,V,and W), otherwise injury may result.

•Do not connect a braking resistor directly to the DC terminals (P(+)and N(-)),otherwise fire may result.

•Ensure that the noise generated by the inverter, motor, or wiring does not adversely affect peripheral

sensors and equipment, otherwise accident may result.

Instructions on operation:

Danger

•Be sure to install the surface cover before turning on power (closed). Do not remove the cover while

power to the inverter is on. Otherwise electric shock may occur.

•Do not operate switches with wet hands, otherwise electric shock may result.

•When the retry function is selected, the inverter may restart automatically after tripping. Design the machine

to ensure personal safety in the event of restart. Accident may result.

•When the torque limiting function is selected, operating conditions may differ from preset conditions

(acceleration/deceleration time or speed). In this case, personal safety must be assured. Otherwise

accident may result.

•As the STOP key is effective only when a function setting has been established, install an emergency

switch independently, and when an operation via the external signal terminal is selected, the STOP key on

the keypad panel will be disabled. Otherwise accident may result.

•As operations start suddenly if an alarm is reset with a running signal input, confirm that no running signal

is input before resetting alarm. Otherwise accident may result.

•Do not touch inverter terminals when energized even if inverter has stopped. Otherwise electric shock

may result.

Caution

•Do not start or stop the inverter using the main circuit power. Failure may result.

•Do not touch the heat sink or braking resistor because they can be extremely hot. Burns may result.

•Carefully check the performance of motor or machine before operating at high speed. Injury may result.

•Do not use the inverter braking function for mechanical holding. Otherwise injury may result.

EQ5 AC Drive Operations Manual

_______________________________________________________________________

TECO – Westinghouse Motor Company Compliance with UL

Instructions on maintenance, inspection, and replacement:

Danger

•Wait a minimum of five minutes (30HP/CT, 40HP/VT or less) or ten minutes (40HP/CT, 50HP/VT or more)

after power has been turned off (open) before starting an inspection. (Also confirm that the charge lamp is

off and that DC voltage between terminals P (+) and N (-) does not exceed 25V.) Otherwise electrical

shock may result.

•Only authorized personnel should perform maintenance, inspection, and replacement operations.(Take off

metal jewelry such as watches and rings and use insulated tools.) Otherwise electric shock or injury

may result.

Instructions on disposal:

Caution

•Treat as industrial waste when disposing it. Otherwise injury may result.

Other instructions:

Danger

•Never modify the product. Otherwise electric shock or injury may result.

EQ5 AC Drive Operations Manual

_______________________________________________________________________

TECO – Westinghouse Motor Company Compliance with UL

Compliance with UL/cUL standards [Applicable to products with UL/cUL mark]

Caution

Tightening torque and wire range: Refer to Table 2-3-5 in Section 2

Apply the following power supply specifications to the inverter:

Inverter Model Maximum input voltage Input source current

EQ5 - 20P2 - N1 to EQ5 - 2032 - N1 AC240V Not more than 100,000A

EQ5 - 2040 - C to EQ5 - 2150 - C

EQ5 - 40P5 - N1 to EQ5 - 4032 - N1 AC480V

EQ5 - 4040 - C to EQ5 - 4800 - C

Caution

* [CAUTION] Hazard of electrical shock. Disconnect incoming power before working on this control.

* [CAUTION] Dangerous voltage exists until charge light is off.

* [WARNING]

* More than one live parts inside the inverter.

* Type1 “INDOOR USE ONLY”

The inverter is approved as a part used inside a panel. Install it inside a panel.

* Suitable for use on a circuit capable of delivering not more than 100,000rms symmetrical amperes.

* Use 60/75C copper wire only.

* A Class2 circuit wired with class1 wire.

* Field wiring connections must be made by a UL Listed and CSA Certified closed-loop terminal connector

sized for the wire gauge involved. Connector must be fixed using the crimp tool specified by the

connector manufacturer.

* Connect the power supply to main power supply terminals via the Molded-case circuit breaker (MCCB) or

a ground fault circuit interrupter (GFCI) to conform to the UL Listing Mark.

(See Instruction Manual basic connection diagram Fig.2-3-1).

* When using auxiliary control-power input (R0, T0), connect as per Basic connection diagram Fig.2-3-1.

* Solid state motor overload protection is provided in each model.

EQ5 AC Drive Operations Manual

_______________________________________________________________________

TECO – Westinghouse Motor Company Index

Contents

Pg.

Before Using This Product ···························· 1

1-1 Receiving Instructions ·························· 1

1-2 Appearance ······································· 1

1-3 Handling the Product ·························2-3

1-4 Carrying and Moving the Product ··········· 3

1-5 Storage ··········································3-4

2. Installation and Electrical Connections ·········· 5

2-1 Operating Environment ························ 5

2-2 Installation Method ····························5-7

2-3 Electrical Connections ························· 8

2-3-1 Basic Power Electrical Connections ·· 8

Fig. 2-3-1 Basic Wiring Diagram.................9

2-3-2 Connecting Input power, Motor and

Ground Terminals ···················10-16

2-3-3 Connecting the Control Terminals 17-21

2-3-4 Input Protection Device Ratings·······22

2-3-5 Terminal Tightening Torque and

Cable Size ·································23

2-3-6 DC Link Choke Wattage Loss…….....24

3. Initial Operation ······································25

3-1 Inspection and Preparation Before

Operation··········································25

3-2 Operation Method ······························25

3-3 Trial Run ······································25-26

4. Digital Operator ······································27

4-1 Appearance of Digital Operator ·········27-28

4-2 Digital Operator LCD screen,

Level Structure ···································28

4-2-1 Normal Operation ························28

4-2-2 Alarm Modes ··························28-29

4-3 Digital Operator Keypad Navigation ·······30

4-3-1 Operation Mode ··························30

4-3-2 Setting the Output Frequency ·········30

4-3-3 Switching to the LED Monitor ·········31

4-3-4 Program Menu Screen ··················31

4-3-5 Setting the Parameter Values ·····32-33

4-3-6 Checking Parameter Data ·············33

4-3-7 Monitoring Operating Status ···········33

4-3-8 I/O Check ··································34

4-3-9 Maintenance Information ···············35

4-3-10 Load Rate Measurement ·············36

4-3-11 Alarm Information ·······················37

4-3-12 Alarm History and Possible

Reasons ···································38

4-3-13 Data Copy, Verify and Error

Processing ···························39-40

4-3-14 Alarm Mode ······························41

Pg.

5. Parameters F,E,C,P,H, A and U·················· 42

5-1 Parameter Summary List ·················42-45

5-2 Parameter Explanation ···················46-86

6. Alarms Codes, Causes and Troubleshooting · 87

6-1 List of Alarm Codes and Causes ·······87-88

6-2 Alarm Reset ····································· 89

6-3 Troubleshooting Alarm Codes and

Causes (Flowcharts)………….….……...90-96

7. Maintenance and Inspection ······················ 97

7-1 Daily Inspection ································· 97

7-2 Periodic Inspection ························97-99

Inspection Notes and Records..................100

7-3 Main Circuit Voltage, Current and Power

Measurements…………………………......101

7-4 Insulation Test ·································102

7-5 Parts Replacement ···························102

7-6 Inquiries about Damaged Products ·······103

7-7 Warranty…………………………………….

8. Specifications ········································104

8-1 Standard Specifications ···············104-106

8-2 Common Specifications ·····················107

8-3 Outline Dimensions and Weights ···108-111

8-4 RS-485 Modbus RTU Serial

Communications ·······························112

8-4-1 Transmission Specification············112

8-4-2 Connection································112

8-4-3 Serial Interface Configuration·········112

8-4-4 Modbus RTU Functions················112

8-4-5 Inverter Function Code Access ······113

8-4-6 Command and Monitor

Data Registers······················113-115

8-4-7 Data Format Specification·······115-119

8-4-8 Communication Errors··················119

9. Options ················································120

10. Electromagnetic Compatibility (EMC) ········121

10-1 General ········································121

10-2 Recommended Installation

Instructions ····························121-124

EQ5 AC Drive Operations Manual

_________________________________________________________________________

TECO – Westinghouse Motor Company Receiving and Handling 1

1. Before Using This Product

1-1 Receiving Instructions

Unpack and check the product as explained below.

If you have any questions about the product,

contact the nearest TWMC sales office or your

local distributor where you purchased the unit.

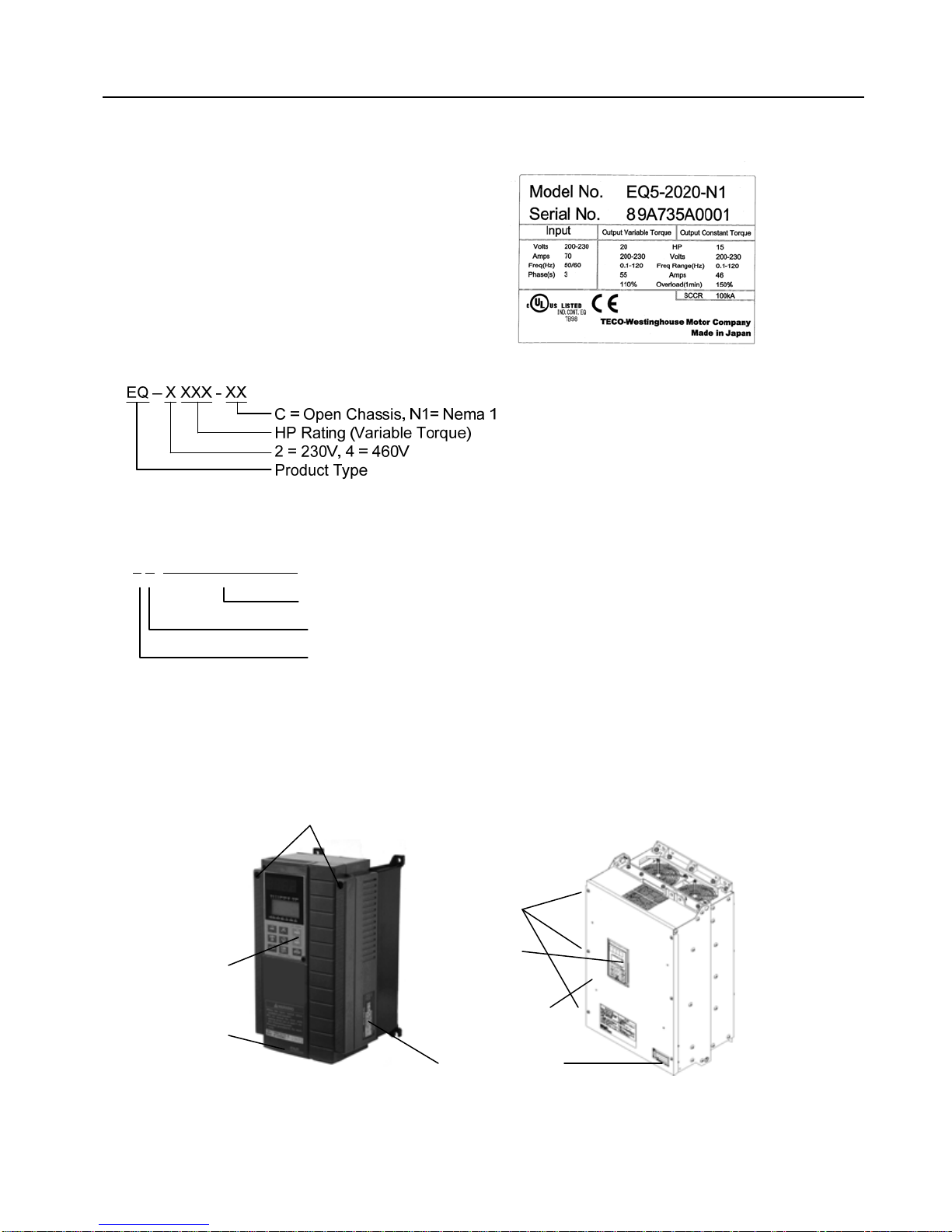

1. Check the ratings on the nameplate to confirm

that the delivered product is the one that was

ordered.

TYPE : Inverter type

SOURCE : Power rating

OUTPUT : Output rating

MASS : Mass (not indicated for products with 30HP/CT, 40HP/VT or less)

SER.No. : Serial number

8 5 XXXXXXXXXXXXX

Productionlotserialnumber

Production month:1 to 9: January to September,

X: October, Y: November, Z: December

Production year: Last digit of year (7 --> 2007)

2. Check for damaged and/or missing parts.

3. In addition to the drive unit and this manual, the package contains rubber bushings (for products of

30HP/CT, 40HP/VT or less) and a terminating resistor (1/2 W, 120) which is packed separately. The

terminating resistor for products rated 40HP/CT, 50HP/VT or more, is installed internally. The

terminating resistor is required for RS485 communication and can remain installed regardless of RS-

485 communication status.

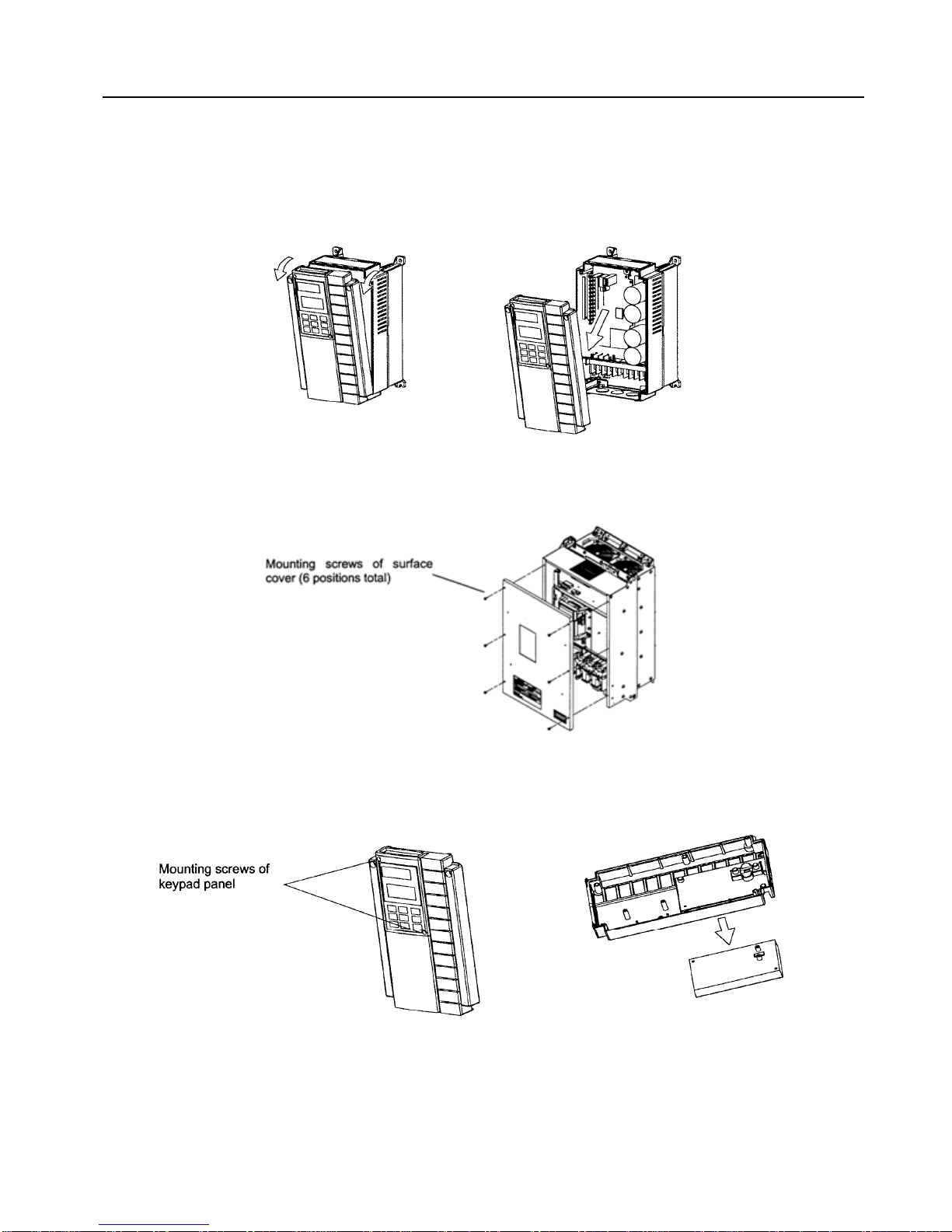

1-2 Appearance

Mounting screws of surface cover

Digital Operator Digital Operator

Mounting screws of

surface cover

(6 screws total)

Ratings nameplate

Surface cover

Intermediate cover

Surface cover

30HP/CT, 40HP/VT or Less 40HP

/

CT, 50HP/VT or More

EQ5 AC Drive Operations Manual

_________________________________________________________________________

TECO – Westinghouse Motor Company Receiving and Handling 2

1-3 Handling the Product

1. Removing the cover

For drives rated 30HP/CT, 40HP/VT or less, loosen the mounting screws of the cover, then remove by

pulling the top (see Fig. 1.3.1).

Fig. 1-3-1 Removing the Surface Cover (for inverters rated 30HP/CT, 40HP/VT or less)

For drives of 40HP/CT, 50HP/VT or more, first remove the six mounting screws, then remove the cover

(see Fig. 1-3-2).

Fig. 1-3-2 Removing the Surface Cover (for inverters rated 40HP/CT, 50HP/VT or more)

2. Removing the digital operator

After removing the cover as explained in (1.), loosen the mounting screws of the digital operator and

remove as shown in Fig.1.3.3.

Fig. 1-3-3 Removing the Digital Operator (30HP/CT, 40HP/VT or less)

EQ5 AC Drive Operations Manual

_________________________________________________________________________

TECO – Westinghouse Motor Company Receiving, Handling, and Storage 3

Temporary Storage

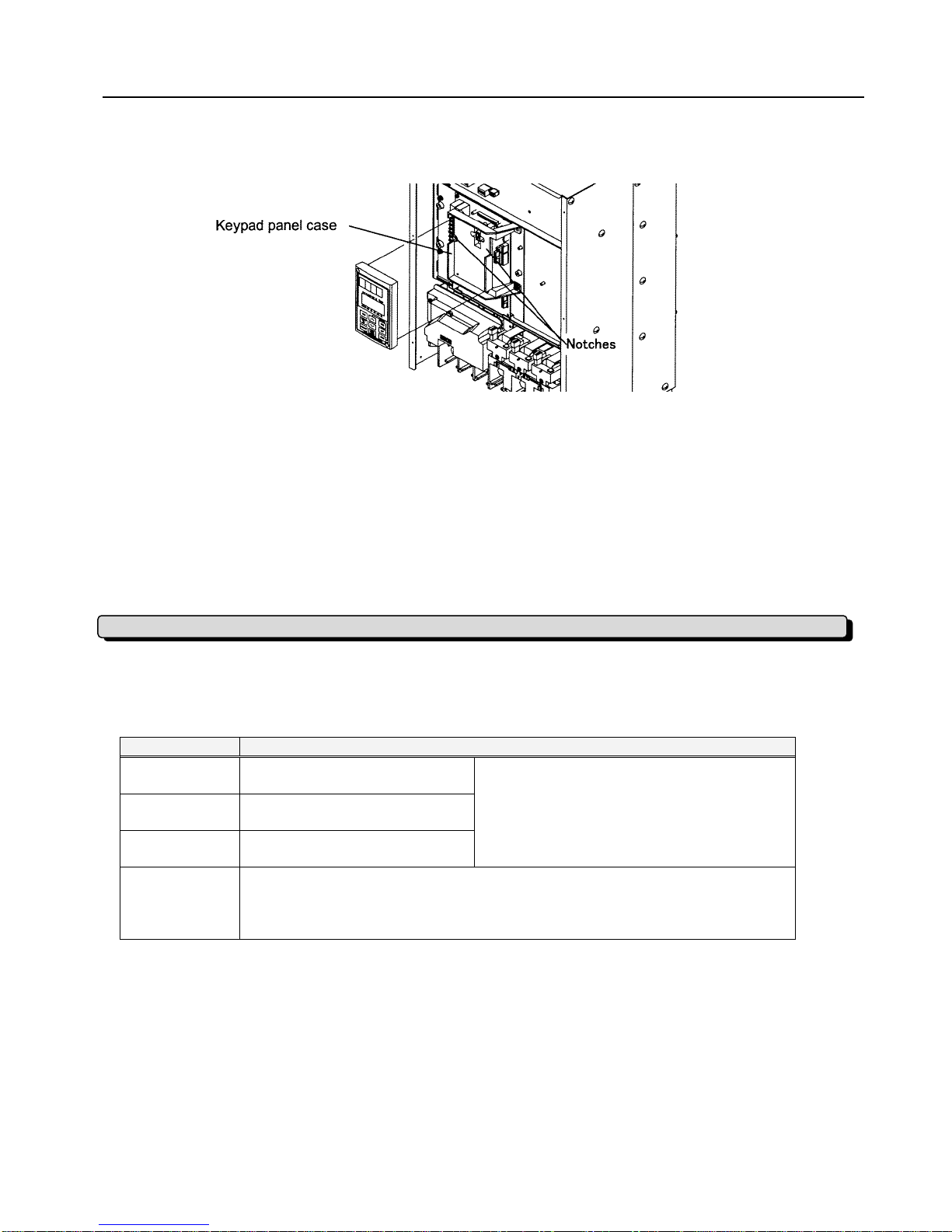

For drives 40HP/CT, 50HP/VT or more, loosen the mounting screws of the digital operator and remove

using the finger holds on the digital operator case (see Fig. 1-3-4).

Fig. 1-3-4 Removing the Digital Operator (40HP/CT, 50HP/VT or more)

1-4 Carrying and Moving the Product

1. Carry the product by the main body.

Do not carry the product while holding the cover or parts other than the main body.

2. Use a crane or hoist to carry a product equipped with handling hooks.

1-5 Storage

Temporary storage of this product must meet those conditions listed in Table 1-5-1.

Table 1-5-1 Storage Environment

Item Specifications

Ambient

temperature -10 (14°F) to +50 (122°F)

Condensation or freezing must not occur as

a result of sudden temperature changes.

Storage

temperature -25 (-13°F) to +65 (149°F)Note1

Relative

humidity 5 to 95% Note2

Atmosphere

The product must not be exposed to dust, direct sunlight, corrosive gas, oil

mist, vapor, or water. There must be a minimum salt content in the

atmosphere. Do not store where condensation may occur as a result of

sudden changes in temperature.

Note1: The storage temperature applies only to short periods of time such as when transporting

the equipment .

Note2: As a large change in temperature within this humidity range may result in condensation or freezing,

do not store where such temperature changes may occur.

1. Do not place this product directly on a floor.

2. To store the product in an extreme environment, pack in vinyl sheeting, etc.

3. If the product is stored in a high-humidity environment, insert a drying agent (e.g., silica gel)

and pack the product in vinyl sheeting.

EQ5 AC Drive Operations Manual

_________________________________________________________________________

TECO – Westinghouse Motor Company Receiving, Handling, and Storage 4

Long-term Storage

If the product is to be stored for an extended period of time after purchase, the method of storage depends

primarily on storage location.

The general long-term storage method is as follows:

1. The above conditions for temporary storage must be satisfied.

When the storage period exceeds three months, the upper limit of ambient temperature must

be reduced to 30º (86ºF) to prevent the deterioration of the electrolytic capacitors.

2. Pack the product thoroughly to eliminate exposure to moisture and include a drying agent to

ensure a relative humidity of about 70% or less.

3. If the product is mounted on equipment or a control panel and is not being unused and is exposed to

the elements such as like moisture or dust (particularly on a construction site), remove the product and

store in a suitable environment.

4. Electrolytic capacitors not provided with voltage for extended periods of time will deteriorate. Do not

store electrolytic capacitors longer than one year without providing voltage to them.

NOTES

EQ5 AC Drive Operations Manual

________________________________________________________________________

TECO – Westinghouse Motor Company Installation Environment & Method 5

2. Installation and Electrical Connections

2-1 Operating Environment

Install this product in a location that meets the conditions listed in Table 2-1-1

Table 2-1-1 Operating Environment Table 2-1-2 Output Current Reduction

Rate Based on Altitude

Item Specifications

Location Indoors Altitude Output current

reduction rate

Ambient

temperature

-10Cº to +50ºC (14ºF to 122ºF) -

For products of 30HP/CT,

40HP/VT or less, the ventilating

covers must be removed if the

ambient temperature exceeds

+40ºC (104ºF)

3300ft or lower (1000m) 1.00

3300-4950ft

(1000 to 1500m) 0.97

4950-6600ft

(1500 to 2000m) 0.95

Relative

humidity 5 to 95% non-condensing

6600-8250ft

(2000 to 2500m) 0.91

8250-9900ft

(2500 to 3000m) 0.88

Atmosphere

The product must not be exposed

to dust, direct sunlight, corrosive

gas, oil mist, vapor, or water.

There must be a minimum salt

content in the atmosphere. Do not

store where condensation may

occur as a result of sudden

changes in temperature.

Fig. 2-2-1

30HP/CT, 40HP/VT or less:

Gap X can be 0.

(side-by- side installation)

40HP/CT, 50HP/VT or more:

Gap X >= 2.0” (50mm)

Altitude 1000 m (3300 feet) or lower - For

altitudes above 1000 m (3300

feet), see Table 2-1-2.

Vibration

3mm peak from 2 to 9Hz, 9.8m/s

2

from 9 to 20Hz,

2m/s2from 20-55Hz, 1m/s2from

55 to 200Hz.

2-2 Installation Method

1. Mounting, dimensional and weight information for all of the inverter models, is covered in Sec. 8-3 of

this manual. Select the model being used and prepare the installation.

2. Securely fasten the product in a vertical upright position on a solid structure with the product

logo facing the front. Do not mount the product upside down or install in a horizontal position

as proper ventilation will be inhibited.

3. As heat is generated during inverter operation, the spaces shown in Fig. 2-2-1 are required to

ensure sufficient cooling. Since heat radiates upward, do not install the product beneath

heat sensitive equipment.

4. During operation, the heat sink may reach a temperature of 90ºC (194ºF), therefore ensure that

the material surrounding the product can withstand this temperature.

DANGER Install this product on nonflammable material such as metal.

EQ5 AC Drive Operations Manual

______________________________________________________________________

TECO – Westinghouse Motor Company Installation Method 6

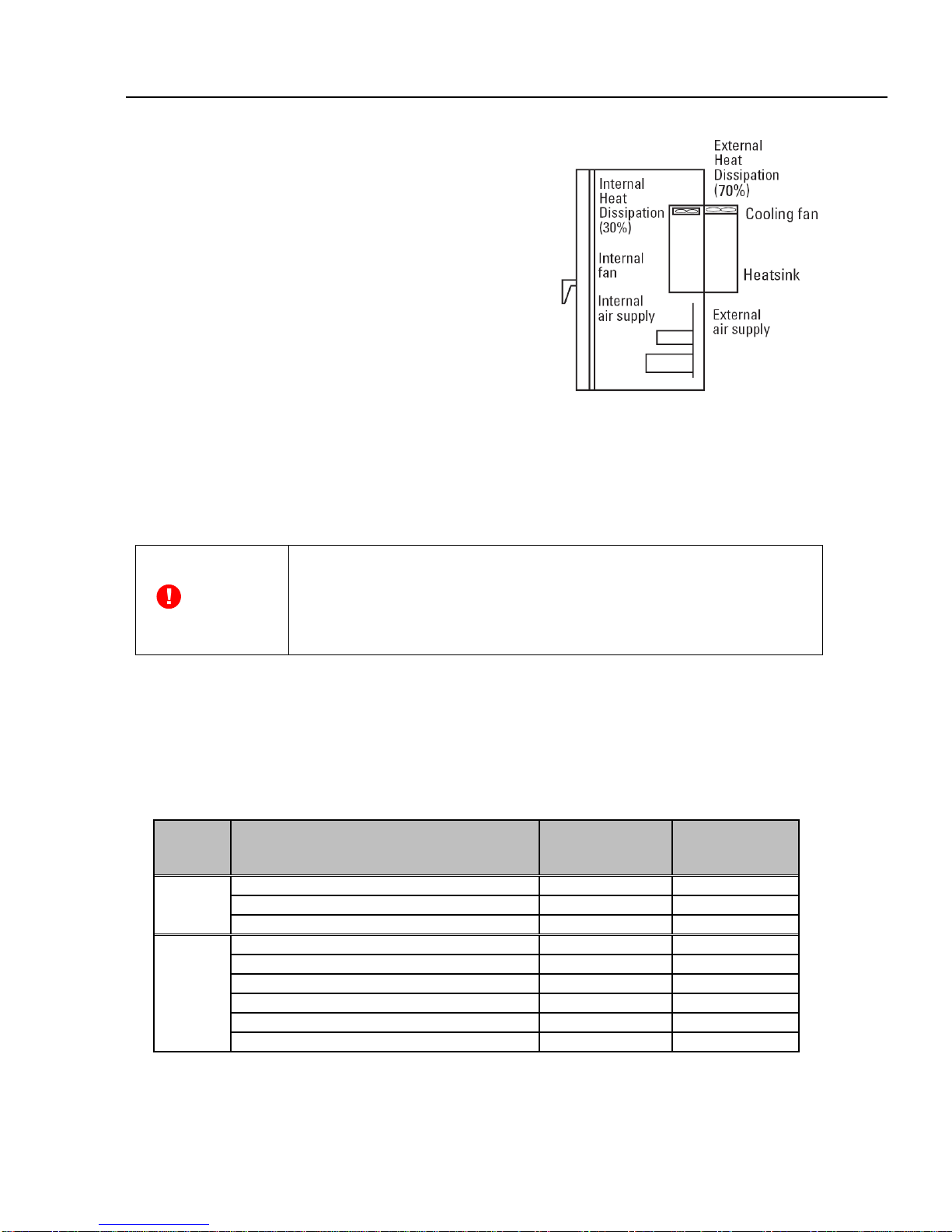

5. When installing this product in a control panel,

ensure that the ventilation is sufficient to prevent the

ambient temperature of the inverter from exceeding

the specified value. Do not install the product in an

area where there is inadequate ventilation,

6. If two or more inverters must be installed in the

same equipment or control panel, arrange the units

horizontally (side by side) to minimize the effect of

heat. If two or more inverters must be installed

vertically (one on top of the other), place an

insulated plate between the inverters to minimize the

effect of heat.

7. When shipped from the factory, inverters provide

internal cooling inside panel. An inverter of

30HP/CT, 40HP/VT or less can be converted to an

external cooling simply by adding an optional

mounting adapter.

In an external cooling system, the heat sink radiates about 70% of total inverter heat (total

loss) and can be placed outside the control panel (see Fig. 2-2-2). When doing this, ensure

that heat sink surfaces are kept free of foreign matter.

DANGER

・In the case of external cooling system, cover the back of the inverter

in order to prevent the exposure of the power capacitor and braking

resistor as electric shock may result.

・Ensure that the inverter and heat sink surfaces are kept free of

foreign matter such as lint, paper dust, small chips of wood or metal,

and dust, as

f

ire ma

y

result.

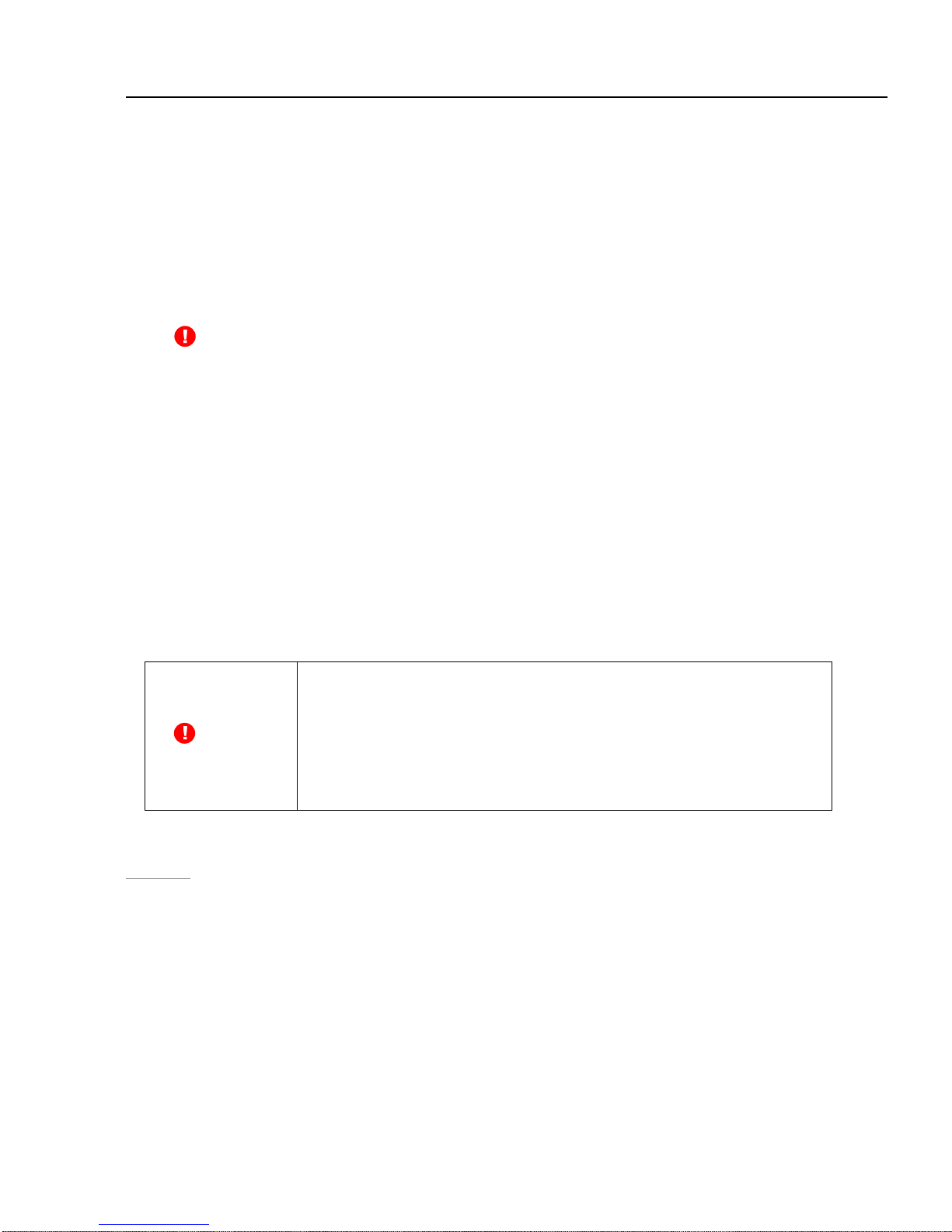

An inverter of 40HP/CT, 50HP/VT or more can be converted to an external cooling type simply by

moving

upper and lower mounting brackets as shown in Fig. 2-2-3. Remove the M6 bracket screws,

move the brackets, then secure the brackets using the M5 case mounting screws. (The

bracket screws are no longer required after changing the bracket mounting position.)

Quantity of Mounting Screws

Voltage

Series Inverter Type Bracket Screws Case

Mounting

Screws

230V EQ5 - 2040 - C to EQ5 - 2100 - C 5 (M6x20) 5 (M5x16)

EQ5 - 2125 - C 7 (M6x20) 5 (M5x16)

EQ5 - 2150 - C 6 (M6x20) 6 (M5x16)

460V

EQ5 - 4040 - C to EQ5 - 4125 - C 5 (M6x20) 5 (M5x16)

EQ5 - 4150 - C to EQ5 - 4200 - C 7 (M6x20) *1 5 (M5x16)

EQ5 - 4250 - C to EQ5 - 4300 - C 7 (M6x20) 7 (M5x16)

EQ5 - 4350 - C to EQ5 - 4400 - C 6 (M6x20) *1 6 (M5x16)

*3 EQ5 - 4450 - C to EQ5 - 4600 - C 6 (M8x20) *2

*3 EQ5 - 4150 - C to EQ5 - 4200 - C 8 (M8x20) *2

*1 Secure the brackets changing the screws, size:M5, length:20mm.

*2 Secure the brackets using the brackets screws.

Fig.2-2-2

EQ5 AC Drive Operations Manual

______________________________________________________________________

TECO – Westinghouse Motor Company Installation Method 7

*3 Do not use the bottom brackets in the bottom surface mount Installation.

Fig. 2-2-3 40HP/CT, 50HP/VT or more Removing Upper and Lower Brackets

8. For inverters of 30HP/CT, 40HP/VT or less, remove the ventilating covers if ambient temperature

exceeds +40°C (104°F)

(1) Removing the ventilating covers:

One ventilating cover is mounted on top of the inverter and the other two or three are mounted at

the bottom.

Fig. 2-2-4 30HP/CT, 40HP/VT or Less Removing Ventilating Covers

EQ5 AC Drive Operations Manual

______________________________________________________________________

TECO – Westinghouse Motor Company Electrical Connections 8

2-3 Electrical Connections

To access the terminal blocks remove the cover in accordance with the instructions in this manual.

2-3-1 Basic Power Electrical Connections

1. Always connect input power to the main circuit power terminals L1/R, L2/S, and L3/T

of the inverter. Check that the input voltage to be applied is within the maximum allowable

voltage marked on the nameplate.

2. Always connect the power output terminals U, V, and W to the motor. Check that output

voltage rating is correct for the motor being used.

DANGER- Do not connect the input voltage to the motor terminals U, V, and W as

extreme damage and / or injury may result.

3. Using the proper wire size and type, always bond the ground terminal to a reliable ground

connection to prevent dangerous situations such as the possibility of fire or electrical shock

and to minimize electrical noise.

4. Use a secure reliable cable crimp connection between the terminal and a cable.

5. After terminating the wiring connection, ensure the following:

a. The connection is correct.

b. All necessary connections have been made.

c. There is no short-circuit or ground fault between terminals and cables.

6. If a wiring change needs to be made after power-up, wait at least 5 minutes before making

any wiring changes. Also ensure that the charge indicating LED is off. This is necessary

because the DC power section capacitor(s) does not discharge immediately after power-down

and maintains lethal voltages. The actual DC voltage may also be checked with a multimeter

and should be 25VDC or less. If short circuiting the DC voltage after power-down, sparks

may occur.

DANGER

•Always properly ground the inverter otherwise electric shock or fire

may result.

•Ensure that a licensed specialist performs all wiring and that all codes

are met.

•Confirm that the power is turned off and that the charge indicator is off

(Wait 5 minutes for 30HP/CT, 40HP/VT and less, 10 minutes for

40HP/CT, 50HP/VT or above) before removing any protective covers as

lethal voltages are present and electrical shock may result.

NOTES

EQ5 AC Drive Operations Manual

______________________________________________________________________

TECO – Westinghouse Motor Company Basic Wiring Diagram 9

EQ5 AC Drive Operations Manual

______________________________________________________________________

TECO – Westinghouse Motor Company Power Terminal Designations & Wiring 10

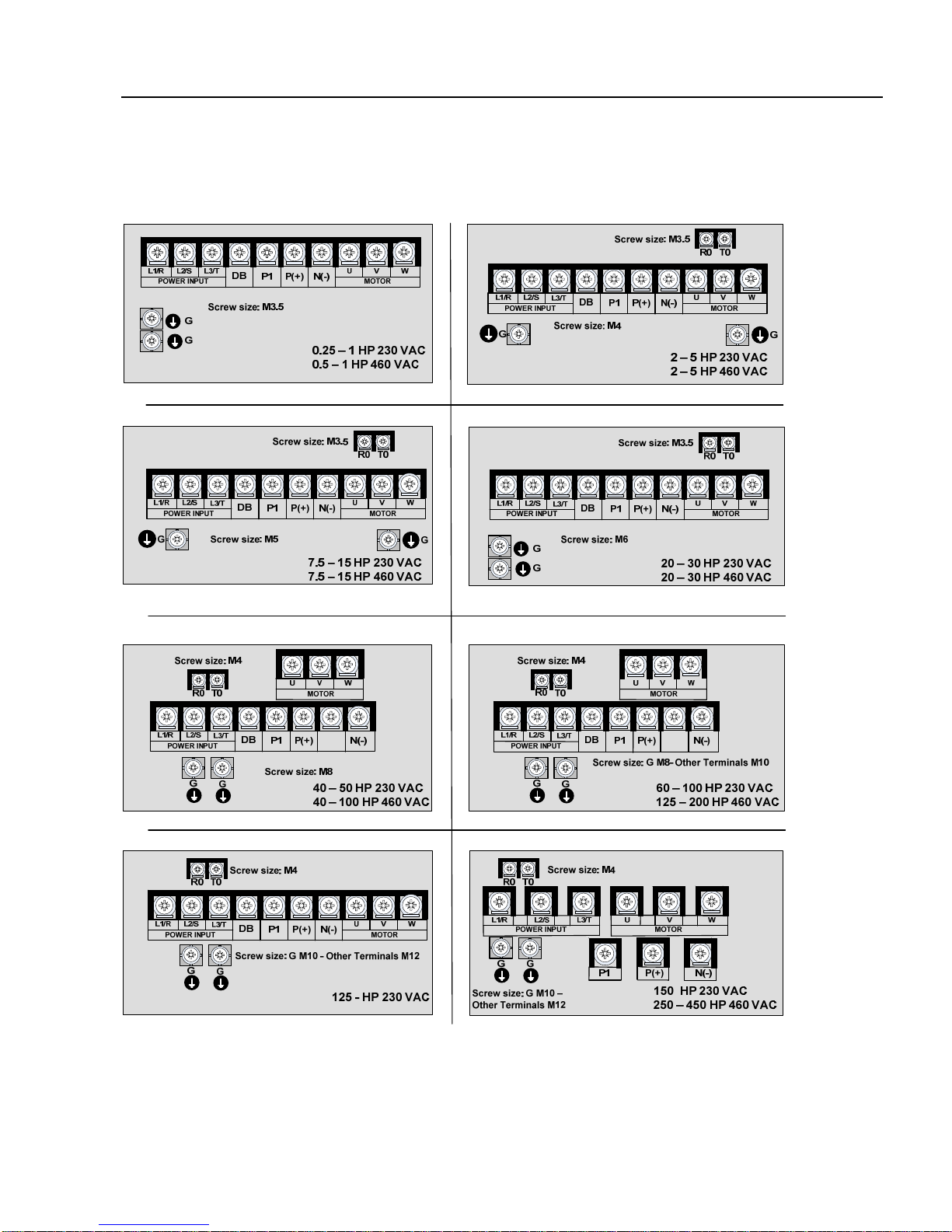

2-3-2 Connecting the Input Power, Motor Output Power, and Ground Terminals

The following shows the terminal arrangements for the various HP ranges of the EQ5.

The terminal screw sizes are also shown for reference.

EQ5 AC Drive Operations Manual

______________________________________________________________________

TECO – Westinghouse Motor Company Power Terminal Designations & Wiring 11

R0 T0

GG

L1/R L2/S L3/T

POWER INPUT

L1/R L2/S L3/T

UVW

MOTOR

UVW

P1

P1

P(+) P(+)

N(-) N(-)

Screw size: M4

Screw size: G M10 –

Other Terminals M12

500 – 600 HP 460 VAC

R0 T0

GG

L1/R L2/S L3/T

POWER INPUT

L1/R L2/S L3/T

UVW

MOTOR

UVW

P1

P1 P(+)

P(+)

N(-)

N(-)

Screw size: M4

Screw size: G M10 –

Other Terminals M12

700 – 800 HP 460 VAC

Table 2-3-1 Functions of Main Circuit Terminals and Ground Terminals

Symbol Terminal Name Description

L1/R, L2/S, L3/T Main circuit input power

terminals. Connects to a 3-phase power supply.

U, V, W Inverter output terminals Connects to a 3-phase motor.

R0, T0 Auxiliary control-power

input terminals.

Connects a backup AC power supply to the

control circuit. (Not applicable to inverters

of 1HP or less)

P1, P (+) DC link reactor terminal

connection. Connects a power-factor correcting DC link

reactor. (optional)

P (+), DB External braking resistor

terminal connections. Connects an external braking resistor for

inverters 10HP/CT, 15HP/VT or less.

P (+), N (-) DC link circuit terminals Supplies DC link voltage to the external

braking or power regeneration unit

(optional).

G Inverter ground terminal Inverter chassis (case) ground.

1.Main circuit input power terminals (L1/R, L2/S, L3/T)

a. For circuit (wiring) protection, connect these terminals to the input power supply using a

molded-case circuit breaker or a ground-fault circuit interrupter. Phase-sequence

matching is unnecessary.

b. To ensure safety, a magnetic contactor should be connected to disconnect the inverter

from the input power supply when the inverter protective function activates.

c. The main circuit input power should be used to start or stop the inverter only if absolutely

necessary and then should not be used more than once every hour.

d. If you need to connect these terminals to a single-phase power supply, please consult

the factory.

EQ5 AC Drive Operations Manual

______________________________________________________________________

TECO – Westinghouse Motor Company Power Terminal Designations & Wiring 12

2. Inverter output terminals (U, V, W)

a. Connect these terminals to a 3-phase motor in the correct phase sequence. If the

direction of motor rotation is incorrect, swap any two of the U, V, and W phases.

b. Do not connect a power factor correction capacitor or surge suppressor to the inverter

output.

c. If the cable from the inverter to the motor is excessively long, a high-frequency current

can be generated by stray capacitance between the cables and result in an overcurrent

trip of the inverter, an increase in leakage current, or a reduction in current indication

precision.

d. When a motor is driven by a PWM-type inverter, the motor terminals may be subject to

surge voltage generated by PWM switching. If the motor cables are excessively long,

particularly the 460V series units, the surge voltage will deteriorate motor insulation

over time. To prevent this, use the following guidelines:

Inverters 7.5HP/CT, 10HP/VT and Higher

Motor Insulation Rating 1000V 1300V 1600V

460 VAC Input Voltage 66 ft (20 m) 328 ft (100 m) 1312 ft (400 m) *

230 VAC Input Voltage 1312 ft (400 m) * 1312 ft (400 m) * 1312 ft (400 m) *

Inverters 5HP/CT/VT and Smaller

Motor Insulation Rating 1000V 1300V 1600V

460 VAC Input Voltage 66 ft (20 m) 165 ft (50 m) * 165 ft (50 m) *

230 VAC Input Voltage 328 ft (100 m) * 328 ft (100 m) * 328 ft (100 m) *

* In this case the cable length is determined by secondary effects and not voltage

spiking.

Note: When a motor protective thermal O/L relay is inserted between the inverter and the motor, the

thermal O/L relay may malfunction (particularly in the 460V series units), even when the cable length

is 165 feet (50m) or less. To correct this, insert a filter or reduce the PWM carrier frequency. (Use

function code “F26 Motor sound”.)

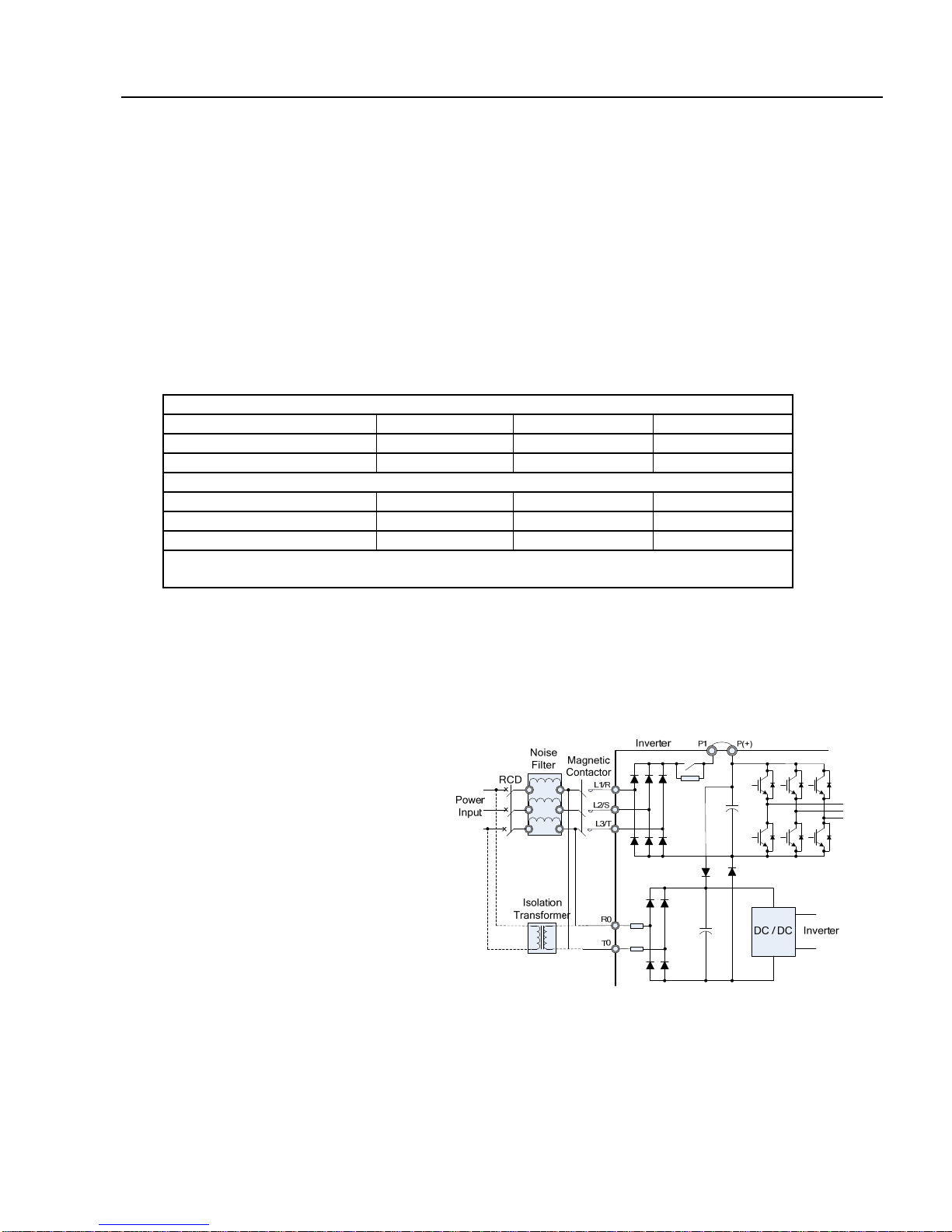

3. Auxiliary control-power input terminals (R0 and T0)

The inverter will operate even if power

is not provided to these terminals. If a

protective circuit is activated and the

magnetic contactor on the inverter

power input side is opened (off), the

inverter control circuit power, the alarm

output (30A, B, and C), and the keypad

display will lose power. To prevent this,

the same AC power as supplied to the

main input circuit must be supplied (as

auxiliary control power) to the auxiliary

control - power input terminals (R0 and

T0). (see Fig. 2-3-2)

a.To ensure effective noise reduction

when using an input noise filter, the

output from the filter must go to

the auxiliary control-power input

terminals. If these terminals are

Fig. 2-3-2 Connecting the Auxiliary Control-Power

Input Terminals

connected to the input side of the filter, the noise reduction is much less effective.

EQ5 AC Drive Operations Manual

______________________________________________________________________

TECO – Westinghouse Motor Company Power Terminal Designations & Wiring 13

b. When the RCD (Residual-current Protective Device) is installed (30HP/CT, 40HP/VT or less), the

terminal R0

and T0 should be connected to the output side of the RCD. If they are connected to the input side,

the RCD will malfunction because the power supply of the inverter is three phase and the

R0 and T0 input is single phase. If it is required to connect terminals R0 and T0 are to the input side

of the RCD, an isolation transformer is required as shown on the Fig. 2-3-2.

4. Connecting a DC link choke to terminals (P1 and P (+))

a. Before connecting a DC link choke to these terminals, remove the

factory-installed jumper. (Fig. 2-3-3)

b. If a DC link choke is not used, do not remove the jumper.

Note: For inverters of 100HP or more, the DC link choke is provided

as separate standard component and should always be

connected. For inverters less than 100 HP, the DC link choke

is not provided and is optional.

P(+)P1 X

DC Link Choke

Inverter

Fig. 2-3-3 Remove Jumper

4. Connecting an external braking-resistor to terminals (P (+) and DB) (10HP/CT, 15HP/VT or less)

(Fig. 2-3-4). For inverters 10HP/CT, 15HP/VT or less, a built-in braking resistor is connected to

terminals P (+) and DB. If this braking resistor does not provide sufficient thermal capacity (e.g.

high operating duty cycle or high inertia loads), an optional external braking resistor must be

installed to improve braking performance.

a. Remove the internal braking resistor from

terminals P(+) and DB and Insulate the

terminals with adhesive insulation tape, etc.

b. Connect terminals P(+) and DB of the external

braking resistor to terminals P(+) and DB of the

inverter.

c. The wiring (cables twisted or otherwise) should

not exceed 16ft (5m).

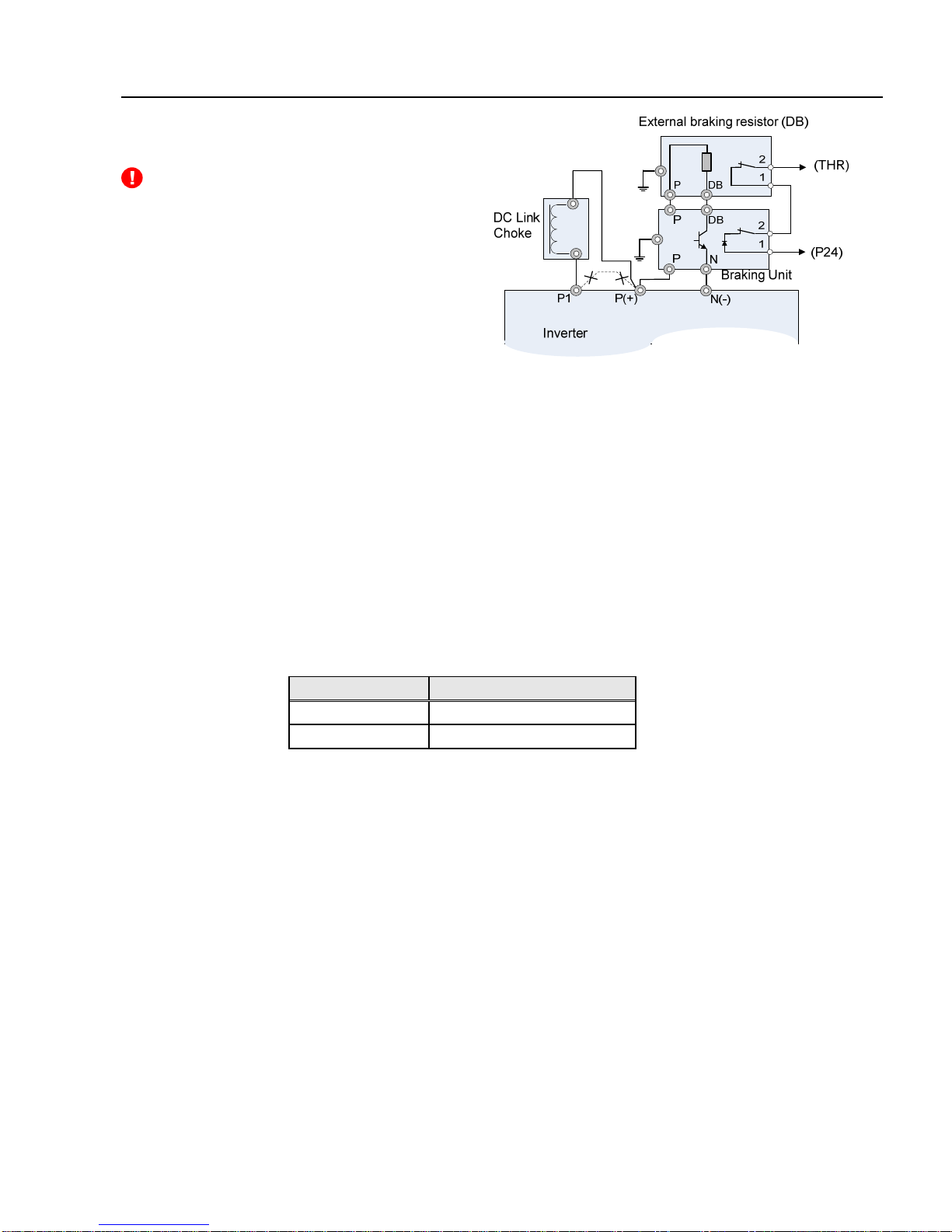

6. DC link circuit terminals (P (+) and N (-)) (Fig.2-3-5).

The EQ5 inverter of 15HP/CT, 20HP/VT or more

does not contain a drive circuit for the braking

resistor. To improve braking performance, an optional

external braking unit and external braking resistor

must be installed.

Fig. 2-3-4 Connection (10HP/CT,

15HP/VT or less)

a. Connect terminals P and N of the braking unit to terminals P(+) and N(-) of the inverter.

The wiring (cables twisted or otherwise) should not exceed 16ft(5m).

b. Connect terminals P and DB of the braking resistor to terminals P and DB of the braking

unit. The wiring (cables twisted or otherwise) should not exceed 33ft (10m).

c. Connect terminals P and DB of the braking

resistor to terminals P and DB of the

braking unit. The wiring (cables twisted or

otherwise) should not exceed 33ft (10m).

EQ5 AC Drive Operations Manual

______________________________________________________________________

TECO – Westinghouse Motor Company Power Terminal Designations & Wiring 14

DANGER- When terminals P (+) and N (-) of

the inverter are not used, leave terminals

open. If P(+) is connected to N (-) the bus

voltage will be shorted, or if braking resistor is

connected directly, the resistor can cause

fire.

d. Auxiliary contacts 1 and 2 of the braking

unit are polarity sensitive. To connect the

braking unit, refer to the "TECO Inverter

Speecon Braking Unit Manual”.

Fig. 2-3-5 Connection (15HP or more)

7. Inverter ground terminal

To ensure safety and noise reduction, always bond the inverter ground terminal. Also,

metal frames of electrical equipment must be grounded as specified in applicable codes

The connection procedure is as follows:

a. Ground all metal frames and chassis to a ground terminal (Ground resistance: 10).

b. In accordance with applicable codes, use a suitable ground cable to connect the inverter

system to ground.

8. Placement of connector (CN UX) for inverters 40HP/CT, 50HP/VT and higher.

When an inverter of 40HP or higher is connected to an input voltage listed in Table 2-3-2,

disconnect the auxiliary power connector CN UX from U1 and connect to U2.

(Refer to Fig. 2-3-7)

Table 2-3-2 Main Input Voltage Requiring Auxiliary Power Connector Change

Frequency [Hz] Input voltage range [VAC]

50 380 - 398

60 380 - 430

9. Placement of fan power connector (CN RXTX) for inverters 40HP/CT, 50HP/VT or higher.

An inverter of 40HP/CT, 50HP/VT or greater uses an AC cooling fan. When the inverter is being

operated with DC Input power, the fan must still be energized from an AC power

source. To do this, position the fan connector (CN RTXT) as shown in Fig. 2-3-9

and provide AC voltage to auxiliary input terminals R0 and T0. For the (CN RTXT)

connector placement method, see Fig. 2-3-7.

Note: When shipped, the fan connector (CN RXTX) is connected to L1/R-L3/T. Do not change the

connector position unless DC power is being used.

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

Firefly

Firefly FF-211 Important Instructions and Specifications

TRIAC

TRIAC THD S09 SERIES Installation & maintenance manual

Middle Atlantic Products

Middle Atlantic Products FC Series instruction sheet

Triconex

Triconex Trident Planning and installation guide

Seltron

Seltron KXD10B manual

Niagara

Niagara Edge-10 installation guide