Niagara Edge-10 User manual

1

BETA DRAFT VERSION

Edge-10 Controller (14039)

Edge-10 Controller

June 29, 2018

BETA DRAFT VERSION

Warnings

Disconnect power before installation or servicing to

prevent electrical shock or equipment damage.

To reduce the risk of re or electrical shock, install in

a controlled environment relatively free of contaminants.

Cautions:

Removal of the controller’s cover is not required.

No congurable or user-serviceable items require cover

removal.

Mounting

Mount the controller in a location that allows clearance

for wiring, servicing, and removal.

Environmental Requirements

NOTE: is product is for indoor use only.

Ambient conditions must be within the range of:

• Operating Temperature: -20°C to 60°C (-4°F to 140°F)

• Storage Temperature: -40°C to 85°C (-40°F to 185°F)

• Relative humidity: 5% to 95% non- condensing

• Supply voltage uctuation and brownout tolerance:

– Allowable voltage uctuation to +/-10%.

– 0-69% input voltage - 40ms

– 70-79% input voltage - 1 second

– 80 - 89% input voltage - 20 seconds

– 90% - 100% input voltage - indenitely

NOTE: Horizontal mounting is strongly recommend-

ed, to achieve maximum heat dissipation and meet the

operating temperature upper limit. Any other mounting

orientation reduces this upper limit.

Description

Edge-10 (14039)

DIN-mount, 24Vac/dc (50/60Hz) powered, Niagara®

controller With 10 I/O points including:

• Five Universal Inputs (UIs) compatible with 0-10Vdc,

0-20mA, dry contacts, 0-100K ohm resistive, or Type

3 thermistor temperature sensors.

• ree digital triac outputs for on/o control of 24Vac

loads upto 1/2 Amp

• Two 0-10Vdc Analog Outputs (AOs) for 0-10Vdc

analog control of loads up to 2.5K ohm minimum or

4mA drain maximum.

See the product data sheet and Edge-10 Installation and

Startup Guide for complete specications and product

details.

Included in this package

• Edge-10 (14039) controller.

• ree-position RS485 connector plug

• Six-position connector for triac output

• Four-position connector for analog outputs

• Eight-position connector for analog inputs

• Two-position power connector, and a grounding wire

• 499 Ohm resistors (Qty. 5) for universal input use

• is Edge-10 Controller Installation Sheet.

Material & Tools Required

• One of the following:

– UL listed, Class 2, 24Vac transformer, rated at min-

imum of 7VA. A dedicated transformer is required

(cannot power additional equipment), or

– User supplied UL Listed Class 2 or LPS AC power

adapter: 24Vdc, capable of supplying at least 7W

(24Vdc at 292mA).

• DIN rail, type NS35/7.5 (35mm x 7.5mm) and

DIN rail end-clips (stop clips), recommended for

installation. Controller is also panel-mountable.

• Suitable tools and fasteners for mounting the unit and

any accessories.

2BETA DRAFT VERSION

Mounting On DIN Rail

1Pull the controller’s locking clip down.

2Tilt the controller to hook over the DIN rail.

3Push down and in on the unit to fasten to the rail.

4Push locking clip up and click into place to secure.

5Carefully secure both ends of the nal assembly with

DIN rail end-clips provided by the DIN rail vendor.

UNIVERSAL INPUTS

1UV0 U2U3U4U5 0V 0V

ANALOG OUTPUTS RS485

0V 0VAO2 AO1

S

A+

A-

24 VAC/DC

SEC PRI

GND

FACTORY

RESET

DEBUG

DIGITAL OUTPUTS

A BBABA

D3 D2 D1

55

Terminal Locations

e Edge-10 provides 5 Universal Inputs compatible

with 0–10Vdc, 0–20mA, dry contacts, 0–100K ohm

resistive, or Type 3 thermistor temperature sensors.

Edge-10 includes ve outputs as:

• ree digital triac outputs for on/o control of 24Vac

loads up to 1/2 Amp

• Two 0-10Vdc Analog Outputs for 0-10Vdc analog

control of loads at 2.5K ohm minimum or 4mA drain

maximum.

Wiring terminal positions are shown below, along with

LED locations.

Connector Locations

UNIVERSAL INPUTS

1UV0 U2U3U4U5 0V 0V

ANALOG OUTPUT RS485

0V 0VAO2 AO1

S

A+

A-

24 VAC/DC

GND

FACTORY

RESET

DEBUG

DIGITAL OUTPUTS

A BBABA

D3 D2 D1

SEC PRI

1 2 3 4

65 7

Field communications ports are as follows:

1Universal inputs (5 inputs on 8-position connector)

2Analog outputs (2 outputs on 4 position connector)

3RS485 port (1 port on 3-position connector)

4Digital (triac) outputs (3 outputs on 6-position con-

nector)

524Vac/dc input (1 input on 2-position connector)

6Earth ground (1 tab for earth ground)

7Ethernet ports (2, 10/100Mb, RJ-45 connectors with

integrated LEDs)

Wiring

Refer to “Connector Locations” and the following images

to locate connectors and other components. Descriptions

are provided for wiring to ground, to power, RS-485,

Ethernet, Inputs and Ouputs.

Wiring Earth Ground & Power

UNIVERSAL INPUTS

1UV0 U2U3U4U5 0V 0V

ANALOG OUTPUT

RS485

0V 0VAO2 AO1

S

A+

A-

24 VAC/DC

GND

FACTORY

RESET

DEBUG

DIGITAL OUTPUTS

A BBABA

D3 D2 D1

SEC PRI

24 Vac

50/60Hz 24 Vdc +

1

2

Earth Ground

2.1 2.2

OR

Because the Edge-10 uses a half-wave rectied pow-

er supply, it should not share a transformer with the

JACE-8000, IO-R-34, or any legacy JACE.

Earth grounding provides protection from electrostatic

discharge or other forms of EMI.

NOTE: Depending on power source used.

2.1 (AC): Dedicated 24V transformer required, with nei-

ther side of the transformer secondary tied to ground.

2.2 (DC): Polarity is critical (uses onboard half wave

diode), -to ground and +to other terminal.

Warning: Before making power terminations, de-en-

ergize the 24V power source. Do not restore power until

completing all other mounting and wiring. See “Power up

and Initial Checkout”.

Prerequiste: A nearby earth grounding point.

1Install the included earth ground wire to the control-

ler’s earth ground spade lug, and terminate the other

end to a nearby earth ground.

2Unplug the controller’s 2-position power connector

plug and terminate the 24V supply source (AC or DC)

to the connector. Leave connector unplugged for now.

3

BETA DRAFT VERSION

RS485 Wiring

UNIVERSAL INPUTS

1UV0 U2U3U4U5 0V 0V

ANALOG OUTPUT

RS485

0V 0VAO2 AO1

S

A+

A-

24 VAC/DC

GND

FACTORY

RESET

DEBUG

DIGITAL OUTPUTS

A BBABA

D3 D2 D1

SEC PRI

UNIVERSAL INPUTS

1UV0 U2U3U4U5 0V 0V

ANALOG OUTPUT

RS485

0V 0VAO2 AO1

S

A+

A-

24 VAC/DC

GND

FACTORY

RESET

DEBUG

DIGITAL OUTPUTS

A BBABA

D3 D2 D1

SEC PRI

Fox

MSTP

NRIO

- Fox

- BACnet/IP

- Modbus/TCP

- SNMP

1 3

2

Supervisor

IO-R-34

Device

Device

IO-R-34

S

+

–

-

+

S

Shielded twisted pair

RS-485

Ground at one

point on

Edge-10

end only

On the controller’s top side, a single, non-isolated, RS485

port provides connection to IO-R-34 module or to other

RS-485 devices (NRIO, MSTP, MODBUS). Do not use

this port to connect to other JACE controllers.

Use shielded, twisted-pair, 18-22 AWG cabling to wire in

a continuous multidrop fashion to other RS485 devices:

“minus to minus”, “plus to plus,” and “shield to shield.

10K bias resistors are permanently connected. Note that

there is no built in termination resistor. Maximum total

cable length is 1,000 feet (304.8 meters).

Connect the shield wire to earth ground at Edge-10 end

only. e image above shows example wiring.

1RS485 port supporting a trunk of MSTP devices (3

devices max).

2RS485 port connected to a single IO-R-34 module.

3Example wire terminations to IO-R-34 using RS-485.

NOTE: Do not mix an IO-R-34 with other types of

RS485 devices on the same RS485 trunk.

NOTE: RS485 devices on the same network should use

the same protocol and baud rate. Up to 3 external devic-

es and 50 external points are supported.

Ethernet Wiring

Two RJ-45 10/100Mb Ethernet connectors are labeled

PRI for primary, and SEC for secondary. Use a standard

Ethernet patch cable to an Ethernet switch. ese ports

are suitable for daisy-chaining Edge-10 controllers (see

image below) or for connection to either a JACE-8000 or

directly to a network.

Daisy Chain using Ethernet

UNIVERSALINPUTS

1UV0 U2U3U4U5 0V 0V

ANALOGOUTPUTS RS485

0V 0VAO2 AO1

S

A+

A-

24VAC/DC

SEC PRI

GND

FACTORY

RESET

DEBUG

DIGITALOUTPUTS

A BBABA

D3 D2 D1 UNIVERSALINPUTS

1UV0 U2U3U4U5 0V 0V

ANALOGOUTPUTS RS485

0V 0VAO2 AO1

S

A+

A-

24VAC/DC

SEC PRI

GND

FACTORY

RESET

DEBUG

DIGITALOUTPUTS

A BBABA

D3 D2 D1 UNIVERSALINPUTS

1UV0 U2U3U4U5 0V 0V

ANALOGOUTPUTS RS485

0V 0VAO2 AO1

S

A+

A-

24VAC/DC

SEC PRI

GND

FACTORY

RESET

DEBUG

DIGITALOUTPUTS

A BBABA

D3 D2 D1

Upon rst startup when IP connectivity is detected, the

Edge-10 initially requests an IP address via DHCP. If a

DHCP address is not found, the controller reverts to a

static IP address based on its serial number. e fallback

IP address is 192.168.1xx.xx, where xx.xx is the last 4

digits of the serial number. For example, if the serial

number is 123456789, the fallback IP address would be

192.168.167.89.

e default subnet mask is 255.255.0.0.

Inputs

Each of the 5 UI inputs supports any of the following:

• Type-3 10K ohm ermistor (see Caution on page 12)

• Resistive 0-100K ohms

• 0–10 Vdc

• 4–20 mA

• Binary Input

Thermistor

e inputs support 10K ermistor temperature sensors.

Input accuracy is in the range of ±1% of span. By default,

conversion is for a standard Type 3 thermistor sensor

with a sensor range of -10° to 135°F (-23.3° to 57.2°C).

Using a conversion type of “Tabular ermistor,” you

can specify a dierent thermistor response curve by

importing a thermistor curve .xml le. e Niagara kitIo

module contains an xml folder with thermistor curves

for a various thermistor temperature sensors. You can

also edit and export (for reuse) customized thermistor

curve xml les. See the NRIO Driver Guide for details.

0V U5 U4 0V U3 U2 0V U1

Cut and tape shield wire

back at Thermistor

Shielded, Twisted Cable,

61m (200 ft) maximum - Stud in enclosure

Shield

10K Thermistor

Resistive 0-100K ohms

e inputs can read a resistive signal within a range from

0 to 100,000 ohms. Wiring is the same as shown for a

ermistor temperature sensor, above.

Caution: UI inputs provide optimum resis-

tive-to-temperature resolution in the 10K ohm range.

For a sensor with a range far from 10K ohms (such as a

100-ohm or 1000-ohm sensor), resolution is so poor as

to be unusable! To successfully use such a sensor, install

a transmitter that produces a Vdc or mA signal, and then

wire the transmitter to the UI according to the 0–10 Vdc

or 4–20 mA instructions.

0-10Vdc

e inputs support self-powered 0–10 Vdc sensors. Input

impedance is greater than 5K ohms.

0–10 volt accuracy is ±2% of span, without user calibra-

tion. 0–10.

4BETA DRAFT VERSION

0V U5 U4 0V U3 U2 0V U1

Cut and tape

shield wire back

at sensor

Shielded, Twisted Cable,

61m (200 ft) maximum - Stud in enclosure

Shield

Range: 0-10 Vdc

Input Impedance > 5K ohms

0-10 Vdc Sensor

(self-powered sensor)

0-10

Vdc

+

-

4-20 mA

e inputs support self-powered 4–20 mA sensors. Input

accuracy is ±2% of span, without user calibration. Use a

499 ohm resistor wired across the input terminals.

Caution: When using an externally powered 4–20

mA sensor, be sure to de-energize its power supply

before making or changing any wiring connections to the

Edge-10 module. is is in addition to removing power

from the Edge-10 module. DO NOT apply external

power to the UI inputs without the 499 ohm resistor in

place. Otherwise, even a momentary application of power

(say, 24Vdc) to the UI terminals without the resistor may

damage circuitry on the Edge-10. Only aer completing

all input wiring should you restore power to such external

power supplies.

0V U5 U4 0V U3 U2 0V U1

Cut and tape

shield wire back

at Thermistor

iShielded, Twisted Cable,

61m (200 ft) maximum - Stud in enclosure

Shield

499 Ohm resistor

(supplied with unit)

4-20 mA Sensor

(self powered sensor)

Range: 0-20 mA

+

-

Binary Input

e universal inputs support normal dry (equipment

status) contacts. Standard dry contacts must have a 1 Hz.

(or less) COS frequency, with minimum dwell time >

500ms. (Contacts must remain open at least 500ms and

be closed at least 500ms.) Dry contacts support 11 Vdc

open circuits or 733 µA short-circuit current.

0V U5 U4 0V U3 U2 0V U1

Cut and tape

shield wire back

at sensor

Shielded, Twisted Cable,

61m (200 ft) maximum

- Stud in enclosure

Shield

Dry Contacts

Outputs

e Edge-10 provide 3 triac digital outputs and 2 0-10Vdc

analog outputs

Binary Triac Outputs

Each digital triac output is rated at 24 Vac +/- 15%,

50/60Hz, at 0.5A max. Relays are not rated for AC mains

(line level) powered loads (instead, 24V maximum).

Outputs are normally open, oating and do not share a

common pin.

NOTE: Triac outputs are suitable for AC only. DC loads

and dry contacts require an intermediate relay.

Warning: Never use a controller’s power transformer

to power I/O loads. Using the controller’s transformer

introduces potentially damaging switching transients into

the unit.

A BBABA

D3 D2 D1

DIGITAL OUTPUTS

1

23

Only 24VAC loads

See Warning

Analog Outputs

Analog outputs (AO) are referenced by the terminals

labeled AOnand 0V (ground). Each AO can supply a

maximum of 4 mA over the entire 0 to 10Vdc range. e

minimum input impedance of a device controlled by an

AO must be greater than 2500 ohms.

0V 0VAO2 AO1

0-10Vdc device

Input impedance is

greater than 2500 Ohms

Common (-)

Input (+)

ANALOG OUTPUT

Power up and Checkout

Power Up and Initial Checkout

1Apply power by inserting the 2-position 24V power

connector plug.

2Check the green STAT (Status) and yellow BEAT

(Heart- beat) LEDs.

When power is applied, the green “STAT” LED will light.

is indicates the system is OK, with power applied.

During bootup, the “BEAT” LED may blink at 3 Hz with

a 50%/50% on/o duty cycle. When bootup completes,

the platform daemon is started, and the normal 1 Hz

ash at 50%/50% on/ o duty cycle of the “BEAT” LED

returns.

5

BETA DRAFT VERSION

Status LEDs, Debug Port and Factory Reset

24 VAC/DC

GND

FACTORY

RESET

DEBUG

SEC PRI

1

2 3

45 6

e controller has three yellow triac status LEDs, one

yellow heartbeat LED, and a single green controller

status LED located on the top of the controller. It also

includes two LEDs for each Ethernet port which are

located on the Ethernet connectors and are visible from

the side of the controller.

1STAT (Green) - Remains illuminated while controller

is powered.

2BEAT (Yellow) - “Heartbeat”, normally 1Hz, 50%

duty cycle.

3D3, D2, D1:Active (Yellow), Inactive: (O).

4SEC and PRI Ethernet , 2 LEDs for each port:

– Green LED on le: Link (On) / Activity (Flicker)

– Yellow LED on right: Speed; 100Mb(On) / 10

Mb(O).

If the “BEAT” LED stays illuminated constantly, does not

light, or blinks very fast, contact System Engineering for

technical support.

e 3Hz, 50%/50% on/o “BEAT” ash at bootup

also occurs during other critical operations, such as a

rmware upgrade to the controller and/or any attached

modules. To be safe, do not remove power from the

controller while its “BEAT” LED ashes with a 90%/10%

on/o duty cycle. Wait for the normal (50%/50%) ash

to return before removing power.

Along the bottom side of the controller is a debug port

for serial debug communications and a Factory Reset

button.

5DEBUG - Micro-A USB for serial debug communica-

tions.

6FACTORY RESET - Pushbutton switch to return the

controller to a factory default settings.

e DEBUG port is a standard Micro-A/B type USB port

for serial debug communications to the controller. Use a

serial terminal program (for example: PuTTY) to access

the controller “system shell” menu. is provides access

to some basic platform settings.

Default DEBUG port settings are: 115200, 8, N, 1 (baud

rate, data bits, parity, stop bits). For details on using a

serial connection to the DEBUG port, see the Edge-10

Install and Startup Guide or the JACE-8000 Install and

Startup Guide.

NOTE: Login requires admin-level platform credentials.

Default platform credentials are: username: “tridium”

password: “niagara”.

Tab Mounting option

1

6.71 in. (170.5 mm)

4.33 in.

(115 mm)

6.38 in. (162 mm)

7.05 in. (179 mm)

3.31 in.

(84 mm)

0.153 in. Dia.

(3.878 mm)

0.330 in.

(8.378 mm)

3.75 in.

(95.25mm)

DIN rail mounting is recommended. Where tab mount-

ing is required, use dimensions in the illustration to

mount the controller.

Caution: Do not mount hardware on both a DIN

Rail and with tab mounts to another surface. is causes

physical stress on equipment and prevents good connec-

tions between controller and modules.

1Edge-10 controller. Allow at least 1.5” (38mm) clear-

ance around all sides.

Information and/or specications published here are current as of the date of publication of this document. Tridium, Inc. reserves the right to

change or modify specications without prior notice. e latest product specications can be found by contacting our corporate headquarters,

Richmond, Virginia. Products or features contained herein are covered by one or more U.S. or foreign patents. is document may be copied

by parties who are authorized to distribute Tridium products in connection with distribution of those products, subject to the contracts that

authorize such distribution. It may not otherwise, in whole or in part, be copied, photocopied, reproduced, translated, or reduced to any

electronic medium or machine-readable form without prior written consent from Tridium, Inc. Complete condentiality, trademark, copyright

and patent notications can be found at: http://www.tridium.com/galleries/SignUp/Condentiality.pdf. © 2018 Tridium, Inc.

Edge-10, JACE, JACE-8000, Niagara Framework, Niagara 4 Framework, and the Niagara AX Framework are trademarks of Tridium, Inc.

32337886-001 M.S. 2018-06-29

Printed in Mexico

中国电子电气产品中有害物质的名称及含量

China EEP Hazardous Substance Information

Restricted Materials Above Threshold

部件名称与型号

Assembly Name and Model

有害物质

Hazardous Substances

型号

Model

部件名称

Assembly Name

铅

(Pb)

汞

(Hg)

镉

(Cd)

六价铬

(Cr6+)

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

14039 PWB组件

PWB Assemblies X O O O O O

本表格依据SJ/T11364的规定编制。

ThistableispreparedinaccordancewiththeprovisionsofSJ/T11364.

O: 表示该有害物质在该部件所有均质材料中的含量均在GB/T26572规定的限量要求以下。

Indicatesthatsaidhazardoussubstancecontainedinallofthehomogeneousmaterialsforthispartisbelowthe

limitrequirementofGB/T26572.

X: 表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T26572规定的限量要求。

Indicatesthatsaidhazardoussubstancecontainedinatleastoneofthehomogeneousmaterialsusedforthispart

isabovethelimitrequirementofGB/T26572

“未列入表内的其他部件,皆不含任何超出限量要求的限制使用物质。

Allothercomponents,notlistedinthetable,donotcontainrestrictedsubstancesabovethethresholdlevel

电子电气产品的环保使用期限依据SJ/T11388标准的规定确定。

TheEPUPvalueofEEPisdefinedaccordingtoSJ/T11388standard.

WEEE (Waste of Electrical and Electronic Equipment)

is symbol on our product shows a crossed-out “wheelie-bin” as required by law regarding the Waste of

Electrical and Electronic Equipment (WEEE) disposal. is indicates your responsibility to contribute in saving

the environment by proper disposal of this Waste i.e. Do not dispose of this product with your other wastes. To

know the right disposal mechanism please check the applicable law.

Table of contents

Other Niagara Controllers manuals

Popular Controllers manuals by other brands

YASKAWA

YASKAWA SI-EM3 installation manual

Freescale Semiconductor

Freescale Semiconductor TRK-MPC5604B quick start guide

TIE DOWN

TIE DOWN 750E Installation, instruction and service manual

Pedigree Technologies

Pedigree Technologies OneView LMU 2630 installation manual

digitalview

digitalview 41721003X-3 instructions

Robotics

Robotics RT-1000 quick start guide

Mitsubishi Electric

Mitsubishi Electric MHK2 installation manual

Ewellix

Ewellix CASM-32 Installation, operation and maintenance manual

Unitronics

Unitronics Vision V130-J-TA24 installation guide

Thermocold

Thermocold MEX VS 15 RH manual

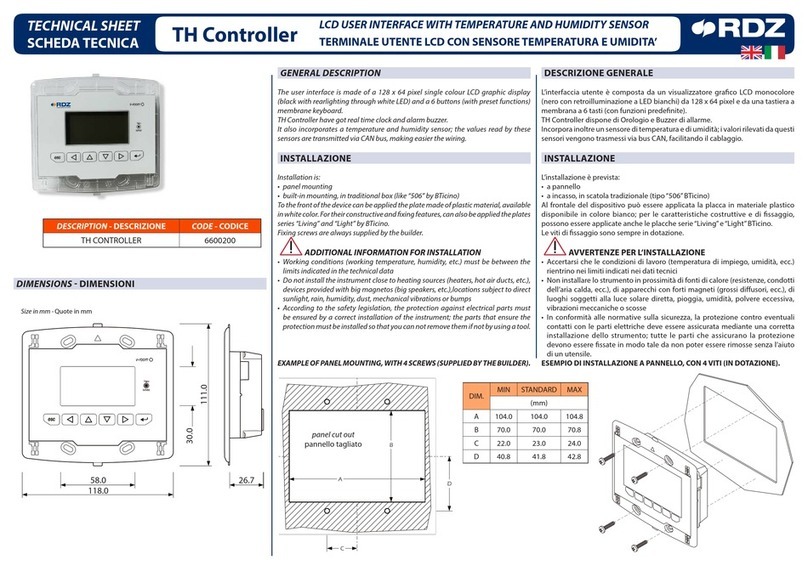

RDZ

RDZ 6600200 Technical sheet

RKI Instruments

RKI Instruments Beacon 110 Operator's manual