TECSYSTEM NT511 MODBUS User manual

http://www.tecsystem.asia

NT511

AD ANALOG &

DIGITAL INSIDE

INSTRUCTION MANUAL

NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

TECSYSTEM SHANGHAI

3rd Floor, Block No.5,For-

ward High-tech Industrial Park,

No.33, Fuhua Road,

Jiading District

SHANGHAI - CHINA

Tel:8621 39905855/56/57

R1.2 17/8/1

TECSYSTEM SHANGHAI

2NT511 AD ANALOG & DIGITAL INSIDE

INTRODUCTION

NT511 is a microprocessor electronic device devoted to the transformer thermal monitoring,

complete with ventilation system control and protection.

The monitoring unit is designed to be directly mounted on the transformer box and it is

equipped with a wide display to show and manage the temperatures, as well as the ventila-

tion switching on and alarm thresholds. It has 4 inputs for 3-wire PT100 sensors and it can

feed and directly monitor the working of 1-6 fans.

The monitoring unit has a current RS485 port with RTU Modbus protocol which allows the

plant remote management.

210×260×90 mm

TECSYSTEM SHANGHAI

3

NT511 AD ANALOG & DIGITAL INSIDE

SUPPLY

• Rated values: 230VAC±10% 50/60Hz

• Maximum absorption: 6VA (fans ex-

cluded), ~2KW fans included

DIMENSIONS

•

• Panel CUT-OUT 182x232 mm (Figure 2

Page20)

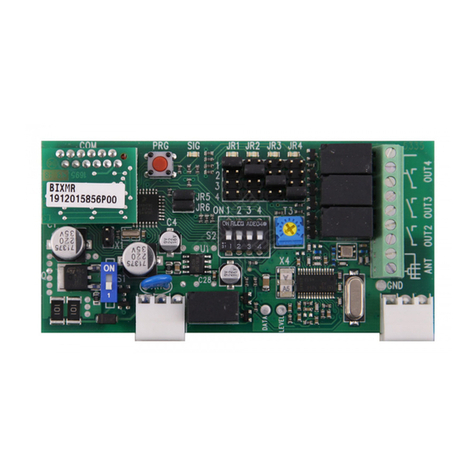

INPUTS (Figure 3 Page 21)

• 4 Inputs for 3-wire PT100 sensors

• Removable rear terminals

• Input channels protected against electro-

magnetic noises

• Cable compensation for resistance bulbs

up to 500 mt (1mm2.)

OUTPUTS (Figure 4 Page 22)

• 2 alarm relays (ALARM-TRIP)

• 6 outputs for fan supply 230VAC

50/60Hz 1.5A x6 (protection fuse 2A)

• 1 relay for sensor fault or working anom-

aly (FAULT)

• Output relays with 5A-250Vca resistive

contacts

• RS485 Modbus RTU digital output

• 4.20 mA analog output

TESTS AND PERFORMANCES

• Assembling in accordance with CE rules

• Protection against electrical noises CEI-

EN-61000-4-4

• Dielectric strength 2500 Vca for 1 minute

between relays and supply, relays and

sensors, sensors and supply

• Accuracy ± 1% full scale value, ± 1 digit

@25°C

• Working temperature from -20°C to +60°

C

• Humidity 90% no condensing

• Housing: switchboard panel by painted

steel

• Digital linearization of sensor signal

• Self-diagnosis circuit

• Program and reading resolution:1 digit

• Front frame in polycarbonate IP65

• Highest absorption 6VA

• Data storage 10 years minimum

• Option: protection treatment of the elec-

tronic part

DISPLAY AND DATA MANAGEMENT

• Display to show temperature and pro-

gramming parameters (°C TEMPERA-

TURE)

• Display to show the displayed channel

(CHANNEL)

• 3 leds to show the display mode (SCAN,

HIGH, TMAX)

• 4 leds to show the state of the alarms

relevant to the displayed channel

(FAULT, FAN, ALARM, TRIP)

• 6 leds to show the motor fault (M1, M2,

M3, M4, M5, M6)

• Led to show the programming phase

(PRG)

• Led to show the fan forced activation

(manual) (MAN)

• Led to show the modbus communication

(RS485)

• Temperature monitoring from 0°C to

200°C

• 2 alarm thresholds (alarm/trip) for each

channel

• 2 thresholds to check ON-OFF ventila-

tion

• Sensor diagnostic (Fcc-Foc)

• Programming access through front key

• Wrong programming display

• Maximum temperatures reached by the

channels, alarm storage and sensor

fault.

• Front key to reset the alarms

TECSYSTEM SHANGHAI

4NT511 AD ANALOG & DIGITAL INSIDE

2) MOUNTING OF NT511 MONITORING UNIT

Make a hole in the panel sheet with dimensions 182 x 232 mm. according to the fixing tem-

plate shown in the Figure 2 at Page 19.

Firmly tighten the device with the enclosed screws.

3) SUPPLY OF NT511 MONITORING UNIT

NT511 Monitoring unit has 230VCA ±10% 50-60Hz supply.

To terminal 37 must always be connected to the ground.

When the monitoring unit is directly fed from secondary winding of the transformer to be

protected, it can be damaged by high-intensity overvoltages.

These problems occur if the main switch is connected without load.

Above mentioned problems are much more evident when the 220 Vac voltage is directly

taken from the transformer secondary bars and there is a fixed capacitor battery to phase

the transformer itself.

In case you have to replace an existing monitoring unit with a new one, in order to

guarantee its safe and correct working, you must replace the sensor/relay/supply

connection terminals with the new terminals supplied, provided that they are of a

brand different from the ones previously mounted.

4) ELECTRICAL CONNECTIONS FOR ALARMS AND VENTILATION

Carry out the electrical connections on the removable rear terminals, after having removed

them from the monitoring unit.

ALARM and TRIP relays switch only when the set temperature limits are reached .

FAULT relay (Fault) switches when the monitoring unit is fed, while gets de-energised when

a fault occurs to Pt100 sensors, data memory fault (Ech) or when supply voltage is lacking.

M1-2-3-4-5-6 outputs can be used to feed the cooling fans (highest range 2A)

5) TEMPERATURE SENSOR CONNECTION

Each Pt100 temperature sensor has a white and two red wires (CEI 75.8 standards).

Figure 3 Page 20 shows the position inside the terminal box of the monitoring unit connec-

tion cables.

CH2 channel must always be referred to the transformer central column.

CH4 channel must be referred either to the transformer core or to Pt100 room sensor, if you

want to thermostat the transformer room using the NT511 monitoring unit.

6) MEASURING SIGNAL TRANSFER.

All the measuring signal transfer cables for Pt100 must absolutely:

• be separated from the power ones

• be made with shielded cable and twisted conductors

• have at least 0,5 mm² section

• be twisted if there is no screen

• be firmly fixed inside the terminal boxes

• have tinned or silvered conductors

All the “NT” series monitoring units have the sensor signal linearization, with a max. error of

1% of full scale value.

5

NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

7) CONNECTION WITH RS485 NETWORK

NT511 can be connected with a data acquiring device (PC, PLC, SCADA) for remote con-

trol. The used interface is RS485-type, which allows to connect 32 devices on the same line,

and it is based on Modbus RTU protocol.

In order to guarantee a proper network working, please follow what laid down by EIA RS485

standard which suggests to use a 24AWG duplex cable.

The duplex cable which connects all the units in RS485 could require a 120 ohm termination

on the last unit of the series.

Connect the duplex cable paying attention to the polarities and lay the network avoiding to

make sharp bends or ring windings in order not to modify the line impedance.

In case of particular noises, it could be necessary to ground the shielding on GND terminal.

8) TEMPERATURE SENSOR DIAGNOSTIC

8) TEMPERATURE SENSOR DIAGNOSTIC

In case of breaking of a temperature sensor mounted on the machine to be protected,

FAULT relay immediately switches with the relevant indication of the defective sensor on

the corresponding channel.

• Fcc for short-circuited sensor.

• Foc for interrupted sensor.

• Fcd temperature fast increasing (see pag.10).

To eliminate the message and reset Fault switching, it is necessary to verify Pt100 connec-

tions and, in case, replace the defective sensor.

Note: CAL message appears when it is determined the damage of the measuring circuit.

The temperature values shown could be incorrect. Please contact Tecsystem to return the

unit for repairing.

9) PROGRAMMED DATA DIAGNOSTIC

In case of breaking of the internal storage or corruption of programmed data, just after

switching on, the Ech wording is displayed with the relevant reporting of the Fault contact.

For safety reasons, in this case the default parameters Alarm Ch1-2-3= 90°C, Trip Ch1-2-3=

119°C, Ch4= Yes, Alarm Ch4= 120°C, Trip Ch4= 140°C, Ch-Fan= 1-2-3, Fan-on= 70°, Fan-

off= 60°, HFN= 000 are automatically loaded.

To remove Ech wording, press RESET and run programming to insert the desired values.

Finally turn off and turn on again the unit to verify the correct memory working; in case it is

damaged and the Ech wording is still displayed, please return the monitoring unit to Tecsys-

tem for repair).

10) TEMPERATURE DIAGNOSTIC

If one of the temperature sensor detects a temperature higher than 1°C compared to set

value as alarm limit, after approximately 5 seconds ALARM relay switches together with the

turning on of ALARM LED of the reference channel (CHn).

When the release temperature limit is passed, TRIP relay switches together with the turning

on of LED TRIP of the reference channel (CHn).

As soon as the taken temperature returns to equal or lower values than the set limit for

ALARM and TRIP relay switching, they de-energise with consequent turning off of relevant

LED’s.

6NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

11) COOLING FAN CONTROL (Figure 4 Page 21)

NT511 Monitoring unit, if opportunely programmed, can control ON-OFF of fans

accompanying the transformer, according to set temperatures.

Fans on machine can be driven in two different ways:

• Using the temperatures taken by the sensors on the three columns

CHF 1.2.3

(ex. ON at 80°C - OFF at 70°C)

Through an extra sensor (CH4/YES) for the room temperature inside the transformer

box.

CHF 4

(ex. ON at 40°C - OFF at 30°C)

12) FAN TEST

It is possible, through programming (HFn), impose that the fans are activated for 5 minutes

each “xxx” hours, regardless of column or room temperature values (ex.: with HFn=001 fans

are activated for 5 minutes each hour).

This function has the aim to periodically verify the working of the fans and their control

apparatus during long idle periods.

Loading 000 value this function is inhibited.

13) DISPLAY MODE

Pressing MODE key, the display mode is loaded:

• SCAN: monitoring unit displays in scansion (each 2 seconds) all the activated channels

•AUTO: monitoring unit automatically displays the hottest channel

• T.MAX: monitoring unit displays the highest temperature reached by the sensors and

possible alarm or fault situations occurred after the last reset.

Select channels with

ST, reset values with RESET.

14) WORKING PROGRAM CONTROL

To check the programmed temperature values, shortly press PRG key. viS indication is

displayed for 2 seconds, confirming entering in the program vision mode.

By repeatedly pressing PRG key, all the previously loaded values are rolled in sequence.

After 1 minute of keyboard no-operation, display-programming procedure will be

automatically left.

To end display, press ENT key.

15) LAMP TEST

Lamp test is carried out when the monitoring unit is turned on and when the data display

and programming phases are over.

During lamp test all the displays are on for 2 seconds.

16) ALARM RELAY SILENCING

If you want to silence the ALARM signal press RESET key: relay de-energises and LED

ALARM, which was fixed, will start to blink.

Silence system is automatically disconnected when the temperature goes under the ALARM

threshold.

17) IMPORTANT NOTICE

Before carrying out the insulation test on the switchboard where the monitoring unit

is mounted, you have to disconnect it from the mains in order to avoid serious

damages.

7

NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

If one of the LED’s should not work, you are kindly requested to return the monitoring

unit to TECSYSTEM.

18) FRONT PANEL

Keyboard

Message and tempera-

ture display

Allarms

Selected

channel

Display mode

Engine failure repor-

ting

Display

selected

channel

FIGURE 1

8NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

19) PROGRAMMING

NOTE: LED PRG-ON OFF: PROGRAM DISPLAY.

LED PRG-ON ON: PROGRAM MODIFICATION

N° PRESS EFFECT NOTES

1 PRG/SET Keep pressed PRG key until PRG-ON led turns

on. After PRG indication, it appears ALARM

threshold for CH 1-2-3

2 load desired threshold

3 PRG/SET it appears TRIP thresold for CH 1-2-3

4 load desired threshold

5 PRG/SET I4 on CH display appears Enabling CH 4

6 Load YES or NO With YES CH 4 is connected

With NO CH 4 is disconnected

7 PRG/SET ALARM threshold for CH 4 appears If CH 4=NO go to point 11

8 load desired threshold

9 PRG/SET TRIP threshold for CH 4 appears

10 load desired threshold

11 PRG/SET CHF is displayed Reference channel for fan swi-

tching on

12 Select: No, 123 or (if ch4 yes)

123 or 4: Reference channels for

fan switching on

No: FAN function excluded go to

point 21

13 PRG/SET Fan Led blinks and the number of fans to be

driven is displayed From 1 to 6 fans

14 Load number of fans (from 1 to 6)

15 PRG/SET Display shows ON FAN turning on

16 PRG/SET ON thresolf for FAN appears

17 load desired threshold

18 PRG/SET Display shows OFF FAN turning off

19 PRG/SET OFF threshold for FAN appears

20 load desired threshold

21 PRG/SET Display shows HFN Fan cyclic test for 5 minutes each

“n” hours

22 PRG/SET Load desired number of hours 000= disabile function

23 Load desired number of hours

24 PRG/SET Display shows FCD <> “datum” Fault for fast temperature increa-

se (°C/sec)

25 Load desired value

(see Page 10) From “no” (excluded function)

to 30 °C/sec

26 PRG/SET Display shows ADR <> “datum” Modbus address

27 Load desired address From 1 to 255

28 PRG/SET Display shows BDR <> “datum” Modbus transmission speed

29 Load desired speed From 4.8 Kb/s to 38.4 Kb/s

30 PRG/SET Display shows PAR <> “datum” Select parity bit

31 Load desired parity bit None (No), Even (EVE),

Odd (ODD)

32 PRG/SET Display shows 420 <> “datum” Programming 4.20 mA output

33 Select desired 4.20 mA output 1-2-3-4; fixed channel

SCA: scanning

HOT: hottest channel

9

NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

20) EXTENSION CABLE FOR Pt100 TECHNICAL SPECIFICATIONS

Cable 20xAWG 20/19 Cu/Sn

Section 0,55 mm²

Insulation against fire PVC105

Standards CEI 20.35 IEC 332.1

Max. working temperature : 105°C

Structure : 4 terns composed of three twisted and coloured wires

Shield in Cu/Sn

Sheath in PVC against fire

External diameter 9,0 mm

Standard packaging in coils of 100 m

FAULT DIAGNOSTIC CAUSES AND RIMEDIES

Monitoring unit doesn’t turn on, even if the termi-

nals are fed.

Connector not well placed inside its seat. Connec-

tion cables are not well tightened in the terminal.

Burnt out feeder. Burnt out fuse protection(500mA

250V Fast)

Take out and give supply again.

CH4 is in FAULT FOC

(just the 3 Pt100 sensors are connected) Monitoring unit wrongly programmed with CH4/no.

Repeat the programming.

One of three/four channels is in FAULT for FOC/

FCC

Check Pt100 sensor connections.

Possible defective sensor.

Replace the damaged sensor.

When turning on the display shows “ECH”

A strong disturbance damaged the stored data.

Please refer to paragraph 8.

If this problem should persist, please contact TE-

CSYSTEM S.r.l. Technical Department.

All the Pt100 sensors are in FCC. Wrong sensor connections. Terminal board

mounted upside down.

Check the connections and the terminal board.

Temperature indicated by one or more channels is

wrong. Contact TECSYSTEM S.r.l. Technical Department

Sudden trip of the main switch. Temperature is on

standard levels. Just one channel has caused the

trip.

Verify through T.MAX fuction possible defective

sensors.

Replace the sensor. Check the measuring signal

support terminal boards .

NOTES:

1) If pressing ENT, “Err” appears, it means that one of the following mistakes has been made:

ALARM ≥TRIP or FAN-OFF ≥FAN-ON. Press PRG to return to step 1 and correct the data.

2) After 1 minute of keyboard no-operation, programming is left without data storage.

34 PRG/SET Display shows END Programming end

35 ENT Loaded data storage and programmino exit Err: wrong programming for va-

lues indicated by LED’s (NOTE 2)

36 PRG/SET Return to step 1

10 NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

21) NOTES ABOUT FCD FUNCTION

NT device series has an innovative control function combined with the Pt100 sensor

dynamic state.

If a temperature sensor should accidentally break down, the defect turns out with a fast

increase of its resistance and therefore of the temperature registered by the monitoring unit.

It is obvious that this increase is not consequential to the increase of power of the machine

to be protected, whether it is a motor or a dry or encapsulated transformer.

Therefore it is advisable to discriminate the state of the sensor and report a Fault notification

rather than an Alarm or, worse, a Trip signal.

In case of temperature control for electrical motors, the fast increase of the temperature

could be the consequence of the working with jammed rotor and not of defective sensor; in

this case the Fault relay, once energised, makes evident this anomalous condition for the

motor working.

By activating the FCD function it is possible to have on 26-27-28 contacts a Fault signal

when the temperature registered by a Pt100 increases with a speed higher than “n” °C/sec

(loadable from 1 to 30).

Depending on the loaded value, you can have a different sensitivity, which can be useful for

various applications:

-from 1 to 10: high sensitivity, for instance useful to immediately report a jammed rotor in a

motor.

-from 10 to 20: medium sensitivity, useful to have indications for possible noises which

affect the sensor reading, connection problems or defective sensors.

-from 20 to 30: low sensitivity, useful for applications where an higher sensitivity could give

rise to faults for undesired FCD.

- loading “no”,FCD function is disabled.

When a channel is in Fault condition for FCD, relevant Alarm and trip signallings are

inhibited in order to just report the anomaly for too fast increase of the temperature.

Press Reset to cancel the FCD signalling of all the channels and restore the fault relay.

11

NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

22) INTRODUCTION TO MODBUS INSIDE MODULE

MODBUS INSIDE expansion module is built in the monitoring unit and it allows the data

transfer on a RS485 network with MODBUS RTU protocol.

23) WORKING NOTES

For a correct working of the module it is necessary to load RS485 network set-up

parameters: address, baud rate, parity bit.

Please refer to the programming steps from 23 to 28 as shown on the table at page 8.

The serial communication of the temperature control monitoring unit is active just when

NT511 is in temperature control working mode in one of the intended modes (Scan, Auto,

and T.Max).

When other functions such as programming, programming display and relay test are

activated, the ModBus communication is temporarily deactivated.

24) DATA TRANSMISSION ON MODBUS NETWORK

The MODBUS INSIDE internal module allows to connect NT511 monitoring unit with a

RS485 network with Modbus RTU protocol in order to read the data shown in the table

section 35 and to write the ones shown in section 32. The module is always in slave mode.

NT511 monitoring unit is connected with the network just when it is temperature reading

mode, and not when it is in programming, programming display or relay test.

25) RS485 ELECTRICAL CONNECTIONS

As far as the signal cable to be used in order to ensure a proper network working is

concerned, we recommend to follow what laid down by EIA RS485 standard which suggests

to use a 24AWG duplex cable.

The duplex cable which connects all the units in RS485 could require the activation of a 120

ohm termination on the last unit of the series.

Connect the duplex cable paying attention to polarities and lay the network avoiding to make

sharp bends or ring windings in order not to modify the line impedance.

If necessary, also the GND terminal for grounding is available

26) DATA FRAME

The frame in asynchronous transmission is composed of: 1 start bit, 8 data bits, 1 parity bit

(even or odd, if the parity has been set) and 1 stop bit.

Admitted baud rates are: 2400, 4800, 9600, 19200 and 38400 b/s.

Where no otherwise specified, the word length (DATA) is of 16 bits.

12 NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

27) DATA PACKET

A complete sequence of request/answer is composed as follows:

Master request.

SLAVE ADDRESS - 1 byte

FUNCTION CODE - 1 byte

DATA - variable, it depends by the function code

CRC - 2 bytes

Slave request.

SLAVE ADDRESS - 1 byte

FUNCTION CODE - 1 byte

DATA - variable, it depends by the function code

CRC - 2 bytes

28) FUNCTION CODE

ModBus module supports the following function codes:

3(10):- holding register reading

16(10):- multiple register writing

If ModBus receives a message and a CRC error is detected, no answer is given.

29) CODE 3(10).

Request:

Slave address, code 3(10), Starting address HI, Starting address LO, Number of Point HI,

Number of Point LO, Crc LO, Crc HI.

Answer:

Slave address, code 3(10), Byte count, Data HI, Data LO……., Crc LO, Crc HI.

13

NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

30) CODE 16(10).

Request:

Slave address, code 16(10), Starting address HI, Starting address LO, Number of Point HI,

Number of Point LO, Byte count, Data HI, Data LO……., Crc LO, Crc HI.

Answer:

Slave address, code 16(10), Starting address HI, Starting address LO, Number of Register

HI, Number of register LO, Crc LO, Crc HI.

The writable registers are the ones containing the following data: Alarm, Trip, Fan-on, Fan-

off.

Therefore the possible starting addresses are: 00-21 for alarm and trip thresholds, 00-29 for

Fan-On and Fan-off thresholds and 00-37 for optional variables which could be present on

special monitoring unit models.

Number of Point LO parameter can be loaded from 1 to 8 (max).

If a writing request is sent to an address different from the above mentioned ones, ModBus

will answer with a 02 error code (wrong data address).

If a writing request is sent to more than 8 registers (Number of point LO), ModBus

won’t be able to grant the request and it won’t give any answer. Therefore the query

will go in “timeout”.

31) NOTES FOR REMOTE PROGRAMMING

In case you want to program a NT511 you have to bear in mind that Alarm settings of chan-

nels 1-2-3 (register 00-17, 00-18, 00-19) must have the same values, since the monitoring

unit handles them as channels with shared thresholds.

The same note must be kept into consideration for Trip thresholds (registers 00-25, 00-26,

00-27).

Fan on thresholds (registers 00-29, 00-30, 00-31, 00-32) have all to be loaded with the

same value.

Fan off thresholds (registers 00-33, 00-34, 00-35, 00-36) have all to be loaded with the

same value.

Also in the remote programming via ModBus phase you must take into consideration that

the Alarm thresholds must be lower than the Trip thresholds and that the Fan-on thresholds

must be higher than the Fan-off thresholds.

Alarm and Trip thresholds must be programmed together in the remote writing operations.

Therefore the group of 8 addresses from 21 to 28 will be considered as a sole writing block.

The same thing is for fan-on and fan-off thresholds: group of 8 addresses from 29 to 36

In case you try to load these thresholds in a wrong way, NT511 monitoring unit won’t pro-

ceed with the programming and data storage; therefore in the coming readings you will read

the data relevant to the previous programming.

After having sent a writing request, the monitoring unit will take approximately 1’’ to store the

data in eeprom; during the storage phase, ModBus interface won’t be able to process fur-

ther requests.

If the programming request successfully concludes, the monitoring unit automatically resets

and loads the new loaded values.

14 NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

32) ERROR CODES (exception code)

In case of wrong request ModBus will answer with modified codes and codified errors ac-

cording to the following points:

1: - Non-supported function code

2: - Wrong data address

3: - Wrong data (for instance length)

33) POLLING FREQUENCY

The max. time to give an answer to a calling never exceeds 1 second; therefore we suggest

not to use polling frequencies with lower duration.

34) MODBUS MAPPING TABLE

Address

HI (10) Address

LO (10) Data HI Data LO Primary

tables Notes

00 01 00 Temperature

Ch1 Holding

register

00 02 00 Temperature

Ch2 Holding

register

00 03 00 Temperature

Ch3 Holding

register

00 04 00 Temperature

Ch4 Holding

register

00 05 00 Stato Ch1 Holding

register

(See note 1)

00 06 00 Stato Ch2 Holding

register

00 07 00 Stato Ch3 Holding

register

00 08 00 Stato Ch4 Holding

register

Range 0-200°

Offset 20(10)

20=0°C

21=1°C

22=2°C

15

NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

Address

HI (10) Address

LO (10) Data HI Data LO Primary

tables Notes

00 09 00 Setting Ch1 Holding

register

(See note 2)

00 10 00 Setting Ch2 Holding

register

00 11 00 Setting Ch3 Holding

register

00 12 00 Setting Ch4 Holding

register

00 13 00 T. max Ch1 Holding

register

Range 0-200°

Offset 20(10)

20=0°C

21=1°C

22=2°C

00 14 00 T. max Ch2 Holding

register

00 15 00 T. max Ch3 Holding

register

00 16 00 T. max Ch4 Holding

register

00 17 00 Story Ch1 Holding

register

00 18 00 Story Ch2 Holding

register

00 19 00 Story Ch3 Holding

register

00 20 00 Story Ch4 Holding

register

00 21 00 Alarm Set

-point Ch1 Holding

register

Addresses

from 21 to 28

constitute a

sole writing

block

00 22 00 Alarm Set

-point Ch2 Holding

register

00 23 00 Alarm Set

-point Ch3 Holding

register

00 24 00 Alarm Set

-point Ch4 Holding

register

(See note 3)

16 NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

Address

HI (10) Address

LO (10) Data HI Data LO Primary

tables Notes

00 25 00 Trip

Set-point Ch1 Holding

register

00 26 00 Trip

Set-point Ch2 Holding

register

00 27 00 Trip

Set-point Ch3 Holding

register

00 28 00 Trip

Set-point Ch4 Holding

register

00 29 00 Fan-On Set

-point Ch1 Holding

register

00 30 00 Fan-On Set

-point Ch2 Holding

register

00 31 00 Fan-On Set

-point Ch3 Holding

register

00 32 00 Fan-On Set

-point Ch4 Holding

register

00 33 00 Fan-Off Set

-point Ch1 Holding

register

00 34 00 Fan-Off Set

-point Ch2 Holding

register

00 35 00 Fan-Off Set

-point Ch3 Holding

register

00 36 00 Fan-Off Set

-point Ch4 Holding

register

00 37 00 General Flag Holding

register (See note 4)

00 38 00 “Free” Holding

register

00 39 00 HFN Holding

register

00 40 00 SET_FCD Holding

register

Addresses

from 29 to 36

constitute a

sole writing

block

Free register

Hours for fan

test cycle

FCD setting

17

NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

Address

HI (10) Address

LO (10) Data HI Data LO Primary

tables Notes

00 41 00 “Free” Holding

register Free register

00 42 00 NUM_CH Holding

register

00 43 00 NUM_FAN Holding

register

00 44 00 FAULT_FAN Holding

register

Number of

enabled

channels –1

EX.: if N°=2

enabled

channels are 3

Number of

enabled fans

Faulty fans

NOTE 1: STATE REGISTER

The state register contains the information relevant to the state of the alarms for the related

channel.

Each bit represents a flag which is active when its value is 1.

NOTE 2: SETTING REGISTER

The state register contains the information relevant to the setting for the related channel.

Each bit represents a flag which is active when its value is 1.

B0: shows that the channel is enabled.

B1: shows that the fan for relevant channel is enabled

NOTE 3: REGISTER FOR HISTORIC ALARMS

The state register contains the information relevant to the storage of the alarm interventions

for the related channel.

Each bit represents a flag which is active when its value is 1.

NOTE 4: GENERAL FLAG REGISTER

The general function register contains the information relevant to the enabling of general

functions.

B0: shows the displayed temperature is lower than 0°C.

B1: shows that an alarm has been reset.

B2: shows that the fan cyclic switching on (duration:5 minutes) is under way

B3: shows the presence of an error in the eeprom writing.

B4: shows that the programming data back-up in eeprom is under way

B5: shows the presence of an error in the monitoring unit calibration

B6: shows that the calibration error has been reset

B7: shows that the fans have been manually set off

B7 B6 B5 B4 B3 B2 B1 B0

TRIP ALARM FREE FAN FOC FCC FCD FREE

B7 B6 B5 B4 B3 B2 B1 B0

FREE FREE FREE FREE FREE FREE FAN-EN CH-EN

B7 B6 B5 B4 B3 B2 B1 B0

TRIP ALARM FREE FAN FOC FCC FREE FREE

B7 B6 B5 B4 B3 B2 B1 B0

FAN-

MAN RESET

OK ERRORE

CAL WRITE

EEPROM ECH CYCLE

FAN RESET

ALL. SIGN -

18 NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

NOTE 5: FAULTY FAN FLAG

Each bit represents a flag which is active when its value is 1.

When the flag is active, it means that the fan, even if fed, is not working because any

current is detected (presence of no-load voltage). One assume that fan is faulty or wrongly

connected.

35) CRC CALCULATION

This protocol includes 2 CRC-16 bytes in each transmission. The characteristic polynomial

(11000000000000101B) is used for the calculation and the result is “hung” at the end of the

package. The polynomial is used in the reverse order with the most significant bit

suppressed because useless for calculation.

36) PARAMETER DESCRIPTION

A - 16-bit register

AL - At low side

AH - At high side

i,j, - KWH METERS

(+) - EXCLUSIVE OR

Di - Frame data «i»th of the packet

N - number of byte of the packet excluded 2 belonging to CRC

G - Polynomial : 1010-0000-0000-0001

shr - right shift

37) ALGORITHM

1) 0xFFFF -> A

2) 0 -> i

3) 0 -> j

4) Di (+) AL -> AL

5) j +1 -> j

6) shr A

7) if carry then G (+) A -> A

8) if NOT j=8 then goto 5

9) i +1 -> i

10) if NOT i = N then goto 3

11) A -> in CRC (result is in the order L,H)

B7 B6 B5 B4 B3 B2 B1 B0

FREE FREE FAN6 FAN5 FAN4 FAN3 FAN2 FAN1

19

NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

38) 4.20 mA OUTPUT

With 4.20 mA output it is possible to connect an acquisition or read-out device.

The allowed load impedance for each output goes from 0 to 500 ohm.

Loop is optoinsulated-type to grant the highest noise immunity. .

4-20 mA signal is referred to 0-240°C range with an accuracy of 1% compare to full

scale value.

It is possible to require a special calibration with reference to a 0-200°C range.

420 INSIDE inner module allows to take from output a 4-20 mA current signal referred

to the programmed channel in the steps 29-30 of the table at page 8.

1-2-3-4: 4.20 mA output is referred to the fixed channel that has been loaded.

SCA: 4.20 mA output automatically scans the active channels every 2 seconds

(default setting)

HOT: 4.20mA output is automatically referred to the hottest channel among the

active ones.

For 0-240 range, the current-temperature relation is as follows:

Iout= (T/15)+4 (T=temperature in °C)

Example:

If T=100°C Iout= 100/15+4= 10,67 mA (±0.2 mA)

For range 0 +150 relation is: Iout= (T/9.375)+4 (T=temperature in °C)

For range 0 +200 relation is: Iout= (T/12,5)+4 (T=temperature in °C)

For range –40 +200 relation is: Iout= (T/15)+6.7 (T=temperature in °C)

Note: temperature range on request, standard set 0°C + 200 °C.

Box unit rear dimensions: 180mm×230mm

20 NT511 AD ANALOG & DIGITAL INSIDE

TECSYSTEM SHANGHAI

38) DRAWING FOR MOUNTING FIGURE 2

100mm

Cutout

182mm

245mm

232mm

φ4

Table of contents

Other TECSYSTEM Computer Hardware manuals