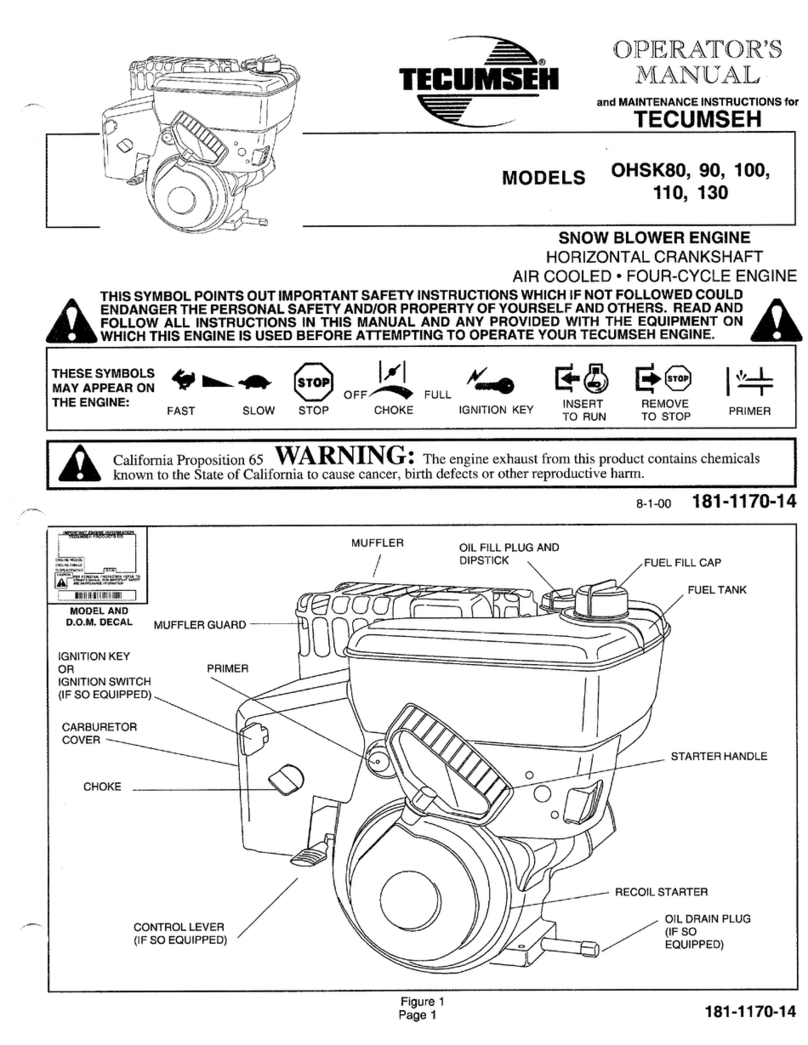

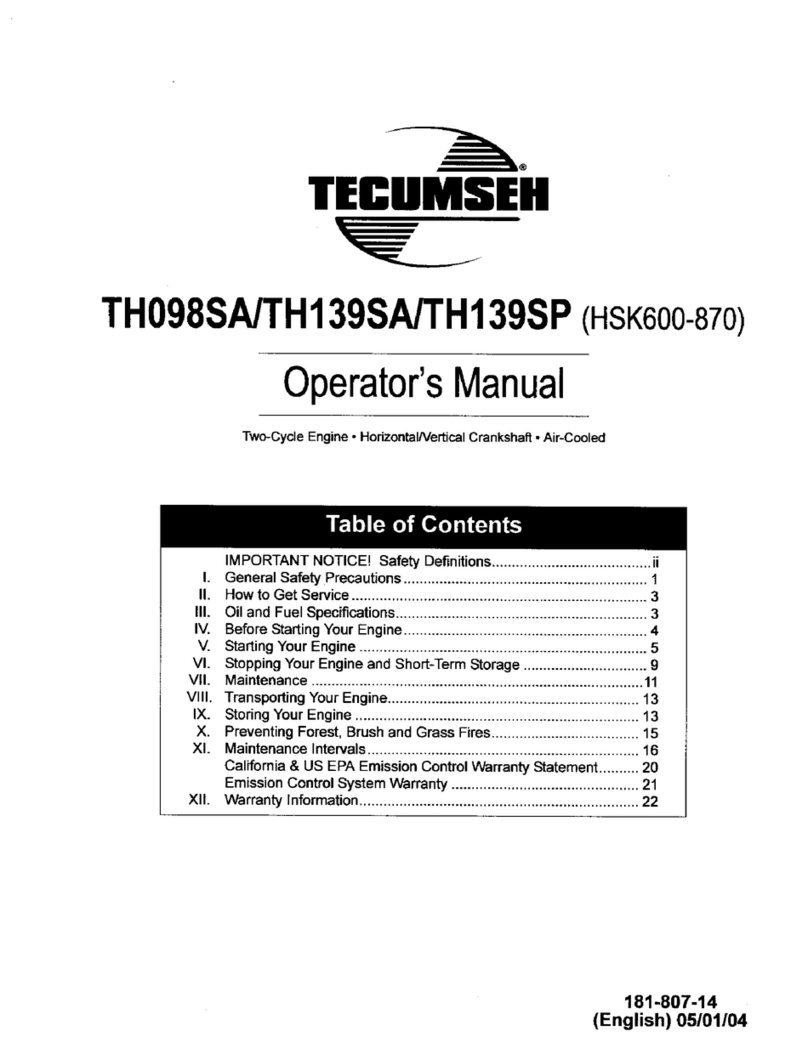

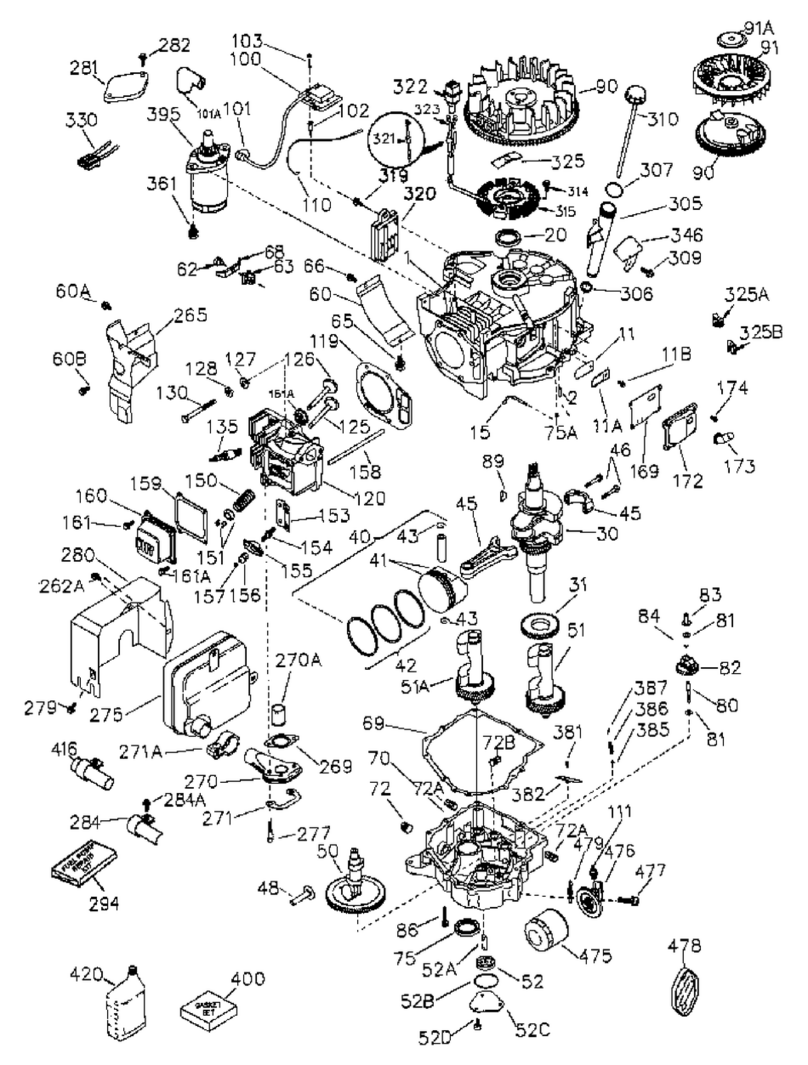

Tecumseh AH-HSK600 - User manual

This manual suits for next models

14

Other Tecumseh Engine manuals

Tecumseh

Tecumseh HM100 User manual

Tecumseh

Tecumseh HM80-155267G User manual

Tecumseh

Tecumseh 100 User manual

Tecumseh

Tecumseh TH098SA User manual

Tecumseh

Tecumseh OHH50 - 65 User manual

Tecumseh

Tecumseh LV148EA User manual

Tecumseh

Tecumseh Snow King LH195SA User manual

Tecumseh

Tecumseh OHV110 User manual

Tecumseh

Tecumseh V-twin User manual

Tecumseh

Tecumseh OHM120-224602A User manual

Tecumseh

Tecumseh OHV155-204509E User manual

Tecumseh

Tecumseh HSK840 User manual

Tecumseh

Tecumseh H30-40 User manual

Tecumseh

Tecumseh TM SERIES User manual

Tecumseh

Tecumseh Snow King HMSK80 User manual

Tecumseh

Tecumseh Snow King HMSK80 User manual

Tecumseh

Tecumseh HSSK50 Installation instructions

Tecumseh

Tecumseh TVT691 User manual

Tecumseh

Tecumseh GEO-TEC User manual

Tecumseh

Tecumseh LH195SA/LH195SP (HSSK40-55) User manual

Popular Engine manuals by other brands

Sole Diesel

Sole Diesel MINI-17 Operator's manual

Navistar

Navistar MaxxForce 7 Operation and maintenance manual

Porsche

Porsche 944 Turbo 1988 Workshop manual

Chicago Electric

Chicago Electric 07570 Assembly and operating instructions

Hitachi

Hitachi SH7750 series Hardware manual

Bosch

Bosch Performance Line owner's manual