2

24:1 FUEL MIXTURE CHART ALLTC ENGINES

NOTE: DO NOT MIX FUEL IN ENGINE OR

EQUIPMENT FUEL TANK.

U.S. METRIC

Gas Oil To Be Added Petrol Oil To Be Added

1/2 Gal. 3.00 oz. 2 Liters 83 ml.

1 Gal. 6.00 oz. 4 Liters 167 ml.

2 Gal. 11.00 oz. 8 Liters 333 ml.

MIXING OIL AND GASOLINE PROCEDURE

1. Fill approved, clean container one quarter full with

the recommended gasoline.

2. Add the recommended amount of oil to the

gasoline.

3. Secure the cap on the container and shake the

container vigorously.

4. Removethecap,addtheremainderofthe gasoline,

secure the cap, re-mix.The fuel is ready to use.

FUEL REQUIREMENTS

Tecumseh Products Company strongly recommends the

use of fresh, clean, unleaded regular gasoline in all

Tecumseh engines. Unleaded gasoline burns cleaner,

extends engine life, and promotes good starting by

reducing the build-up of combustion chamber deposits.

Leaded gasoline, gasohol containing no more than 10%

ethanol, premium gasoline, or unleaded gasoline

containing no more than 15% MTBE (MethylTertiary Butyl

Ether), 15% ETBE (Ethyl Tertiary Butyl Ether) or 10%

ethanol, can be used if unleaded regular gasoline is not

available.

Reformulatedgasolinethatis nowrequiredin severalareas

of the United States is also acceptable.

NEVER USE gasoline, fuel conditioners, additives or

stabilizers containing methanol, gasohol containing more

than 10% ethanol, unleaded regular gasoline containing

more than 15% MTBE (Methyl Tertiary Butyl Ether), 15%

ETBE (EthylTertiary Butyl Ether) or 10% ethanol, gasoline

additives, or white gas because engine/fuel system

damage could result.

See “STORAGE” instructions in Technician’s Manual,

Operator’s Manual, or Bulletin 111.

For year round fuel stability in and out of season, use

Tecumseh's fuel stabilizer part number 730245.

FUEL ADDITIVES

Only fuel additives such as Tecumseh's fuel stabilizer part number 730245 or liquid varieties can be used when mixed

properly. For winter applications, Isopropyl alcohol fuel dryers may be used in the fuel system but must be mixed at

the proper ratio recommended by the manufacturer. NEVER USE METHANOL BASED DRYERS.

Gasoline and oil containers must be clean, covered, and rust-free. Old gas or fuel contamination can restrict or block

fuel filters, and small fuel ports and passages in the carburetor. If the engine is to be unused for 30 days or more see

"Storage" for fuel system instructions.

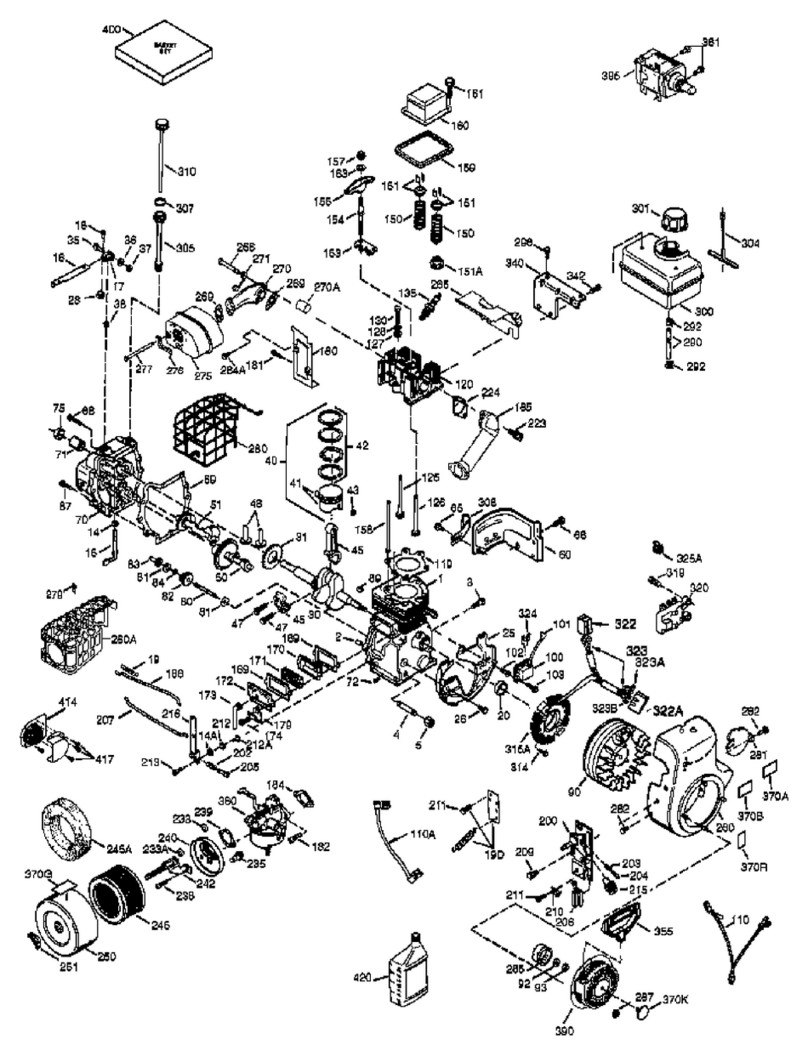

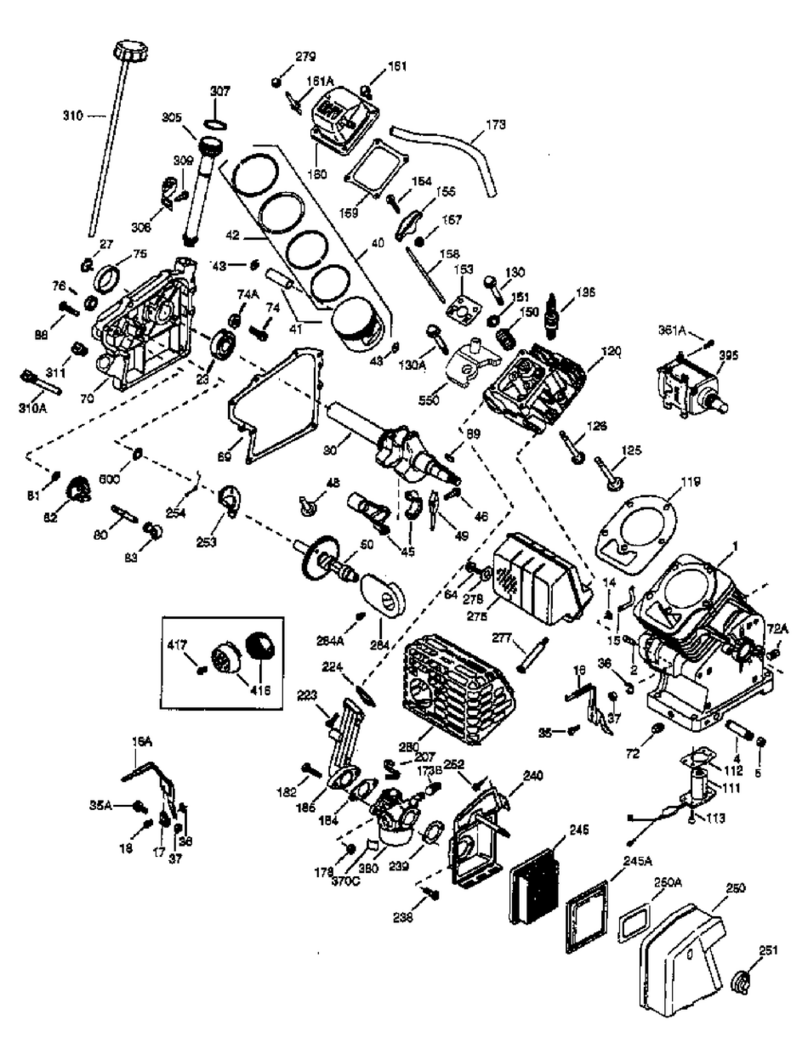

TUNE-UP PROCEDURE

The following is a minor tune-up procedure. If the engine does not perform properly after the tune up is completed,

consult the "Troubleshooting Engine Operation Chart" found in Chapter 7. Repair procedures are listed in each chapter.

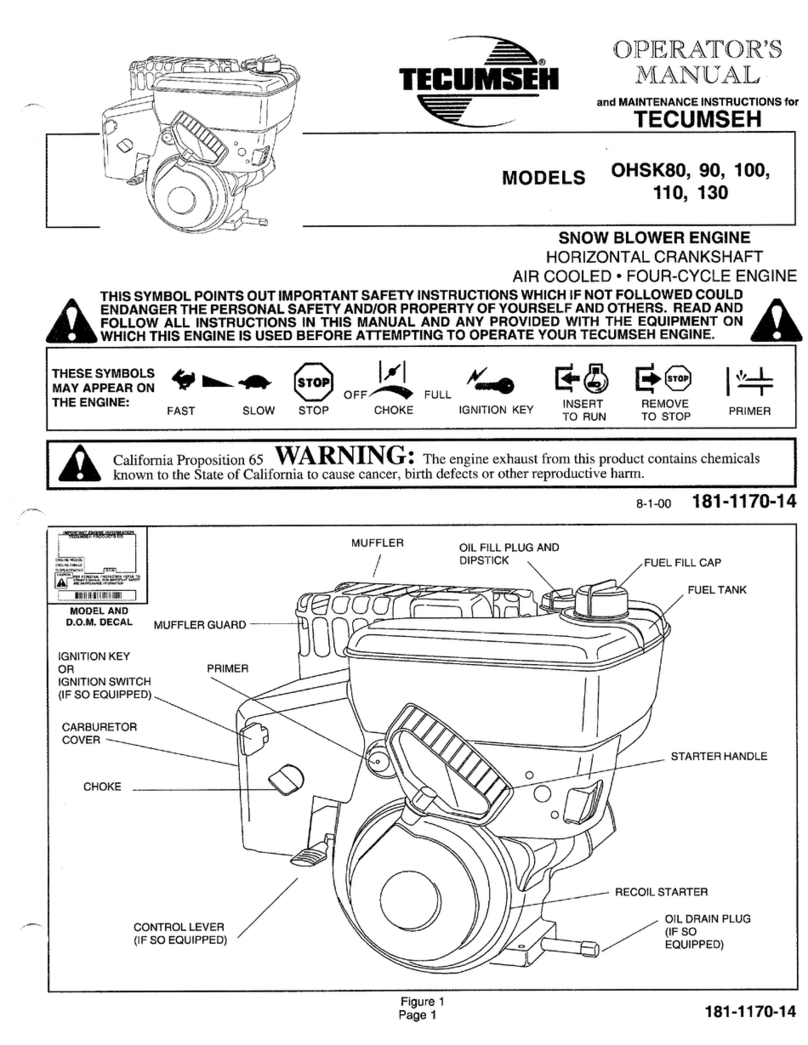

CAUTION: REMOVETHE SPARK PLUGWIRE BEFORE DOING ANY SERVICEWORK ONTHE ENGINE.

1. Service or replace the air cleaner as necessary.Usetheapplicableprocedure foundin Chapter 2 under "Service".

2. Removethe fuel from the fuel tank byrunning the engine until stopping or draining into an approvedfuel container.

3. Remove the fuel tank and blower housing to clean all debris from the air intake screen, cylinder cooling fins,

governor and carburetor linkage.

4. Replace the blower housing and check all remote linkage for proper adjustment and operation.

5. Check to see that the engine is properly secured to the equipment. On rotary lawnmowers, balance the blade

and check the blade hub and crankshaft key for wear. Replace as necessary. Torque the bolts to the correct

specification.

6. Replace the spark plug with the correct replacement by using the Master Technician's Parts Manual. Set the

spark plug gap at .030" (.762 mm) and install it in the engine.Tighten the spark plug to 230 inch pounds (2.6 Nm)

of torque.If a torque wrench isn't available, screw the spark plug in as far as possible by hand.Use a spark plug

socket or wrench to turn the spark plug 1/8 to 1/4 turn further if using the old spark plug, or 1/2 turn further if a

new spark plug is used. Reinstall the spark plug wire.

1-4

Not For Resale

www.SmallEngineDiscount.com