~~=i~

4

1.2

~

---,

~

•

12

,

~

I

I

l

~

..

.,

,,

~

-

'0

.....

. ,

,~

oo

OO~(eT

!)IIlvt

...

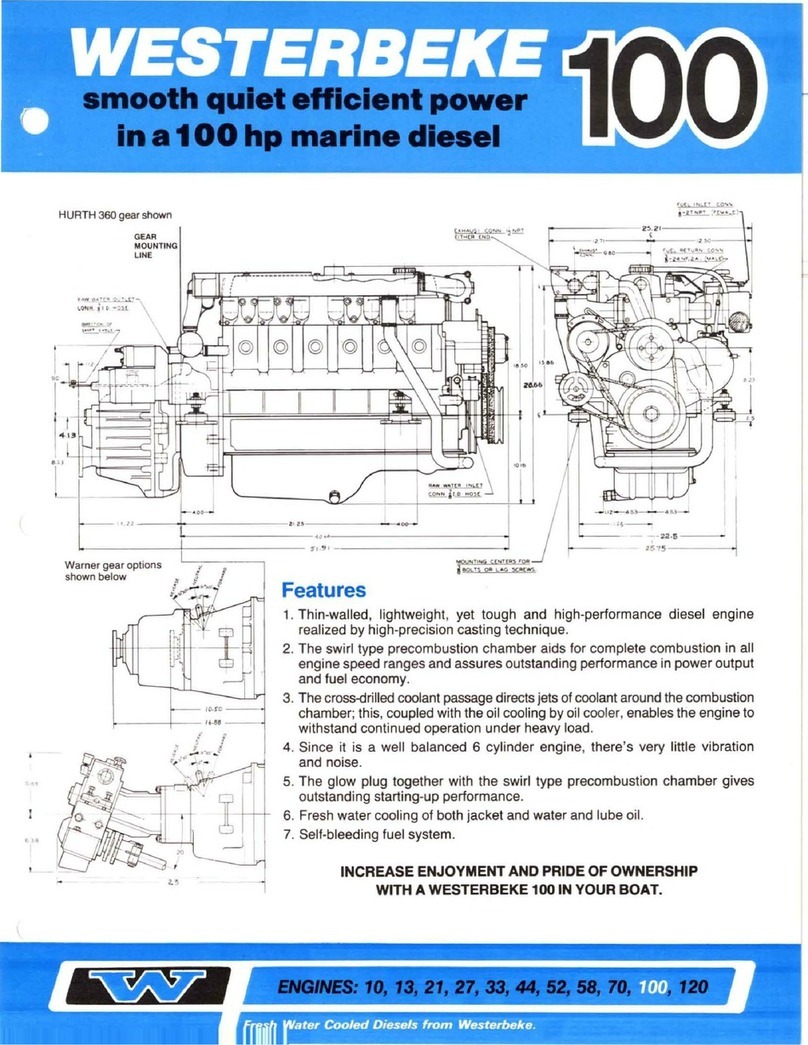

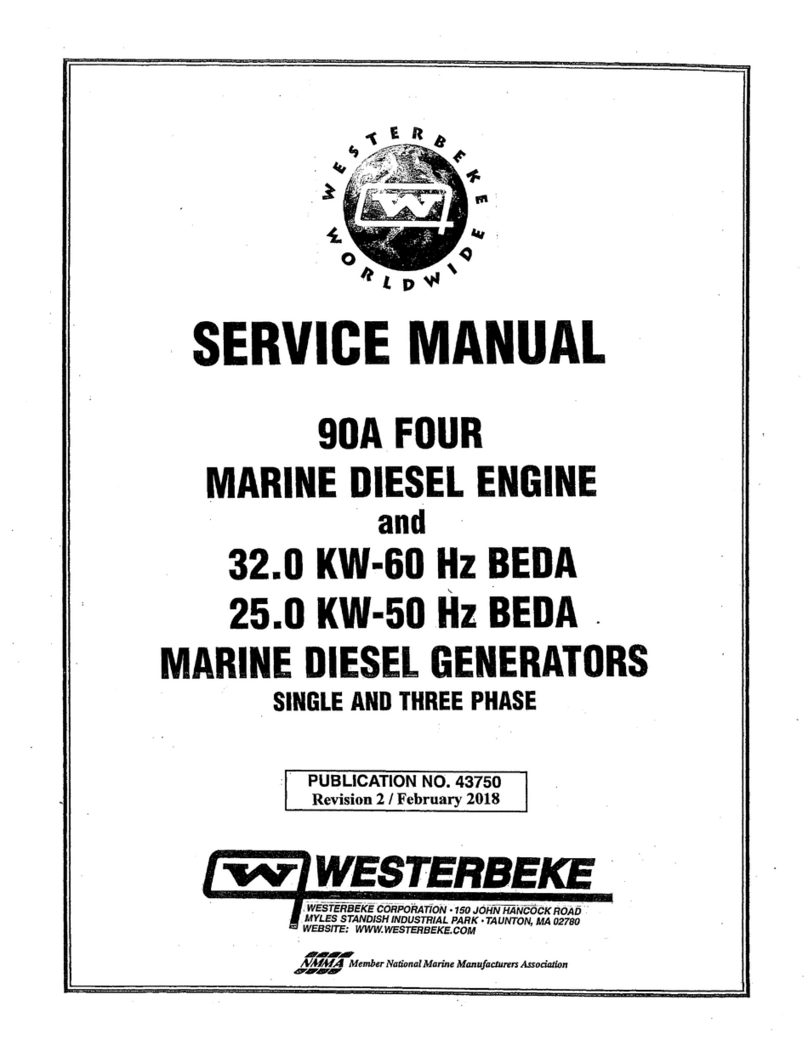

WESTERBEKE PERFORMER-SIX

SPECIFICATIONS

I

-

-

Type: Direct

injection,

naturally aspirated, four cycle, six

cylinder

in line, fresh water cooled marine diesel engine.

Displacement:

345.3 cu. in. Bore 3.86 inches (98mm). Stroke

4.92

inches

(125mm).

Power: 115 hp at

2600

rpm (certified rating in accordance

with

BSAU

141.

(1971) -See power curve.

Compression

ratio:

16.5:1.

Weight:

1240 Ibs.

direct

drive.

Cylinder

block

: Cast iron

monobloc,

ribbed for rig

idity,

with

weHype

cast iron

cylinder

liners and seven replaceable main

bearings.

Cylinder

head:

Cast iron

with

renewable valve guides.

Crankcase: Nylon-coated steel

for

longer life.

Crankshaft:

Special alloy steel forging, dynamically and

statically

balanced,

with

seven bearings and a torsional

vibration

damper.

Camshaft:

Steel

forging

with

integral cams in seven bearings.

Pistons

: Forged

aluminum

with

toroidal

combustion

chamber, three

combustion

rings and one scraper ring.

Connecting

rods:

Drop forged and

obliquely

split

for

removal

up

through

cylinder bore.

Timing

gear: The

camshaft

and auxiliaries are driven by a

simple

train

of

helical gears

of

generous

width

, hardened and

ground

. Backlash is

closely

controlled

for

long life and

quiet

operation.

Fuel system:

Distr

ibuto

r type

injection

pump

with

mech-

anical governor. Fuel transfer

pump

, hand

primer

, and Single

stage fuel

filter

.

Lubrication

system:

Pressure

lubrication

with engine-driven

gear

pump

,

piston

type relief valve,

full

flow

lube

oil

filter

with

spin-on element, and an

efficient

oil

cooler. A by-pass

safeguards

oil

supply

in case

of

a choked

filter

element.

Cooling

system:

Fresh water

cooli

ng by engine-mounted

heat exchangerand rubber

impeller

raw water

pump

. Exhaust

manifold

fresh water

coole

d for longer life.

Electric

system:

12 volt starter

motor

.

12

volt

55

ampere

alternator

. Pre-wiring

is

available.

Reverse and reduction gears: Hydraulic actuated

with

multi-

ple

disc

clutch

for

forward operation ;

full

capacity reverse

band requiring no

adjustment

; large

oil

cooler

to provide

correct operating oil temperature. Ratios 1:1, 1.5:1, 2:1,

2.5:1, and 3:1, by Paragon

or

Warner. V-drives aiso available.

Rotation

:

Most

gears turn a left hand propeller. (see price

IisL)

Installation

data:

Mounting

Centers

22112"

.

Installation

angle

i

'J.

....

maximum

. Seawater

pump

inlet

JA"I

PS

. Fuel

inlet

5/16"

.

Fuel return 1

A

".

Oil pressure

connection

1

f8"

IPS. Water

temperature

connectlon

"h

" IPS. Exhaust 2

112"

IPS flange.

, I

'"

~I

.c

'

lel

TOIIOUt

."

'"

1

'i.QLU-~T~

no

'"

~IPSJ

'"

Q!l

'"

/'j(

~

~

Q..

..

!!

~

" ,

ri

~I

,

••

<

"

,3

.~

~

*To;

CQ:l!2!

" ,.

M..

~!I

O!

•

kAy

tt-tWI

~

2:

"

..

-900

-I

'

.~

,~

0<

.

.,

'"

rUCL

•

G.l~

lOOO

"'QttT 1

000

14 00

11

0 0

lZ

OO

2.

00

. R.P.M.

ll~~T

"

...

POWER CURVE (A) BSAU 141a (1971) Is an up-to-date and meaningful

engine rating system used in response

to

environmental requirements and

the desire

to

be faclual. Engines are rated

for

maximum

horsepower and

rpm with all necessary auxiliaries

wortl:

lng. They

must

comply

with

modern

standards

of

noise level, exhaust emissions and fuel

consumption

. Curve

(8) shows the power available

for

Intermi

ttent

use. Curve (C)

shows

the

power available

for

co

ntinuous

use. Curve (0)

is

the propeller law curve.

STANDARD EQUIPMENT

Fresh water

cO~ling

system

with

surge tank and

pump

mounted

on en9lne; raw water

pump

and heat exchanger

mounted

on engine; 12 volt, 55 amp alternator

with

transistor

regulator; adjustable flexible

mounts·

propeller

shaft

co~pling

;

hydraulic reverse gear; full flo"'; lube

011

filter

with

sp,ln-on eler:nent ; secondary fuel

filter

; fuel

pump

hand

pnmer;

fleXible hoses for fuel

inlet

and return; key

switch

panel;

sump

pump

and hose; threaded exhaust

flange'

Instruction

manual. '

OPTIONAL EQUIPMENT

All electric

instrument

panel

with

tachometer,

hour

meter,

ammeter

, water temperature and oil pressure gages; engine

pre-wiring;

engine alarm

system;

high

capacity

primary

fuel

filter

;

ext~a

85

or

120 amp

alternator;

flexible shaft

coupling;

keel

cooling;

extra crankshaft

pulleys;

spare parts

kits.

PERFORMER ECONOMICS

The design

of

the Westerbeke PERFORMER-SIX

follows

an

earlier model

with

years

of

dependable performance. It has

been redesigned and updated

to

conform

to

the

most

modern

environmental, power, and service standards.

In

redesign

ing,

major

imp

rovements were made In valve size,

combustion

chamber and

injectors

, resulting In better breathing,

smooth-

er

combustion

, better

efficiency

and fuel

economy

, clean

exhaust and improved cold starting. Unusual care was given

to

simplifying

service, and extending the periods between

maior

overhauls.

The

block

of

the PERFORMER-SIX lends

itself

nicely

to

marine use.

Its

clean

lines

permit placement of pi

ping

and

accessories

most

logically

, where they are out

of

the bilge

and handy

for

service, and where they

do

not interfere

with

work

on

other

parts

of

the engine. This makes the PER-

FORMER-SIX easy and inexpensive to service.

Ea

sily

replace-

able internal parts reduce the cost

of

major

overhauls.

Longer intervals between routine service and between

major

overhauls means lower service

costs

and more

time

on the

job

. Its

dependability

,

durability

, safety, and resale value are

factors,

which

when translated

into

dollars

and

cents

make

the PERFORMER-SIX

an

economical engine

for

any

boat,

commercial

or

pleasure.

(

(

J.

H.

WESTERBEKE

CORP.

LEDEN AVENUE,

AVON

INDUSTRIAL PARK,

AVON

,

MASS

. 02322

CABLE

: WESTCORP, AVON TELEX: 92-4444

15200 Pr

int

ed in U.S.A.