Tecumseh Silensys B08Z User manual

This manual suits for next models

20

Table of contents

Other Tecumseh Heat Pump manuals

Tecumseh

Tecumseh SILENSYS User manual

Tecumseh

Tecumseh Wintsys WINT9450Z Manual

Tecumseh

Tecumseh WINTSYS Series User manual

Tecumseh

Tecumseh CAJ Series User manual

Tecumseh

Tecumseh CDU4524EGF-S Service manual

Tecumseh

Tecumseh SILENSYS SILRG2426Z User manual

Tecumseh

Tecumseh SILENSYS SILAJ2432P User manual

Popular Heat Pump manuals by other brands

Lennox

Lennox EL16XC1 Series Installation and service procedure

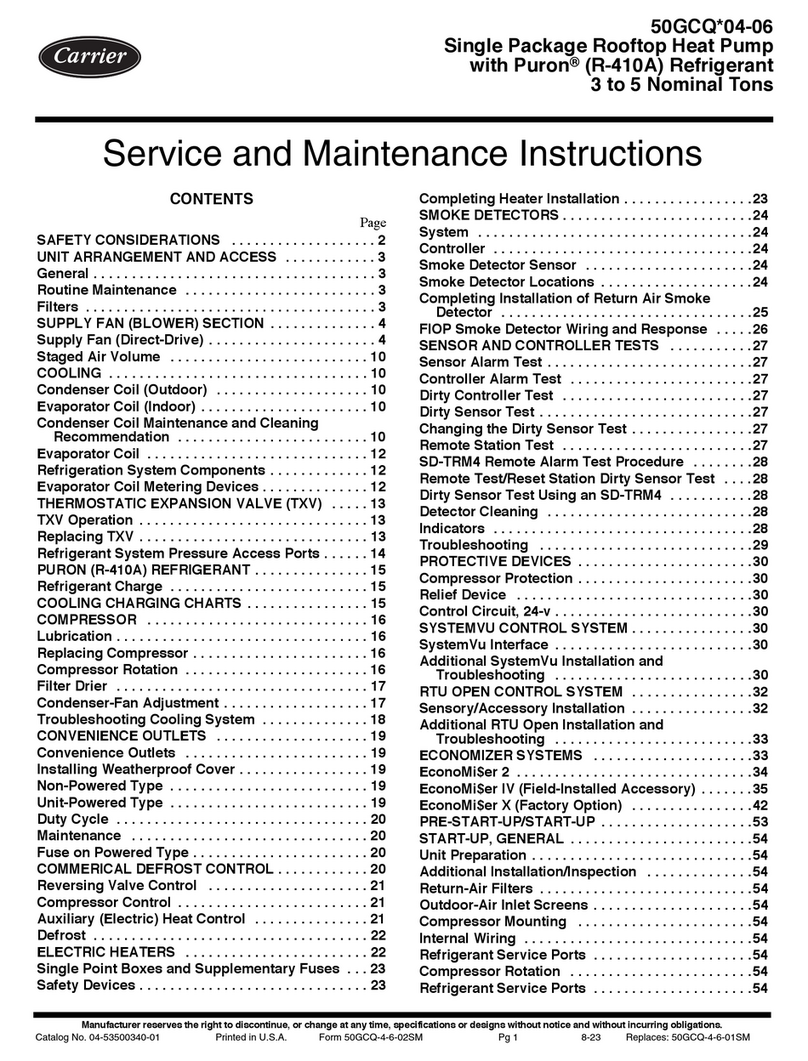

Carrier

Carrier 50GCQ Series Service and maintenance instructions

Solahart

Solahart ATMOS AIR 270 Operation & installation manual

Dimplex

Dimplex SI 22TU Installation and operating instructions

Uponor

Uponor Smatrix Wave quick guide

Electra

Electra FS 1200 Technical & service manual

CTC Union

CTC Union Connect+ GS 6 manual

aquatherm

aquatherm AT75 owner's manual

Dimplex

Dimplex LA 17TU Installation and operating instructions

Danfoss

Danfoss DHP-A user guide

STIEBEL ELTRON

STIEBEL ELTRON WPL 07 ACS classic Operation and installation guide

CLIVET

CLIVET WSAN-XSC 352 Installation and use manual