TeeJet Technologies Sentry 6141 User manual

SENTRY 6141

USER MANUAL

ISOBUS Tip Flow Monitor

Software Version 1.00

Copyrights

© 2016 TeeJet Technologies. All rights reserved. No part of this document or the computer programs described in it may be reproduced, copied,

photocopied, translated, or reduced in any form or by any means, electronic or machine readable, recording or otherwise, without prior written

consent from TeeJet Technologies.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their respective companies or organizations.

Limitation of Liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR IMPLIED.

NO COPYRIGHT LIABILITY OR PATENT IS ASSUMED. IN NO EVENT SHALL TEEJET TECHNOLOGIES BE LIABLE FOR ANY LOSS OF

BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS, OR FOR INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS BEEN ADVISED OF SUCH DAMAGES ARISING FROM

TEEJET TECHNOLOGIES SOFTWARE.

iii

98-05343-ENUS R0

Sentry 6141 ISOBUS Tip Flow Monitor

Table of Contents

PRODUCT OVERVIEW 1

SAFETY INFORMATION 1

COMPONENTS 2

Boom Interface Module Harness Connection......................................................................................................................................4

INSTALLATION 5

NOZZLE BODY WITH FLOW METER AND TIP SENSOR INTERFACE 5

Flow Meter Assembly....................................................................................................................................................................................5

POWER 6

Home Screen....................................................................................................................................................................................................6

MAIN SETUP MODE 7

MACHINE 7

Implement Parameters.................................................................................................................................................................................7

Tip Balance Allowance.....................................................................................................................................................7

Number of Boom Sections...............................................................................................................................................7

Number of Tips per Section .............................................................................................................................................7

Alarm Congurations....................................................................................................................................................................................8

Tip Alarm Deviation Allowance.........................................................................................................................................8

Tip Alarm Delay................................................................................................................................................................8

USER INTERFACE 8

User Preferred VT............................................................................................................................................................8

HELP 8

Diagnostic .........................................................................................................................................................................................................8

VT Data.....................................................................................................................................................................8

TECU........................................................................................................................................................................9

About ..................................................................................................................................................................................................................9

OPERATION 10

TIP BALANCE 10

Initiating The Balancing Procedure..........................................................................................................................10

On Screen Indicators .................................................................................................................................................................................. 11

Boom Sections........................................................................................................................................................ 11

Status Box .............................................................................................................................................................. 11

Tip Flow Indicator....................................................................................................................................................11

Buttons ...................................................................................................................................................................11

1www.teejet.com

Sentry 6141 ISOBUS Tip Flow Monitor

PRODUCT OVERVIEW

Congratulations on the purchase of your new ISOBUS Tip Flow Monitor built on the ISOBUS architecture. When used within the guidelines of this

manual, the ISOBUS Tip Flow Monitor controller will be a reliable application tool.

This manual covers the functions of the ISOBUS Tip Flow Monitor.

Use with your existing UT

• Works seamlessly and displays on any ISOBUS UT

• Easy navigation menu and data rich display

• Automatic boom section control upgrade option

• Variable rate control available providing your UT has GPS and task control capability

• Add additional ISOBUS ECUs as your needs change

• Provides basic rate control

• Standardized plugs, cables and software simplify installation and connectivity and result in true “plug and play” technology. ISOBUS Tip Flow

Monitor resides on the implement, reducing hardware in the cab

Figure 1: ISOBUS Tip Flow Monitor Job Computer & Sample Console

SAFETY INFORMATION

TeeJet Technologies is not responsible for damage or physical harm caused by failure to adhere to the following safety requirements.

As the operator of the vehicle, you are responsible for its safe operation.

The Sentry 6141 ISOBUS Tip Flow Monitor is not designed to replace the vehicle’s operator.

The Sentry 6141 ISOBUS Tip Flow Monitor is designed to support and improve efciency while working in the eld. The driver has full

responsibility for the quality and work related results.

Photos and illustrations may vary form the actual components provided. This may be due to different installation options, operation modes or

production models.

Always try to use original parts. Built to the highest standards of safety and reliability, TeeJet Technologies parts are to be used for this system

as others might jeopardize the safety and function of the system. TeeJet is not responsible for any redesign or adaptations of the Sentry 6141

ISOBUS Tip Flow Monitor. Any changes to the Sentry 6141 ISOBUS Tip Flow Monitor voids the company warranty.

2

98-05343-ENUS R0

Sentry 6141 ISOBUS Tip Flow Monitor

COMPONENTS

Unpack the installation kit and identify the required parts for your installation.

Item Part Number Description Quantity

A 78-05119 ISOBUS Tip Flow Monitor................................................................................................................................................1

B 45-09037 ISOBUS Tip Flow Monitor Interface (TFMI) Harness.......................................................................................................1

C 78-05091 Boom Interface Module (BIM)..........................................................................................................................................1

D 45-10142* Boom Interface Module (BIM) Harness ...........................................................................................................................1

E varies Harness to Tip Sensor Interface Extension Cable...................................................................................................varies

45-05857: 3′/1 m, 45-05858: 6′/1.8 m, 45-05859: 12′/3.6 m, 45-05864: 35′/10.7 m

F 78-05104 Tip Sensor Interface.................................................................................................................................................varies

G 78-05105 Dual Tip Sensor Interface ........................................................................................................................................varies

H 57-00122 Nozzle Flow Meter...................................................................................................................................................varies

I 45-05856 Terminator, End (Male) ....................................................................................................................................................1

J 45-05855 Terminator, Start (Female) ...............................................................................................................................................1

*Actual harness may be machine specific.

Item Part # Description Illustration

A 75-05119 ISOBUS Tip Flow Monitor

B 45-09037 ISOBUS Tip Flow Monitor Interface

(TFMI) Harness

C 78-05091 Boom Interface Module (BIM)

D 45-10142

Boom Interface Module (BIM)

Harness (Actual harness may be

machine specific.)

E

45-05857: 3′/1 m,

45-05858: 6′/1.8 m,

45-05859: 12′/3.6 m,

45-05864: 35′/10.7 m

Harness to Tip Sensor Interface

Extension Cable

F 78-05104 Single Tip Sensor Interface

3www.teejet.com

Sentry 6141 ISOBUS Tip Flow Monitor

Item Part # Description Illustration

G 78-05105 Dual Tip Sensor Interface

H 57-00122 Nozzle Flow Meter

I 45-05856 Terminator, End (male)

J 45-05855 Terminator, Start (female)

Figure 2: System Diagram

(A) ISOBUS

Tip Flow Monitor

78-05119

(B) ISOBUS Tip Flow Monitor

Interface (TFMI) Harness

45-09037

(D) Boom Interface

Module (BIM) Harness

45-10142

(C) Boom Interface

Module (BIM)

78-05091

(E) Harness to Tip Sensor

Interface Extension Cable

45-05857 3ft

45-05858 6ft

45-05859 12ft

45-05864 35ft

(G) Dual Tip Sensor

Interface

78-05105

(F) Single Tip Sensor

Interface

78-05104

(J) Terminator, Start (female)

45-05855

(I) Terminator, End (male)

45-05856

(H) Nozzle Flow Meter

57-00122

John Deere

“T” Cable

45-09034

Raven

“T” Cable

45-09035

Case IH

“T” Cable

45-09036

IBBC ISO

Hitch “T” Cable

45-09036

4

98-05343-ENUS R0

Sentry 6141 ISOBUS Tip Flow Monitor

Boom Interface Module Harness Connection

With each machine having a different possible switchbox conguration, With each machine having a different possible

switchbox conguration, the location to T-Tap into the valve harness cannot be specied.. However, the following guidelines

may provide some assistance in completing the installation.

1. Identify boom section cable that runs from the Boom Switchbox to the boom valves.

2. Use a T-Tap (or similar product) to connect into the signal wire.

NOTE: In some cases, the Boom Interface Module Harness wires can be connected directly to the switches inside the

Switchbox using the proper spade terminal.

3. Repeat this process for each individual boom section.

Figure 3: Boom Interface Module Harness Connection

45-10142

Boom Interface Module Harness

RATE CONTROLLER

Ground

Wire

+Power

Wire Boom Valve

Signal Wire

Boom Interface

Module Harness

Boom Wire

Wire Tap

A

Detail A

5www.teejet.com

Sentry 6141 ISOBUS Tip Flow Monitor

INSTALLATION

If there are questions concerning the installation of the Sentry 6141 ISOBUS Tip Flow Monitor system on this vehicle, or due to the

changes in component specications the parts supplied in the kit are not exactly as presented in this document, please contact your

dealer or TeeJet Customer service representative for clarication before installation. TeeJet Technologies is not responsible for misuse

or incorrect installation of the system.

NOZZLE BODY WITH FLOW METER AND TIP SENSOR INTERFACE

The turbine style ow meter used with the Sentry 6141 ISOBUS Tip Flow Monitor is compact, reliable and proven. The threaded connection allows

the sensor to be added onto a wide range of standard TeeJet single and multiple outlet nozzle bodies. ChemSaver® diaphragm check valves

remain in place allowing for positive spray tip shutoff. Ample clearance inside the ow meter means minimal ow restriction and generous free

passage for particles contained in the spray solution. Long wearing materials are used in bearing surfaces to ensure a consistent ow reading and

the ow meter sensor is mounted externally to prevent any direct contact with the spray solution for long-term reliability.

Flow Meter Assembly

1. Remove end cap from nozzle body.

2. Attach end cap to ow meter (H).

►The ow meter gasket has two different sides. The side with the

larger center is to be inserted towards the sensor or inside the

ow meter.

3. Attach ow meter to nozzle body. Hand tighten.

4. Loosely secure Tip Sensor Interface (F or G) close to nozzle

body / ow meter assembly. Cable ties (not included) can be

threaded through Tip Sensor Interface slots.

5. Push sensor of Tip Sensor Interface into slot on ow meter. Clips

on ow meter should be in the groves on the center of the sensor.

6. Secure Tip Sensor Interface.

7. Connect Start Terminator (J) to section 1 Tip Sensor Interface.

8. Connect each Tip Sensor Interface moving from left to right (while

standing at the back of the machine).

►Extension cables from Boom Interface Module Harness (D) and

Tip Flow Monitor Interface Harness (B) will connect between two

Tip Sensor Interfaces.

9. Connect End Terminator (I) to the last section’s Tip Sensor

Interface.

Figure 4: Flow Monitor Assembly

Tip Sensor Interface

to next Tip Sensor Interface

or End Terminator

to next Tip Sensor Interface

or Start Terminator

Tip Sensor Interface LEDFlow Meter

Nozzle Body End Cap

Nozzle Body & Tips

Tip Sensor

Figure 5: Flow Meter and Gasket Detail

Flow Meter

Gasket

Towards ow meter

Figure 6: Nozzle Body with Flow Meter Assembly

Flow Meter

Nozzle Body

Nozzle Body End Cap

6

98-05343-ENUS R0

Sentry 6141 ISOBUS Tip Flow Monitor

Figure 7: Sensor & Clips

Sensor

Clips

Figure 8: Tip Sensor Interface Slots

Tip Sensor Interface slots

POWER

On power up the ISOBUS Tip Flow Monitor (A) detects the number of Tip Sensor Interfaces (TSI) (F or G) located on each boom. The monitor

then indicates the status of system components.

The Status Box displays if all tips are OK or if any errors are found.

During start up, LED’s (see Figure 9) on each TSI turn on and turn off as each is detected and given a unique address. TSI unique addresses are

assigned from left to right begining at the Start Terminator.

►Sensor connected to the Start Terminator (female) (J) on the left side of the machine will be #1

►Sensor connected to the End Terminator (male) (I) on the right side of the machine will be the last sensor.

Figure 9: Tip Sensor Interface LEDs

Single Tip Sensor Interface

Dual Tip Sensor Interface

Figure 10: Splash Screen

Software Software Version

Home Screen

The errors that prevent the console from going into normal operation

are now displayed on the Home Screen in a status box.

Figure 11: Home Screen

Status / Error Box

NOTE: Screen option may vary depending on enabled or disabled

functions as well as function availability.

7www.teejet.com

Sentry 6141 ISOBUS Tip Flow Monitor

MAIN SETUP MODE

If there are questions concerning the set up of Sentry 6141 ISOBUS Tip Flow Monitor, please contact your dealer or TeeJet customer service

representative for clarication before operation. TeeJet Technologies is not responsible for misuse or incorrect operation of the system.

The main setup menu contains three options. Each of these options either directly access settings or additional menus.

Figure 12: Main Setup Screen

Home Key

Down One Option

Up One Option

Forward One Screen

Back One Screen

MENU STRUCTURE

|||

Machine User interface Help

►Implement parameters ▼Diagnostic

►Alarm conguration ►Virtual terminal (VT)

►TECU

►About

MACHINE

Machine congures machine settings. Options include, Implement Parameters and Alarm Congurations.

1. From the Main Setup Screen , select MACHINE.

2. Select from:

►Implement Parameters – establishes Tip Balance Allowance, Number of Boom Sections, and Number of Tips Per Section

►Alarm Congurations – establishes alarm parameters

Implement Parameters

Figure 13: Implement Parameters

Tip Balance Allowance

The tip balance allowance is the maximum ow deviation each tip is

allowed from the boom average, without an alarm being triggered.

Number of Boom Sections

Enter the number of boom sections. The sections are numbered from

left to right while standing in the forward facing direction of the machine

and begin at the Start Terminator. Range is 1-15 sections.

Number of Tips per Section

Enter the number of tips on each boom section. Sections are numbered

from left to right while standing in the forward facing direction of the

machine and begin at the Start Terminator. Range is 1-120 tips.

8

98-05343-ENUS R0

Sentry 6141 ISOBUS Tip Flow Monitor

Alarm Congurations

Figure 14: Alarm Configurations

Tip Alarm Deviation Allowance

Sets the error reporting range for the tip sensors. If the ow rate

of an individual tip falls below, or rises above this range, the

console will generate an alarm. The value entered is the percentage

above and below the average ow that a tip must excede to trigger an

alarm.

Tip Alarm Delay

Sets a time delay for the console to wait after an error has been

encountered before sounding a tip alarm. If the error is corrected

within this time, no alarm will sound or error will display on screen.

Range is 1-10 seconds.

USER INTERFACE

User Interface allows the operator to select the system universal

terminal (UT) [referenced on screen as a virtual terminal (VT)].

1. From the Main Setup Screen , select USER INTERFACE.

Figure 15: User Preferred VT

User Preferred VT

Use Preferred VT sets the universal terminal preference to either on or

off. If “On” is selected, the preferred UT will be used. If “Off” is selected,

the system will arbitrarily select which UT to use (if more than one UT is

available on the ISOBUS CAN).

NOTE: This should always be set to “off” unless another UT is on the

CAN bus. HELP

HELP

The Help menu allows the operator to choose between Diagnostics and

the display of information about serial number, CAN BUS information,

etc. These menus are typically accessed upon Customer Service

personnel request only.

1. From the Main Setup Screen , select HELP.

2. Select from:

►Diagnostic – used to troubleshoot input/output of the controller

(sensor or actuator).

►About – provides information on the console such as software

version, build number, etc.

NOTE: Settings are NOT automatically saved when selected. The

ACCEPT KEY must be selected to save the setting. Select

the ESCAPE KEY to escape without saving settings and

return to the previous menu.

Figure 16: Help

Diagnostic

Troubleshoots input/output of the controller (sensor or actuator).

VT Data

The UniversalTerminal (UT) [formally known as Virtual Terminal (VT)]

menu provides information regarding the virtual terminal controller (i.e.,

address version, etc.).

• If more than one UT is on the bus, switch between these by

pressing the GO TO NEXT VT KEY .

• Press the DELETE OBJECT POOL KEY to delete saved

information on the UT. This forces the UT to upload all information

from the ISOBUS Tip Flow Monitor on the next power cycle.

9www.teejet.com

Sentry 6141 ISOBUS Tip Flow Monitor

Figure 17: VT Data

TECU

The TECU is a control unit, residing on the tractor, that performs basic

functions such as power handling, speed info, etc. The TECU data are

displayed on this page.

Figure 18: TECU

About

The About screen provides information on the ISOBUS Tip Flow

Monitor such as software version, build number, etc. This information

may become useful in case of technical support.

Figure 19: About

10

98-05343-ENUS R0

Sentry 6141 ISOBUS Tip Flow Monitor

OPERATION

In Operation Mode, the system will monitor all the tips and their the ow rate if their respective boom section is turned on. The ow rate of each tip

must be within the percentage range (entered in the Setup mode) of the boom’s average. The LED on the Tip Sensor Interface (H or I) will also

be illuminated corresponding to the tip or tips that are at fault.

TIP BALANCE

Balancing the tips is required for the system to compare and monitor individual tips. The system will scan all the tips to get the ow rate. The

ow rate of each tip must be within the tip balance percentage range of the average ow rate in order to balance successfully. If any tip is

outside this range, an error will be generated, and the user will need to inspect the tip or ow meter for obstructions.

NOTE: In order to maintain system accuracy, balancing the tips is required anytime a tip is changed. The console will not be able to detect small

flow changes until a tip balancing is completed successfully.

Figure 20: Tip Balance

Balance

Home

Status Box showing tip error

Boom Status

Next Error

Figure 21: Tip Balance Process Initiating The Balancing Procedure

1. All boom sections must be on.

2. Press Work Button on Home Screen.

3. Press BALANCE button to start the balance check, a

message box will appear.

4. If an error occurs, the alarm error chart appears with details.

Inspect the tip(s) noted on the Status Box. The LED on

the Tip Sensor Interface (H or I) will also be illuminated

corresponding to the tip or tips that are at fault.

The NEXT ERROR button is only enabled if more than three

errors are found when balancing the tips.

5. After correcting the problem, press BALANCE button to start

new balance check.

11 www.teejet.com

Sentry 6141 ISOBUS Tip Flow Monitor

On Screen Indicators

Boom Sections

►Blue Bar, Blue Spray – turned on

►Red Tip, No Spray - turned off, empty, no spray

►Red Bar, Blue Spray – a tip on that section has an

error and needs to be inspected

Status Box

►Green Check Mark – shows all tips are operating normally

►Hazard Icon – an error occurred.

• Tip Error – the Status Box will show the tip number(s) that is

at fault with the percentage off.

• System Error – the status box will show an error code

Tip Flow Indicator

►Dashed Green Line – the average output of the entire boom.

►Solid Red Line – the tip alarm error reporting range.

►Blue Bar – variation from the boom’s average. If it reaches the

red line, an alarm will sound.

Buttons

►Reset Error – inactive unless an error occurs. It is then

enabled to run the system again after checking the tips.

►Next Error – only enabled if more than three errors are found

when operating. It allows the user to cycle through the list of tips

that need to be checked.

►Tip Balance – press this button to balance tips.

Figure 22: Operation – All Tips OK

Figure 23: Operation – Tip Error

SENTRY 6141

USER MANUAL

www.teejet.com

Identifying Plugged Spray Tips Has Never Been Easier

Worn, plugged or partially blocked spray tips can have a signicant impact on the quality

of your spraying job. Streaks in the eld caused by misapplication can result in yield

reductions, increased weed pressure and the need to re-apply – all of which can be

costly. The Sentry 6141 Tip Flow Monitor provides a simple, reliable solution to this age-

old problem. Flow sensors, mounted at each spray tip location, precisely measure the

ow passing through the tip and provide instantaneous feedback to the operator should

a tip become clogged, lost, or a nozzle body unintentionally rotated to an incorrect

position. By eliminating the need to detect plugged tips visually from the cab, operators

can cover more acres in a day, and know, with condence, that their spray tips are

operating properly.

98-05343-ENUS-LT R0 English/-US

© TeeJet Technologies 2016

Table of contents

Popular Measuring Instrument manuals by other brands

Omntec

Omntec OEL8000II installation manual

Makita

Makita LVH800 manual

PCB Piezotronics

PCB Piezotronics 625B11/-0008 Installation and operating manual

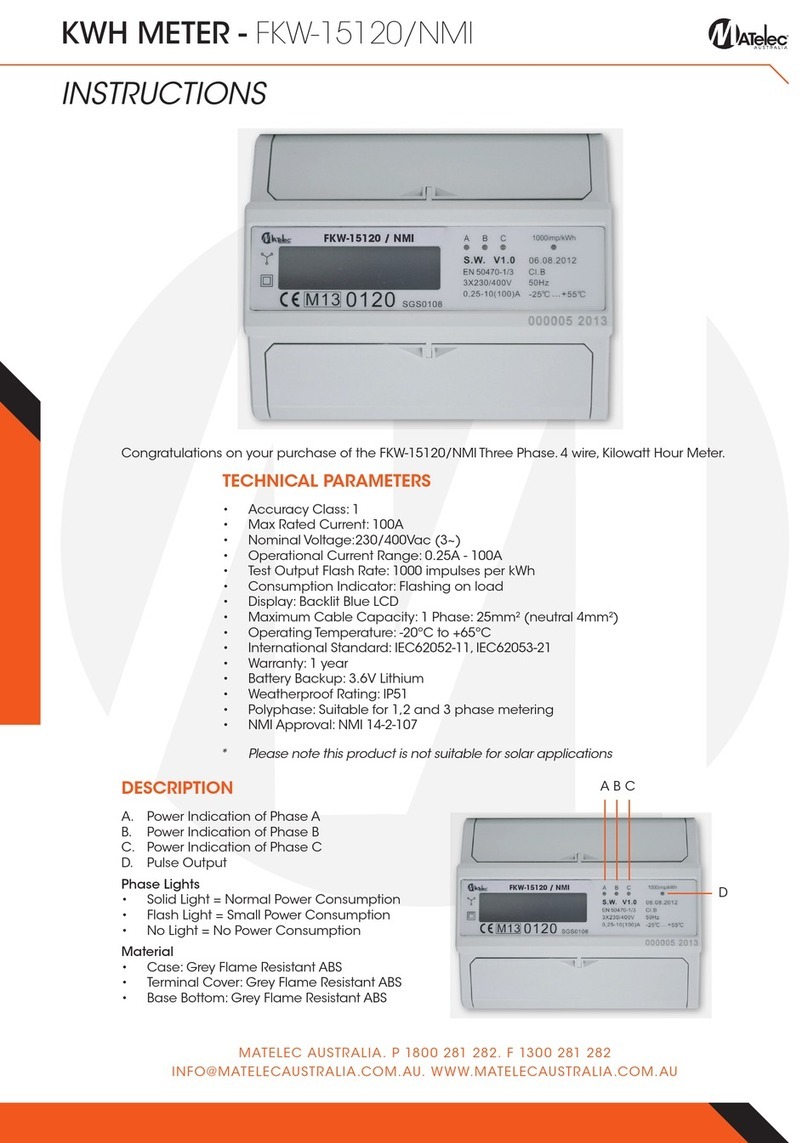

Matelec

Matelec FKW-15120/NMI instructions

Technische Alternative

Technische Alternative ATON End user guide

Wealtec

Wealtec SpectroArt 200 Installation and operation manual