30119-21 Rev. 4.6/07-09

4

Routine preventative maintenance should be performed

on all meters, which includes cleaning and an inspec-

tion of the propeller and its bearing. The intervals

between inspections depend on the water quality and

the usage of the meter. The initial inspection should

be performed after one to two years of service, to

determine the period between future inspections.

After five to ten years, the complete meter should

be inspected to ensure years of dependable service.

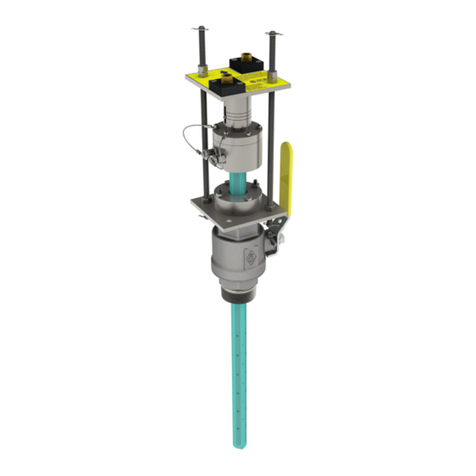

IV. METER HEAD ASSEMBLY should be removed from

the tee or meter tee tube by removing the meter

head bolts (#20) and lifting the entire head assembly

upward, taking care not to damage the propeller as-

sembly as it is pulled clear of the tee flanged end.

Inspect the meter head O-ring or flat gasket (#19)

for any signs of damage and replace, if necessary.

Replace the meter head assembly with a dummy cover

plate if the service line is to remain in operation.

V. WORKING AREA chosen for disassembly and re-

assembly of the meter components should be clean

to reduce the chance of dust or dirt particles being

introduced into the propeller area.

VI. PROPELLER ASSEMBLY (#1) inspection includes

cleaning the ceramic sleeve bearing (#8), separator

assembly (#12), drive magnet (#9), and the propeller

assembly (#1).

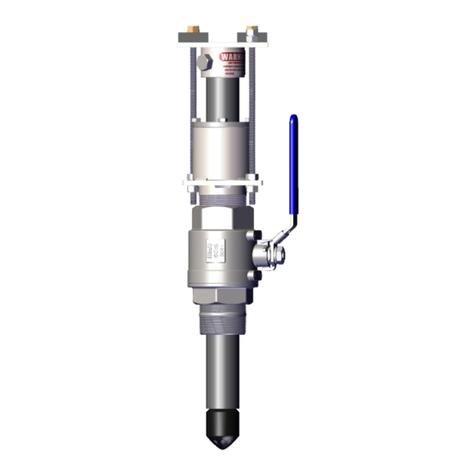

1. PROPELLER REMOVAL can be accomplished by

first removing the thrust bearing cartridge assembly

(#5). Loosen the set screw (#3) in the side of the

nose of the propeller. Remove the thrust bearing

cartridge (#5) by turning it counterclockwise while

holding the propeller in place.

2. REVERSE THRUST BEARING CARTRIDGE

(#6) must now be removed. Turn the propeller (#1)

so that the Allen wrench clearance hole is lined up

with the set screw in the side of the reverse thrust

bearing cartridge (#6). The location of the set screw

is marked by a small hole drilled in the face of the

reverse thrust bearing cartridge. With a 5/64” Allen

wrench, loosen the set screw (#7) in the reverse thrust

bearing cartridge (#6) one turn, which will allow the

set screw to protrude about 1/32” and should allow

cartridge to be unscrewed without damaging the

spindle thread. Note: If the bearing area appears

to be clogged with dirt or sediment, making it dif-

ficult to locate the set screw (#7) or to allow the

Allen wrench to fit into the set screw socket, then

the bearing area should be flushed out with water.

Insert Tool T-2402-X into the propeller through the

threaded nose. The tabs in the tool should engage in

the screwdriver slot in the end of the reverse thrust

bearing cartridge (#6). Remove the propeller assembly

(#1) and reverse thrust bearing cartridge (#6) by

turning tool T-2402-X counterclockwise, unscrewing

the reverse thrust bearing cartridge (#6) from the

spindle (#12). The propeller assembly with reverse

flow cartridge will now slide off the spindle.

WARNING: If the reverse thrust cartridge does not

unscrew easily, it may be because the set screw was

not unscrewed enough. If unscrewing of reverse

flow cartridge is continued with set screw binding

on spindle thread, damage to thread could occur.

3. WATER LUBRICATION of the ceramic sleeve

bearing (#8) is achieved by means of two openings

in the end of the thrust bearing cartridge (#5) which

allow air to be purged from the bearing area. These

should be cleared of any foreign material by running

a small wire through the holes on either side of the

screwdriver slot.

4. CERAMIC BEARING CARTRIDGE (#8) and

drive magnet (#9) should be cleaned of any foreign

material and inspected for damage. Using a bottle

brush, thoroughly clean the ceramic bearing surface

(#8) and the magnet inside diameter (#9). After clean-

ing the propeller, flush the inside out with water.

The outside surfaces of the propeller should also be

cleaned to ensure a smooth, unrestricted flow across

the surface of the propeller. Do not use an oil-based

solvent in cleaning, as damage to the assembly could

occur.

5. SPINDLE CERAMIC SLEEVE and the O.D. or

surface of the separator (#12) should be cleaned

and inspected for any substantial amount of wear.

The thrust bearing (#5) should be checked for any

damage. If it is determined that the spindle ceramic

sleeve or separator (#12) are worn sufficiently, the

separator/support spindle assembly (#12) should be

replaced.

6. SEPARATOR/SUPPORT SPINDLE ASSEMBLY

(#12) can be removed for replacement by removing

the four mounting screws (#13) which thread into the

drop pipe. Separator o-ring (#14) should be replaced

and the new o-ring (#14) covered with a thin coat of

silicone grease. The separator and support spindle

assembly (#12) can then be replaced in the front of

the drop pipe (#7) with a firm push, gently rotating

the assembly at the same time. Replace and tighten

the four mounting screws (#13).

7. PROPELLER INSTALLATION is accomplished

by following these steps:

a) The reverse thrust cartridge set screw (#7)

should be protruding 1/32” out of the reverse thrust

cartridge so it will not bind up on the spindle thread.

Note: Look through the hole in the reverse thrust

cartridge to be sure the set screw is not showing.

b) Slide the propeller assembly onto the support

spindle (#12) until the reverse thrust bearing cartridge

(#6) contacts the threads on the end of the spindle

(#12). If you feel any resistance when threading

the reverse thrust cartridge, stop at once and check