TeeJet Technologies 844E User manual

844E

SPRAYER CONTROL

Installation, Programming, and Operating Manual

iii

844ESprayerCrontrol

98-70006 R3

TableofContents

INTRODUCTION 2

MOUNTING SPRAYER COMPONENTS 3

Pressure Regulator in Bypass Mode...................................................................................... 3

Pressure Regulator in Throttling Mode ................................................................................ 5

Flow Meter .............................................................................................................................. 6

Boom Control Valves .............................................................................................................. 6

Pressure Transducer ............................................................................................................... 6

INSTALLING THE SPEED SENSOR ASSEMBLY 7

Components.................................................................................................................................................7

Speed Step 1 - Location.......................................................................................................... 7

Proximity Sensor (optional)........................................................................................................................7

Speed Step 2 - Installing The Wheel Magnets ...................................................................... 8

Speed Step 3 - Installing the Magnetic Sensor..................................................................... 9

Speed Step 4 - Conrming Speed Sensor Installation....................................................... 10

Magnetic Wheel Sensor............................................................................................................................10

Radar..........................................................................................................................................................10

MOUNTING THE TEEJET 844 CONSOLE 11

Console Step 1 - Location..................................................................................................... 11

Console Step 2 - Mounting................................................................................................... 11

Console Step 3 - Power Connection .................................................................................... 12

Console Step 4 - Connecting Component Cables............................................................... 14

Connect Step 1 - Wiring Layout ........................................................................................... 15

Connect Step 2 - Making The Connection........................................................................... 16

iv www.teejet.com

844ESprayerControl

PROGRAMMING GUIDELINES 19

IMPORTANT PRELIMINARY INFORMATION 19

Steps to Successful Programming....................................................................................... 19

PROGRAMMING THE 844E SPRAYER CONTROL SYSTEM 20

SYSTEM SETUP MODE 20

Program Units....................................................................................................................... 20

Setting Your Program Mode (U.S., Turf, NH3, Imperial, S.I.)...................................................................20

Reset Defaults....................................................................................................................... 20

Reset To Default Settings.........................................................................................................................20

Sensor Type........................................................................................................................... 21

Flow Meter or Pressure Based.................................................................................................................21

Flow Meter Calibration.........................................................................................................21

Flow Meter Pulses.....................................................................................................................................21

Pressure Transducer ............................................................................................................. 22

Maximum rating (P Hi)...............................................................................................................................22

Low Pressure Calibration (P rEF)............................................................................................................22

Nozzle Spacing...................................................................................................................... 23

Tips Per Boom Section..........................................................................................................23

Number of Spray Tips Per Boom Section...............................................................................................23

User Program Tip .................................................................................................................. 24

User Programmable Tip............................................................................................................................24

Pressure Regulation ............................................................................................................. 25

Pressure Regulation Mode.......................................................................................................................25

Regulation Adjustment Speed ............................................................................................ 26

Coarse RegulationAdjustment Speed....................................................................................................26

Fine RegulationAdjustment Speed.........................................................................................................26

Control Valve Type................................................................................................................ 27

Boom Control Valve Type: 2-Way/3-Way.................................................................................................27

v

844ESprayerCrontrol

98-70006 R3

Calibrate Speed .................................................................................................................... 27

Speed Sensor Calibration.........................................................................................................................27

Proximity/Magnetic Pulses.......................................................................................................................27

Automatic Calibration:.................................................................................................................................28

Manual Calculation:.....................................................................................................................................28

Radar Speed Pulses .............................................................................................................. 29

Automatic Calibration:..............................................................................................................................29

Manual Calculation:.....................................................................................................................................29

Distance Counter .................................................................................................................. 29

Simulated Ground Speed..................................................................................................... 29

Program Specic Gravity ..................................................................................................... 30

Liquid Specic Gravity (Density) ......................................................................................... 30

Communications................................................................................................................... 31

Minimum Pressure................................................................................................................ 31

Minimum Regulating Pressure Setting....................................................................................................31

APPLICATION SETUP MODE 32

Target Application Rate ....................................................................................................... 32

Nozzle Selection ................................................................................................................... 33

Calculation Troubleshooting ............................................................................................... 35

Adjust Speed:............................................................................................................................................35

Adjust Pressure:........................................................................................................................................35

Liquid Density:...........................................................................................................................................35

OPERATING INSTRUCTIONS 37

SPRAYER CHECKOUT 37

THE SPRAYING OPERATION 38

vi www.teejet.com

844ESprayerControl

FEATURES 39

Boost Mode ........................................................................................................................... 39

Area/Volume Feature ........................................................................................................... 39

Flow Rate Feature ................................................................................................................. 40

Application Alarm................................................................................................................. 40

No Flow Alarm....................................................................................................................... 40

Printing.................................................................................................................................. 41

TROUBLESHOOTING GUIDE 42

FLOW METER CALIBRATION 48

Method 1 – Known Volume.................................................................................................. 48

Step 1 – Known Value ...............................................................................................................................48

Step 2 – Programming Calibration Number............................................................................................48

Step 3 – Resetting Volume Counter.........................................................................................................48

Step 4 – Spraying Known Volume............................................................................................................48

Step 5 – Entering in New Flow meter Calibration Number....................................................................48

Step 6 – Double-checking the New Value................................................................................................48

Step 1 – Check Tip Size............................................................................................................................49

Step 2 – Count Tips...................................................................................................................................49

Step 3 – Calculated Flow..........................................................................................................................49

Step 4 – Measure.......................................................................................................................................49

Step 5 –Adjustments................................................................................................................................49

1

844ESprayerCrontrol

98-70006 R3

844E SPRAYER CONTROL

Copyrights

© 2011 TeeJet Technologies. All rights reserved. No part of this document or the computer programs described

in it may be reproduced, copied, photocopied, translated, or reduced in any form or by any means, electronic or

machine readable, recording or otherwise, without prior written consent from TeeJet Technologies.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their

respective companies or organizations.

Limitation of Liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER

EXPRESSED OR IMPLIED. NO COPYRIGHT LIABILITY OR PATENT IS ASSUMED. IN NO EVENT SHALL

TEEJET TECHNOLOGIES BE LIABLE FOR ANY LOSS OF BUSINESS, LOSS OF PROFIT, LOSS OF USE OR

DATA, INTERRUPTION OF BUSINESS, OR FOR INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS BEEN ADVISED OF SUCH DAMAGES

ARISING FROM TEEJET TECHNOLOGIES SOFTWARE.

2www.teejet.com

844ESprayerControl

INTRODUCTION

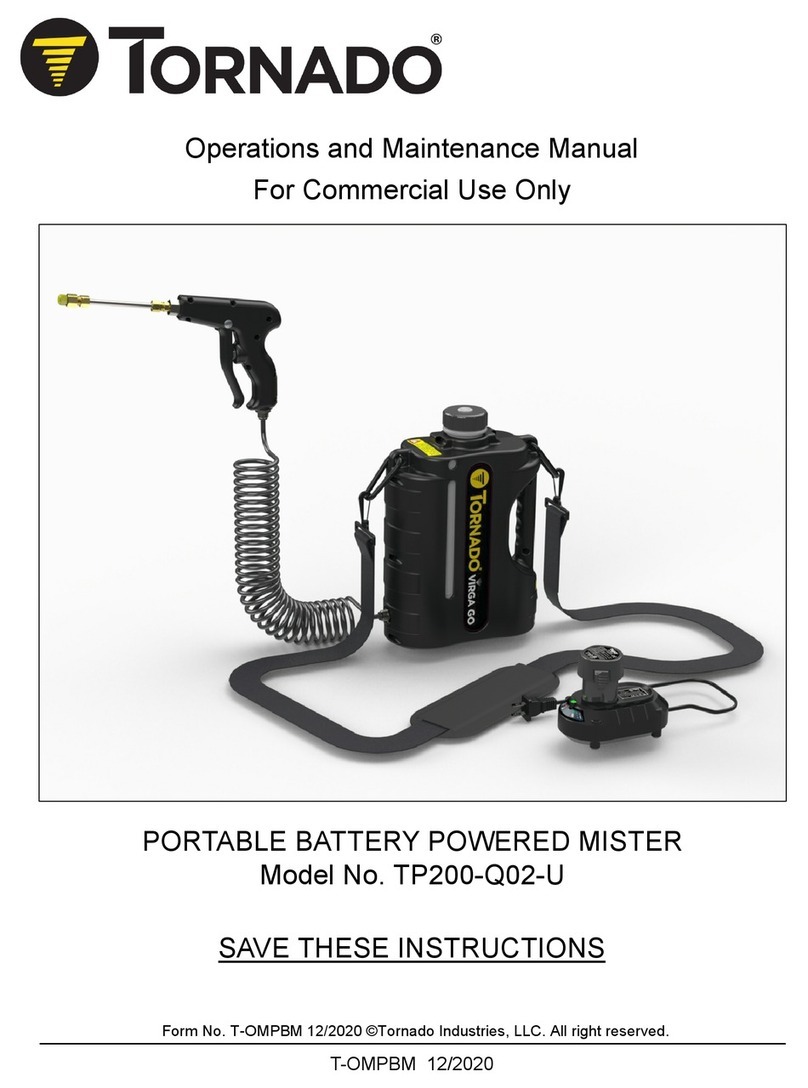

Congratulations! And thank you for choosing TeeJet Technologies’ advanced 844 sprayer control system. With its

proper installation and maintenance, you can enjoy many seasons of accurate and uniform spray application with

fingertip convenience and ease of operation.

Installation and Programming of your control system will be covered in easy to follow, step-by-step instructions.

NOTE: WE RECOMMENDTHAT YOU READTHESE INSTRUCTIONS COMPLETELY before attempting

installation and programming of your 844 sprayer control. The unit’s performance will depend on its proper

installation and programming, along with planned preventative maintenance of your entire sprayer.

Easily Accessible

Programming Mode

is very user-friendly. The

process is made simple

with a series of easy-

to-follow, symbol-driven

programming steps.

844E SPRAYER CONTROL

Auto/Manual Control

gives the operator a

manual application option

for fail-safe reliability.

Master Shuto

controls all boom sections

with one switch.

Color-Coded Tip Selection Bar

allows for easy user programming by

matching the color of TeeJet VisiFlo®

spray tips.

Individual Boom Controls

give independent control of up to five boom sections,

allowing better management of varying field features

like waterways and terraces.

Boost Mode

will temporarily increase or

decrease application rates for

special situations, such as in

patches of heavy weeds.

A Large, Backlit Display

continuously displays all vital spraying

functions. With a quick glance, the

display reveals the application rate

(automatically switches between

target and actual), pressure, speed,

and area covered.

Aluminum Console Housing

with sealed computer switch panel

resists electronic interference and

damage through rough handling for

years of reliable service.

e

h

e

e

n

r

B

target

a

d

d

y

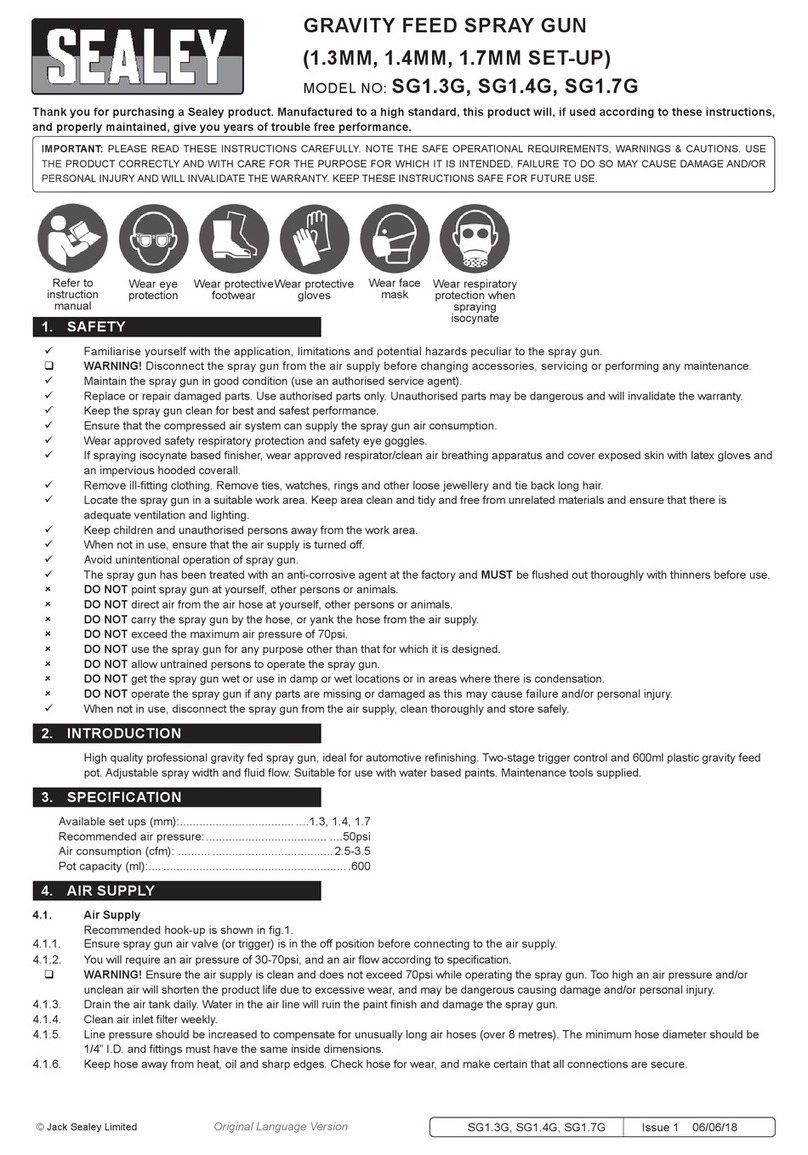

• Full-featured sprayer control with industry-leading

ease of use

• Large back-lit display shows all spraying

information at a glance

• Color-coded tip selection for easy programming

• Communication Port for PC and GPS interfacing

• Flow or pressure based regulation options provide

reliability and flexibility

• Five boom section switches plus master shutoff

• Built in application planning tool

• Durable, weather-resistant aluminum housing

• Single cable connection for quick hookup

3

844ESprayerCrontrol

98-70006 R3

MOUNTING SPRAYER COMPONENTS

Pressure Regulator in Bypass Mode

All pressure regulating valves for the 844 will be wired for use in a

by-pass system. While plumbed in a by-pass mode, with the Auto/

Man key in the “MAN” mode, the valve should close when the

key is pressed and open when the key is pressed.

The pressure regulating valve can also be mounted in a throttling

situation as an alternative location. Refer to page 5, and Figures

1-3 and 1-4.

NOTE: The diagrams in Figures 1-1 and 1-2 are shown as general

guidelines to follow when plumbing the 844 components.

The type of pump used and location of other components

can vary from sprayer to sprayer. It is important to ensure

that if a pressure transducer is used, it is located as close

to the spray tips as possible. Normally, this is at the boom

control valves. However, if one particular boom section is

always used, the pressure transducer can be mounted on

that particular boom section. If a flow meter is used, make

sure that all of the flow going through the flow meter is

directed to the spray tips. Make sure that proper distance

is allowed on the inlet and outlet side of the flow meter

(refer to figures 1-2 and 1-3).

4www.teejet.com

844ESprayerControl

Figure 1-1: Bypass Plumbing Diagram - Pressure Based System

Figure 1-2: Bypass Plumbing Diagram - Flow Based System

5

844ESprayerCrontrol

98-70006 R3

Pressure Regulator in Throttling Mode

The pressure regulating valve, as shown in the figures below, can be located in the supply line before the boom

control valves. If you choose this location, the 844 will need to be properly programmed to reverse the polarity of

the valve. This step can be found in the System Setup instructions on page 23. When in throttling mode, the valve

should open when the key is pressed, and close when the key is pressed. Be sure to check this before

plumbing the valve into the system.

Figure 1-3: Throttling Plumbing Diagram - Flow Based System

Figure 1-4: Throttling Plumbing Diagram - Pressure Based System

6www.teejet.com

844ESprayerControl

Flow Meter

To ensure accurate readings, the flow meter (if used) must be

mounted 10″to 12″(25-35 cm) from other pipe fittings, preferably

in a vertical position with the flow going up. It should also be

mounted with the direction of flow arrow pointing toward the boom

control valves. Refer to Figures 1-2 and 1-3.

Be sure the flow meter is plumbed so that all liquid passing

through it is routed to the booms and not back to the tank. When

using three-way boom control valves, refer to page 25 of this

manual for programming guidelines.

Boom Control Valves

The Boom Control Valves are connected in tandem and centered

in front of the boom sections. See the Control Valve Instruction

Manual for mounting instructions. If using three-way valves, refer

to the instruction manual of the valves you are using for valve

calibration instructions.

Pressure Transducer

The pressure transducer (if used) should be installed as close to

the spray tips as possible. Normally this is at the boom control

valve assembly. Refer to Figures 1-1 through 1-3. Mount the unit

vertically on a short stand pipe to help protect the sensor.

NOTE: Pressure drop, to some degree, is found in most plumbing

systems. Pressure drop is created when there is any kind

of restriction in the spray line that reduces flow rate and

is quite often produced between the boom control valve

assembly and the spray tips. If one of the boom sections

on the sprayer is always used, the pressure transducer

can be installed on that particular boom section,

minimizing any potential pressure drops between the

sensor and spray tips. If the pressure drop in your system

is greater than 5 psi (0.3 bar), you should consider this as

an alternative location for the pressure transducer.

Check all components to make sure they are mounted securely to

avoid excessive vibration.

7

844ESprayerCrontrol

98-70006 R3

INSTALLING THE SPEED SENSOR ASSEMBLY

Components

Two (2) magnets, Sensor with attached connector cable, and mounting hardware. If

you are installing a radar ground speed sensor, follow the instructions supplied with

that unit.

Speed Step 1 - Location

The speed sensor assembly should be installed on a non-driven wheel to avoid

potential errors that are likely to occur from a slipping drive wheel. Refer to Figure 1-6.

Proximity Sensor (optional)

An optional proximity sensor is available to use in cases

where space is limited or for drive shaft mounting.

The proximity sensor will work by sensing any metal object.

The proximity sensor must be mounted so that the sensor face

is within 1/8″to 3/8″(3-10 mm) of the metal object being read.

CABLE

MAGNET

RIM

SENSOR

TIRE

NOTE:

TARGET FACES

TIRE LUGS

Figure 1-5: Wheel Mounting of Magnetic Speed Sensor

Figure 1-6: Wheel Mounting of Speed Sensor

8www.teejet.com

844ESprayerControl

Speed Step 2 - Installing The Wheel Magnets

Check for pre-drilled holes in the wheel rim. If pre-drilled holes are not available, layout a pattern as shown in

Figure 1-7 and drill two 3/8″(10 mm) holes near the outer edge of the rim if possible, and 180° from each other.

Place the magnets into each of the two holes on the inside rim and securely fasten them using the nuts and

washers provided.

Figure 1-7: Magnet Locations

TIRE

WHEEL

3/8Ý(10 mm)

HOLE FOR

MAGNET

Figure 1-8: MagnetAssembly

NUT

NUT

MAGNET

WASHER

9

844ESprayerCrontrol

98-70006 R3

Speed Step 3 - Installing the Magnetic Sensor

The flat, pressed L bracket of the wheel speed sensor kit should be secured to a vertical member near the

non-driven wheel. The round, right angle steel bracket is then secured to the flat bracket with the two U-bolts

and necessary hardware provided. The round, right angle bracket is then used to secure the magnetic sensor

mounting clamp.

The magnetic sensor should be inserted into the mounting clamp and positioned within 1/8″to 3/8″(3-10 mm) of

the wheel magnet. Tighten the sensor clamp using the clamp screw per Figure 1-10.

Your installation will likely vary from the example. It may be necessary to customize the installation to

accommodate your specific machine. Keep in mind that the two magnets must be spaced an equal distance

around the wheel. The magnetic sensor must be mounted in-line with the magnets and positioned within 1/8″to

3/8″(3-10 mm) from each magnet as they pass the Sensor assembly.

Figure 1-9: Sensor Mounting Figure 1-10: SensorAssembly

CLAMP

SCREW

SENSOR

BRACKET

FLAT

L BRACKET

10 www.teejet.com

844ESprayerControl

Speed Step 4 - Conrming Speed Sensor Installation

Magnetic Wheel Sensor

After your wheel or proximity sensor is installed and once the 844 console is installed and powered up, you

can test the speed sensor installation. Connect the wheel speed or proximity sensor to the sensor cable, and in

turn connect the sensor cable to the 844 console. When the connection is made, rotate the wheel on which the

magnets are installed. If using a proximity sensor, you will be sensing metal objects and not magnets. Each time a

magnet (metal object for proximity sensor) passes the sensor a red LED (orange LED for proximity sensor) on the

back of the sensor will light. The LCD display on the console will also indicate a speed as the sensor receives and

sends electronic pulses.

Radar

If you are using a radar speed sensor it should be connected to the speed sensor connector on the sensor

end cable. An adapter cable will be necessary when using most radars and are available through your TeeJet

Technologies dealer. The 844 will automatically sense if the speed sensor is a wheel speed, proximity type or

radar type sensor during calibration. The 844 is automatically adapted to most brands of radar speed sensors

provided that the appropriate adapter cable is used. If using a radar sensor, the 844 will display rAd during the

calibration procedure.

11

844ESprayerCrontrol

98-70006 R3

MOUNTING THE TEEJET 844 CONSOLE

Console Step 1 - Location

Determine the best location for the control console in the cab or operator’s compartment. Allow sufficient

clearance, approximately 4-5″(10-12 cm) to accommodate for the cable that will be connected to the right side of

the console.

Console Step 2 - Mounting

Mount the console to a firm support within the cab area, and secure using the slots provided on the top, back, or

bottom of the Console. Although two simple brackets are supplied with the unit, some additional bracketing may

be necessary. The slots in the 844 will accept 1/4″(6 mm) bolts.

Figure 1-11: Brackets ProvideAngleAdjustment

12 www.teejet.com

844ESprayerControl

Console Step 3 - Power Connection

Locate the power cable that has a black connector on one end and two battery terminal rings on the other. Extend

the battery terminal ring end of this cable from the cab to the battery.

NOTE: Some tractors use two 6 Volt batteries as a power source. Make sure there are a total of 12 Volts

delivered to the controller by connecting to the (+) terminal on one battery and the (-) terminal on the other

battery. Reliable operation of the 844 Sprayer Control depends on a clean power supply. Ensure this by

connecting the power cables directly to the battery and not to another power source.

Connect the battery terminal rings to the battery posts, making sure that the positive (red) and negative (black)

wires correspond with the polarity of the battery terminals.

NOTE: The power cable is designed to provide the simple addition of a remote master boom switch in a

convenient location (i.e. on the throttle, gear shift, or floor switch). To install a remote boom switch, simply

install a switch to the brown wire in the power cable. The switch should be rated to handle the total current

used by all boom section valves combined. If installed, the remote master switch will operate in series with

the boom switches on the console.

Connect the battery cable to the power cable lead that extends from the main cable.

Test the installation by pressing the key once to turn the 844 console on. If the display shows information, you

have wired the power correctly.

NOTE: TheTeeJet 844 Sprayer Control has an automatic power down feature. With the master boom switch

in the “off” position, the 844 will automatically shut down after 10 minutes of no inputs.This prevents

possible battery drainage. To turn the console “off” with the Master Switch located in the “off” position,

press and hold the key while pressing the key once, and then releasing both keys. The console

will shut down providing no other keys are pressed.

13

844ESprayerCrontrol

98-70006 R3

Figure 1-12: Power Connection

14 www.teejet.com

844ESprayerControl

Console Step 4 - Connecting Component Cables

Now that you have the console installed you can begin connecting it to the other components of the 844 system.

The standard kit contains a main cable that attaches to the boom control valves, the pressure regulating valve,

flow meter and/or pressure sensor, a magnetic wheel speed sensor, and a proximity speed sensor or radar speed

sensor. Lay out each of the valve and sensor leads before installing the sprayer components to be sure the cables

are long enough in length from the sensor connections to the 844 console connection. If your installation requires

longer cables, several extension cables are available. If an exit hole has to be cut in the cab, be sure the edges

are deburred and protected to prevent damage to the cables.

Figure 1-13: Wiring Diagram

844 SPRAYER CONTROL

TANK

POWER

JET AGITATOR SPEED SENSOR

SOLENOID VALVES

BOOM SECTIONS

STRAINER

TANK SHUT-OFF

CENTRIFUGAL

PUMP

AGITATOR

VALVE

PRESSURE

TRANSDUCER

(IF USED)

PRESSURE

REGULATING

VALVE

10-12Ý

(25-35 CM)

5-7Ý

(12-17 CM)

FLOW METER

(IF USED)

COMMUNICATION

CABLE CONNECTION

MAIN CABLE

CONNECTION

15

844ESprayerCrontrol

98-70006 R3

Connect Step 1 - Wiring Layout

Determine the best cable routing to the sprayer control components on the sprayer. This may be along the flow

line, main frame of the sprayer, or wherever the cables can be conveniently secured. Avoid any situation where

the cables may lay in puddles, or come in contact with extreme heat sources.

WARNING: System Components should be mounted at least 3 ft / 1 m from areas of excessive vibration

(i.e. engines) to avoid high frequency interference.

Figure 1-14: Wiring Layout

Table of contents

Other TeeJet Technologies Paint Sprayer manuals