5

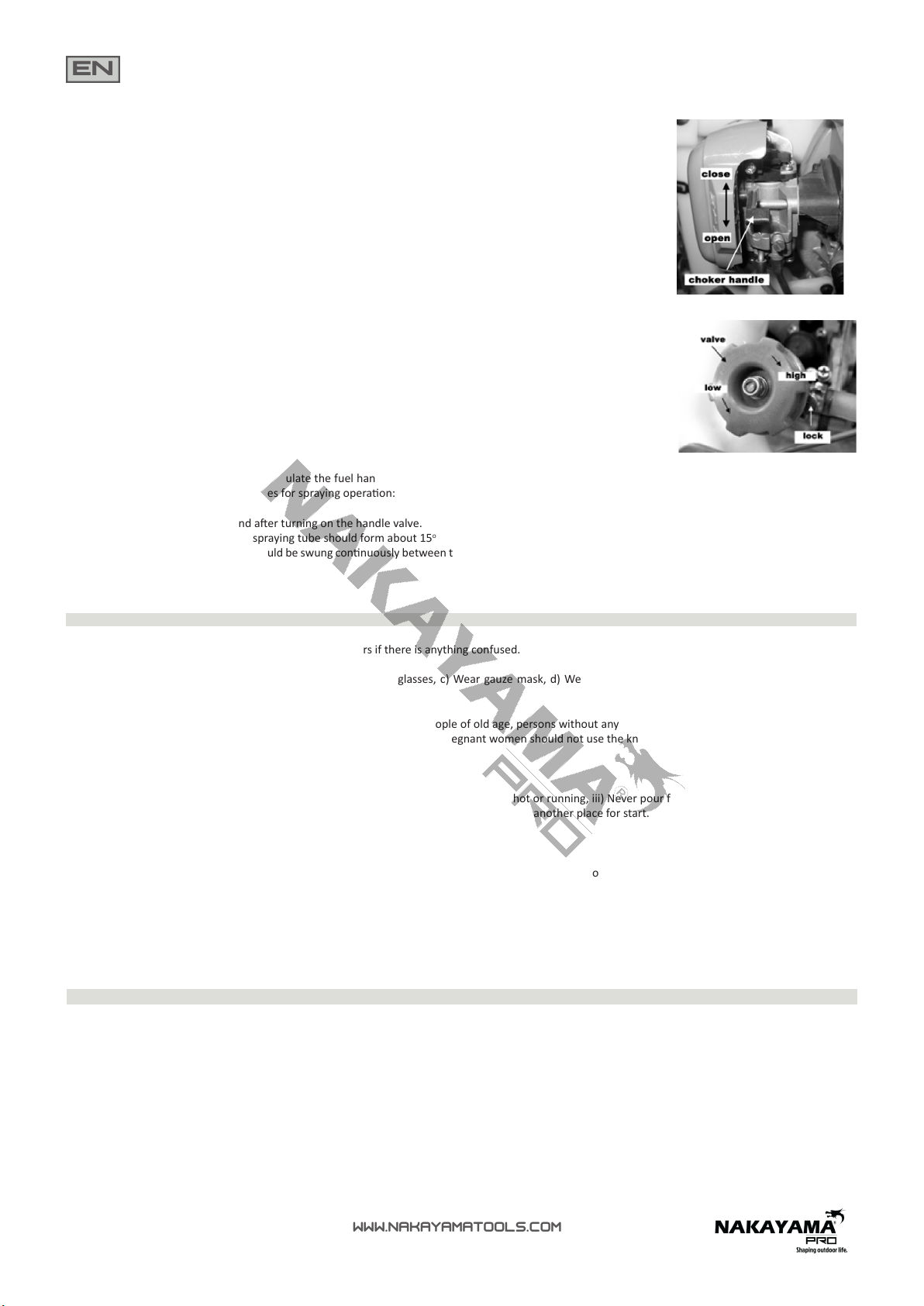

Regulate the choker (see Figure 4) to close posion in winter and at the rst me to full open posion when the engine

is hot. Pull the starter lightly for 3-5 mes to make the fuel ow to the cylinder. Then pull it fast to start the engine.

Note: Aer start, the start rope should be contracted back slowly with hand’s help. If the rope contracts back fast, it may

cause damage of the starter. Aer start, put the choker slowly to full open posion. Regulate the fuel handle to a proper

posion to run at low speed for 3-5 minutes, then make spraying operaon. New machine should not work at full open

posion within the rst 4 hours. The speed should be controlled at 4000-5000 rpm thus enabling the engine to have a

good match and do reliable job.

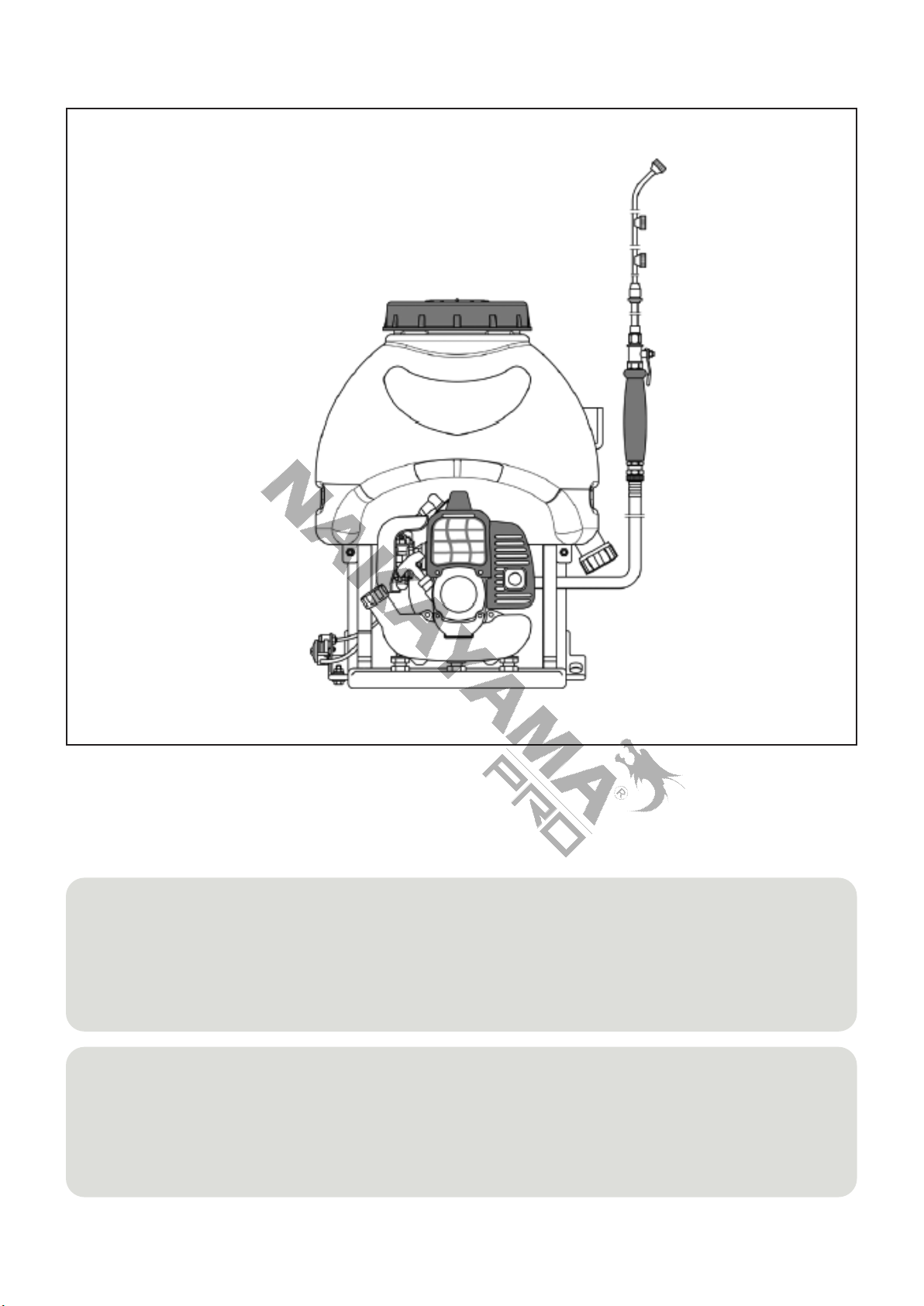

Spraying

Adding chemical liquid: Before adding chemical liquid, spray which water to test if there is leakage. When adding chem-

ical liquid, it should be neither very fast nor excessive full. The liquid must be assured to be through the lter in order to

avoid foreign maer coming into the chemical tank to cause coming into the chemical tank to cause machinery break-

downor nozzle block. Aer nish of adding liquid, screw down chemical tank lid in order to avoid leakage, when adding

liquid, the machine need not stop, but should be at low speed.(i. e. not at spraying posion).

Pressure regulaon

When the engine’s speed is 5000-6000r/min, regulate the water pressure of plunger pump. This has been done before

leaving the factory. If it is necessary to regulate, please do this procedure as per the instrucon of Figure 5.

Spraying: Put the machine on the back. Regulate the fuel handle to let the machine run at about 6500 rpm and turn on the handle spraying valve, then start

spraying operaon. Some important notes for spraying operaon:

a. Swing the spraying tube with hand aer turning on the handle valve. In order to avoid chemical harm, it is strictly prohibited to spray only at one place.

b. Operator should face to wind. The spraying tube should form about 15ο angle with level.

c. During spraying, the spraying tube should be swung connuously between the le and the right to increase spraying range. Advanced steps should cooperate

with the swing speed.

Safe Operaon

Read the instrucon book carefully. Inquire the local retailers if there is anything confused.

Protecve clothing: a) Wear anged cap, b) Wear dirt/fog-proof glasses, c) Wear gauze mask, d) Wear coat guarding against poisons, e) Wear long-sleeve

gloves, f) Wear boots.

Mentally disabled, persons that have consumed alcohol, underaged or people of old age, persons without any knowledge of the machine, persons who have

just exercised strenuously or slept inadequately and also breast feeding or pregnant women should not use the knapsack sprayer under no circumstances.

Avoidance of re

i) Do not make re or smoke nearby the machine, ii) Never refuel the machine when it is hot or running, iii) Never pour fuel on the machine. If you do, please

clean it o. Aer adding fuel, please screw down the fuel tank lid, then move the machine to another place for start.

Spraying operaon

i) Chemical-spraying should be performed under cool weather with lile wind. For example, in the early morning or in the late aernoon. This can reduce evap-

oraons and dri of chemicals and improve protecng eect, ii) The operator should move towards winds, iii) If chemical spaered into mouth or eyes, wash

them with clean water and then go to see the doctor, iv) If the operator has o headache or dizziness, stop working immediately and go to see the doctor in me.

v) For the operator’s safety, spraying must be carried out strictly according to the instrucon of the chemicals. It is strictly prohibited to spray extreme poison-

ous chemicals.

Maintenance and long me storage

Daily maintenance:

The following maintenance should be done aer daily job: a) Clean the surface of the machine b) Clean chemical tank with clean water and dry it, c) Check all

the connecons whether there is leakage of water or fuel. If there is leakage, remedy procedures are very necessary, d) Check all the screws to see if they are

loose or lost. If there is, please screw ghtly or replace, e) Lubricang oil should be injected into the oil inlet aer every 24-hour’s operaon, f) This machine

aer maintenance should be put in dry and venlang place. It must be far away from re source and avoid sunlight.

Long term storage:

a) Clean the machine surface carefully, b) Discharge fuel in the tank and carburetor enrely, turn o the choker, pull the starter 3-5

mes, c) Remove the spark plug and pour some oil into the cylinder, then pull the starter for 2-3 mes lightly, nally put on the spark plug d) Inject lubricang

oil into the gearbox and crankcase, e) All the plasc parts must neither exposed to the sunlight nor pressed by heavy maer.

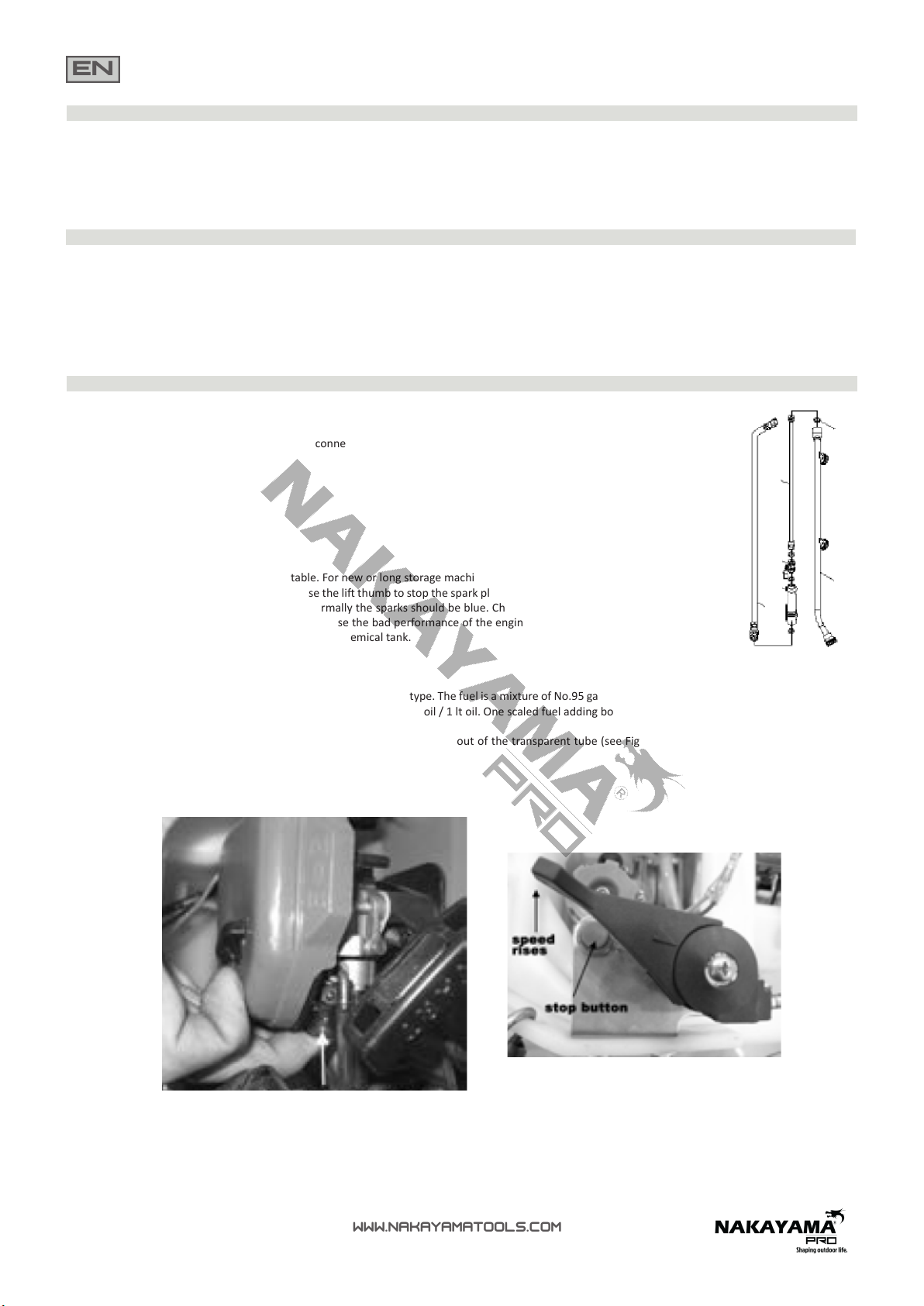

Figure 2 Figure 4

Figure 5