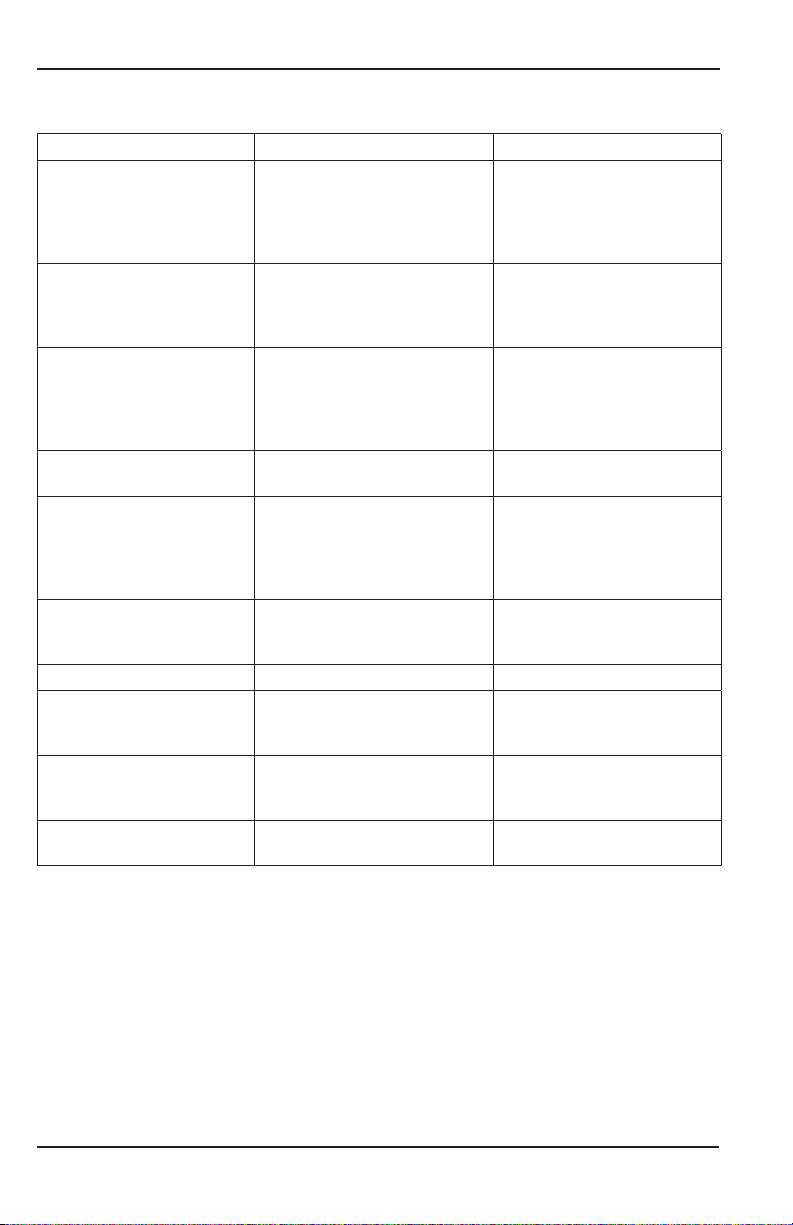

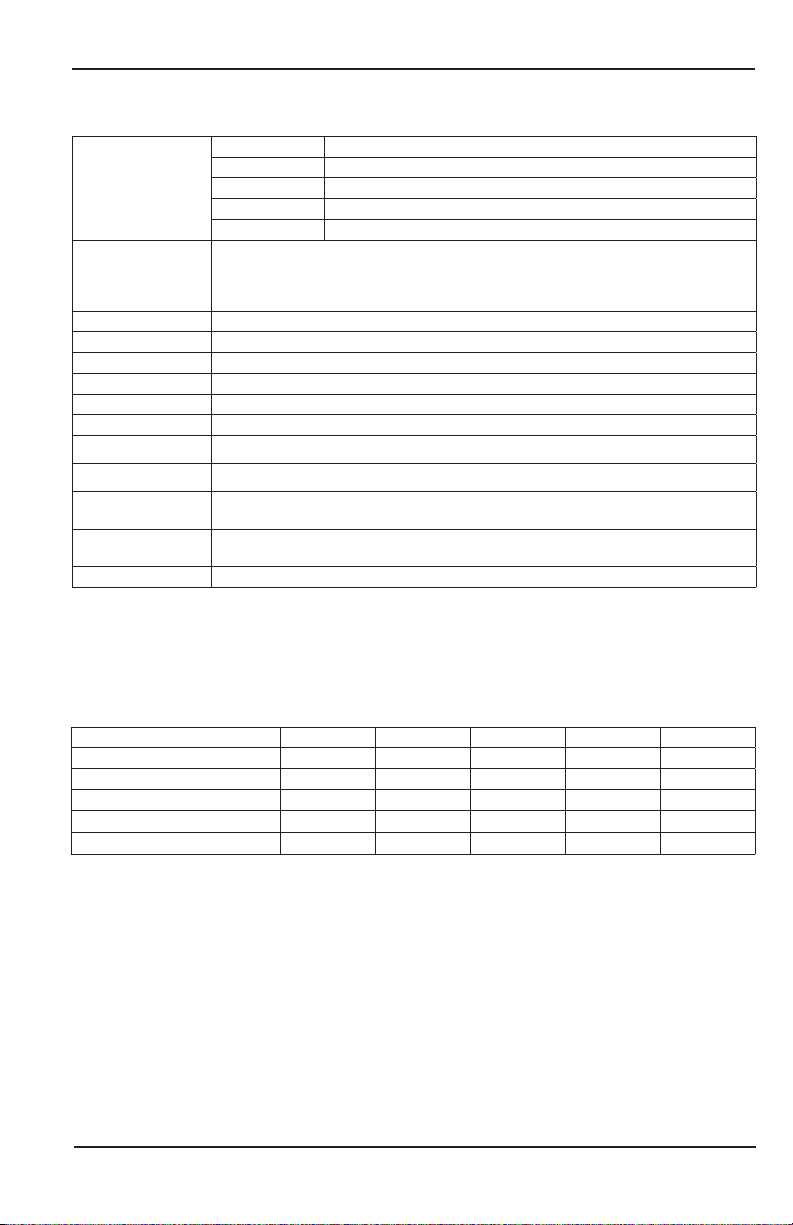

Part Number Information

Page 13April 2020 TRB-UM-00287-EN-06

PART NUMBER INFORMATION

Part

Number*

Meter Bore

Size × Line

Size (in.)

PED

Compliant

Flow

Range

Strainer

Mesh

Approx. K-Factor

pulses/US gal Weight

Max. Pres-

sure Drop

(psi)

B131-038 3/8 × 1 Coming soon

See “Flow

Range

Chart”

60 18,000 —3�75

B131-050 1/2 × 1 Coming soon 60 13,000 —6�5

B131-075 3/4 × 1 Coming soon 60 3300 —18

B131-088 7/8 × 1 Coming soon 60 3100 —20

B131-100 1 × 1 Coming soon 60 870 —20

B132-050 1/2 × 2 Coming soon 60 13,000 —12

B132-075 3/4 × 2 Coming soon 60 3300 —18

B132-088 7/8 × 2 Coming soon 60 3100 —20

B132-100 1 × 2 Coming soon 40 870 —20

B132-150 1-1/2 × 2 Coming soon 20 330 —16

B132-200 2 × 2 Yes 20 52 —9

B132-250 2 × 3 Yes 10 52 —10

B133-300 3 × 3 Yes 10 57 —10

B133-380 3 × 3 Yes 10 57 —10

B134-400 4 × 4 Yes 10 29 —10

B136-600 6 × 6 Coming soon 4 7 —10

B138-800 8 × 8 Coming soon 4 3 —10

B139-900 10 × 10 Coming soon 4 1�6 —10

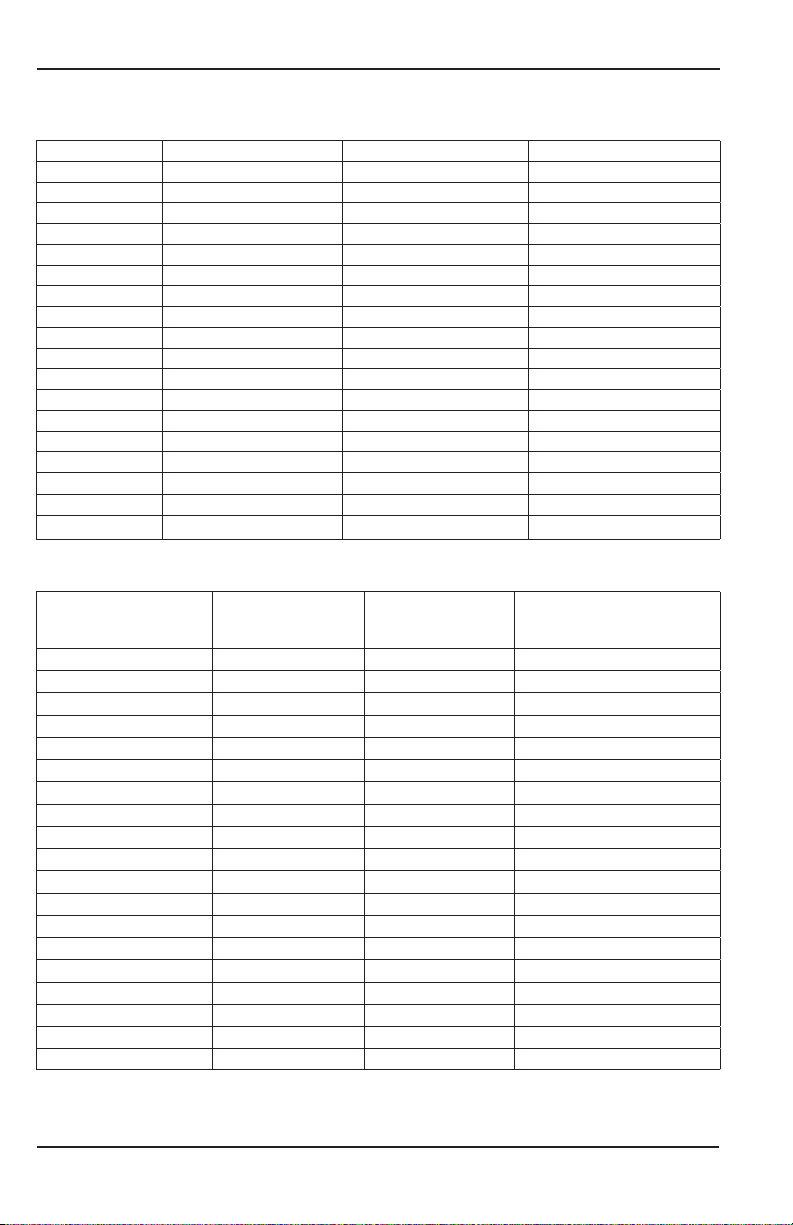

Flow Range Chart

Part Number

Flow Ranges

gpm (lpm) bpd m3/d

B131-038 0�60…3�00 (2�27…11�36) 20…100 3�3…16

B131-050 0�75…7�50 (2�84…28�39) 25…250 4�1…41

B131-075 2�00…15�00 (7�57…56�78) 68…515 10�9…81�75

B131-088 3�00…30�00 (11�36…113�56) 100…1000 16…160

B131-100 5�00…50�00 (18�93…189�27) 170…1700 27�25…272�5

B132-050 0�75…7�50 (2�84…28�39) 25…250 4�1…41

B132-075 2�00…15�00 (7�57…56�78) 68…515 10�9…81�75

B132-088 3�00…30�00 (11�36…113�56) 100…1000 16…160

B132-100 5�00…50�00 (18�93…189�27) 170…1700 27�25…272�5

B132-150 15�00…180�00 (56�78…681�37) 515…6000 82…981

B132-200 40�00…400�00 (151�42…1514�16) 1300…13,000 218…2180

B132-250 40�00…400�00 (151�42…1514�16) 1300…13,000 218…2180

B133-300 60�00…600�00 (227�12…2271�25) 2100…21,000 327…3270

B133-380 80�00…800�00 (302…3028) 2750…27,500 430…4300

B134-400 100�00…1200�00 (378�54…4542�49) 3400…41,000 545…6540

B136-600 200�00…2500�00 (757�08…9463�53) 6800…86,000 1,090…13,626

B138-800 350�00…3500�00 (1324�89…13248�94) 12,000…120,000 1,363…19,076

B139-900 500�00…5000�00 (1892�71…18927�06) 17,000…171,000 2,725…27,252