Tek-Air VorTek VT-5000 series Instruction manual

Vortek

AIRFLOW TRANSMITTER

SERIES VT-5000 & VT-7000

INSTALLATION, OPERATION

& MAINTENANCE MANUAL

RELEASE 2.1

APRIL 2005

PROTECTED BY US PATENT 4,770,035

TEK-AIR SYSTEMS

41 EAGLE ROAD

DANBURY, CT 06810

TEL. (203) 791-1400

FAX (203) 798-6534

WWW.TEK-AIR.COM

Doc.# VT5 OM 050499, Rel. 2.1

FOREWORD

This manual is designed to provide the user with the information required to install, wire, configure, calibrate,

operate, maintain, and trouble shoot VorTek Air Flow Transmitters. It is important that this manual be read in its entirety

prior to installation and commissioning of VorTek.

While we would like to think that this manual is complete in content and clear in instruction, there may

be questions that we haven’t anticipated. If you have questions that you would prefer to direct to a live

person, we encourage your calls. Technical assistance is available from the service department, at 203-791-

1400 from 8:30 AM to 5:00 PM ET.

Tek-Air also offers a variety of service and maintenance packages to keep the equipment at peak

performance. For further details contact the Service Department at the above phone number.

WARRANTY

Tek-Air Systems Inc. warrants that the products it manufactures, under normal use and service as de-

scribed in the Operation and Instruction manual, is free from defects in workmanship and material for a

period of thirty-six months from the date of shipment to the customer. This limited warranty is subject to

the following conditions:

With respect to any repair services rendered, Tek-Air warrants that the parts repaired or replaced will be

in good working condition, under normal use, for the period of the original warranty, or for 90 days from

date of shipment to the customer if the original warranty period has expired.

This warranty is based on the return of the product to Tek-Air’s factory and does not include field repairs.

Periodic maintenance required, as outlined in the Operation and Instruction manual, is the responsibility

of the user.

Unless specifically authorized by Tek-Air in writing, no warranty is made with respect to, and no liability is

assumed in connection with, any goods which are incorporated into other products or equipment by the

Buyer.

The foregoing is in lieu of all other warranties and is subject to the conditions and limitations stated

herein. No other expressed or implied warranty of fitness for particular purpose or merchantability is

made.

The exclusive remedy of the user or purchaser, and the limit of the liability of Tek-Air or any other seller for

any and all losses, injuries, or damage resulting from the use of this product shall be the return of the

product and the refund of the purchase price, or, at the option of Tek-Air or any other seller, the repair or

replacement of the product. In no event shall Tek-Air or any other seller be liable for any incidental or

consequential damages.

Products manufactured by other manufacturers but supplied by Tek-Air carry the original manufacturers

warranty.

3VORTEK Doc.# VT5 OM 050499, Rel. 2.1

TABLE OF CONTENTS

1.0 OPERATION

1.1 General Description.................................................................4

1.2 Specifications ..........................................................................5

1.3 Operation of VorTektm Sensors ................................................6

1.4 Transmitter Operation..............................................................7

1.5 Options ....................................................................................8

2.0 INSTALLATION

2.1 Probe Bar Mounting and Location...........................................8

2.1.1 Duct-Mounted Probes.............................................................................8

2.1.2 Fan Inlet- Mounted Probes .....................................................................9

2.2 Transmitter Mounting and Location .......................................10

2.3 Probe Bar and Transmitter Connection................................. 11

2.4 Transmitter Wiring ................................................................. 11

3.0 STARTUP ADJUSTMENTS

3.1 General Description...............................................................12

3.2 Normal Operation..................................................................13

3.3 Damping Adjustment .............................................................13

3.4 Zero Check............................................................................13

3.5 Quick Calibration Check........................................................14

3.6 Threshold Adjustment............................................................14

4.0 CALIBRATION & MAINTENANCE

4.1 Field Calibration ....................................................................14

4.2 Bench Calibration..................................................................15

4.3 Offset Adjustment..................................................................16

4.4 Calibration Check..................................................................16

4.5 Wave Form Check with an Oscilloscope...............................16

4.6 Troubleshooting.....................................................................17

APPENDICES

AppendixA - VorTek Minimum Installation Requirements ........... A1

VorTek Duct Probe Installation Diagrams..........A1-A4

VorTek Fan Inlet Probe Installation Diagrams .A5-A10

Appendix B - Cleaning of VorTek Airflow Measuring Probes....... B1

4VORTEK Doc.# VT5 OM 050499, Rel. 2.1

1.0 OPERATION

1.1 General Description

The Tek-Air VorTektm airflow measurement system consists of one or more duct

insertion probes and an electronic transmitter. The VorTek measurement system

is capable of measuring airflow volume in ducts of all sizes and shapes, as well

as fan inlet bells.

VorTek insertion probes have multiple velocity sensors located along their length.

Each sensor measures airflow velocity using a unique, patented (4,770,035)

application of the digital velocity sensing technique using the principles of vortex

shedding.

Vortex shedding is the generation of eddy currents created by an obstruction in

an air stream. Airflow through each VorTek sensor creates a succession of eddy

currents which are then sensed as pressure pulses. The frequency at which

these pulses are generated, is directly proportional to the velocity of airflow

around the sensor.

In large ducts, the profile of the air velocity across a duct is often uneven due to

the bends and transitions in the ductwork. In-line devices such as dampers,

elbows, and transitions also create disturbances in the flow profile. To compen-

sate for these varying velocity profiles, multiple VorTek sensors are utilized within

a duct. The frequency outputs of individual sensors are averaged to obtain the

average duct velocity.

The VorTek transmitter totalizes the frequency signals from the individual sensors

to perform true velocity averaging. From this average, an electronic signal (4-

20mA) is generated for direct input to a customer’s control system.

The VorTek transmitter provides several beneficial features to the user, including

adjustable damping, on-line zero check, on-line calibration, sensor diagnostics,

and optional digital indication. This manual will cover the operation, installation,

startup, and calibration of the VorTek probes and transmitter.

Chapter 1 Operation

5VORTEK Doc.# VT5 OM 050499, Rel. 2.1

1.2 Specifications

Sensors and Probes

Sensor Type: Vortex shedding

Velocity Range: 350 to 9500 FPM

Probe bar Length: 8" to 72"

Probe bar Configuration: Rectangular, Round, Oval, Fan Inlet

Materials of Construction; Standard:

Mounting Plate: Galvanized steel

Probe bar: Extruded aluminum

Sensor Assembly: Aluminum and ABS

Miscellaneous: EPDM finishing strip

Materials of Construction; Fume hood:

Mounting Plate: Stainless steel

Probe bar: CPVC

Sensor Assembly: CPVC and ABS

Materials of Construction; Stainless steel: (High Temp.)

Mounting Plate: Stainless steel

Probe bar: Stainless steel

Sensor Assembly: Stainless steel

Probe bar Support: Mounting Flange Plate and Threaded Rod w/nuts

Sensors Per Probe: 1 to 6 per Bar

Number of Probe bars per Transmitter: 1 to 4 (16 sensors maximum)

Operational Temperature: -20 to 200°F, (160°F for CPVC)

320°F maximum for high temperature

Weight: Function of probe configuration

Transmitter Electronics

Input: One to Sixteen sensors

Output: 4-20mA, fully isolated; 1-5VDC ; 2-10 VDC

Load Capability: 650 ohms

Voltage: 20-28VAC, 60 Hz

Power: 8 VA, .33 amps at 24 VAC

Probe bar Connections: Plug-in cable, Plenum Rated,10 ft. provided

(longer available as a special option)

Calibration: Adjustable from 0 to 7000 for ducts; 0 to 9000 for inlets

Operational Temperature: 0 to 140°F

Frequency Conversion Error: less than ±0.25% FS (8 sensors)

Temperature Error: less than ±0.5% over 25 to 125°F

Signal Damping: 2 or 4 seconds, selectable

Setup & Diagnostic Controls: Zero check, sensor check, Internal Cali

bration Standard: 122 Hz

Dimensions: 7.5" x 7.5" x 3.5" (WxHxD)

Weight: 5 lbs

Mounting: Surface mount for wall, duct, or panel

Chapter 1 Operation

6VORTEK Doc.# VT5 OM 050499, Rel. 2.1

Chapter 1 Operation

1.3 Operation of VorTektm Sensors

The VorTek Sensing system measures air velocity by a physical principle called

vortex shedding. The vortex shedding phenomena can be witnessed all around

us in everyday life. Swirling vortices, or eddy currents, are generated whenever

air or liquids flow around an obstruction in their flow path. Common examples are

the eddy currents which develop behind rocks in a stream, and in the fluttering of

a flag behind a flag pole. The flag and the flag pole provide the most visual ex-

ample of how vortex shedding works.

The flag pole presents an obstruction in

the path of the airflow, which is the wind.

As the wind passes around the flag

pole, vortices (eddies) are created in the

wake of the pole. These vortices, in

accordance with the laws of nature, are

developed and shed in an alternating

manner, from one side of the flag pole to

the other. The evidence of the shedding

of vortices is in the waving of the flag

itself.

Tek-Air’s unique VorTek flow sensors

use a trapezoidal shaped obstruction

placed in a small tube section to gener-

ate stable vortices over a wide range of

low velocities. Pressure sensors sense

the passing of individual eddies. Multiple

VorTek sensors are mounted on probe

supports to provide ample coverage of

the duct cross section.

AIR FLOW

Low Pressure

High Pressure

Pulse No Pulse

AIR FLOW

Low Pressure

High Pressure

Pulse

No Pulse

7VORTEK Doc.# VT5 OM 050499, Rel. 2.1

Chapter 1 Operation

1.4 Transmitter Operation

The enclosure located on the external end of each duct probe bar is the probe

electronics housing. It contains the electronics which sense the vortices gener-

ated by the VorTek probes. At the bottom of the enclosure is the electronic con-

nector required to connect each duct probe to the transmitter. A ten foot long

connecting cable is provided for each duct probe for this purpose.

The VorTek transmitter is capable of accepting inputs from as many as four probe

bars from one measuring station, each with a maximum of four VorTek sensors

each. Up to six sensors may be located on a single probe support bar but the

total number of sensors can not exceed 16.

In the simplest sense, the transmitter electronics can be considered a pulse

frequency-to-analog converter. The transmitter receives electronic pulses from

each of the VorTek sensors. As every pulse represents the same increment of

velocity, the pulses need only be summed together and integrated over time to

determine velocity. Additional circuitry converts the total pulses per second into

analog, 4-20mA signal which is proportional to either CFM or FPM.

The VorTek transmitter consists of a minimum of two circuit boards: the Amplifier

board and the mother board. The amplifier board performs the required signal

conditioning on up to eight VorTek sensor inputs. Either one or two amplifier

boards are provided depending on the number of probe bars used at the station.

The mother board accepts the conditioned pulses from the amplifier board(s),

sums them, integrates them, and converts them into a 4-20mA output signal. The

mother board also provides the power supply, calibration adjustments, internal

calibration standard, and circuitry to drive the optional digital display.

A “PROGRAM MODULE” is installed on the mother board and programs the unit

for the correct number of sensors required for the specific configuration. This

module “plugs-in” and can be changed easily for an alternate configuration if

required.

Because airflow is inherently turbulent, it tends to produce fluctuating electronic

output signals if not damped when high turbulence is present. Also, some com-

mercial direct digital temperature control systems update control outputs only on

changing input signals. The rapid input changes caused by airflow turbulence

can cause these types of systems to effectively overload and crash. To allow the

user to select the damping to meet his application, the transmitter includes a

switch-selectable damping constant of either 2 or 4 seconds.

8VORTEK Doc.# VT5 OM 050499, Rel. 2.1

1.5 Options

Many users prefer to have a digital display as a part of the transmitter. This type

of display is available as an option with the VorTek transmitter. A 3-1/2 digit dis-

play is available allowing a display of 0 to 1999 in either CFM or FPM, which is

specified by the customer at the time of purchase. Multipliers of either x10 or

x100 can be used to display up to 200,000 CFM.

2.0 INSTALLATION

The VorTek measurement system consists of two basic elements: the probes and

the transmitter. The VorTek probe bars are inserted into the duct and measure

the velocity of the air moving through the duct. The VorTek transmitter, which is

mounted in close proximity to the probes, converts the electronic pulses gener-

ated by the probes into an electronic signal compatible with most DDC control

systems.

The following details are provided on the mounting and installation of the VorTek

transmitter and flow probes. Please read this data carefully and install the equip-

ment in strict accordance with the instructions provided. Should you have any

questions, contact Tek-Air directly.

2.1 Probe Mounting and Location

2.1.1 Duct- Mounted Probes

(refer to drawings on pages A-2 thru A-4 of Appendix A)

General- VorTek probe bars are designed for installation in ducts, regardless of

the duct size. Usually, the larger the duct, the more sensing points are required to

provide an accurate measurement of airflow volume. In a typical application,

multiple probe support bars are directly inserted in the duct. Each probe bar has

multiple VorTek sensors for measurement of the air velocity in the area of the

duct it serves.

Turbulent Airflow- Probe design allows for installation in ductwork without the

requirement for special air straighteners. However, care should be taken to avoid

installation within close proximity to:

• Balancing dampers

• Modulating opposed blade dampers

• Non-airfoil type, parallel-blade dampers

• Elbows

• Transitions

• Humidifiers

• Coils

Refer to the drawing “Minimum Installation Requirements”, AppendixA, page A-1

for the minimum acceptable installation criteria for specific applications. If more

space is available, probe bars should be located so that they have two thirds of

the straight duct length upstream of the probe bars. Keep in mind that locations

other than those specified as minimums often have areas with very high turbu-

Chapter 2 Installation

9VORTEK Doc.# VT5 OM 050499, Rel. 2.1

Chapter 2 Installation

lence and reverse flow. Accurate airflow measurement is impossible in these

locations.

Direction of Flow- VorTek airflow probe bars must be mounted so airflow direc-

tion corresponds to the direction indicated by the flow arrow on the duct mounting

flange. Failure to mount the units properly will result in an erroneous or no flow

output. Probes can be mounted in any plane, vertical, or horizontal without effect-

ing the measurement quality. Sensors must be mounted straight in the airflow

stream.

Temperature- VorTek probes are designed for use in normal HVAC applications.

Continuous operation with temperatures over 200 degrees with standard materi-

als of construction is not recommended. Fume hood exhaust sensors with CPVC

construction have a limit of 180°. Close proximity to steam humidifiers and coils

is not recommended. Should a steam valve leak when air is not flowing, tempera-

tures in excess of the recommended maximum can occur. Moisture can also

cause incorrect readings.

Airborne Contaminants- Normal dirt and dust associated with air conditioning

applications will not effect sensor performance. The presence of agglomerating

or sticky particles can cause performance problems and should be avoided.

Should this occur, the probe bars can be removed for cleaning (see Appendix C).

Inspection- Carefully unpack and inspect the probes. If probes have been bent

or broken in shipment, advise Tek-Air immediately.

Installation- Probes are mounted across the duct and attach to the duct on both

sides. A 3 3/4" diameter hole should be located on the side of the duct where the

probe will be inserted. A 5/16" diameter hole is required in the duct wall on the

opposite side of the duct for probes longer than 12".

A sensor probe mounting plate is provided with a neoprene gasket and does not

require the application of special sealants. The flange plate should also not be

insulated to allow for easy removal if ever desired. See Diagram, Appenidix A,

PageA-2.

Largeducts need multiple Probe Barsso flow can be averaged.The barsshould be

spaced out on the same “plane” of the duct so the sensors are located to pick up

the flow. Refer to the A1, A2, A3,A4 (as required) dimensions on submittal schedule.

2.1.2 Fan Inlet- Mounted Probes

(refer to drawings on pages A-5 thruA-10 in Appendix A)

General- The VT-7000 Series Vortek Fan Inlet Probes are in pairs of bars for

each inlet. For single-inlet fans, one pair is provided. For double-inlet fans, two

pairs are provided. One Transmitter serves all bars in the one or two-pair set. On

bars sized for fan inlet diameters of 24" I.D. or less, the bar electronics are

mounted in an enclosure which mounts separately from the bars and is perma-

nently connected to the bars via flexible non-metallic conduit. On bars sized for

fan inlet diameters greater than 24" I.D., the bar electronics are housed in enclo-

10VORTEK Doc.# VT5 OM 050499, Rel. 2.1

sures which are mounted in the center of each bar. In both cases the bar elec-

tronics connect to the Transmitter via prefab cables, which are factory-connected

to the bar electronics enclosures.

Direction of Flow- The probes must be positioned so that they face into the

airflow: the Safety Cables on the ends of the bars leading out of the fan inlet bell,

and the mounting brackets facing back into the fan inlet bell. On bars for fan

inlets over 24" I.D., the bar electronics controller has an airflow direction label

affixed to it for your convenience.

Mounting the Probe Bars- Hold the bars in place as shown in the drawing

(choose the drawing that matches the fan type which you are working with).

Make sure the bars are positioned as described above. Mark, on the inlet bell

surface, the mounting hole locations of the brackets on the ends of the bars.

Remove the bars from the inlet and drill pilot holes for #14 self-tapping screws

where you marked them.

Remove the brackets from the ends of the bars (be careful not to lose the bolts,

nuts and Safety Cables). Screw the brackets to the inlet bell surface using thread

locking compound and #14 self-tapping screws.

Re-attach the bars to the installed mounting brackets, being careful to face the

bars in the correct direction, and to re-attach the Safety Cables as they were

before. Tighten the NyLok nuts on the bar mounting bolts sufficiently to prevent

loosening of the nuts through vibration. Note: If a screw, nut, or bolt is stripped,

replace it with the same type fastener. If a drilled pilot hole is stripped, DRILL

ANOTHER HOLE and move the probe according.

DO NOT USE STRIPPED HOLES OR FASTENERS AS DAMAGE TO THE

PROBESAND FAN CAN RESULT FROM PROBES COMING LOOSEAND

BEING DRAWN INTO THE FAN WHEEL!

Stretch the Safety Cables outward from the bars towards the outside of the fan,

leaving no slack in the cable. The eyelet on the end of the cable must be

screwed to a sturdy, metallic surface such as the bell, fan casing, or bearing

support. Mark where you intend to srew the eyelets, and drill #14 self-tapping

screw pilot holes. Using thread locking compound and #14 self-tapping screws,

screw the eyelets down, tighening the screws sufficiently to prevent loosening

due to vibration, but DO NOT STRIP THEM!

Run the cables out to where the Transmitter will be mounted, leaving sufficient

slack to allow easy plugging and unplugging of the cables into the transmitter

receptacles.

2.2 Transmitter Mounting and Location

General- The transmitter is typically located in close proximity to the duct inser-

tion probe bars and transmits a 4-20mA signal over long distances to the custom-

ers control system.

Transmitter Location- The VorTek transmitter is small and designed for mount-

Chapter 2 Installation

11VORTEK Doc.# VT5 OM 050499, Rel. 2.1

Chapter 3 Startup Adjustments

ing either on the duct or on a wall, column, or other support close to the point of

measurement. The transmitter housing is a general purpose enclosure and is

therefore not designed for mounting outdoors or in areas requiring explosion-

proof classification. For outdoor use, a Nema 4 enclosure can be purchased as

an option. For installation in explosion-proof areas contact factory. Areas where

the temperatures are expected to exceed 125°F for extended periods of time are

to be avoided.

2.3 Probe and Transmitter Connection

Probe Connection- Ten foot connecting cables are provided for each insertion probe.

This cable has a shielded 8 pin connector from the probe electronics enclosure and is

plugged into either connector on the bottom of the transmitter.

12

34

CABLE CONNECTORS

CONDUIT ENTRY

TRANSMITTER

Probe Cable Connection Points

Figure 1

Probes should be plugged in to the transmitter in numeric sequence (ie. 1, 2, 3, 4). If one

probe is used it should be plugged into connector 1. If three probes are used they should

be plugged into connectors 1, 2, and 3. It is not important however which probe is plugged

in to a particular connector. After connectors have been plugged in it is advisable to an-

chor them with tie wraps.

2.4 Transmitter Wiring

Terminations- Inside the transmitter on the bottom right are two pairs of terminals. The

left most pair are the signal output terminals. (See Fig. 3) The right most are for 24VAC

Power input. Transmitter power is 24 Volts AC, 8VA maximum current. Power may fluctu-

ate ±20% without effect.

Signal and power wiring can be run in a common shielded cable or separately. If run

separately, signal cable should be shielded. In either case, shields should be tied to the

input device (controller) common and taped back on the other end. (See Fig. 2) Typically,

shields are terminated at the controller.

Output Signal- Transmitter output is 4-20mA and is capable of driving up to 650 ohms of

load. Control equipment which accepts voltage inputs can be accommodated with internal

jumpers that will generate a 1-5VDC output or a 2-10 VDC output. SEE DRAWING ON

NEXT PAGE.

12VORTEK Doc.# VT5 OM 050499, Rel. 2.1

24 VAC

POWER

- +

4-20ma

OUTPUT

INPUT

+ -

24VAC

POWER

SHIELD Tape Back Drain Line

at Transmitter &

Tie to Controller Common

CONTROLLER COMMON

Transmitter Power and Signal Wiring

Figure 2

3.0 STARTUP ADJUSTMENTS

3.1 General Description

The VorTek airflow transmitter has several modes of operation which are deter-

mined by setting the four position DIP (Dual Inline Package) switch located on the

upperright cornerof the motherboard.This switchis utilized foradjusting thedamp-

ing, transmitter zero check, and quick calibration check.In addition to this switch,

potentiometers are available for adjusting Transmitter Zero, Full Scale, Frequency

Offset, and digital indicator output. See Figure 3 below.

Chapter 3 Startup Adjustments

Figure 3 - Vortek Mother Board, (left); VorTek mother board showing Amplifier board installed (right).

POWER

DISPLAY

OUTPUT

SETUP

DIP

PROGRAM

MODULE

PROBE BAR INPUTS

SIGNAL

JUMPERS

AMPLIFIER

BOARD

MOTHER

BOARD

RIBBON

CABLE

ZERO

SPAN

OFFSET

DISPLAY

TP5

TRANSFORMER

TP1

ZERO

SPAN

OFFSET

DISPLAY

DISPLAY

OUTPUT

SETUP

DIP

PROGRAM

MODULE

SIGNAL

POWER

JP1 (3-pin)

THRESHOLD POT.

MOTHER

BOARD

JP2 JP3

TRANSFORMER

TP5

TP1

13VORTEK Doc.# VT5 OM 050499, Rel. 2.1

Chapter 4 Calibration and Maintenance

Transmitter output checks can be made by connecting a voltmeter set for DC

milliamps, in series as follows;

24VAC

2.34

- + + -

+

-

SIGNAL WIRES

SIGNAL POWER

DVM

Figure 4

3.2 Normal Operation

In order for the transmitter to function properly as a flow measurement device the DIP

switch must be set as follows;

DIP 1 On or Off

DIP 2 On

DIP 3 On

DIP 4 Off

3.3 Damping Adjustment

Dampingcanbesetby using DIP switch number 1. With switch one in the “on” position minor

damping is in effect. With switch one in the “off” position the normal damping is doubled.

3.4 Zero Check

Transmitter zero output (4-20mA) can be simulated by setting DIP switches 2, 3, and 4

as follows, and removing the probe connectors from the bottom of the transmitter;

DIP 1 On or Off

DIP 2 Off

DIP 3 Off

DIP 4 Off

With the voltmeter set for milliamps and connected in series (See fig. 4) with the 4-

20mA output, the zero-flow output can be adjusted by utilizing the zero calibration

potentiometer. At these settings the meter should read 4mA. Reinstall the probe con-

nectors when complete. Remember to return DIP switches to normal operation or

continue on to Quick Calibration Check.

14VORTEK Doc.# VT5 OM 050499, Rel. 2.1

3.5 Quick Calibration Check

Transmitter calibration can be checked quickly by setting DIP switches 2, 3, and 4 as

follows, and then removing the probe connectors from the bottom of the transmitter;

DIP 1 On or Off

DIP 2 Off

DIP 3 Off

DIP 4 On

The proper output of the transmitter can be established by making the following calcula-

tion. Full scale Hz data can be obtained from the transmitter label on the front door;

Expected mA= [16*(122/Full Scale Frequency Hz)]+4

If the value observed does not agree with the value expected, ±0.5% full scale, then the

transmitter may require recalibration. The use of this internal frequency standard for

calibration of full scale values is possible but will not be as accurate as calibration using

a frequency generator set at full scale Hz.

3.6 Threshold Adjustment

The threshold adjustment is normally made on a calibration bench. However, the thresh-

old can be set empirically in the field by following the procedure in section 4.2. The

threshold adjustment serves to limit the lower operating limit of the transmitter to in-

crease sensitivity at low flow conditions.

Threshold is factory set at a point equivalent to 350 FPM. Below this level the threshold

circuit forces the output to go to 4.0 ma. Lowering the threshold below 350 increases

chances that the transmitter may show flow when none is present if a high ambient

noise condition is present.

The threshold should only be adjusted if the transmitter indicates flow when in fact there

is none present. Before adjusting, check to see that zero is properly adjusted. Then,

with no flow in the duct, turn the threshold adjustment clockwise until the transmitter

indicates 4 ma.

4.0 CALIBRATION & MAINTENANCE

4.1 Field Calibration

The VorTek transmitter comes calibrated for the CFM or FPM specified by the customer.

The calibration factor is established as a function of the type of VorTek sensor utilized in

the construction of the probe bars. These calibration factors are established by test and

represent flow conditions expected when normal Minimum Installation Requirements are

observed. (See Appendix A, page A-1)

When these conditions are not present and duct turbulence is a problem, corrections

may be required to match flow transmitter output to readings observed by traverse. In

these cases transmitter span can be adjusted to read the desired output. Adjustment of

transmitter span will not effect transmitter zero.

Chapter 4 Calibration and Maintenance

15VORTEK Doc.# VT5 OM 050499, Rel. 2.1

For best results, a traverse should be done with the airflow at a fixed CFM. This can be

done by: Fixing the output to the damper/valve which throttles the air in that duct, or by

removing the output to the valve/damper, and keeping all doors closed in the area that

is affected by this airflow.

The CFM reading can then be compared to the transmitter output. Amilliamp meter

should be connected in series with the output signal wires. (refer to figure 4 on page 11).

The reading will fall between 4 and 20 mA. Use the formula below to convert the mA

value to the equivalent CFM. The transmitter Full Scale CFM can be found on the

transmitter enclosure.

Current Transmitter CFM Value = [Full Scale CFM/16]*(milliamp reading - 4)

If the transmitter CFM reads differently than the traverse, then an adjustment can be

made. If there is a front end system receiving the control signal. Amultiplication con-

stant should be added to the scaling formula to agree with a balancer reading. If this is

not possible, the transmitter itself can be adjusted. First calculate the corresponding

milliamp value which matches the traversed CFM with this formula:

New desired mA value = [(traversed CFM/Transmitter Full Scale CFM)* 16]+4

Turn the span potentiometer (see figure 3) clockwise to increase the mA signal, counter

clockwise to decrease the signal, until the desired mA signal is output.

4.2 Bench Calibration

Full transmitter calibration is normally calibrated at a bench, although it is possible to

bring the bench calibration instruments to the transmitter in the field. Connect a digital

voltmeter to the transmitter as shown in figure 4. Afrequency generator is required and

can be used in conjunction with a Multi-meter. The full procedure is as follows.

Set Zero- Set switches 2, 3, and 4 to “OFF”. Adjust the “ZERO” potentiometer until 4.00

mA is read on the digital voltmeter.

Set Full Scale- (see figure 5, next page) Set switches 2, 3, and 4 off. Connect the

negative lead of the frequency generator to TP 1 on the mother board (next to the wire

connectors). Connect the positive lead to TP 5. Set the generator to the full scale Hertz

indicated on the label fixed to the transmitter enclosure. Set the frequency generator to

sinusoidal

wave and the output voltage to the minimum level.Adjust the span potenti-

ometer until the output reads 20.0 mA. Turn the span potentiometer clockwise to in-

crease the mA signal, counter clockwise to decrease the signal.

Set Optional Display- With the above connections and settings in place from the

previous step, adjust the “DVM” potentiometer to read the appropriate scale display

value. As the maximum display is 1999, a multiplier of x10 or x100 may have to be

utilized to get the total CFM display.

Threshold Adjustment- With the above connections and settings in place from the

previous step, set the frequency generator to approximately 60 Hz. Turn the “THRES”

potentiometer clockwise until the transmitter output switches to 4 ma. Then, slowly turn

the “THRES” adjustment counter clockwise until the output switches back to a reading

other than 4 mA. Threshold is now set.

Return To Service- Return switches 2 and 3 to the “ON” position prior to returning the

unit to service.

Chapter 4 Calibration and Maintenance

16VORTEK Doc.# VT5 OM 050499, Rel. 2.1

4.3 Offset Adjustment

The tag on the transmitter enclosure may have two separate values for frequency; Full

scale Hz and Span Hz. If this is the case, the transmitter was factory calibrated with an

offset. To set the offset, follow the set up procedure in 4.2 first. Next turn the offset

potentiometer (see figure 5) counter clockwise all the way. Now input the span fre-

quency to the transmitter, and adjust the span potentiometer until the output is 20.0 mA.

Next input the Full Scale frequency. The mAoutput will go up. Turn the offset potentiom-

eter clockwise until the output is 20.0 mA again. The adjustment is complete.

4.4 Calibration Check

1. Follow the setup instructions shown in section 4.2 (in the “Set full scale” section) of

the manual.

2. The check should include 3 points: 1/2 full scale frequency, 3/4 full scale frequency,

and the full scale frequency. Input these frequencies using the method in “Set full

scale”. The transmitter output will be 12 mA, 16 mA, and 20 mArespectively.

3. If the calibration does not match the above, recalibration will be required. The cali-

bration should match the entire range of operation. If it agrees at the maximum fre-

quency but not in the center, there may be a problem with the way the unit is configured.

It is likely that jumper JP 1 is not set properly. It should be in the down position if full

scale frequency is greater than 600 Hz.

4.5 Wave form check with an oscilloscope

Voltage Input - See figure 5, below. Set up the oscilloscope to read wave forms clearly

on the screen. To check the power input, set the scope to read 24VAC. Touch the

negative test lead to either screw in the power wire connector (A), and the positive lead

to the other screw. The screen should read 60Hz.

Connect the negative lead to the test point 1 (TP1) (B) on the mother board. Connect

the positive lead to one of the exposed metal jumpers (C) on the amplifier board. A

clean, square wave should appear, and the numerical frequency value should not

bounce more the 20% for a good signal. Check each of the thin metal jumpers and read

the values. The average frequencies of the jumpers should be fairly close in value. If

there are two amplifier boards on top of the mother board, the top amplifier board must

be removed.

POWER

DISPLAY

OUTPUT

SETUP

DIP

PROGRAM

MODULE

PROBE INPUTS

SIGNAL

JUMPERS

SUMMI NG

BOARD

MOTHER

BOARD

RIBBON

CABLE

ZERO

SPAN

OFFSET

DISPLAY

TP5

TRANSFORMER

TP1

ZERO

SPAN

OFFSET

DISPLAY

DISPLAY

OUTPUT

SETUP

DIP

PROGRAM

MODULE

SIGNAL

POWER

JP1 (3-pin)

THRESHOLD POT.

MOTHER

BOARD

JP2 JP3

TRANSFORMER

TP5

TP1

Figure 5 - Vortek Mother Board, (left); VorTek mother board showing summing board (right).

A

B

C

Chapter 4 Calibration and Maintenance

17VORTEK Doc.# VT5 OM 050499, Rel. 2.1

Chapter 4 Calibration and Maintenance

4.6 Trouble Shooting

The following flow charts are designed to aid in trouble shooting the transmitter

and flow sensors should problems be experienced in commissioning the airflow

measurement system.

No Signal

Output

24VAC

Present

Output

Polarity Correct?

No

_

Output

w/signal lines connected

Output w/signal lines

Disconnected

Correct

Power

(Maintain Polarity)

Correct

Polarity

Contact

Tek-Air Systems

for Assistance

Correct possible signal

transmission line problems

a. Open Circuit

b. Loop resistance above 650 Ohms

c. Short to ground in “+” wire

Yes

Yes

Yes

No

No

No

Output Signal

always at 4mA

Flow Above

350 FPM with

Linear Profile?

DIPs

Set to Operate?

Probe Cables

Plugged in?

Establish

Flow in Duct

Set as Follows:

1-Either ON or OFF

2-ON

3-OFF

4-OFF

Plug in

Cables

Contact Tek-Air Systems

for Assistance

Yes

Yes

Yes

No

No

No

Probes in

Backwards?

No

Yes Reinstall in

Proper Direction

18VORTEK Doc.# VT5 OM 050499, Rel. 2.1

Chapter 4 Calibration and Maintenance

High or Constant

Output, Output

w/No

_

Flow Present

in duct (verified)

DIPs

Set to Operate?

Unplug Cables,

4mA?

Set as Follows:

1-ON or OFF

2-ON

3-ON

4-OFF

Plug-in Cables

Place Unit in

Operation

Contact

Tek-Air Systems

for Assistance

Yes

Yes

Yes

No

No

Probes

mounted in duct

Backwards?

No

Yes

Reinstall in

Proper Direction

Check Zero

(Section 3.4)

4mA?

No

Large Difference between

actual Measured CFM &

Vortek indicated CFM

Yes

Yes

No

No

Probes in

Proper Location?

Set as Follows:

1-Either ON or OFF

2-ON

3-ON

4-OFF

DIPs

Set to Operate?

Relocate probes; refer to

Appendix 1, Page A-1

Unit may be out of calibration.

See section 4.1, Field Calibration

19VORTEK Doc.# VT5 OM 050499, Rel. 2.1

20VORTEK Doc.# VT5 OM 050499, Rel. 2.1

Appendices Appendix A

2X 5X

4X 3X

General Notes

X = Average Duct Dimension

Dampers

Duct Transitions

Fans

Angle Fittings

Centrifugal Inlet Centrifugal Discharge Vane-Axial Discharge

Elbows

Sweep

2X

90°Vaned

2X X

X

Duct Take-Offs

Hoods

Formulas

>15°

<15°

(12" Min)

Not

Recommended

5X

2X

6X

2X 2X

2X

30°

X

30°2X

2X

3X Bell Transition

D = Diameter H = Height in InchesW = Width in Inches

Rect. Duct Area = W x H

144

Circ. Duct Area =

π

x

144

D

2

2Design CFM

Duct Area

Design Velocity =

Duct Velocity

3020

2

Oval Duct Area = 2

H+ ((W - H) x H)

2

144

π

x

Probe Velocity

Pressure =

Engineering Department

43 Beaver Brook Road

Danbury, CT 06810

(203) 791-1400 Phone

(203) 798-6534 Fax

VorTek

Airflow Measuring Probes

Minimum Installation Requirements

& Formulas

Revision Letter: A Dwg. No:

Revision Date: 4/21/97

Filename: VT-MIN.CDR

Drawn By: GV

A-1

This manual suits for next models

1

Table of contents

Popular Measuring Instrument manuals by other brands

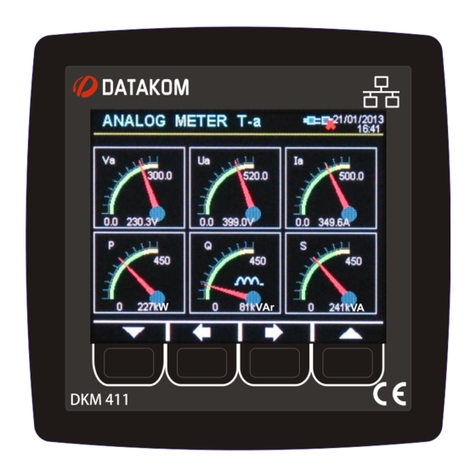

Datakom

Datakom DKM-411 quick start guide

KROHNE

KROHNE OPTIWAVE 7300 C quick start

Bühler technologies

Bühler technologies 222 AMEX Series Installation and operation instruction

AEMC instruments

AEMC instruments SL261 user manual

Nic

Nic EMP-2 Simplified manual

HYDAC International

HYDAC International AquaSensor AS 8000 Series operating manual