Toshiba TS2000 User manual

Other Toshiba Controllers manuals

Toshiba

Toshiba G3 Plus Pack User manual

Toshiba

Toshiba BMS-CT5121E User manual

Toshiba

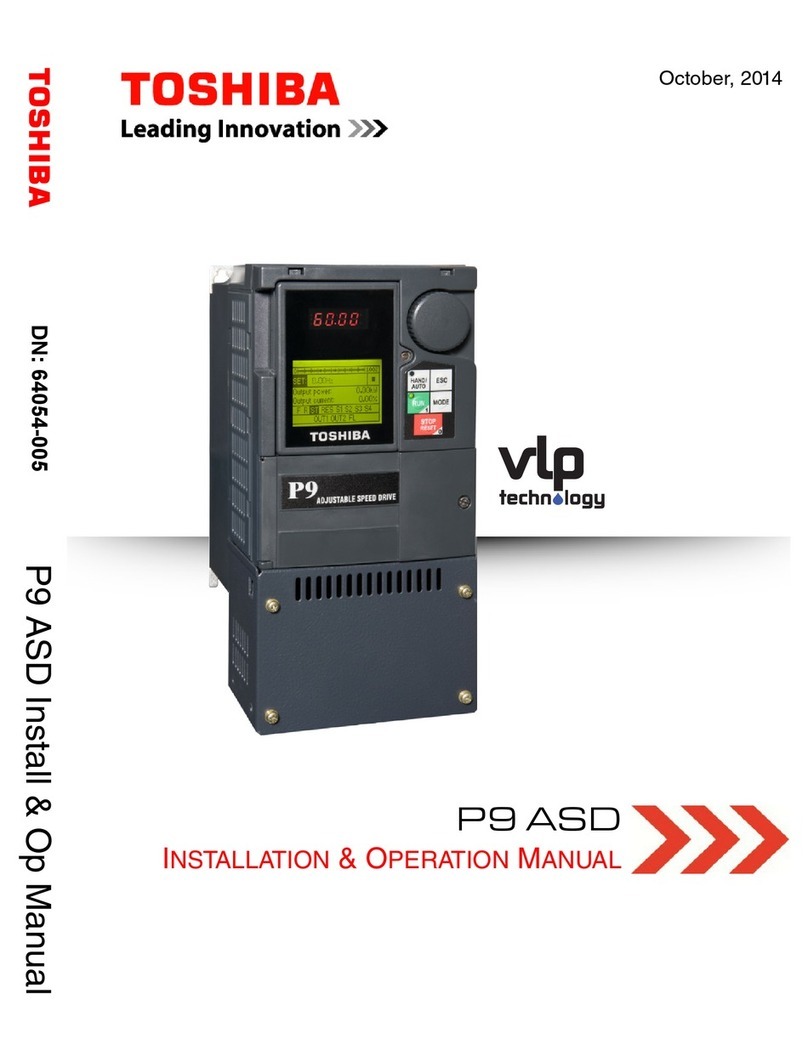

Toshiba P9 ASD User manual

Toshiba

Toshiba V Series User manual

Toshiba

Toshiba nv Series User manual

Toshiba

Toshiba RBC-MTSC1 User manual

Toshiba

Toshiba Vm Series User manual

Toshiba

Toshiba V Series User manual

Toshiba

Toshiba TS2000 User manual

Toshiba

Toshiba EX500 User manual

Toshiba

Toshiba V Series User manual

Toshiba

Toshiba nv Series User manual

Toshiba

Toshiba V200 Series User manual

Toshiba

Toshiba V Series User manual

Toshiba

Toshiba TSL3000E User manual

Toshiba

Toshiba TOSVERT VF-S15 series User manual

Toshiba

Toshiba 2000 User manual

Toshiba

Toshiba ME00070B User manual

Toshiba

Toshiba GX9 User manual

Toshiba

Toshiba TDP T3 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions