Tekneka 170 User manual

OIL TESTER MANUAL

TEK170/en_V0.1

1

Table of Contents

2.Safety .....................................................................................3

3.Technical Specication.............................................................. 4

4.Measurements.......................................................................... 5

4.1 The Effect of Additives............................................................ 5

4.2 Contrast with Laboratory Methods............................................ 5

4.3 Measuring............................................................................. 5

4.4 Start Measuring...................................................................... 6

4.5 Please follow the points below to get the most accurate results 6

in the meaurement ................................................................. 6

5. Conguration Mode.................................................................. 6

6. Conguration Options...............................................................7

7. Set the high and low alarm.........................................................7

7.1 Set the TPM alarm...................................................................7

8. User calibration....................................................................... 8

9. Restore Factory Settings........................................................... 8

TEK170/en_V0.1

The Tekneka 170 is a deep-frying oil tester that helps you determine the quality of frying oil with

a measuring range of 0 to 40% TPM. It can also measure temperatures from 30 to 200°C (86 to

392°F). This deep-frying oil tester has an LCD screen that shows both the total polar material

(TPM) value and temperature. You may evaluate the cooking oil’s age and quality using the TPM

valve. The quality deteriorates over time due to the effects of heating. The TPM value measures

the level of thermal-oxidative stress in frying oil, and the multi-color LED indicator directly shows

the oil quality.

OIL TESTER MANUAL

2

1. Introduction

OIL TESTER MANUAL

TEK170/en_V0.1

Please read this manual carefully and completely before you use the device for the rst time. Only

trained personnel may use this device, and only they may repair it. Our liability is disclaimed, and our

warranty does not apply to damage or injuries brought on by a failure to follow the manual.

• The device must only be used as described in this instruction manual. If used otherwise, this can

cause dangerous situations for the user and damage to the meter.

• The instrument may only be used if the environmental conditions (temperature, relative humidity,

etc.) are within the ranges stated in the technical specications. Do not expose the device to extreme

temperatures, direct sunlight, extreme humidity, or moisture. The device is intended for indoor use.

• Before the measurement, the device should have stabilized at ambient temperature, which is import-

ant when moving from cold to warm rooms and vice versa.

• Do not expose the device to shocks or strong vibrations.

• The case should only be opened by manufacturer/qualied personnel.

• Before making a measurement, make sure the device is entirely closed.

• Never use the instrument when your hands are wet.

• You must not make any technical changes to the device.

• The appliance should be cleaned with a damp cloth after each use. Use only pH-neutral cleaner, no

abrasives or solvents.

• The device must only be used with accessories from TEKNEKA or equivalent.

• When the frying oil tester is not used for a longer period of time, remove the batteries.

• Do not store the meter together with any chemicals.

• Before each use, inspect the case for visible damage. If any damage is visible, do not use the device.

• Wear your personal protective equipment during each measurement to avoid injury. This also applies

to other people near the measuring location as oil splashes can cause serious injury to human skin

and eyes.

• To avoid burns, never touch the sensor or the metal shaft directly after the measurement as these

parts can become very hot when they are immersed into hot oil

• Remove the oil quality meter from the oil when you leave the place.

• Do not use the instrument in explosive atmospheres. Also avoid proximity to explosive, easily am-

mable or chemical substances when the sensor is hot.

• Only use the device in systems that are electrically tested on a regular basis. Never connect the

conductive metal parts of the meter with a source of voltage. Inspect the system visually before each

measurement. If there are any signs of damage, do not carry out any measurements until the problem

has been resolved.

• The measurement range as stated in the specications must not be exceeded under any circum-

stances.

• Non-observance of the safety notes can cause damage to the device and injuries to the user.

3

2. Safety

TEK170/en_V0.1

We do not assume liability for printing errors or any other mistakes in this manual.

Weexpressly pointtoour generalguaranteeterms, whichcanbe foundinour general termsofbusiness.

the end of this manual.

Function Parameters

Temperature measurement 30 to 200°C/ 86 to 392°F

Accuracy ±1.5°C

Resolution 0.1°C

TPM Measurement 0 to 40% polar fractions

Accuracy ±3% (@30 to 90°C)

Resolution 0.1%

Display LCD, 3 digits

Response Time <30s

Alarm Function LED (Green, Blue & Red) and beep alert

Protection Rating IP68

Temperature sensor PTC sensor

Oil Sensor Capacitive Sensor

Operating Temperature 0 to 50°C

Storage Temperature -20 to 70°C

Material ABS

Measurable oils rapeseed oil, olive oil, soybean oil, peanut oil, sesame oil and

palm oil, as well as other vegetable oils or animal fat

Power Supply 2 x 1.5V AAA battery

Lifetime about 25 hours of continuous usage (500 measurements)

Dimension 365x48x31mm

Weight 185g

OIL TESTER MANUAL

4

3. Technical Specication

OIL TESTER MANUAL

TEK170/en_V0.1

• Oil testers can achieve rapid continuous measurement, so after the completion of a measurement,

without waiting for the next direct measurement, they can carry out another.

What kind of oil I grease can this instrument apply to?

• In principle, all frying oils and lipids can be measured. such as rapeseed oil, soybean oil, sesame

oil, palm oil, olive oil, peanut oil, and other vegetable oils.

• Animal fat can also be measured. Depending on the type of grease, the TPM value of the fresh oil

will uctuate by a few percent, and the maximum use time of the frying oil is different.

For example, fresh palm oil has a higher % TPM value than other oils, but its aging is much slower

than that of other oils.

Oil Tester is designed for the measurement of pure oil/fat products. If additives are used, the results

may be offset.

• Frying oil is a mixture of different polar substances. In the process of aging of frying oil, the num-

ber of high polarity ingredients will increase. Laboratory chromatography can distinguish between

polar and non-polar materials, the content of the total component of the frying oil ls dened as

% TPM (total polar group Minute).

• The value of the% TPM measured may produce subtle changes by the column method due to the

setting of the polar component and the non-polar component boundary.

• Depending on the type of grease, the polarity of the polar and nonpolar components may also

produce subtle changes. But the change in the column method is not recognized.

• On the other hand, Oil Tester can measure the entire polarity of the frying oil and thus get the

actual polar component and the nonpolar component. Therefore, in some measurements.Oil

Tester measured values may be higher or lower than the results of the column method.

For example, coconut oil, Oil Tesrer on ils measured TPM value higher than the column method, this

oil is not suitable for deep frying, mainly suitable for a short panic frying pan.

• Free Fatty Acids (FFA)

The oil Tester measures the total amount of polar components in the frying oil evaluate the deteri-

oration of oil after deep frying. While free fatty acids are used to determine the degree of aging of

the grease at room temperature after long-term storage, the indicators are not suitable for judging

the fry of oil esh. oil Tester is not used to measure free fatty acids.

• Polymerized triglycerides (PTG)

Polyglycerol is increasingly being used to assess the quality of frying oil. The measurement results

of this method can be proportional to% lPM values in most cases.

PTG ≈ % TPM/2 5

4. Measurements

4.1 The Effect of Additives

4.2 Contrast with Laboratory Methods

4.3 Measuring

TEK170/en_V0.1

1. Press the Power [ ] button and release It.

2. The temperature bar shows “LO”

3. TPM measurement shows - - -

4. Press the HOLD button in the measurement mode to activate the HOLD mode

5. The temperature bar ashes “HI” to indicate that the measured temperature is above the range.

6. The temperature bar ashes “LO” to indicate that the measured temperature is below the range.

• Turn off the induction frying pan during the measurement because the electromagnetic eld will

affect the measurement result.

• Remove the fried objects from the frying oil in the measurement and wait for 5 minutes.

• Clean the probe before each measurement or before the next continous measurement

• Try to avoid touching metal objects, such as frying baskets, pots, because these things can affect

the measurement results, and the minimum distance from the metal should be at least 1 cm.

• Uneven oil temperature in the frying oil may cause a measurement error. Please stir the instrument

in the frying oil.

• If the measurement results are suspected to contain an error due to water inclusion:

Please repeat the measurement after 5 minutes (do not fry during this period). If the new reading

goes low, measure it again after 5 minutes until the reading is stable.

• Please replace frying oil when 24% TPM is reached. Refer TPM limits as per your county regula-

tion/standards. Be sure to replace frying oil before reaching limit.

• We recommend that you wear your hand strap while using this instrument to prevent the instrument

from slipping.

Turn on the instrument and press [Hold] and [◄] at the same time at least 3 s while instrument is under

test mode

1. Units changing °C or °F

• Use [◄] or [ ►] to set the temperature unit (° C / °F).

• Press [Hold] to conrm the set temperature unit.

2. Audible Alarm (ALA) mode

• Press [◄] or [ ►] to turn ON or OFF the buzzer alarm.

• Press [Hold] to conrm.

3. Auto Power Off (APO) mode

OIL TESTER MANUAL

6

4.4 Start Measuring

4.5 Please follow the points below to get the most accurate results

in the meaurement

5. Conguration Mode

OIL TESTER MANUAL

TEK170/en_V0.1

Conguration Options

Shift Temperature Units select °C or °F

Audible Alarm Sound (ALA) on: enable sound alarm (beep)

off: disable alarm

Device Auto Power Off (APO) on: select to enbale APO

off: disable APO

LED Light ash (LEO) on: LED ash indication (Green,Blue,Red)

off: disable LED ash

Perform Calibration (CAL) on: perform calibration

off: disable calibration mode

Factory Reset (RST) on: enable factory reset

off: disable RST mode

Display backlight (BL) on: enable display backlight option

off: disable BL mode

1. Turn on the instrument Press and hold [◄] for at least 3 seconds in the test mode, it enters the

high alarm setting, and the LED turns into RED.

2. Then click or press [◄],[ ►] to set the high & Low limits

3. Click [Hold] to save and exit. Click [ ] power to exit only

• Press [◄] or [ ►] to enable or OFF Auto power off option

• Press [Hold] to conrm.

1. LED colour code indication (LEO) mode

• Press [◄] or [ ►] to turn the LED on or off.

• Press [Hold] to conrm.

2. Device Calibration (CAL) mode

• Press [◄] or [ ►] to turn on or off to enter calibration mode.

• Press [Hold] to conrm.

3. Display backlight (BL) option

• Press [◄] or [ ►] to turn the backlight ON or OFF.

• Press [Hold] to save and exit.

Press the power [ ] key in conguration mode to save the congurations and exit

7

6. Conguration Options

7. Set the high and low alarm

7.1 Set the TPM alarm

TEK170/en_V0.1

1. Heat the calibration oil to about 50°C.

2. After entering the user calibration immerse the sensor into the calibration oil, pay attention to the

depth of invasion.

3. When the TPM value shown in the table is stable, short press [◄] or [ ►] to increase /decrease

the measured value by increments 0.5 %TPM

4. When the displayed TPM value matches the value of the calibration oil, short press [Hold] to save

the user calibration value

1. After entering the factory settings, the screen displays RST.

2. Press the [ ►] and [Hold] keys simultaneously to reset the user calibration data to the factory

settings.

If the instrument is overheated, it may cause a risk of burns (probe and probe rod)

• Do not touch the hot parts on the instrument.

• Allow the instrument to cool before cleaning.

• If you are burned, immediately rinse the wound with cold water. If necessary, to see the doctor

health.

• Use a clean cleaner, standard water or soapy water.

• Clean the probe gently with a soft paper towel or rinse it in water.

• Wipe dry the probe with a soft paper towel

Interpretation of the measured values % TPM LED Flash

Oil is new and good to use 0 ... 18.5 % GREEN

Oil quality classied as critical

It is recommended to renew the oil partly or completely.

19 ... 24 % BLUE

The oil in the fryer should no longer be used. If the set thresh-

old value has been exceeded, it will ash RED colour code.

The oil must be change/rell the oil completely.

>24 %

(default setting: 24 %)

RED

OIL TESTER MANUAL

8

8. User calibration

9. Restore Factory Settings

Warning

Copyright © 2023 Tekneka, Canada.

All rights reserved including the right of reproduction in whole or in part in any form

www.tekneka.com

TEK170/en_V0.1

Table of contents

Popular Test Equipment manuals by other brands

MARTINDALE

MARTINDALE RC2000 instruction manual

Andatech

Andatech AlcoSense SURETY user manual

pizzi instruments

pizzi instruments Portable Readout Unit user manual

Phenix Technologies

Phenix Technologies PAD56 Operation and application manual

Megger

Megger MIT415 user guide

System Sensor

System Sensor RTS451KEY Installation and maintenance instructions

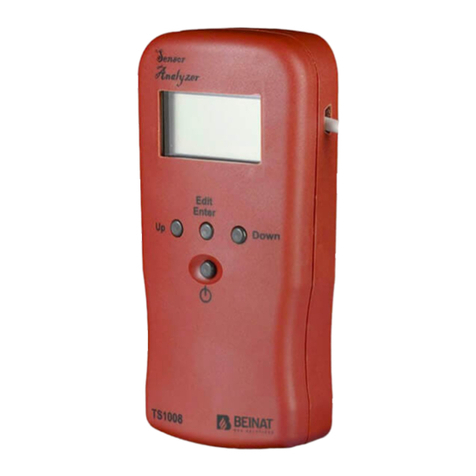

BEINAT

BEINAT TS1008-V1 USER GUIDE AND MAINTENANCE

Gossen MetraWatt

Gossen MetraWatt AT3-III E operating instructions

BC Group International

BC Group International BC Biomedical ULT-2020 Series user manual

Vaisala

Vaisala PTB210 SERIES user guide

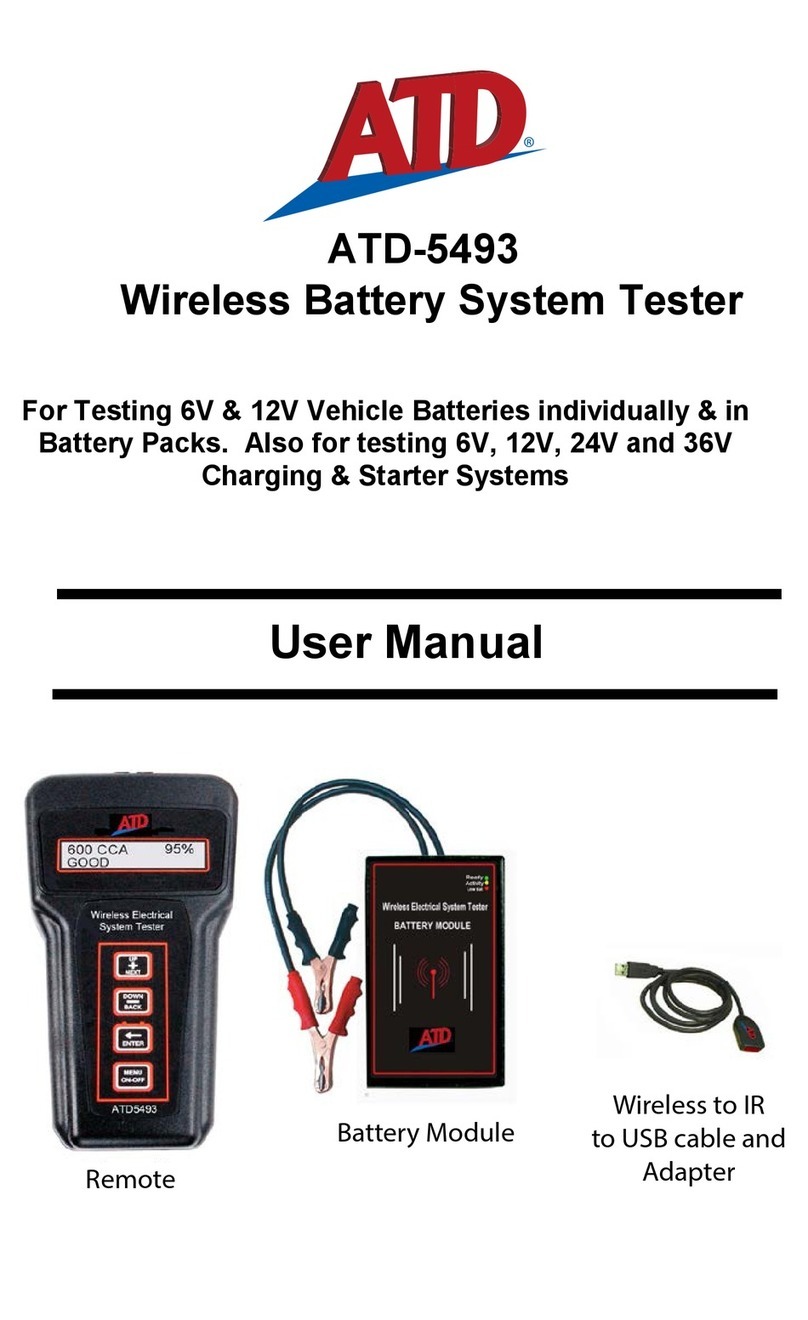

ATD Tools

ATD Tools ATD-5493 user manual

Monarch

Monarch Nova-Strobe BBX instruction manual