-4-

2. DESCRIPTION

The Digital RCD Tester is ideally suited for the testing of

Residual Current Protection Devices, in compliance with the 17th

Edition of the IEE Wiring Regulations.

The tester is designed to test the most common RCDs in use,with

a selector switch providing Fast, I and ½ Trip current settings.

The Fast setting provides 150mA trip current for RCDs not

exceeding 30mA. The I setting provides full rated trip current,

which should cause the RCD under test to trip.The ½ setting

provides half the rated trip current whereby the RCD should not

trip.

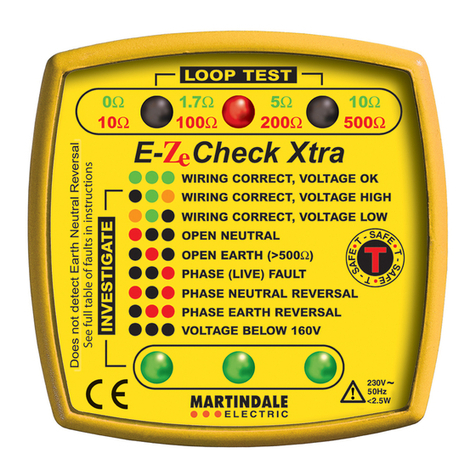

Other features include a polarity switch with 0° and 180°settings

which permits a test cycle to commence with a positive or

negative going wave form from the zero cross-over point. The

facility to establish whether the system under test is correctly

wired is provided by means of neon lamps and monitoring of the

voltage present on the earth terminal.

The instrument has thermal and fuse protection. The thermal

protection provides a time delay between tests, which will vary

with the range of model. When the time delay is in operation the

READY symbol is disabled. At the end of the time delay the

READY symbol is displayed and testing can continue.

-5-

3. OPERATING INSTRUCTIONS

Preparation

Note 1

Note that, when the RCD is tripped during the RCD testing procedure,

mains power will be removed from all electrical equipment connected

to the mains circuit that is protected by the RCD.

Similarly, all connected equipment will re-start when the RCD is

reset at certain stages in the testing procedure.

There are safety implications associated with both these

occurrences that should be taken into account.

For this reason it is recommended that all relevant equipment is

switched off and disconnected from the mains circuit before RCD

testing begins.

Note 2

In addition, some equipment may have a level of earth leakage that is

significant. For example, a leakage of 3mA can be typical of PCs.

Since a 30mA RCD MUST trip before 30mA leakage is detected,

and MAY trip at a level of earth leakage as low as 22mA, a mains

circuit with eight PCs connected may be operating with enough

earth leakage to cause an RCD to trip unexpectedly even before the

RCD testing procedure is begun. Under these conditions, the RCD

tripping characteristics cannot be measured accurately by the RCD

tester.

For the purpose of measuring accurately the sensitivity of the RCD

to earth leakage currents, it is recommended that all relevant

equipment is switched off and disconnected from the mains circuit

before RCD testing begins.

-6-

Note 3

Thirdly, certain types of equipment should be taken into account,

which contain capacitors or which contain motors. If these are

left connected and powered ON while the RCD testing procedure

is followed, the effect of stored capacitance or motor free-

wheeling can be to inject power into the disconnected mains

circuit after the RCD has tripped, causing a delay in the collapse

of the voltage in this circuit. As a result, the RCD tester may

record considerably longer RCD tripping times than may be truly

the case.

For the purpose of measuring accurately the response time of the

RCD, it is recommended that all relevant equipment is switched

off and disconnected from the mains circuit before RCD testing

begins.

To operate

For testing RCDs to BS EN 61557

To operate the RCD, the tester should be connected to a

convenient outlet socket on the electrical circuit supplied from

the RCD to be tested. The mains lead provided with the

instrument facilitates this connection as one end plugs into the

CEE 22 (IEC 320) socket at the top of the instrument while the

other end allows connection to the outlet socket with a suitable

mains plug.

-7-

(A) Connect the mains lead into the tester by means of the

IEC socket provided.

(B) Connect the mains lead to a socket outlet supplied from

the RCD to be tested.

(C) Set the trip current selector switch to the current rating of

the RCD to be tested. Set the range switch to I and the

polarity switch to 0°. It is recommended that the test is

repeated with the switch in the 180°position.

(D) Switch on the supply and check that both lamps on the

tester, marked P/N and P/E, have illuminated . If this is

the case then proceed with the test. If either or both of

the lamps are off, discontinue the test and correct the

wiring fault before proceeding. (An indication of

possible wiring faults can be found on page 9).

(E) To proceed with the test the READY symbol must be

displayed. Press and hold the test switch and the reading

displayed will be the time taken in mSec for the RCD to trip.

(F) Should the RCD under test fail to trip within 2000

milliseconds the OVER RANGE symbol on the tester

will indicate that the unit has failed. Where the RCD

under test trips within 500 or 2000 milliseconds, the trip

time will be displayed on the LCD. With a fault current

flowing equivalent to 100% of the rated tripping current of

the RCD, the device will open in less than 200ms.

(G) The RCD should also be tested to ensure that it can

withstand half the rated trip current without tripping. Set

the range switch to ½ then test as before. The RCD under

test should not trip and the OVERRANGE symbol will

indicate a successful test after 2000 milliseconds have

elapsed.