Teknic EF-785 User manual

E

F-785

P

OWER

D

ISTRIBUTION AND

S

AFETY

C

ONTROL

C

ENTER

V

ERSION

1.42

/

A

UGUST

26,

2005

I

NSTALLATION

G

UIDE

T

EKNIC

,

I

NC

F

AX

(585)784-7460

V

OICE

(585)784-7454

T

HIS PAGE INTENTIONALLY LEFT BLANK

E

F-785

O

VERVIEW

......................................................3

eF-785 Benefits.............................................................................. 6

EF-785 Safety Features ..................................................................7

Segmented Machine Support.............................................7

Guard-lock Control ............................................................7

Automatic Safety System Checkout ...................................7

Controlled Stopping Function (ControlPoint™ Only) ..... 8

Integration Steps at a Glance........................................................ 8

I

NTEGRATION

S

TEPS

................................................10

Step 1: Complete a risk assessment and select guard-locks or

interlocks for guarded areas.........................................................10

EN1050 risk assessment ..................................................10

Select Guard-locks or Interlocks (for each guarded

Hazard) ..................................................................................10

Step 2: Select eF-785 configuration options................................ 11

Definitions........................................................................ 11

Step 3: Mount the eF-785 ............................................................21

Important Mounting Dimensions....................................21

Mounting Orientation ..................................................... 22

Cooling............................................................................. 22

Rack Slides ...................................................................... 23

Step 4: Set up the 24VDC Power Distribution............................ 24

Selecting the Power Supplies .......................................... 24

Connecting 24VDC Power supplies (J5)......................... 24

Connecting 24VDC loads (P9-P11) ..................................27

Step 5: Set up DC Motor Power Distribution 48-90VDC .......... 30

Selecting the Power Supplies .......................................... 30

Connecting DC Motor Power Supplies (P6) ................... 30

Connecting the Loads (DC Motor Drives) (P7A, P7B, J8A,

J8B)........................................................................................31

Step 6: Connect AC Powered Motor Drives (P3, J4) .................. 36

Wiring Configurations..................................................................37

Step 7: Connecting other miscellaneous AC loads (J2).............. 38

Step 8: Connect Incoming AC Power.......................................... 39

Incoming Power (P2) ...................................................... 39

Add a Power Disconnect Switch (if required)................. 39

Step 9: Connect the embedded control computer .......................41

CPU, Display and Peripheral Power (JA, JB)..................41

Host Control Connections................................................41

Step 10: Mount and connect the Power/Enable Switch(es)....... 43

Power/Enable Circuits (P14) .......................................... 43

Step 11: Mount and connect the safety control components...... 45

Selecting External Safety Devices ................................... 45

Safety harness for non-segmented machine (P12) ......... 48

Safety harness for segmented machine (P12)................. 49

Auxiliary Safety Connector (p13).................................... 50

Step 12: Optional: Connect ControlPoint™ Components.......... 52

Where does ControlPoint™ technology fit in? ............... 52

R

UNNING A

M

ACHINE WITH THE E

F-785 ..................53

Powering up......................................................................53

T

EKNIC

,

I

NC

F

AX

(585)784-7460

V

OICE

(585)784-7454

Safety alarm check ...........................................................53

Recovering after an E-Stop event ....................................53

Shutting down..................................................................53

Finding and replacing a blown fuse.............................................55

DC Power Over-current Alarm ........................................ 55

AC Control Power Circuit Protection .............................. 55

E

XTENDING THE

S

YSTEM

.........................................57

Controlling External Hazardous Energy ..................................... 57

Example: 3-Phase Power Control................................................ 57

A

PPENDIX

A:

M

EETING THE

EU

M

ACHINERY

D

IRECTIVE FOR

CE

COMPLIANCE

............................58

What is the Machinery Directive (And why is it important even

outside of the EU) ........................................................................58

A

PPENDIX

B:

S

PECIFICATIONS

.................................63

A

PPENDIX

C:

C

ABLE

D

IAGRAMS

...............................64

48–90VDC Load Area to SSt (J8A, J8B) ....................................64

48–90VDC Main Area to SSt (P7A, P7B) ....................................65

48–90VDC Load Area to ISC (J8A, J8B)....................................66

48–90 VDC Main Area to ISC / SSt-ISC (P7A, P7B) ..................67

AC Servo Power Cable, Load Area (J4) .......................................68

AC Servo Power Cable, Main Area (P3).......................................69

SSt-6000, 3000 DC Power Jumper Cable ..................................70

SSt-6000, 3000 AC Input Cable ................................................. 71

Single 24VDC Supply Cable (J5) .................................................72

Dual 24VDC Supply Cable (J5)....................................................73

70 – 90VDC Supply Cable – SSt-EMF75 (P6) ............................74

24VDC Dist. Cable/IOC-APC (P9-P11)...................................... 75

40VDC Power Tap Distribution Cable (P18)...............................76

Front Panel Harness power/enable circuits (P14) ...................... 77

Integration & Testing Cheater Plug safety control ckts (P12).....78

Extension Cheater Plug (P13)......................................................79

Input Power Cable (J2)............................................................... 80

A

PPENDIX

D:

F

IELD

M

ODIFIABLE

O

PTIONS

..............81

Changing the Jumper Settings .................................................... 81

A

PPENDIX

E:

24VDC

S

UPPLY

W

IRING

.....................83

A

PPENDIX

F:

S

AFETY

S

TANDARDS

R

EFERENCE

.....85

Safety standards Referenced in this manual...................85

Miscellaneous safety standards .......................................85

A

PPENDIX

G:

C

ONNECTOR

R

EFERENCE

.................87

Cable Stock.................................................................................. 88

2

V

ERSION

1.42

/

A

UGUST

26,

2005

E

F-785

O

VERVIEW

The eF-785 is Teknic’s patented power distribution and safety control

center, for use in OEM automated machinery. The “eF” designation

stands for “Electrical Foundation”, an appropriate description as the eF-

785 consolidates nearly all of the required safety, power management

and distribution functions required in an automated machine into one

easy-to-integrate box.

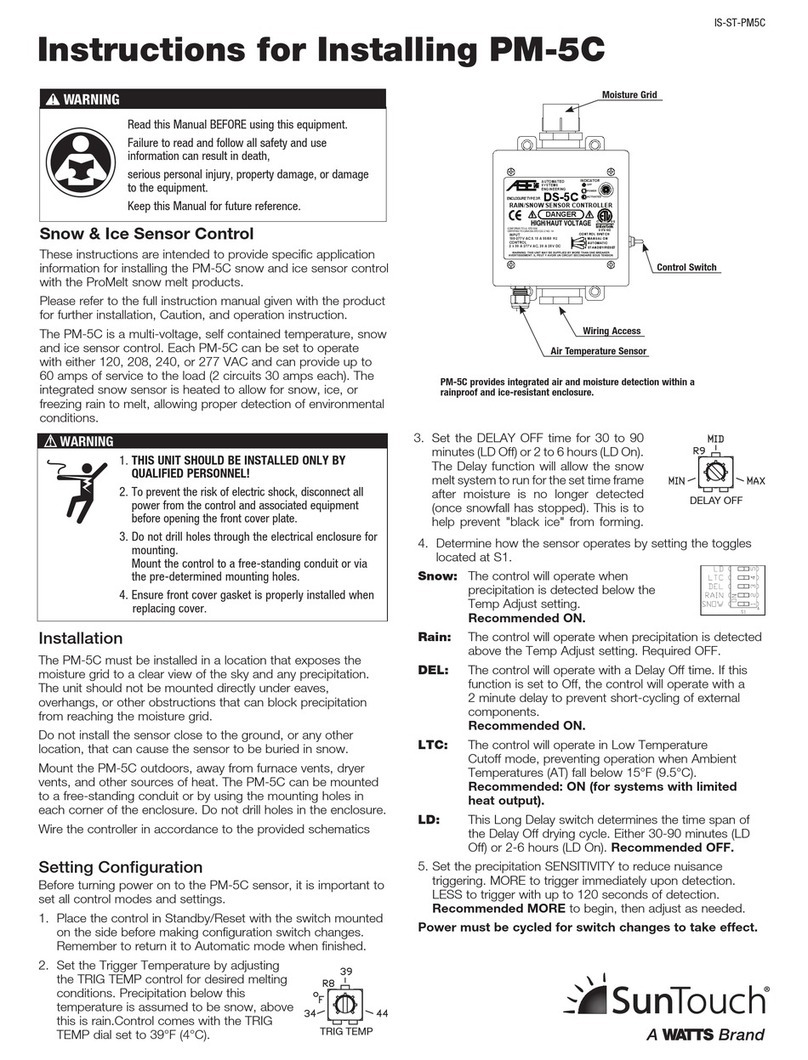

F6

24

VDC

Ckt. 3

10A Max. 40

VDC

ControlPoint

TM

24

VDC

Safety

F7 F8 F10F9

DC Servo Main

15A Max.

DC Servo Option

15A Max.

CB2 CB3

Status

24

VDC

Ckt. 2

10A Max.

24

VDC

Ckt. 1

10A Max.

SAFETY ALARM

Do not operate or service

machine if sounding

eFoundation- Power Distribution & Safety Control Center

CB1, UL489 Rated Input Breaker

10,000A Interrupting

When installed according to the

accompanying instructions this unit meets:

- UL 61010-1 2nd Edition

- EN 61010

- EN 60204

- EN 954-1 (Class 2)

- Semi S2

- EN 61326

Teknic, Inc.

F

e

785

CUS

CM

I

N

T

E

R

T

E

K

L

I

S

T

E

D

20

20

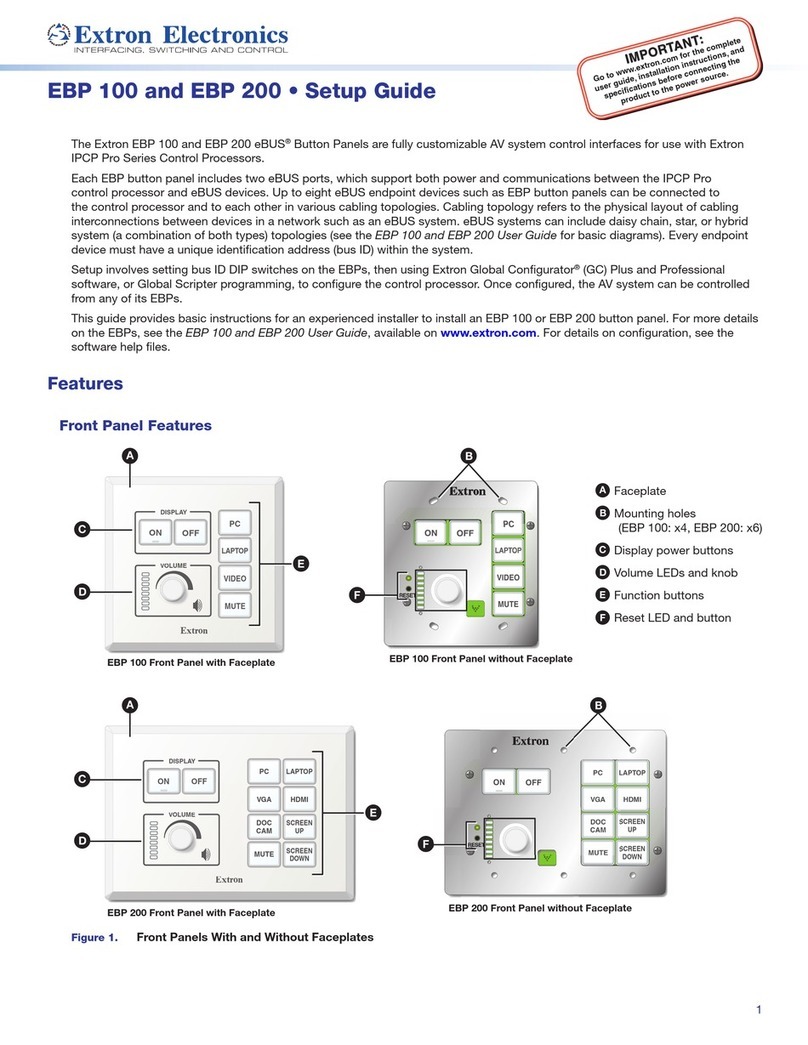

eF-785 Power Distribution and Safety Center (front panel pictured)

Experienced machine designers know that successfully complying

with the myriad of complicated, often ambiguous compliance standards,

means spending laborious hours working on the electrical distribution,

control, and safety circuits before compliance testing can even begin.

Purchase the eF-785, and most of that work is already done. The eF-785

provides all of the critical “foundation” functions you need in a pre-

tested, value priced, off-the-shelf assembly. Though these functions do

not, typically, provide the OEM with a huge differential advantage, the

eF-785, properly implemented, will reduce your engineering burden,

assure that safety and compliance standards are met with a minimum of

hassle, and speed your product to market.

Time after time our field engineers have come back to report a

product rollout hampered or delayed by oversights and last minute

testing and rework of these critical circuits. As a direct result of these

observations, Teknic set out to build a better solution for our OEM

customers. The eF-785 is that solution. It’s the all-in-one answer to your

machine’s power distribution, safety and control requirements. It’s

economical, easy to integrate, and can greatly improve your machine

production time. Why reinvent the wheel when you can join a growing

number of customers who call the eF-785 Compliance in a Box™.

eF-785

I

NSTALLATION

M

ANUAL

3

T

EKNIC

,

I

NC

F

AX

(585)784-7460

V

OICE

(585)784-7454

4

V

ERSION

1.42

/

A

UGUST

26,

2005

F6

24

VDC

Ckt. 3

10A Max. 40

VDC

ControlPoint

TM

24

VDC

Safety

F7 F8 F10F9

DC Servo Main

15A Max.

DC Servo Option

15A Max.

CB2 CB3

Status

24

VDC

Ckt. 2

10A Max.

24

VDC

Ckt. 1

10A Max.

SAFETY ALARM

Do not operate or service

machine if sounding

eFoundation- Power Distribution & Safety Control Center

CB1, UL489 Rated Input Breaker

10,000A Interrupting

When installed according to the

accompanying instructions this unit meets:

- UL 508

- EN 61010

- EN 60204

- EN 954-1 (Class 2)

- Semi S2

- EN 50081-2

- EN 50082-2

Teknic, Inc.

F

e

785

2020

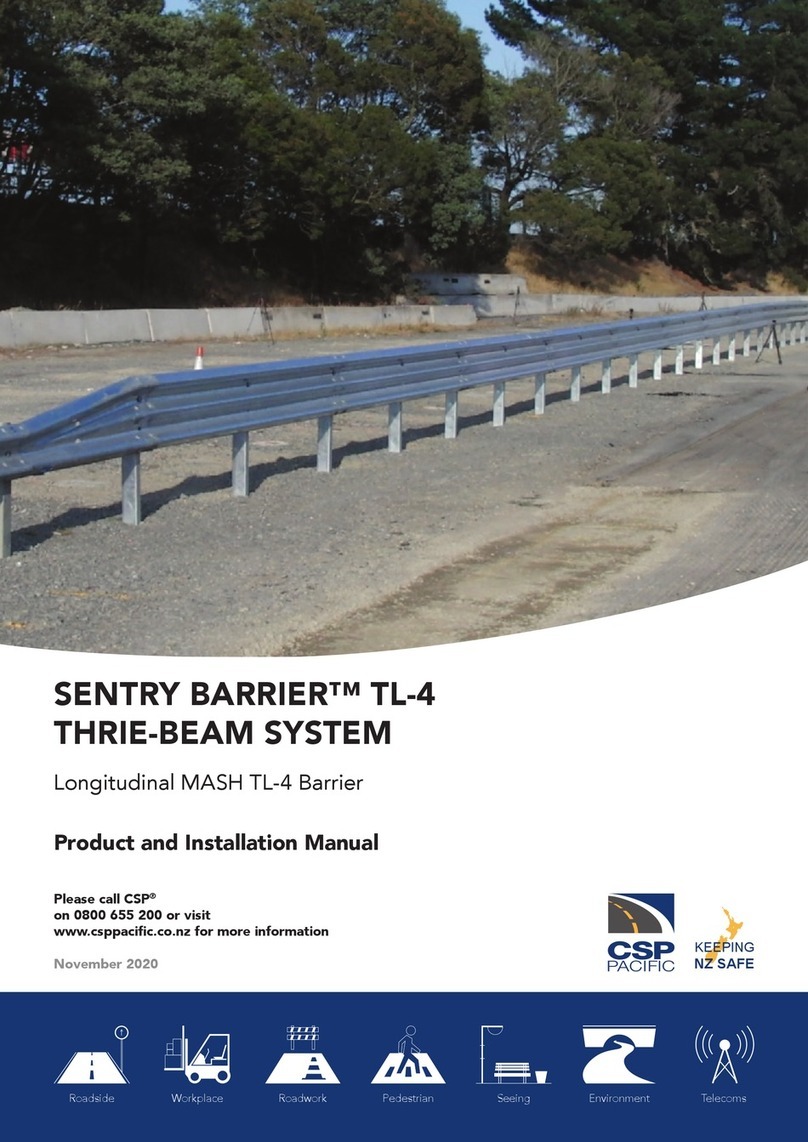

Control Computer

Door Interlocks

(with or without locks)

Controlled / Protected Power Distribution

On/Off

Reset

Disconnect

Switch

EMO

Switch

24VDC Dist.

(6 Circuits)

Hazardous AC

AC Servo Dist.

(2 Circuits)

DC Servo Dist.

(4 Circuits)

Power

Supplies

AC

ACControl

DC

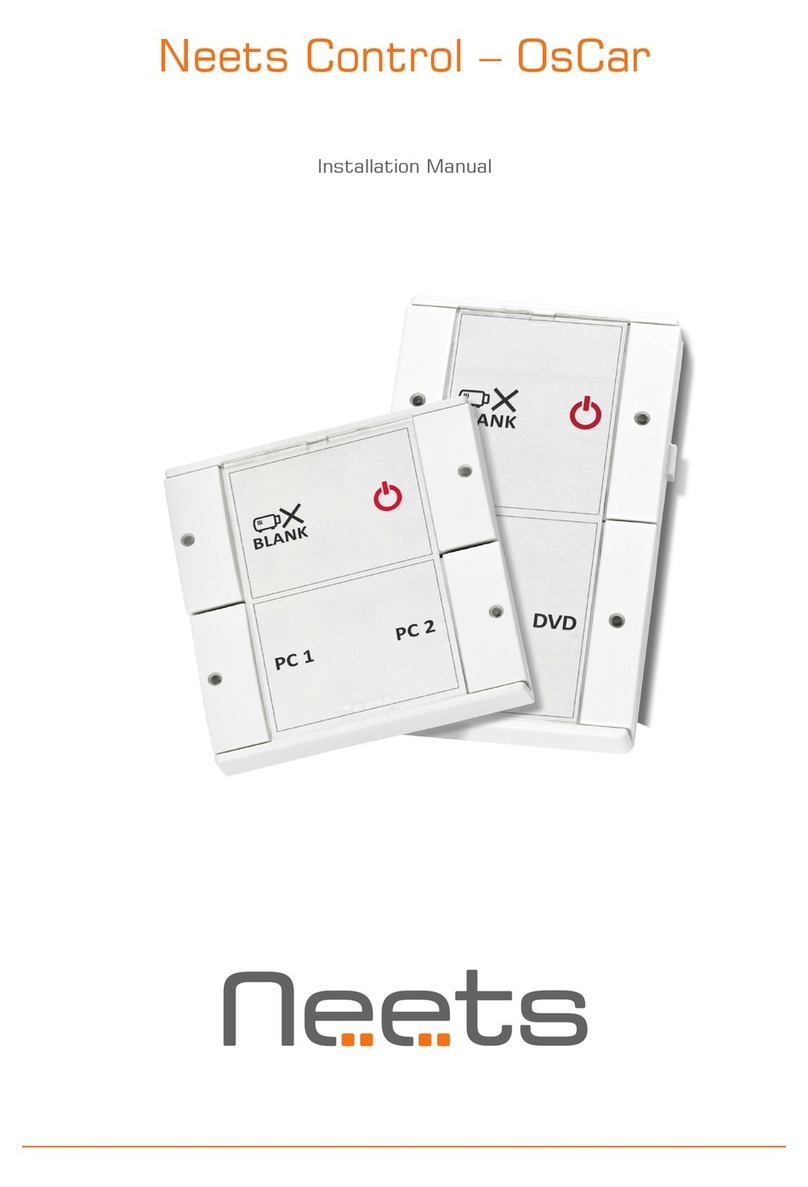

eF-785 Simplified Context Diagram

As shown in the context diagram above, the eF-785 manages a number of

critical functions in your machine including:

•

•

•

•

•

•

•

Power control

Power sequencing

Safety disconnect

Over-current protection

Safety guard lock control/interlocks

Regenerated power dissipation

Conducted EMI filtering

In fact, creating a complete machine power system based on the eF-

785 requires only a comparatively small amount of work. And, if you

follow the installation instructions in this manual, your machine’s power

control system will meet US, European and world standards for electrical

and machine safety, including EN 954-1, EN 60204, EN 61010 and

Semiconductor safety standards SEMI S8 and S2.

The eF-785 can easily manage the power control requirements of a

“two-area” (segmented) machine. This type of machine features a Main

Area and an operator accessible Load/Unload Area, each under separate

control. The eF-785 allows a machine operator to safely disable

hazardous power to the Load/Unload Area while the Main Area of the

machine continues core processing operations. Your customers will

appreciate the greater machine throughput this affords them.

The eF-785’s power-disconnect and safety control is fully compliant

with EN-954-1 (required for compliance with the CE Machinery

Directive). This hazardous power-disconnect is fully single fault tolerant

to component and machine wiring faults and is monitored to detect any

single fault. You won’t need any additional safety control components

(safety relays or controllers) when using the eF-785.

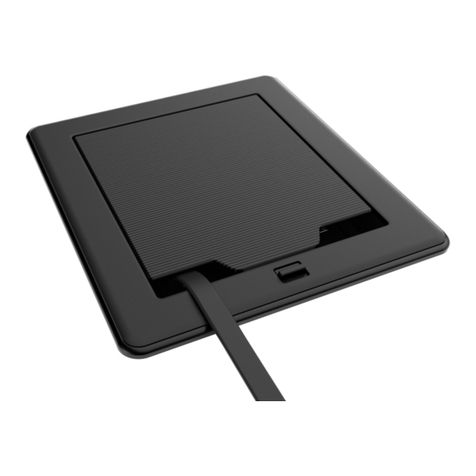

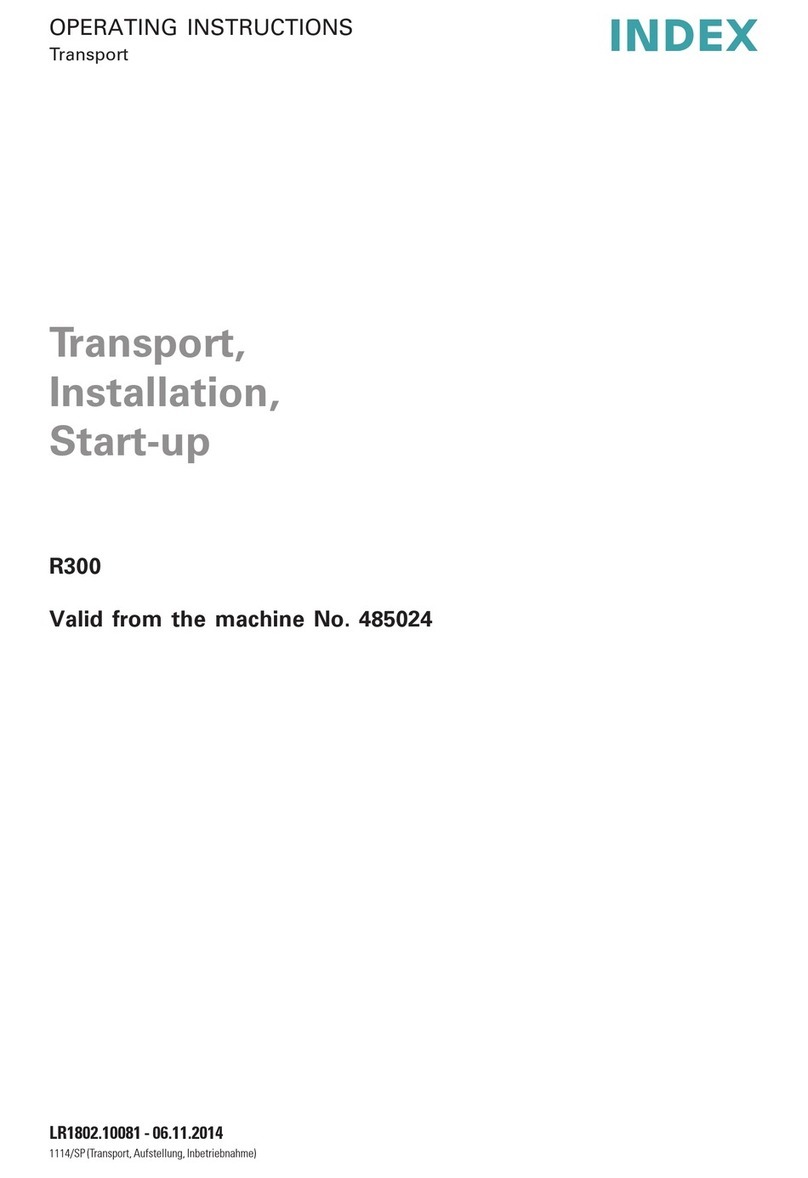

JA

Host Power

JB

Host Power

P3

Main AC

Motor Power Load AC

Motor Power

J4

F1, F2

Host Pwr. 8A Max

P14

P13

P12

Safety Harness Safety Control Ext.

IEEE-1284 Host Port

J17

P18

40V Net Out Net In

RED BLK

100-125/200-240

VAC~ 20A, 50-60Hz

P2

P9 A,B

24VDC

Ckt. 1

P10 A,B

24VDC

Ckt. 2

J8A J8B

Option DC Motor Pwr.

90VDC Max.

Main DC Motor Pwr.

90VDC Max.

P7A P7B

DC Servo

Supply

24VDC

Supply

Hazardous

AC Out

J2 J5 P6

P11 A,B

24VDC

Ckt. 3

SA

USB

P15 P16

115V

DC

AC

48-90VDC

Power Supply

(2 max)

DC

AC

24VDC

Power Supply

(2 max)

DC Motor Drives (4 circuits total)

24VDC Devices (6 circuits total)

Guardlocks

AC Motor Drives

Load Area

Main Area

Main Area

Load Area

Interlocks or Guardlocks

AC power

to Control PC

AC power

to Control PC

E-Stop

AC Power

to miscellaneous

(hazardous) devices

Power/Enable

AC Power Source

Control PC

Main Area

(2 circuits)

Load Area

(2 circuits)

Hooking up the eF-785

eF-785

I

NSTALLATION

M

ANUAL

5

T

EKNIC

,

I

NC

F

AX

(585)784-7460

V

OICE

(585)784-7454

6

V

ERSION

1.42

/

A

UGUST

26,

2005

...Plus, if you need to control more than 4KVA of power, use 3-

phase power, or if your machine has other hazards you’d like the eF-785

to manage, you can extend the system’s capabilities by utilizing the eF-

785’s safety control and feedback signals. These signals are readily

available on the rear panel connector, P13. Learn how to do this in the

Extending the System section of the manual.

Another handy feature, the Soft Shutdown, allows the operator to

power up the control computer from the machine’s front panel On/Off

switch and automatically shut off power to the machine after the control

computer has completed its shutdown process.

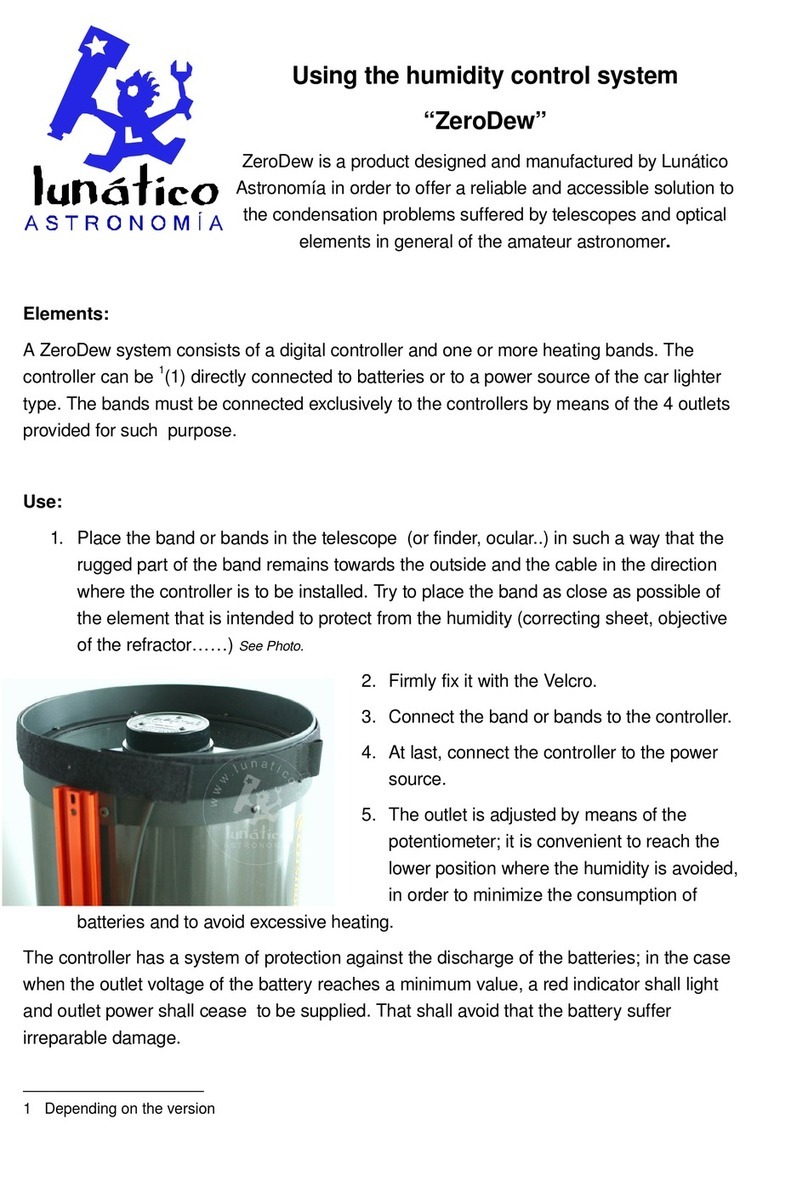

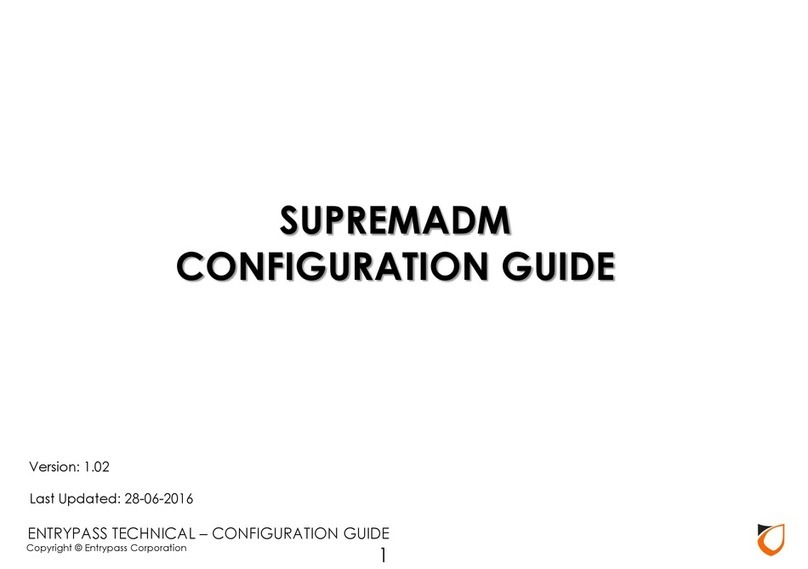

24 VDC

Fault-Tolerant

Hazardous Power

Control

Control Computer

Disconnect

Feedback

Contactor

Control

Command

& Monitoring

Control

Data

Control System

Power

Safety

Control

Power

AC Power to

Hazardous Loads

24VDC Power to

Non-Hazardous

Sensors,

Actuators, Valves

Lamps, etc.

48-90VDC Power

to Hazardous

Loads

Main

Breaker

Regeneration and

Power Dump Loads

Front Panel

Power Control

Over-current

Annunciation

Safety Fault

Alarm

Servo or Stepper Motors

Connected to Mechanical

Hazards

eF-785

Power Hub &

Safety Manager

Optional

ControlPoint

Network Hub

E-Stop

Switch(es)

Guard Interlock

Switch(es)

Guard Solenoid

Lock{s)

AC Power

Distribution Hub

24 VDC

On-Off Control

&

Safety Supply

Safety Control

Expansion Signals

EMI

FiItering

Hazardous Power

Disconnect and Clamp

Motor

Drive

Motor

Drive

External Power

Supplies

Motor

Drive

Preemptive

E-stop signal

48-90 VDC

AC Power

DC Power

Control Signals

Optional ControlPoint Network

Control

INT

P

Power

Sequencing &

Monitoring

Main

Disconnect

DC Power

Distribution Hub with

Over-current

Protection

Safety and Compliance highlights in the eF-785

E

F-785

B

ENEFITS

zSignificantly reduces electrical system design, integration and

debug effort, reducing time to market

zEases wiring requirements, lowering total machine costs

zIntegrates numerous functions in one compact enclosure,

supporting a smaller machine footprint

zSpeeds compliance inspection and testing of a machine for:

oEMC (electromagnetic compatibility),

oMachine Safety (mechanical hazards)

oElectrical Safety (shock and fire hazards)

zSignificantly reduces the risk of failure during machine testing,

making your product launch more predictable

zFeatures a monitoring function to help pinpoint wiring errors in

the safety control system during integration and assembly

zAllows for controlled motor stopping during an Emergency Stop,

minimizing wear and tear on the machine

zVirtually eliminates intermittent connections within e-stop

switches and contactors via proprietary wiring

EF-785

S

AFETY

F

EATURES

S

EGMENTED

M

ACHINE

S

UPPORT

The eF-785 can be configured so that AC power to mechanical hazards is

controlled independently in two different functional areas of a machine.

This means that an operator can easily power down the mechanical

hazards in one part of a machine (Load Area) while the Main Area of the

machine continues to process material, samples, etc, allowing an

operator to feed and retrieve material from the machine while it

continues to do useful work. This can result in a significant,

demonstrable throughput advantage on many automated machines.

G

UARD

-

LOCK

C

ONTROL

The eF-785 has specific outputs that control any installed guard-locks

that open guard doors when hazardous power is removed from a given

machine area. These guard-locks are controlled by user software and

electromagnetic logic control. To open guardlocks, two things must

occur: 1) the user software must issue an “open guardlock” request and 2)

removal of hazardous power must be confirmed by the electromagnetic

logic control.

A

UTOMATIC

S

AFETY

S

YSTEM

C

HECKOUT

The monitoring systems within the eF-785 perform several functions:

they monitor the e-stop and interlock switches (and wiring) for faults,

continuously check the contactors for the proper electromagnetic status

of the hazardous power and guard-lock power. In the event that the

monitoring system detects any errors during operation, it reinforces the

removal of power (which is enforced by the electromagnetic logic control)

and reports the errors to the host computer.

The eF-785 has two important safety diagnostic functions. One

function forces the user to perform a safety test of the e-stop and

interlock switches at each power-up cycle. Periodic checking of these

switches is required by EN 954-1 and this mechanism makes the

procedure automatic. This function removes the requirement for writing

and enforcing periodic inspection procedures and attaching placards or

writing custom software to instruct operators. This function can be

disabled during machine development.

The eF-785 firmware also maintains data on the complete state of the

safety control system just before and after a fault is detected. This

information can help pinpoint the fault to a few possible failures,

speeding up root cause identification.

eF-785

I

NSTALLATION

M

ANUAL

7

T

EKNIC

,

I

NC

F

AX

(585)784-7460

V

OICE

(585)784-7454

C

ONTROLLED

S

TOPPING

F

UNCTION

(C

ONTROL

P

OINT

™

O

NLY

)

The eF-785 can act as a network hub for connecting Teknic’s open

ControlPoint™ networked motion and I/O control nodes. These nodes

can control servomotor or stepper motor axes. When using the eF-785

with ControlPoint™ components in charge of the motion control,

controlled stopping of the motion axes within a machine can be

automatically initiated by the eF-785 when a safety shutdown occurs.

This, combined with the eF-785 ’s hazardous power disconnect delay

function, forces the axes to a smooth controlled stop (in the fraction of

the second before power removal) during an E-Stop, interlock open and

most other safety shutdown events. This typically saves the material in

process, reduces wear and tear on the machine, and generally increases

the perceived quality of the machine by the customer.

I

NTEGRATION

S

TEPS AT A

G

LANCE

Create a complete power & safety system for your machine

using the eF-785 by following these simple steps:

1. Complete a risk assessment of your machine hazards, and then

select guard-locks or interlocks for guarded areas.

2. Select the eF-785 configuration options that fit your machine

requirements.

3. Mount the eF-785.

4. Select and connect the external 24VDC power supplies and devices

to the eF-785. Example cables are shown in Appendix C of this

manual.

5. Select and connect the external DC motor power supplies and DC

motors to the eF-785. Example cables are shown in Appendix C of

this manual.

6. Connect AC powered servo drives. Example cables are shown in

Appendix C of this manual.

7. Connect any other AC loads.

8. Connect incoming AC power, and if required, an incoming power

disconnect switch.

9. Connect the embedded control computer to the eF-785 using off-

the-shelf cables (modular power cord, USB cable, IEEE-1284

cable).

10. Mount the machine’s on-off switch(es) and connect them to the eF-

785. An example cable including recommended switches is shown

in Appendix C of this manual.

11. Mount the safety system components (e-stop switches, interlock

switches and/or guard locks) and connect them to the eF-785. You

will find recommended devices for all of these components in this

manual.

12. Optional: Connect Teknic ControlPoint™ motion and I/O

components via standard Category 5 patch cables.

This manual contains all of the instructions you’ll need to complete each

of these tasks quickly with a minimum of research, while meeting all of

the required safety standards.

8

V

ERSION

1.42

/

A

UGUST

26,

2005

Within the manual you’ll find many detailed drawings, illustrations

and schematics created with you, the OEM Machine Manufacturer, in

mind. Our objective is to provide you with all of the information you need

to successfully visualize, integrate and install the eF-785 in your

machine. To that end we’ve included a complete set of cable drawings,

each with a comprehensive bill of materials. Additionally, we’ve

researched, tested and recommended a number of critical components

including switches, interlocks and guard-locks.

eF-785

I

NSTALLATION

M

ANUAL

9

T

EKNIC

,

I

NC

F

AX

(585)784-7460

V

OICE

(585)784-7454

I

NTEGRATION

S

TEPS

S

TEP

1:

C

OMPLETE A RISK ASSESSMENT AND SELECT GUARD

-

LOCKS OR INTERLOCKS FOR GUARDED AREAS

EN1050

RISK ASSESSMENT

For each risk in your machine you must perform a risk assessment

according to the EN 1050 standard. Naturally, you should acquire a copy

of the EN 1050 standard and follow it to accomplish this. The results of

this risk assessment will help you determine the appropriate level of

safety control system required per EN 954-1 (levels B, 1, 2, 3 or 4) for

each hazard. The eF-785 can meet levels B,1,2, and 3. Therefore, in order

to use the eF-785 as a “stand-alone” safety control center, none of the

hazards in your machine can exceed EN 954-1 level 3 requirements.1

S

ELECT

G

UARD

-

LOCKS OR

I

NTERLOCKS

(

FOR EACH GUARDED

H

AZARD

)

IMPORTANT: You should read Appendix A of this manual:

“Meeting the EU Machinery Directive for CE Compliance” to

ensure your machine meets certain requirements. If your machine meets

the assumptions described in Appendix A, you can follow the rules below

for selecting between interlock switches (which simply indicate the

open/closed state of a guard) and guard-lock switches (which are

interlock switches with physical solenoid-driven locking devices):

You can use interlock switches (without locks) on guards in the Main

area of your machine when:

a. The hazards are such that the EN 954-1 assessment concludes that

they require a level B, 1, or 2 safety control system,

or

b. when the guards are clearly marked as containing hazards behind

them and the guard can only be opened with a tool or key.

Guard-locks must be used if the hazards are such that the EN 954-1

assessment concludes that they require a level 3 safety control system.

Guard-locks may be required in some areas while only interlocks may be

required in others. See Appendix A for more details.

In the Load area of your machine, guard-locks (interlock switches

with power-off locks) must always be used, regardless of the types of

hazards.

If you are unsure where to use guard-locks vs. interlocks you can

safely elect to use guard-locks in all positions as they offer superior safety

qualities. This will provide you with an additional method of control over

user access, often advantageous for other operational reasons.

1It’s usually possible to extend the eF-785 with external components to meet EN-954

level 4 compliance but that topic is beyond the scope of this manual. It’s often easier to

reduce the hazards in the machine to lower the required level of the safety control

system, by eliminating pinch points, having mechanical interlocks with guards, etc.

10

V

ERSION

1.42

/

A

UGUST

26,

2005

S

TEP

2:

S

ELECT E

F-785

CONFIGURATION OPTIONS

Now it’s time to specify your eF-785. For this task you should know a few

things:

1. Your machine’s operational and power requirements

2. The definitions of a few key terms used in this section

3. The available options from which to choose

4. How to “build” a valid eF-785 part number

Assuming that your machine requirements are known, we will

proceed into an explanation of the definitions, available options, and how

those options are expressed as a part number. The objective here is to

give you the information necessary to understand, specify, and order the

eF-785 that will best meet your project requirements.

D

EFINITIONS

Please read the following definitions before proceeding:

Segmented Machine A machine that has more than one work

processing area. A segmented machine is one

that is designed to allow an operator to safely

load or unload raw or finished product in one

(Load) area while main processing activities

continue undisturbed in another (Main) area

under separate power and safety control.

Main Area The main functional area of an automated

machine. The Main Area is typically where the

core processing work of the machine is

performed. All machines have a Main Area;

whereas, segmented machines may have both a

Main and a Load area.

Load Area A specific section of a segmented machine,

separate from the Main Area. The Load Area is

typically a secondary area of a segmented

machine such as an operator Load/unload

access area. It is often advantageous from both

a machine throughput and safety standpoint to

operate the Load Area under separate power

and safety control from the Main Area. The eF-

785 is designed to support this.

eF-785

I

NSTALLATION

M

ANUAL

11

T

EKNIC

,

I

NC

F

AX

(585)784-7460

V

OICE

(585)784-7454

12

V

ERSION

1.42

/

A

UGUST

26,

2005

P

OWER

C

ONTROL

O

PTIONS

The eF-785 offers you several options as to how you distribute power to

AC and DC servo or stepper motor drives in your automated machine.

Not only can you power multiple AC and/or DC motor drives

simultaneously through the eF-785, but you can control the flow of power

to these drives in two separate areas of your machine (Main and Load

Area) under separate safety and power control. This flexibility provides

you with an easy way to create a segmented machine (defined on the

previous page) that offers several advantages in terms of safety and

throughput to your end user.

In this section we will describe the available power control options for

the eF-785, illustrating each with a small schematic diagram. Below is a

brief table summarizing the available options and the appropriate code to

use when ordering.

Main Area Load Area Option Code

DC powered drives None DN

AC or [AC and DC]

powered drives None AN

DC powered drives DC powered drives DD

AC or [AC and DC]

powered drives DC powered drives AD

AC or [AC and DC]

powered drives

AC or [AC and DC]

powered drives AA

Single-area MachineSegmented Machine

eF-785 Motor Drive Power Options

AA- This is the most versatile of the 5 power control options. The AA

model leaves all of your design options open. It supports both AC and DC

powered motor drives in the Main Area, and both AC and DC powered

motor drives in the Load Area. Example part number:

EF-785-AAxx-xxx-x

J2

P3

P7B

P7A

J8B

J8A

J4

P6

Main Load

Safety Control

48-90VDC

Supply

CB1

P2

Interlock

switches

E-Stop

switches

To general hazardous

loads

To Main Area

AC Motor Drives

To Load Area

AC Motor Drives

To Main Area

DC Motor Drives

To Load Area

DC Motor Drives

AC

DC

AA Configuration

Door locks

Simplified power flow schematic-AA

AD- The AD model supports AC and DC powered motor drives in the

Main Area, and DC powered motor drives in the Load Area. Example part

number: EF-785-ADxx-xxx-x.

J2

P3

P7B

P7A

J8B

J8A

P6

Main Load

Safety Control

48-90VDC

Supply

CB1

P2

Interlock

switches

E-Stop

switches

To general hazardous

loads

To Main Area

AC Motor Drives

To Main Area

DC Motor Drives

To Load Area

DC Motor Drives

AC

DC

AD Configuration

Door locks

Simplified power flow schematic-AD

eF-785

I

NSTALLATION

M

ANUAL

13

T

EKNIC

,

I

NC

F

AX

(585)784-7460

V

OICE

(585)784-7454

14

V

ERSION

1.42

/

A

UGUST

26,

2005

AN- The AN configuration supports AC and DC powered motor drives

in the Main Area, but no Load Area drives. In the AN configuration, the

J8 circuits, normally reserved for Load Area functionality, may be used

as additional Main Area circuits. Example part number:

EF-785-ANxx-xxx-x.

J2

P3

P7B

P7A

J8B*

J8A*

P6

Main Load

Safety Control

48-90VDC

Supply

CB1

P2

Interlock

switches

E-Stop

switches

To general hazardous

loads

To Main Area

AC Motor Drives

To Main Area

DC Motor Drives

AC

DC

AN Configuration

Door locks

*see text

Simplified power flow schematic-AN

DD- The DD configuration supports DC powered motor drives in the

Main area and DC powered motor drives in the Load area. Example part

number EF-785-DDxx-xxx-x.

J2

P7B

P7A

J8B

J8A

P6

Main Load

Safety Control

48-90VDC

Supply

CB1

P2

Interlock

switches

E-Stop

switches

To general hazardous

loads

To Main Area

DC Motor Drives

To Load Area

DC Motor Drives

AC

DC

DD Configuration

Door locks

Simplified power flow schematic-DD

DN- The DN configuration supports DC powered motor drives in the

Main Area only, but no Load Area. In the DN configuration, the J8

circuits, normally reserved for Load area functionality, may be used as

additional Main Area circuits. Example part number:

EF-785-DNxx-xxx-x.

J2

P7B

P7A

J8B*

J8A*

P6

Main Load

Safety Control

48-90VDC

Supply

CB1

P2

Interlock

switches

E-Stop

switches

To general hazardous

loads

To Main Area

DC Motor Drives

AC

DC

DN Configuration

Door locks

* see text

Simplified power flow schematic-DN

PURCHASING A UNIT FOR DEVELOPMENT

For the purposes of machine design and development, Teknic

recommends that you initially order the AA configuration. This leaves

your design options open (the AA configuration can do the work of any

of the other four power configurations). Once your machine design is

stable, order only the options you need.

EMI

FILTERING

O

PTIONS

The eF-785 offers two available EMI filtering options, two-stage (D) and

four-stage (Q).

T

WO

-S

TAGE

(D

UAL

)

F

ILTERING

The basic level of EMI filtering offered for the eF-785 is two-stage (Dual)

filtering indicated by the letter Din the position shown above. The 2-

stage option is standard in configurations where only DC powered motor

drives are present in the machine (i.e. power control configurations DD

or DN). This (lesser) magnitude of filtering is usually sufficient for

machines in which there are no AC powered motor drives present.

F

OUR

-S

TAGE

(Q

UAD

)

F

ILTERING

Quad or four-stage filtering is specified by the letter Q. Four-stage

filtering comes standard on all eF-785s configured for AC powered motor

drives (i.e. power configurations AA, AD, and AN). With this level of

filtering, your machine can meet EN 50081-2 and EN 50082-2 for

emissions and susceptibility without individual line filters for each servo

drive (typically a notable cost savings).

eF-785

I

NSTALLATION

M

ANUAL

15

T

EKNIC

,

I

NC

F

AX

(585)784-7460

V

OICE

(585)784-7454

16

V

ERSION

1.42

/

A

UGUST

26,

2005

Optionally, 4-stage filtering may be added as an upgrade to DC motor

drive configurations if additional EMI filtering is required.

CP

N

ETWORK

H

UB

O

PTIONS

Using ControlPoint™ components can greatly simplify wiring

complexity, reduce integration effort, and decrease the number of

assemblies in your machine. Ultimately this will save money and help

reduce errors in design and implementation. ControlPoint™ also

provides a controlled shutdown function for all connected motor drives

when an E-Stop is detected or door interlocks are opened. This works

seamlessly with the optional eF-785 Power-Off Delay to provide very

controlled machine shutdowns.

This position of the eF-785 part number indicates the presence (C) or

absence (X) of the optional Teknic ControlPoint™ network hub and

integrated 40V network power supply. If you are currently using Teknic’s

ControlPoint™ components, you’ll quickly realize the benefits of

incorporating the CP network hub and 40V network power supply into

your eF-785.

If your design does not include the ControlPoint™ hub with 40VDC

network power supply, order your eF-785 with an Xin the indicated

position. With or without ControlPoint™ options, the eF-785 provides

excellent power distribution and safety control functionality.

P

OWER

-

OFF DELAY

O

PTIONS

(M

AIN

)

The eF-785 offers you some options as to how quickly hazardous power is

removed from the Main Area of your machine. Q: When can this option

be valuable? A: In cases where the sudden removal of power from a

motor axis could cause significant (read expensive) damage to the

machine, its payload, or both.

The safety guidelines outlined by EN 954-1 allow for a power-off delay

as long as certain criteria are met, and the eF-785 meets these guidelines.

The delay should be selected to allow for a controlled stop of the relevant

motor axes in the event of an E-stop event. The delay can also be

independently configured for the Load/Unload Area, if the machine is

segmented. Available options and codes are listed below.

NNo Delay Required

FFast Delay (150mS) - For smaller axes or axes where high rates of

deceleration are tolerable.

SSlow Delay (450mS) - For larger axes or axes where more time is

required to complete a controlled removal of power.

P

OWER

-

OFF

-

DELAY

O

PTIONS

(L

OAD

)

The power-off-delay in the Load Area is configured in the same way as

described in the Main Area. If there is no Load Area select code X in the

F-785 part number where indicated.

NNo delay required

FFast delay (150 mS) - For smaller axes or axes where high rates of

deceleration are tolerable.

SSlow Delay (450mS) - For larger axes or axes where more testtime is

required.

XNot applicable. No Load Area designated.

S

UPPLEMENTARY

O

PTIONS

C

ONFIGURING

S

UPPLEMENTARY

O

PTIONS

The Soft Shutdown and Post E-Stop Enable features comprise the eF-785

Supplementary Options. Each of these two options is factory

preconfigured to your specification, but can be reconfigured by

repositioning one or two hardware jumpers. Below is a list of the 4

possible Supplementary Option configurations available with the eF-785.

BHost Soft Shutdown disabled; Post E-Stop Enable bypassed

CHost Soft Shutdown enabled; Post E-Stop Enable bypassed

DHost Soft Shutdown disabled; Post E-Stop Enable required

EHost Soft Shutdown enabled; Post E-Stop Enable required

S

OFT

S

HUTDOWN

F

EATURE

The soft shutdown feature allows you to power off your machine by

shutting down the host computer. This feature is user configurable by

installing (or removing) an internal hardware jumper. See the appendix

for details.

Example scenario of a system with Soft Shutdown enabled:

Power up with Soft Shutdown enabled - An operator initiates the

machine power-up cycle by pressing the machine’s front panel “on”

button (which is wired into the eF-785). The machine powers up and the

eF-785 sends AC power to the host computer which then powers up as

well. Immediately, the PC sends a signal, via USB connection, to the

eF-785, creating a feedback loop. And, as long as the USB signal is

present at the eF-785’s USB port, the system remains powered. Note: to

use this feature, the BIOS on the control PC must be configured to power

up the PC when AC power is detected.

eF-785

I

NSTALLATION

M

ANUAL

17

T

EKNIC

,

I

NC

F

AX

(585)784-7460

V

OICE

(585)784-7454

Power down with Soft Shutdown enabled – When the operator

powers down the host PC, the USB signal to the eF-785 turns off. When

the eF-785 no longer detects the USB signal, it shuts down the entire

machine.

Note: When Soft Shutdown is enabled, pulling the USB cord out of the

eF-785 will have the same effect as turning the eF-785 off via the power

switch.

Follow these steps to provide Soft Shutdown functionality in

your machine

1) Select one of the two options that feature host Soft Shutdown

enabled (see the Configuring Supplementary Options section

below).

2) Configure the host PC BIOS to power up the PC when AC power is

present.

3) Connect the PC to the eF-785 with a standard USB cable.

P

OST

E-S

TOP

E

NABLE FUNCTION

The Post E-Stop Enable function is an extra layer of protection that

serves to provide independent confirmation from the operator that it is

safe to resume normal machine operation after an Emergency Stop (E-

Stop) has occurred.

Consider a typical machine that has several E-Stop buttons on it.

When the machine operator observes that a dangerous condition exists,

he would actuate (i.e. “hit”) the nearest E-Stop button on the machine,

terminating machine operations as a result. When the Post E-Stop

Enable function in the eF-785 is functional, the operator must reset the

E-Stop button to its normal ‘run’ position, and then press the machine’s

On/Enable button in order for the machine to resume normal operations.

Note: The operator should always follow safe machine operating

procedures and return to a safe operating position prior to any machine

restart. If operation were to immediately resume after an E-Stop button

was restored to the ‘run’ position, an undesirable, potentially dangerous

operational condition could occur. Always know and follow your

machine’s safe operation guidelines.

Having the Post E-Stop Enable feature enabled is especially important

in cases where it is possible for an operator (or parts of an operator) to be

inside a machine while the interlocks are closed.

For general safety and compliance requirements, Teknic recommends

that you configure your eF-785 with the Post E-Stop Enable feature

activated (options Dand E).

The Post E-Stop Enable feature satisfies the ‘Manual Reset’ step

required by EN 954-1. As previously stated, the machine safety design

engineer should perform a complete safety assessment prior to selling

machines with this function disabled. Read EN 954-1 carefully to

decide if your machine can operate with the Post E-Stop

Enable function bypassed.

During the engineering design and development phases, the Post E-

stop Enable function can be inconvenient. By disabling the Post E-Stop

Enable function, machine operation can resume immediately after an

actuated E-Stop button has been restored to its normal “Run” position,

assuming that the system software is configured to allow this and the

18

V

ERSION

1.42

/

A

UGUST

26,

2005

Table of contents