iii

5. Field Setting by Remote Controller ..............................82

5-1 Wired Remote Controller <BRC1C62> ........................... 82

5-2 Wireless Remote Controller <BRC4C, 7C, 7E>.............. 85

5-3 Simplified Remote Controller

<BRC2C51 (BRC2A51)>................................................. 86

5-4 HRV <BRC301B61>........................................................ 88

Part 4 intelligent Touch Controller...................... 91

1. Part Names and Functions............................................92

1-1 Front and Side View........................................................ 92

1-2 Part Names on the Monitoring Screen and

the Functions................................................................... 93

2. System Configuration....................................................99

2-1 System Outline................................................................ 99

2-2 Double intelligent Touch Controllers ............................... 99

3. Specification.................................................................100

3-1 Specification.................................................................. 100

3-2 Dimension ..................................................................... 100

4. Functions......................................................................101

4-1 Functions....................................................................... 101

5. Electric Wiring..............................................................104

5-1 Terminals on the Back of

intelligent Touch Controller............................................ 104

5-2 Points of Installation...................................................... 105

5-3 Wiring for Force Stop Input and for

Electric Power Distribution ............................................ 106

5-4 Connection to Public Telephone Line............................ 107

5-5 Connection to LAN........................................................ 107

5-6 DIII-NET Plus Adaptor Connection................................ 108

5-7 Connection for Unification Adaptor................................ 108

5-8 DII-NET Plus Adaptor.................................................... 109

5-9 Wiring Example for intelligent Touch Controller

(DCS601C51)................................................................ 111

6. Web function.................................................................117

Part 5 Control Devices ....................................... 123

1. <DCS302CA61> Central Remote Controller...............124

1-1 Function......................................................................... 124

1-2 System Configuration.................................................... 125

1-3 Specifications / Dimensions .......................................... 128

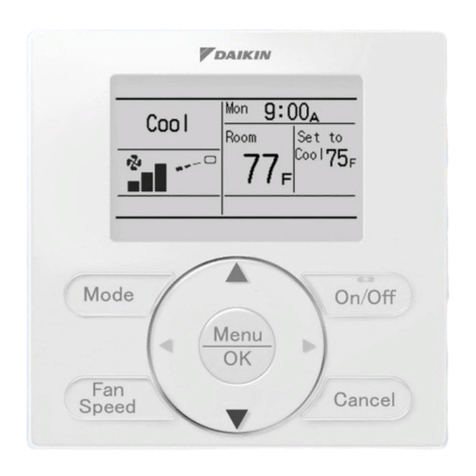

1-4 Names and Functions of Operating Part....................... 129

1-5 Description of Functions................................................ 131

1-6 Selection of Control Mode No. ...................................... 139

1-7 Initial Setting.................................................................. 142

1-8 Electric Wiring ............................................................... 143

1-9 Special Function Settings.............................................. 144

1-10 Refreshed Operation..................................................... 145

1-11 Error Diagnosing Function............................................. 146

1-12 Installation ..................................................................... 149