TEKSAN DIESEL GENERATOR SETS User manual

Everlasting Company

EVERLASTING

COMPANY

OPERATION AND MAINTENANCE MANUAL

FOR DIESEL GENERATOR SETS

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

3

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

Dear User

First of all, thank you for preferring our product and company.

TEKSAN, sustains all its activities at its modern facilities, according to its principle of providing reliable products

and services at high quality with CE norms and “ISO 9001:2000; Quality Management System” certification. Your

generator set is subjected to several test and quality controls at every stage of production. There are several test

and control procedures carried out on the time interval between the very first “assembling” step and the very last

“delivery” step. TEKSAN products are also manufactured environment friendly at norms with “ISO 14001; 2004

Environment Management System” certification.

Our documents are being prepared carefully with the help of the academic education we have received and also the

knowledge and experience we have obtained from being in this business for the last 25 years. As a standard TEKSAN

documentation, the “Operation and Maintenance Manuals” for your “Diesel Engine”, “Alternator” and “Generator

Set” must have been delivered to you together with your generator set. Your duty as our customer, is to read,

understand and remember all information shared in these documents before using your generator set. This will help

you avoid any possible accidents that may be harmful for you, people around you or the generator set itself.

You may also sign for a “Periodical Maintenance Agreement” and get regular, complete and economical maintenance

and reparation services from TEKSAN Dealers, and receive good quality service for your product.

Please let us know about your wishes and suggestions in order to contribute to our product and service quality.

TS ISO 8528-5 CERTIICATE

ISO 9001 QUALITY MANAGEMENT SYSTEMS CERTIFICATE

ISO 14001 ENVIRONMENTAL MANAGEMENT SYSTEMS CERTIFICATE

OHSAS 18001 OCCUPATIONAL HEALTH AND SAFETY MANAGEMENT SYSTEMS CERTIFICATE

EAC EURASIA CUSTOMS UNION CERTIFICATE

CONFORMITY OF EUROPE

ISO 27001 Information security management system Certificate

ISO 10002 Customer atisfaction

4

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

1.SAFETY PRECAUTIONS ................................................................................................................................6

1.1.General Instructions ........................................................................................................................... 6

1.2.Lifting and Handling ..........................................................................................................................7

1.2.1.Using Slings .........................................................................................................................7

1.2.2.Using Forklift........................................................................................................................8

1.2.3.Towing Trailer Mounted Generator Sets.............................................................................9

1.3.Moving Parts...................................................................................................................................10

1.4.Hot Surfaces, Sharp Edges and Corners.........................................................................................10

1.5.Fire and Explosion...........................................................................................................................11

1.6.Hazardous and Corrosive Substances ............................................................................................12

1.7. Environmental Protection...............................................................................................................12

1.8.Electrical Equipment and Connections ...........................................................................................13

1.8.1. First Aid In Case Of Possible Electrical Shock Accidents ..............................................14

2. GENERAL DEFINITIONS.............................................................................................................................15

2.1.Identifying Sets ...............................................................................................................................15

2.2.Generator Set ..................................................................................................................................15

2.2.1 Canopy Type Generator Sets .............................................................................................16

2.2.2 Container Type Generator Sets .........................................................................................17

2.2.3 Drop Over Canopy Type Generator Sets............................................................................18

2.2.4 Mobile Generator Sets.......................................................................................................19

2.3 Diesel Engine...................................................................................................................................20

2.4 Alternator ........................................................................................................................................20

2.5 Fuel Tank.........................................................................................................................................21

2.6 Base Frame .....................................................................................................................................22

2.7 Vibration Isolators...........................................................................................................................22

2.8 Exhaust System and Silencer .........................................................................................................23

2.9 Control Systems..............................................................................................................................23

3-INSTALLATION ...........................................................................................................................................24

3.1.Selecting Room Location ................................................................................................................24

3.2.Ground and Platform .......................................................................................................................25

3.3.Vibration ..........................................................................................................................................25

3.4.Cooling and Ventilation ...................................................................................................................25

3.5.Exhaust System..............................................................................................................................27

3.6.Fuel System.....................................................................................................................................28

3.6.1.Storage of Diesel Fuel .......................................................................................................29

3.7.Electrical Connections ....................................................................................................................30

3.7.1.Starter Batteries ................................................................................................................31

3.8.Noise Control...................................................................................................................................32

3.9.Fire Precautions..............................................................................................................................33

3.10.Earthing .........................................................................................................................................33

4-CONTROL SYSTEM .....................................................................................................................................34

4.1.Introduction.....................................................................................................................................34

4.2.Manual and Automatic Control Panel.............................................................................................34

4.3.Synchronization Panels...................................................................................................................37

4.4.Basic Procedures To Be Followed Before Operation.....................................................................37

4.5. Battery Charger..............................................................................................................................38

4.6.Engine Jacket Water Heaters.........................................................................................................39

4.7.Transfer Panels...............................................................................................................................40

TABLE OF CONTENTS

5

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

5-MAINTENANCE...........................................................................................................................................40

5.1.General ............................................................................................................................................40

5.2.Maintenance of the Diesel Engine..................................................................................................41

5.3.Maintenance of the Alternator .......................................................................................................41

5.4.Lubrication Oil .................................................................................................................................42

5.5.Coolant ............................................................................................................................................42

5.6.Fuel..................................................................................................................................................43

5.7.Maintenance of Batteries ...............................................................................................................43

5.8.Maintenance of Radiator ................................................................................................................44

5.9.Low Load Operation ........................................................................................................................45

5.10.Long Term Storage........................................................................................................................46

5.11. General Maintenance Schedule...................................................................................................48

6-TROUBLESHOOTING ...................................................................................................................................49

6.1.General ............................................................................................................................................49

7-WARRANTY ................................................................................................................................................52

6

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

1.SAFETY PRECAUTIONS

1.1.General Instructions

Before installing or running the generator set, it is a responsibility for the user or operator to read the whole

documentation that is included within the generator set. (“Generator Set Operation and Maintenance Manual”,

“Diesel Engine Operation and Maintenance Manual” and “Alternator Operation and Maintenance Manual”). All the

safety instructions stated in these manuals must be provided in order for a safe operation.

The person who is in charge for installing, maintaining or using the generator set, is the only responsible for

anything that risks the safety of operation. For this reason, these people must follow and obey all the instructions

stated in all provided documentation, so that the risk of accident shall be minimized.

Because of this responsibility to take, the people who will install, maintain or use the generator set, must be

trained and authorized about the procedures for installation, usage and maintenance. Any disorder or disobeying

about these procedures, rules, instructions, methods or measures in manuals, will increase the probability of failure

and accidents that may end up with injuries or maybe death.

Pay attention to all labels and warnings on the generator set. Install and operate the generator set fully in

conformity with the related standards, rules and regulations. Furthermore, the local rules and regulations should be

followed too.

Make sure that the generator set is at OFF position before performing any maintenance, repair or setting activity. In

this way, you will be isolating the generator set from any unauthorized access.

Do not start the generator set until you are definitely sure that it is absolutely safe to run it. Under any unsafe

condition, disconnect all the battery cables.

Use required safety equipment during periodical inspections and maintenances

This manual and the appendices are integral in total. All safety instructions are clearly stated in the relevant

sections of this manual. Also remember that you can always get in contact with TEKSAN and ask for advice about

any issue that is not understood clearly.

7

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

1.2.Lifting and Handling

1.2.1.Using Slings

Use the lifting lugs located on the generator set, while you are trying to lift or move the generator set.

Before lifting the generator set, be sure that you have checked all the lifting lugs or any connection points for any

welding cracks, breakages, twists or rust that may cause any problem during the lifting process.

Make sure that all lifting equipment and supporting components are in a good condition, so that they can resist a

load 10% more than the gross weight of the generator set as a minimum (extra margin for any snow, ice, mud or

attached spare parts/equipment on set).

Make sure that all the lifting hooks or locks have functional safety clips and all of them are connected correctly.

Be sure to use guide ropes or equivalents in order to prevent any rotation or swing action, when the machine is

lifted and there is no contact left between the machine and the ground.

Do not try to lift the generator set if there is a strong blowing wind around.

Once the generator set is lifted, be careful about the people around and keep them at a safe distance.

Once the generator set is lifted, also be sure that the operator of the lifting machine is always ready to handle any

case of emergency.

Always be sure that the generator set is placed on a flat surface. This surface to be selected, has to be able to

resist a weight 10% more than the gross weight of the generator set. Also be sure that there is not any risk of

sliding, after you put down the generator set.

Before closing and locking the doors of the generator set, be sure that there is nobody left inside the canopy or

container.

8

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

1.2.2.Using Forklift

Unauthorized personnel shall not ride on forklifts.

Only trained and qualified personnel shall operate forklifts. All forklifts shall be strictly maintained in accordance

with the manufacturer’s recommendations.

Ensure that forklift has enough capacity to handle the generator set safely and properly.

Then firstly lower the forklift forks to minimum/ground level and drive the forklift forks into the forklift pockets under

the baseframe of the generator set slowly and carefully. Once the forklift forks are completely inside the pockets,

then raise the level of forklift forks slowly around 15-20 cm and so the generator set shall be lifted from the

ground. After being completely sure that the lifted generator set has no contact with the floor, then drive the forklift

carefully to the place that the generator set will be dropped off.

For unloading the forklift and putting the generator set to its place safely, lower the forks once again slowly and

safely and then remove the forks carefully out from the pockets so the generator set shall sit on its place safely.

** Forklift pockets are offered as a sales option.

9

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

1.2.3.Towing Trailer Mounted Generator Sets

Be sure that there is nothing wrong about the towing system including the towing bar, connection points, hooks,

pins, etc... Check the chain, brake or electrical interconnections if there is available. Also check the moving parts,

connection or interlock points of the generator set. Be sure that they will not cause any problem during this

transportation process.

Make sure that all tires on the trailer are in conformity with norms and standards and in good condition. Also be

sure that the air pressure inside these tires, is at a specified level depending on the gross weight of the trailer and

generator set. Do not change the size or type of tire without the confirmation of manufacturer. Furthermore, make

sure that all the bolts, nuts and parts are tightened with an appropriate torque.

If there are any available, make sure that all the headlights, signal lights, brake lights or the fog lights are running

properly and their covering lenses or glasses are clean and in good condition.

Do not let people to stand on the towing bar or travel on the generator set. Keep your hands and fingers away from

the tightening points. Do not attempt to pull the trailer by manpower.

If possible, choose a dry place for parking or placing the trailer. Also it is important to use wheel chocks for fixing

all the wheels.

Act in accordance with all laws and regulations that define the traffic rules. Especially be sure not to not exceed

the allowed speed limit while travelling with the trailer.

Do not drive in traffic with uncertified trailer.

** Trailer is not a standard product but a sales option.

10

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

1.3.Moving Parts

Keep your body (especially hands, arms and hair) and clothes away from gearwheels, pulleys, belts or other

moving and rotating parts.

Do not attempt to run the generator set, if any protection cover of fans or other moving parts is removed.

Be sure that your clothes completely fit on you, if you are working around a generator set that is running. Also tie

your hair if it is long.

Keep all the access doors closed, excluding the cases of starting up, control, maintenance, repair or service.

Before starting the generator set, be sure that everyone around is at a definite safety distance.

In order to minimize the risk of accidents due to sliding or falling, keep your hands, feet or the ground clean of fluids

like fuel, diesel, grease, anti-freeze or water.

1.4.Hot Surfaces, Sharp Edges and Corners

Avoid anyone from touching the hot grease, hot coolant, any hot surface, sharp edge and corners.

Keep your hands or any part of your body, at a safe distance to the hot exhaust pipes and gases

While working inside, outside or around a generator set, wear protective clothes and accessories like gloves, boots

and helmets.

Keep a first aid kit close to you and seek for medical help urgently in case of any personal injury. Do not neglect

any small cuts or injuries.

11

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

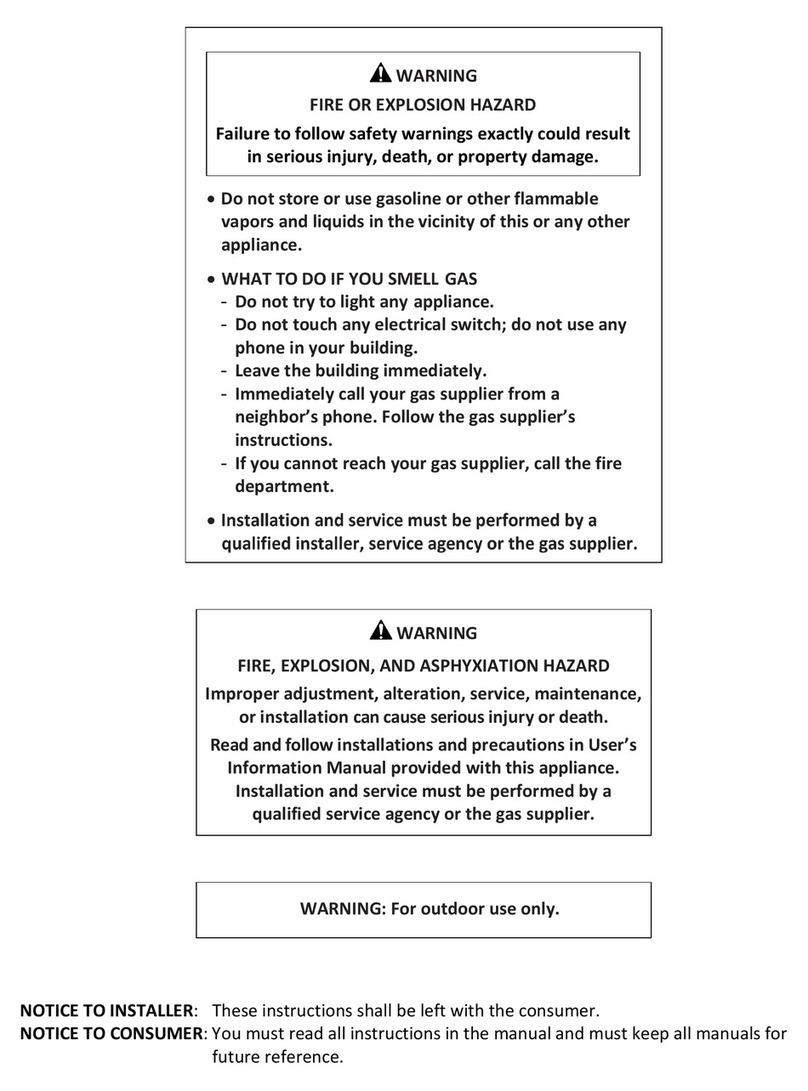

1.5.Fire and Explosion

Be sure that the fuel that will be used is a well-designed combination of appropriate ingredients, according to its

purpose of use and all related norms and standards.

Keep the floor clean around the generator set in order not to face any accidents due to slippery floor covered with

grease, battery electrolyte or coolant.

Shut down the generator set long before any maintenance activity like refuelling it, checking the battery electrolyte

level, checking or changing the lubrication oil. So that the engine can get cooled before doing any maintenance on

it.

Keep any spark, flame or other combustibles away from the generator set. Do not smoke and allow smoking

around the generator set.

Do not let any formation of waste oil or fuel layer on the generator set. Clean any dirt on the engine, alternator,

base frame or canopy with an industrial cleaner. Be sure not to use combustive chemicals for cleaning purposes.

Before connecting or disconnecting the batteries, be sure to remove the charger connections on batteries.

Remove the connections from negative (-) poles of the batteries before any maintenance. Also place a warning on

the battery for preventing any short-circuit accidents.

In order for preventing any possible incorrect connections that may be done by anyone unauthorized, be sure to

attach a warning notice on the battery connections.

Keep any cables, battery terminals or other electrical equipment in a good condition. Replace any cracked, broken

or defective cables, terminals, isolators or any electrical equipment.

Provide a proper grounding for all the conductors and electrical equipment that is directly exposed to electricity.

This will prevent the accidents due to any arc or spark occurrences caused by the electrical current flowing

through or around them.

If any leakage has been inspected on or around the fuel tank or pipes, never start the generator set before resolving

the leakage problem. Do not attempt to repair the damaged fuel tanks or pipes but change them directly with the

new ones.

Always keep in mind that the temperature of the exhaust gas, exhaust manifold and the exhaust outlet pipes is

up around 550oC. Due to this fact; provide the necessary insulation to all hot surfaces and keep yourself and any

flammable material away from these hot points.

Be sure to keep any flammable material away from the generator set before doing any welding work on the

generator set. Also take any dirty (oil, fuel, etc...) cloth pieces, chemical waste, leaf, garbage or any other

flammable material away from the generator set.

Before any maintenance or service activity, be sure that there is at least one full and well-maintained fire

extinguisher around the generator set.

If there are any trees or wood around the generator set, avoid contacts of leaves and branches with the generator

set’s hot exhaust system.

Do not install or run the generator sets in places that are not approved or prescribed as dangerous.

12

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

1.6.Hazardous and Corrosive Substances

The generator set must be installed and operated in outdoor or well-ventilated areas.

Do not install or operate the generator set, unless there is a proper ventilation. Also be sure that the ventilation windows

stated in the previous sections of this manual are provided.

If the generator set will be operating at an indoor place, be sure to provide a proper exhaust outlet system so that the exhaust

gases can be released outdoor. Also provide a proper ventilation window for any natural gas leakage emergency case.

Be careful that the exhaust gas outlet is not redirected to indoor places, living areas, ventilation or fresh air suction points of

any machine.

Any material used for the engine (lubrication oil, grease, coolant, battery electrolyte, etc…) are industrial chemicals, so

any of them must be kept away from any part of your body. If there is any of these chemicals on any part of your body by

accident or somehow, you have to wash this exposed part/area using plenty of soap and water.

Wear a uniform that is resistant to acid and a glass for covering you face while maintaining the batteries. If any part of your

clothes or skin is exposed to the acidic electrolyte solution inside the batteries, then wash this exposed part using plenty of

soap and water.

1.7. Environmental Protection

Generator sets have some potential risks for the environment such as lubrication oil, fuel, exhaust gas, battery.

There may be local set of rules, regulations or limitations about the usage of diesel generator sets and also about the disposal

of the environment-risky materials listed above.

It is the customer’s / user’s responsibility to be aware of these rules or regulations and also to obey and conform with these

rules while using and maintaining diesel generator sets.

Disposal Of Waste / Risky Material For Environment

• Be sure that there is no lubrication oil spilled around while changing the engine oil or keeping the used oil in your

stocks.

• Keep the engine lubrication oil that has been drained, at a safe place and be sure to deliver it to authorized

organizations for properly disposal.

• Keep also the oil and fuel filters that have been replaced from the engine, at a safe place and again be sure to deliver

it to authorized organizations for properly disposal.

• Do not throw the damaged or dead batteries to trash and again be sure to deliver them also to the authorized

organizations for properly disposal.

• Be sure to collect and keep all these wastes and damaged parts inside an isolated and fireproof waste tank.

• Be sure to prevent any fuel or oil from leaking and spilling around to environment.

• Be sure to check and conform with your “Local Environmental Regulations” before getting your generator set started

and operated.

13

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

1.8.Electrical Equipment and Connections

Cable classification and connections of a generator set should be made and checked by only trained and qualified

electricians.

Do not touch the electrical hardware of the generator set directly with you bare hands or with the help of any

conducting material.

Before connecting or disconnecting power cables, or before starting the generator set, make sure that the

generator set is properly grounded in accordance with all related rules and regulations.

Do not run, connect or disconnect the generator set underwater or on a wet ground. Remind the conductivity of

water.

Before establishing any electrical connection to the generator set; first stop the engine, then remove the supply

connection from the charger input, then remove all battery connections and finally remove all non-grounded

conductor connections at the load side.

Avoid touching the electrical and moving parts of the generator set with bare hands or any tool. Also be sure that

you are standing on a dry and insulated ground if you have to touch them (electrical installation or equipment) for

any repair or maintenance purposes.

Be sure to keep the insulators at the alternator output on their places. Put them back to their places right after

any connection or disconnection activity. Do not run the generator set if these insulators are not mounted on their

places.

Close and lock all the doors if the generator set is out of service, so nobody unauthorized can get in the generator

set.

Keep the towing truck and equipment at least 3 meters away from the generator set and the power cables.

Perform any repair, maintenance or service activity in clean, dry, well illuminated and ventilated areas.

Be sure that the load connected is proper, according to the loading characteristic and capacity of the generator set.

Do not load the generator set more than its loading capacity. Also ensure that the power cables used between the

load side and generator set are at proper rating and specifications in accordance with related rules and regulations.

Never connect or disconnect electrical cables or equipment in case of gas leakage on supply line or the generator

set.

14

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

1.8.1. First Aid In Case Of Possible Electrical Shock Accidents

If you witness an electrical accident it is important to respond quickly but with caution at the same time. So do not

touch the victim until being sure that the electricity is switched off, otherwise you may receive an electric shock

too. If you are not able to switch off the electricity, you can try to rescue the victim by using some dry and dielectric

equipment as an alternative.

After taking the patient to a safe place far from the electrical installation;

1. Call for emergency service or any medical support.

2. Keep patient lying down at a prone position. (A) Put the head on arms and turn it to one side for allowing any

possible fluid drainage.

3. Remove all objects like denture, tobacco or chewing gum out from the patient’s mouth in order to provide an

ease on breathing or any possible fluid drainage. Using your palms, firmly press between the shoulders of patient. Be

sure that the patient’s tongue is released.

4. Kneel down in such a position that your knee is near the patients head and your other foot is close to his/her

shoulder. (B)

5. Put your hands on the patient’s shoulders and place your palms on his/her scapula.

6. Push your arms forward in a vertical position. Slightly apply pressure (10-15 kg.) on the patient’s scapula for

2,5 seconds.

7. Release the pressure by sliding your hands over the patient’s shoulder to his/her elbows in around 1 second.

Then lift up the patient’s arms and shoulders slightly by holding from his/her elbows. Just after holding the arms

and shoulders for a short time, push them backwards for around 2,5 seconds for stretching (C). After all, release the

patient’s arms back (D) and put your hands back onto the patient’s scapula.

8. Repeat all these steps in order to help the patient for breathing.

9. At the meantime someone is doing these movements for helping the patient to breathe, anyone else must;

a. Loose the clothes on the patient for making the patient breathe easier,

b. Keep the patient warm until the patient feels better.

10. If the patient stops breathing, apply artificial respiration and go on doing it until the patient breathes again. It

may take up to 4 hours.

DO NOT GIVE ANY LIQUID IF THE PATIENT IS STILL UNCONSCIOUS

15

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

2. GENERAL DEFINITIONS

2.1.Identifying Sets

Generator sets and its main pieces (engine, alternator) do have nameplates

on them for easing the identification process for the user.

A brief information about the generator set (model codes, serial numbers,

etc...) can be found on these identification nameplates.

An example of “generator set nameplate” can be seen in the picture on the

right.

The customer / user has to provide the supplier the “serial number” of the

subjected generator set while requesting any spare parts or while applying

for a warranty case about that generator set.

2.2.Generator Set

TEKSAN produces reliable generator sets at high quality in accordance with

ISO8528 standards. Generator set specifications, options, electrical and

mechanical drawings are all recorded and followed under the unique serial

number of the generator set.

Main components of the generator set are shown in the figure below.

1Lifting Lug 6Earthing point 12 Turbocharger

2Jacket Water Heater 7Lifting Lug 13 Engine

3Fuel Tank 8Connection Box 14 Exhaust Outlet

4Starter Motor 9Control Panel 15 Radiator Cap

5Batteries 10 Alternator 16 Radiator

6Vibration Isolators 11 Air Filter 17 Baseframe

Figure: Main components of a diesel generator set.

16

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

2.2.1 Canopy Type Generator Sets

Teksan manufactures canopies for outdoor installation with the following features and specifications;

• Weather and sound proof capability,

• High level of noise reduction,

• Sheet metal structure painted with electrostatic powder paint ,

• High durability against corrosion and rust,

• Assembly of the parts is carried out with screws with no-welding, so the replacement of the damaged parts

are easier.

• Ease of transportation with lifting lugs.

• Exhaust silencer fitted inside the canopy,

• Emergency stop button fitted outside the canopy,

• Fresh air inlets for adequate ventilation of the generator set,

• Hot air outlet from the top for discharging the hot air and exhaust gas from the same direction,

• Rain cap in exhaust silencer outlet,

• Radiator filling cap,

• Cable entry area for easy installation.

17

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

2.2.2 Container Type Generator Sets

Teksan manufactures containers for outdoor installation with the following specifications;

• Interior surface of canopy is covered with non-flammable noise isolation foams.

• Improved sound insulation performance with the sound insulation cells and sections at the air inlet and outlet

of the container.

• Various container dimensions depending on the rating of the generator set.

• Exhaust silencers are fitted inside canopies. For some models exhaust silencers may be fitted on the canopy

due to limited space inside canopy. The internal structure of exhaust design is proper for a silent ambient.

• One emergency exit door that is close to the side of the radiator for providing a more easy access to the

generator. Also a cabinet door is located when transfer switch will be inside container in some systems.

• The fuel tank is put inside a separate section in the container in some models if sub-base fuel tank is not

available on the baseframe.

• Anti-vibration rubber pads mounted in between baseframe and canopy.

• There are four lifting lugs available on a standard container for lifting it from its top.

• In order to increase the strength of the container, the exterior surface is formed with trapezoidal sheets.

18

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

2.2.3 Drop Over Canopy Type Generator Sets

Teksan manufactures drop over canopies for outdoor installation with the following specifications;

• Interior surface of canopy is covered with non-flammable noise isolation foams.

• Sound insulation for air inlet and outlet.

• Cabinet doors on both sides, for reaching around the generator set easier.

• Transfer panel can be included inside the canopy, or it can be put somewhere outside the canopy.

• Generator should not be lifted up using the lifting lugs on the canopy. Firstly generator set must be located on the

platform and then drop over canopy must be put on it. Drop over canopy can be mounted and unmounted easily on

a generator set, so this provides the user an easier installation process.

• Drop over canopy must be fixed to the ground on the generator set platform.

19

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

2.2.4 Mobile Generator Sets

Trailer Mounted Generator Sets & Lighting Tower

Generator sets can be supplied with trailers for mobile usage. Equipped with tires to provide full mobility services

for easy movement to the site where power is required, these generator sets can be utilized as lighting towers,

rental power, military, construction etc. applications. These sets can also be designed as ‘ultra silent’ upon

customer request.

20

BBK-V.122018_ENG People First...

EVERLASTING COMPANY

EVERLASTING

WE

COMPANY

AREYOUR

EVERLASTING

WE

COMPANY

AREYOUR

2.3 Diesel Engine

Teksan uses the diesel engines those are manufactured with latest technology, in accordance with ISO3046

standards and designed for generator sets. The diesel engines used; are designed for low fuel consumption, with

4-stroke type, direct injection, with all needed limiting and level sensors, with diesel electronic or mechanical

type governor mounted on fuel pump for sensitive speed adjustment or regulation. The engines used, may have oil,

air or water type cooling systems, depending on customer request and the diesel engine. There are also oil, fuel,

air filters which are designed for heavy operation conditions, which provide the engine a long lifetime with a high

performance. All the equipment that is needed for the diesel engine for operating safely and reliably, is provided

along with the generator set.

2.4 Alternator

Alternators used on TEKSAN generator set are designed in compliance with the standards IEC600341, CEI23,

BS4999, BS5000, VDE0530, NF51100, NF51111, OVEM10 and NEMA MG 1.22.

Their insulation systems are in compliance with CE regulations and have UL certification.

They have brushless type self-excitation systems which do not require any maintenance action.

They provide a precise voltage regulation under steady-state and linear loading conditions.

Further information can be found inside the engine and alternator manuals which are

supplied together with the generator set.

Table of contents

Other TEKSAN Portable Generator manuals

Popular Portable Generator manuals by other brands

Champion

Champion 46597 Owner's manual & operating instructions

Tronair

Tronair 5731 OPERATION & SERVICE INSTRUCTIONS

Sony

Sony AC-V60A Service manual

Tesla

Tesla TI3000 GPU-24-INV-1800 user manual

Bioclimatic

Bioclimatic Aerotron 30 Installation, operation and maintenance guide

Kodiak

Kodiak SGA2300GC Operating instructions and parts manual