tekton 46845 User manual

OPERATOR’S MANUAL

WARNING: BEFORE USE, READ AND UNDERSTAND OPERATOR'S MANUAL. Wear impact-resistant

protective eyewear in work area at all times. This reel must only be mounted to a load bearing structural object

such as a stud, rafter, or floor which can support the combined weight of reel and hose and can withstand pulling

forces on hose when in use. Air hose is designed for use on regulated air compressor systems. DO NOT

EXCEED MAXIMUM WORKING PRESSURE. Be sure to restrain hose as it rewinds—do not allow hose to

rewind at full speed. Never exceed air pressure rating for any air tool. Read and follow all air tool owner’s manuals

and instructions. Certain air tools, such as paint spray guns, sanders, grinders, and sandblasting equipment,

present specific dangers and hazards. Consult applicable material safety data sheet for precautions and possible

respirator recommendation.

CALIFORNIA WARNING: This product contains chemicals known to the State of California to cause birth defects

or other reproductive harm. Please wash hands thoroughly after handling.

STORE THIS MANUAL IN A SAFE

PLACE FOR FUTURE REFERENCE

®

Model #s

46845, 46848

Save time, contact us first.

888-648-8665

NEED HELP?

!

?

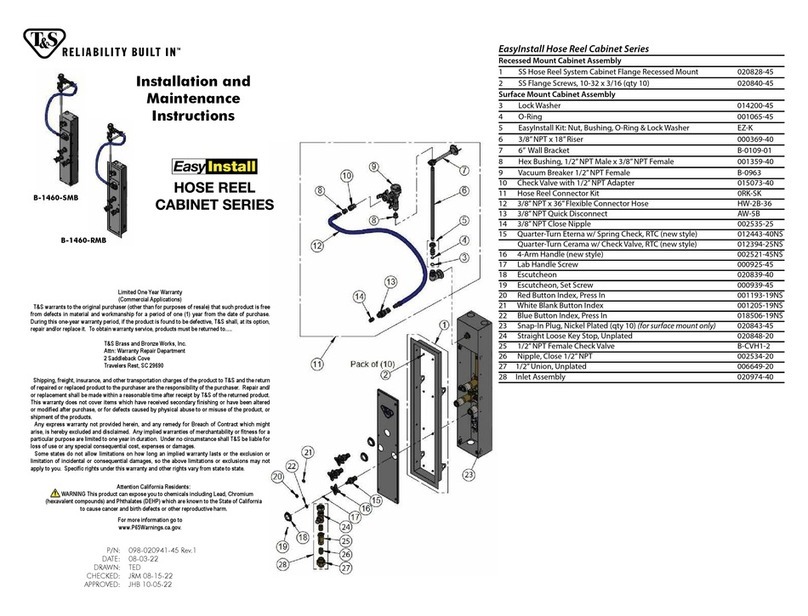

AUTO REWIND AIR HOSE REEL

Air Hose

Hose Stopper

page 2

For complete parts diagram, see

page 6-7, centerfold of book

Guide Arm

Support Leg

Air Inlet Valve

Guide Roller

Collar

Drum

Base

Model # 46848

• Air Hose Size: 1/2" x 50'

•Reel Air Inlet (F): 1/2" NPT

•Air Hose Outlet (M): 1/2" NPT

•Max Working Pressure: 250 PSI

•Maximum Air Flow: 35 CFM

Model # 46845

• Air Hose Size: 3/8" x 50'

•Reel Air Inlet (F): 1/4" NPT

•Air Hose Outlet (M): 1/4" NPT

•Max Working Pressure: 250 PSI

•Maximum Air Flow: 25 CFM

OPERATING AIR HOSE REEL

BEFORE MOUNTING AIR HOSE REEL, please take a few minutes to understand how the reel works. Practice operating

the hose reel a few times, pulling hose out and retracting it back onto reel. This will familiarize you with basic functions

and can help you understand where best to mount the air hose reel.

This air hose reel automatically retracts air hose using an internal spring motor. When hose is pulled from reel, it is pulled against

the tension of the spring motor. The more hose is pulled out, the greater the tension built up in spring motor. NEVER LET GO OF

HOSE WHILE PULLING FROM REEL. Letting go will allow hose to rewind at uncontrolled speed, possibly damaging the internal

spring or guide collar.

1. Grasp air hose and pull slowly from reel. As hose is pulled from reel, the entire reel drum rotates. To prevent extra wear on air

hose, periodically check to be sure guide rollers inside collar are rolling smoothly.

2. As reel drum rotates, the locking gear and pawl make a short series of four clicking sounds each 1/2 revolution. In one

revolution, there are a total of eight locking positions.

3. TO LOCK REEL IN POSITION, slow down pulling motion as desired length of hose is reached. While slowly pulling, listen for

each short series of clicking sounds. As the reel is clicking, stop pulling hose and decrease tension. Reel should lock in

position.

TO RETRACT HOSE ONTO REEL, slowly pull hose out until the first series of clicks stops. This means the locking pawl has

cleared the locking gear. DO NOT LET GO OF HOSE! Slowly allow hose to rewind onto reel until hose stopper rests against

guide collar.

page 3

Locking pawl

Locking gear

PULL

DO NOT PULL HOSE OUT BY

GRASPING ATTACHED TOOL.

This will damage air hose. Pull

only by grasping air hose itself.

1 2

3

R

O

T

A

T

E

page 4

MOUNTING HOSE REEL

Choosing a Location

DO NOT MOUNT HOSE REEL OUTDOORS OR ON VEHICLE. This hose reel is not designed to resist constant

exposure to weather or continuous vibration. Mount under cover in an area not directly exposed to weather.

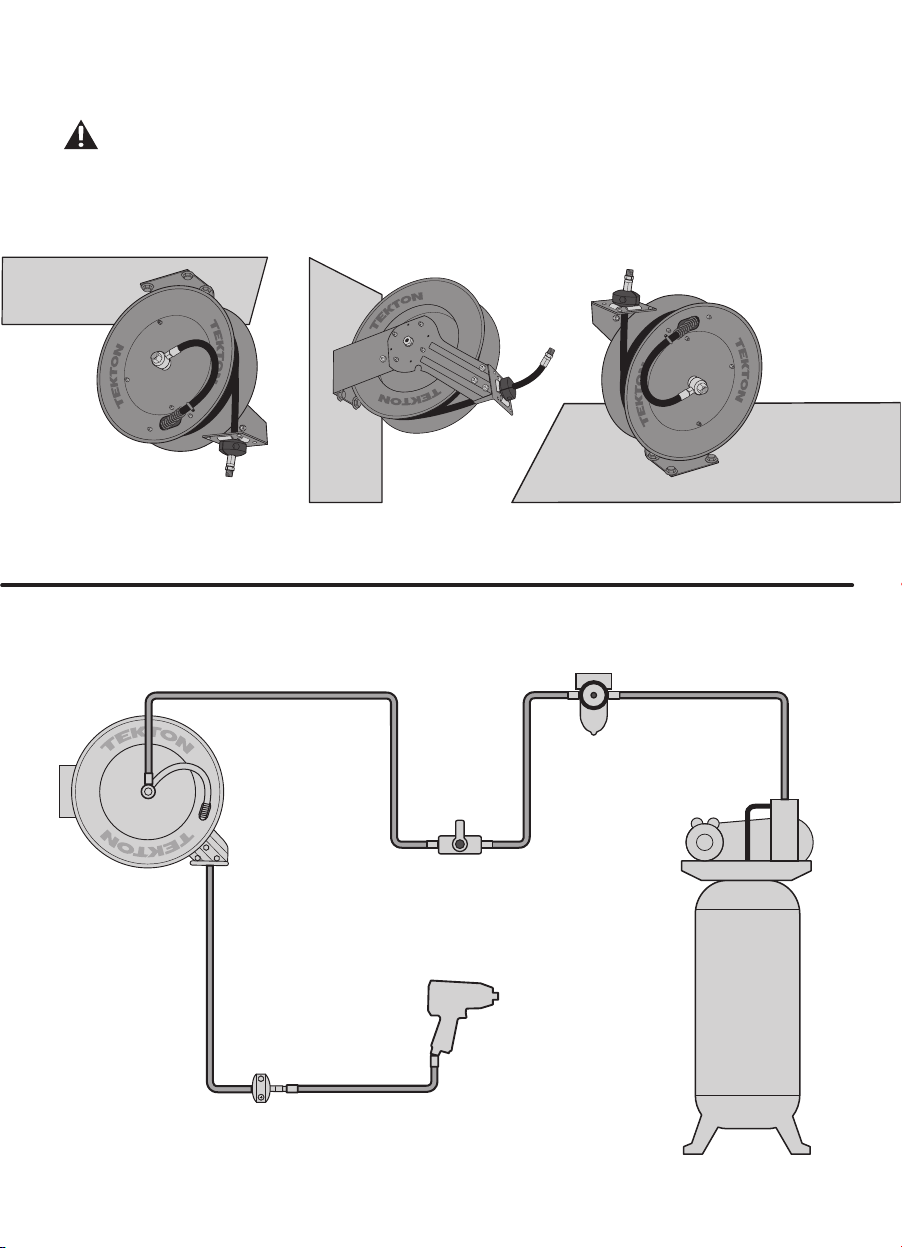

Reel can be mounted on the floor, ceiling, or wall, wherever it is convenient. When choosing a location, remember that you

can only mount reel to a load-bearing structural member capable of supporting combined weight of reel, hose, and

forces caused by pulling or manuevering hose. Mounting reel near air compressor may be desirable since you can connect

the two with a shorter, less expensive length of hose. Also, air compressor controls will be conveniently nearby.

FLOOR

CEILING

WALL

COMPRESSOR

WHIP HOSE

TOOL

SHUTOFF VALVE

REGULATOR

MOISTURE TRAP

LUBRICATOR

AIR

HOSE

REEL

Typical Compressed Air System

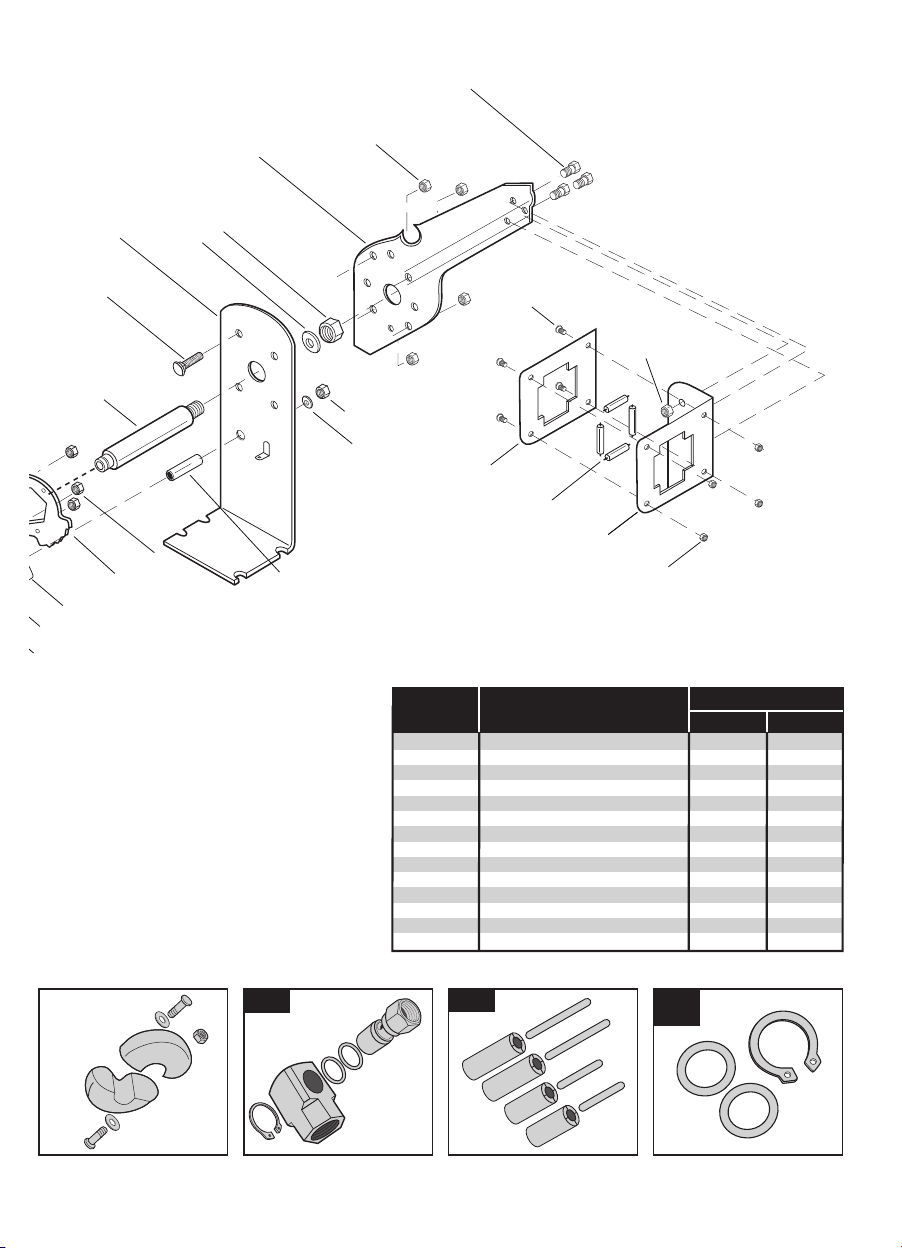

1. Use included mounting template to mark hole locations.

Use a level to position template. Tape securely in position

before marking. Remove template when finished.

3. Pre-install lower pair of hardware and tighten down leaving

just enough space to snugly fit base.

4. Hang hose reel by sliding slotted base onto pre-installed

hardware. Carefully let go of hose reel, making sure its

weight is being supported. Hose reel should support itself

in this position long enough to install remaining hardware.

5. Immediately install second set of hardware. Tighten all

hardware until snug. Do not overtighten.

CAUTION: CEILING MOUNTING REQUIRES TWO PEOPLE. DO NOT

ATTEMPT TO MOUNT HOSE REEL TO CEILING BY YOURSELF. USING

A LADDER CAN BE DANGEROUS AND IS NOT RECOMMENDED.

1. Use included mounting template to mark hole locations. Tape securely in position

before marking. Remove template when finished.

2. Drill holes for bolts. Keep drill steady and in line with hole to prevent wobbling and

enlarging of hole.

3. Pre-install one pair of hardware and tighten leaving just enough space to fit base.

4. Hang hose reel by sliding slotted base onto pre-installed hardware. DO NOT LET

GO OF HOSE REEL!

5. While continuing to support reel, install second pair of hardware. Tighten all

hardware until snug. Do not overtighten.

1. Use included mounting template to mark hole locations. Tape securely in

position before marking. Remove template when finished.

2. Drill holes for bolts. Keep drill steady and in line with hole to prevent

wobbling and enlarging of hole.

3. Set reel in position, aligning base with holes. Install all hardware,

tightening until snug. Do not overtighten.

CEILING

WALL

FLOOR

MOUNTING TEMPLATE

2. Drill holes for bolts. Keep drill steady and in line with hole to

prevent wobbling and enlarging of hole.

WOOD - Lag bolt,

lock washer, and

washer

4X 4X 4X

METAL - Bolt, two

washers, lock washer,

and nut

MASONRY - Bolt, lock

washer, washer, and

anchor

page 5

ATTENTION - Mounting bolts

can loosen with heavy use or over

time. Check condition of mounting

bolts every 6 months.

1. Main Spring Cover - Outside

2. Main Spring

3. Main Spring Cover - Inside

4. Drum - Outside

5. Drum - Inside

6. Support Leg and Base

7. Guide Arm

8. Hose Guide Collar

9. Back Plate

10. Rollers (4) & Pins (4)

11. Air Inlet Valve

12. Swivel Connector

13. Retaining Ring

14. Washer

15. Nut (4)

16. Bolt (4)

17. Nut (4)

18. Hose Clamp

19. Bolt

20. Nut

21. Carriage Bolt (3)

22. Nut (3)

23. Axle

24. Washer

25. Nut

26. Locking Gear Hub

27. Locking Gear

28. Locking Pawl

29. Locking Pawl Axle

30. Locking Pawl Spring

31. Spacer

32. Washer

33. Nut

34. Carriage Bolt (4)

35. Nut (4)

36. Bolt (3)

37. Nut (3)

38. Bolt (4)

39. Nut (4)

40. Hose Stopper

41. Bolt (2)

42. Washer (2)

43. Nut (2)

44. Air Hose

45. Bend Restrictor

P

ARTS

L

IST

page 6

1

16

11

23

4

5

17

12

13 14

20

19

18

21

26

2928

30

15

99001 99002

99040

45

43

40

41

44

42

99006 99018 99041

99042

page 7

23

34

25

24

35

36

6

7

26

29

22

28

30

27 31

32

33

38

37

8

10

9

39

ASSEMBLY DESCRIPTION

99001 3/8" Air Inlet Assembly

99002 Locking Pawl Assembly

99003 Guide Collar and Roller Assembly

99004 3/8" Hose Stopper Assembly

99005 Main Spring Canister Assembly

99006 1/2" Air Inlet Assembly

99007 1/2" Hose Stopper Assembly

99008 3/8" x 25' Air Hose

99009 3/8" x 50' Air Hose

99010 1/2" x 50' Air Hose

99018 Guide Rollers and Pins

99040 Locking Pawl Assembly

99041 3/8" O-Ring Kit

99042 1/2" O-Ring Kit

FITS THIS HOSE REEL

46845

•

•

•

•

•

•

•

•

46848

•

•

•

•

•

•

•

•

page 8

MAKING ADJUSTMENTS

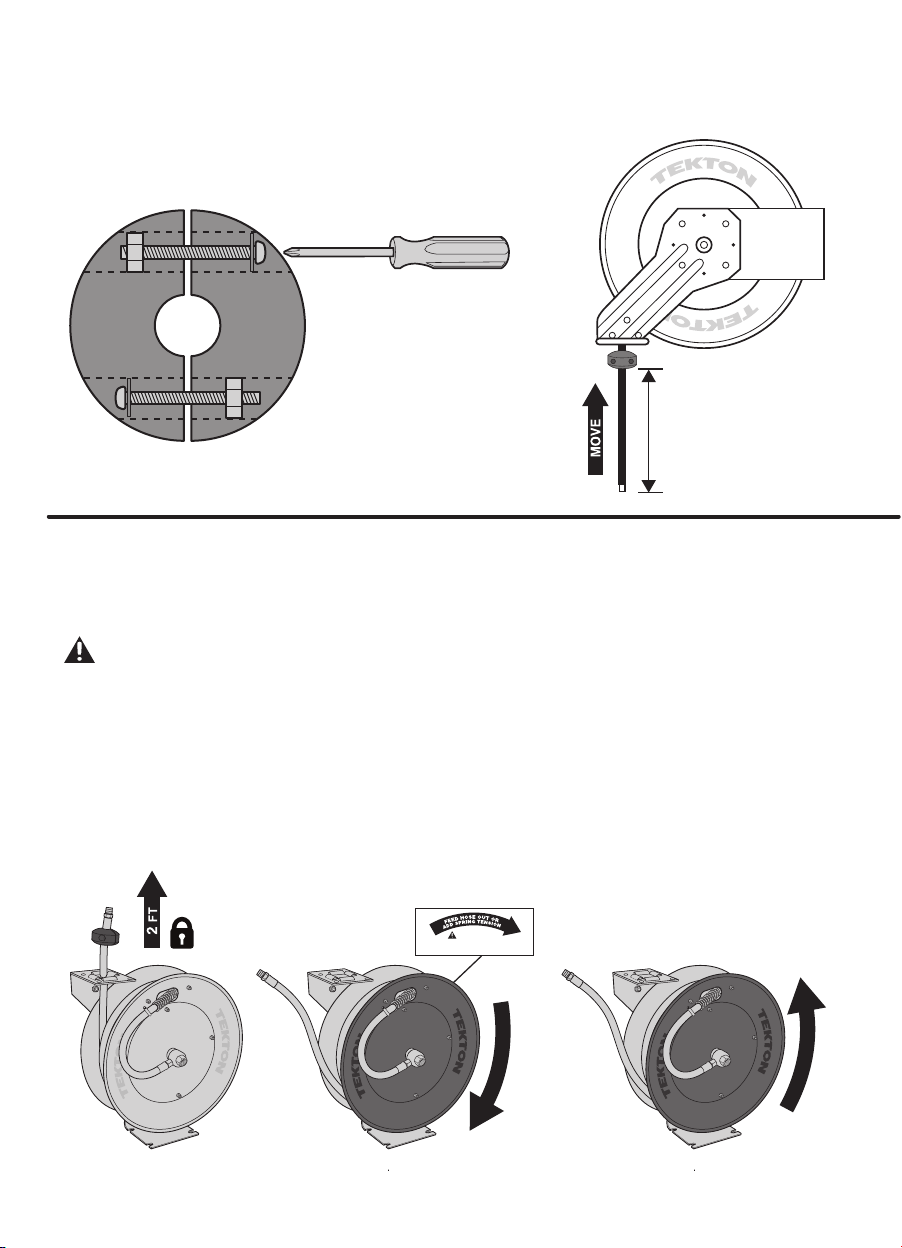

Adjusting the Guide Arm

1. Pull out 3-4 feet of hose and

lock reel in position.

3. Rotate guide arm to one of five positions desired. Replace four bolts and tighten.

2. Remove the four bolts connecting

guide arm to base.

12

34

Assemble bolts

as shown

BASE

GUIDE ARM

OUTSIDEINSIDE

1

4 5

2 3

page 9

Adjusting Recoil Tension

Hose reel is shipped with spring tension properly set. Be aware that spring tension is calibrated to retract entire length of air

hose. If you are working with only part of the air hose length, recoil action may seem slower than expected. However, if you feel

hose rewinds too quickly or too slowly, you can easily adjust the tension of the main recoil spring by simply turning the reel drum

to a new "home" position.

DO NOT SET TOO MUCH TENSION IN SPRING. Damage to spring could result.

1. Disconnect incoming air supply.

2. Pull out about two feet of hose and lock reel in position.

3. Remove hose stopper. Pull hose backward through hose guide.

4. While firmly gripping edge of reel drum, turn reel clockwise (as viewed from air inlet side) just enough to release locking pawl.

DO NOT LET GO OF REEL DRUM, or it will spin uncontrolled until all spring tension is lost.

To Increase Tension: Turn reel drum clockwise until desired tension has been added. Lock reel in nearest locking position.

To Decrease Tension: Allow reel drum to slowly turn counterclockwise until extra tension has been released. Lock reel in

nearest locking position.

5. Feed hose through hose guide. Re-attach hose stopper.

6. Connect incoming air supply.

Adjusting Hose Stopper Position

The hose stopper determines the length of hose that remains outside of reel. To adjust stopper position, first pull

hose out past the desired position of hose stopper. Lock reel in position. Loosen (but do not remove) both stopper

bolts just enough so stopper can slide along hose. Move stopper to desired position. Tighten stopper bolts until

hose stopper cannot slide. Do not overtighten bolts.

Loosen but do not

remove bolts

D

E

C

R

E

A

S

E

I

N

C

R

E

A

S

E

See label

DO NOT OPEN THIS COVER!

Spring motor inside is under tension.

CAUTION

Desired length

of hose

DO NOT

TURN

page 10

ATTACHING INCOMING AIR

For maximum leak-free performance, air inlet valve is made of solid brass. Brass is a soft metal and overtightening or rough

handling can cause damage or breakage. Use care when working with air inlet valve. For a tight, leak-free connection, follow all

instructions carefully.

Option 1

Wrap incoming hose end with thread sealing tape. AIR INLET VALVE CANNOT ROTATE, do not attempt to turn. To prevent

rotation, hold air inlet valve with wrench to stabilize it while connecting air hose. Thread air hose into air inlet valve. Using second

opposing wrench, tighten connection just until snug.

Option 2

Locate included 90˚ connector. Wrap threaded end with thread sealing tape. AIR INLET VALVE CANNOT ROTATE, do not

attempt to turn. To prevent rotation, hold air inlet valve with wrench to stabilize it while connecting air hose. Thread 90˚ connector

into air inlet valve. Using second opposing wrench, tighten connection just until snug. Next, wrap incoming hose end with thread

sealing tape. Thread into swivel end of 90˚ connector. Using two opposing wrenches, tighten connection just until snug.

To ensure optimum performance and efficiency, check all connections for leaks. With air system pressurized, brush

each connection with soapy water. Inspect closely. Air bubbles indicate leaking air. Tighten any leaking fittings.

OPTION 1

Incoming

Air

0º

OPTION 2

Incoming

Air

90º

46848

air inlet design

DO NOT

TURN

page 11

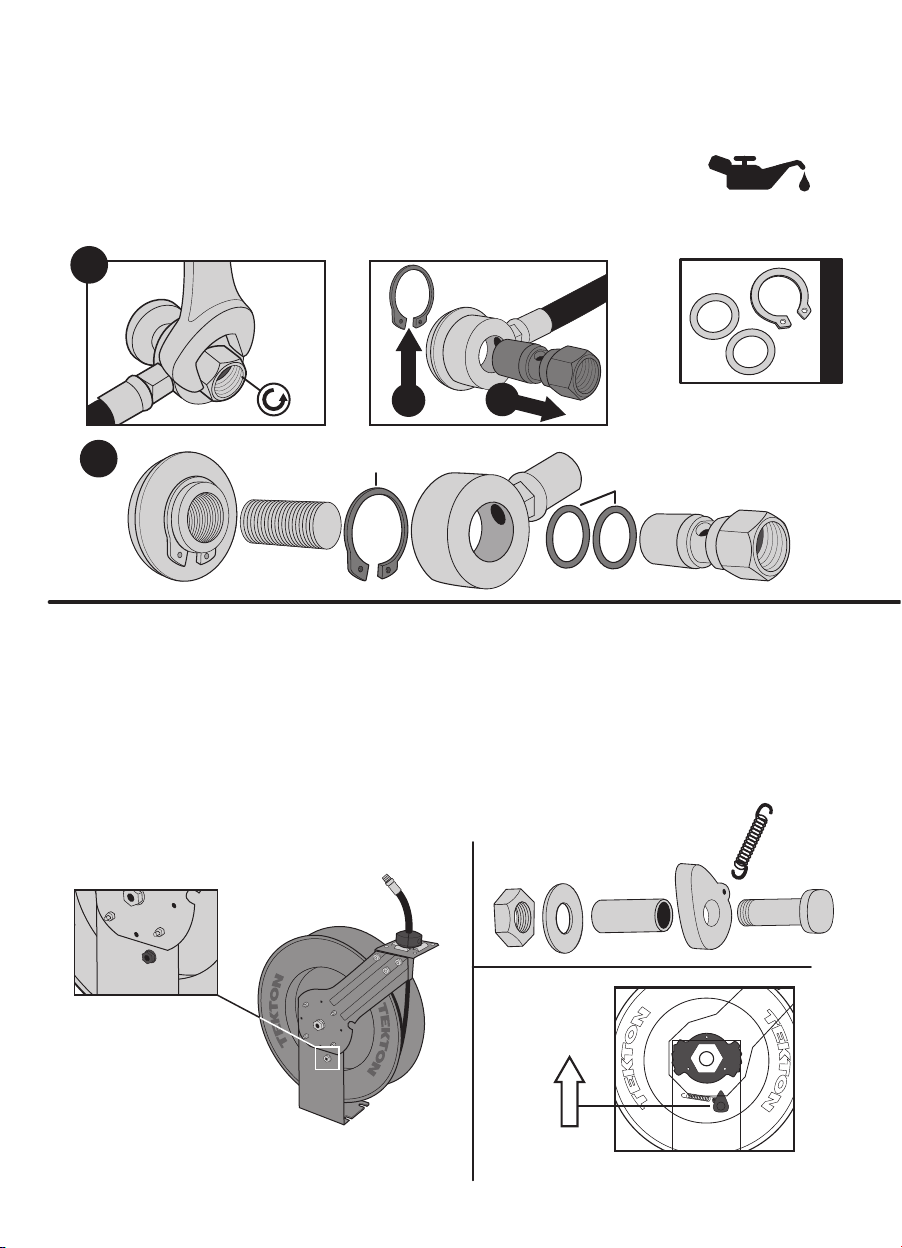

Replacing Air Inlet Valve O-rings

The O-ring seals inside the air inlet valve assembly wear over time. If leaking around air inlet valve

is observed, O-rings should be replaced. An O-ring replacement kit is shipped with this hose reel.

Store in a safe place for future use.

1. Disconnect incoming air supply. Unscrew air inlet valve assembly (part 11) from axle

(part 23) by fitting wrench onto hex portion of valve and turning counterclockwise.

2. Remove retaining ring (part 13) and slide air inlet valve swivel connector (part 12) off

from swivel connector.

3. Remove worn O-rings from air inlet valve and replace with new parts.

Reverse above procedure to re-assemble.

INCLUDED KIT

For easy installation and

best seal, thinly coat

O-rings with petroleum jelly.

Replacing Locking Pawl

Sometimes with heavy use, the locking pawl can begin to wear causing poor engagement with ratchet teeth. This can result in

slipping or difficulty locking. It is easy to replace and can be done while hose reel is mounted.

1. Reel should be in fully retracted position ("home"), with hose stopper resting against guide roller collar. Be sure locking pawl

is not engaged with ratchet teeth, and that there is enough clearance between pawl and teeth to allow free and easy removal

and installation of locking pawl assembly.

2. Unhook return spring from anchor point. Loosen and remove lock nut. Remove old locking pawl assembly from support leg.

3. Insert new locking pawl assembly through support leg. Thread on lock nut and tighten until snug. Hook end of return spring

through anchor point.

4. Verify function of locking pawl by pulling hose out and locking reel in position.

Stop pawl nut

Install stop pawl

pointed toward

center of reel

Retaining Ring

O-Rings

3

1

2a 2b

This manual is the sole property of Michigan Industrial Tools. No part

of this manual, may be reproduced in any form, without the express

written consent of Michigan Industrial Tools.

© Copyright 2015

Michigan Industrial Tools

WWW.TEKTON.COM

Michigan Industrial Tools

3707 Roger B Chaffee SE

Grand Rapids, MI 49548

Printed in China

Replacing Hose

If hose becomes damaged, it may be necessary to replace it. In most cases, air hose can be replaced while reel is

still mounted. Replace air hose with same diameter and length of original hose. Installing a longer or shorter

hose will require Adjusting Recoil Tension (page 9).

1. Disconnect incoming air supply. Pull out about 1 foot of hose and lock reel in position. DO NOT UNLOCK HOSE

REEL during this installation process. If reel becomes unlocked, it will spin at uncontrolled speed, possibly

resulting in damage to internal spring.

2. Remove hose stopper. Pull hose backward through guide roller collar. Unwrap (counterclockwise, when viewed

from air inlet side) until reel is empty.

3. Remove hose clamp. Save for re-installation. Disconnect hose end from air inlet assembly. Pull hose end back

through slot in reel drum. Remove spring guard from old hose.

4. Place spring guard on new hose. Feed hose end through slot in reel drum. Wrap end of new hose with thread

sealing tape. Connect to air inlet assembly. Re-install hose clamp. Make sure spring guard is aligned correctly in

slot to protect hose from sharp metal edges.

5. Wrap hose around reel (clockwise) until 1-2 feet of hose remains.

6. Feed hose end through guide roller collar. Re-attach hose stopper in desired position. Unlock hose reel

and rewind until hose stopper rests against guide roller collar. Connect incoming air supply.

1 YEAR REPLACEMENT GUARANTEE

This product is guaranteed for 1 YEAR. If it does not meet your expectations, we will replace

it or provide replacement parts free of charge. To arrange for shipping of your replacement

us at 1-888-648-8665. Please have receipt or other proof of purchase available.

1

4

DO NOT OPEN THIS COVER!

Spring motor inside is under tension.

CAUTION

See label

W

R

A

P

5 6

U

N

W

R

A

P

2 3

This manual suits for next models

1

Table of contents

Other tekton Tools manuals