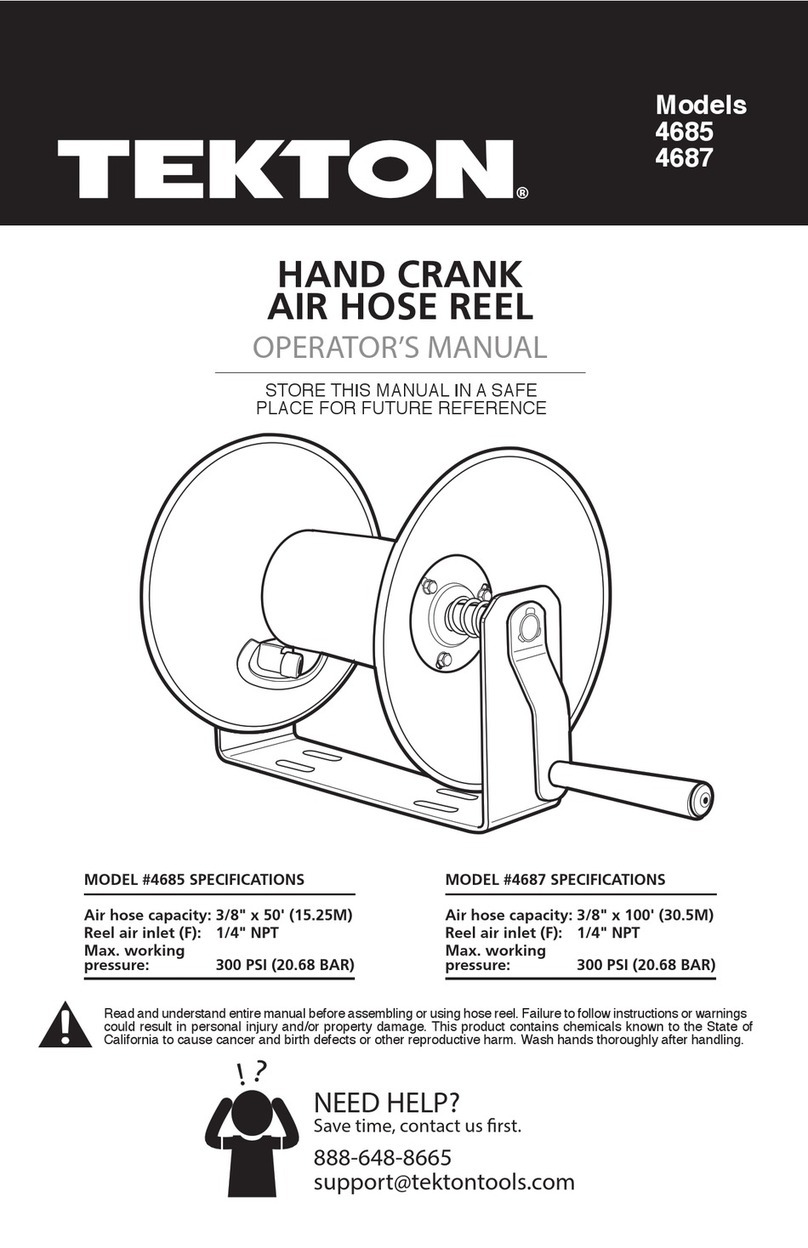

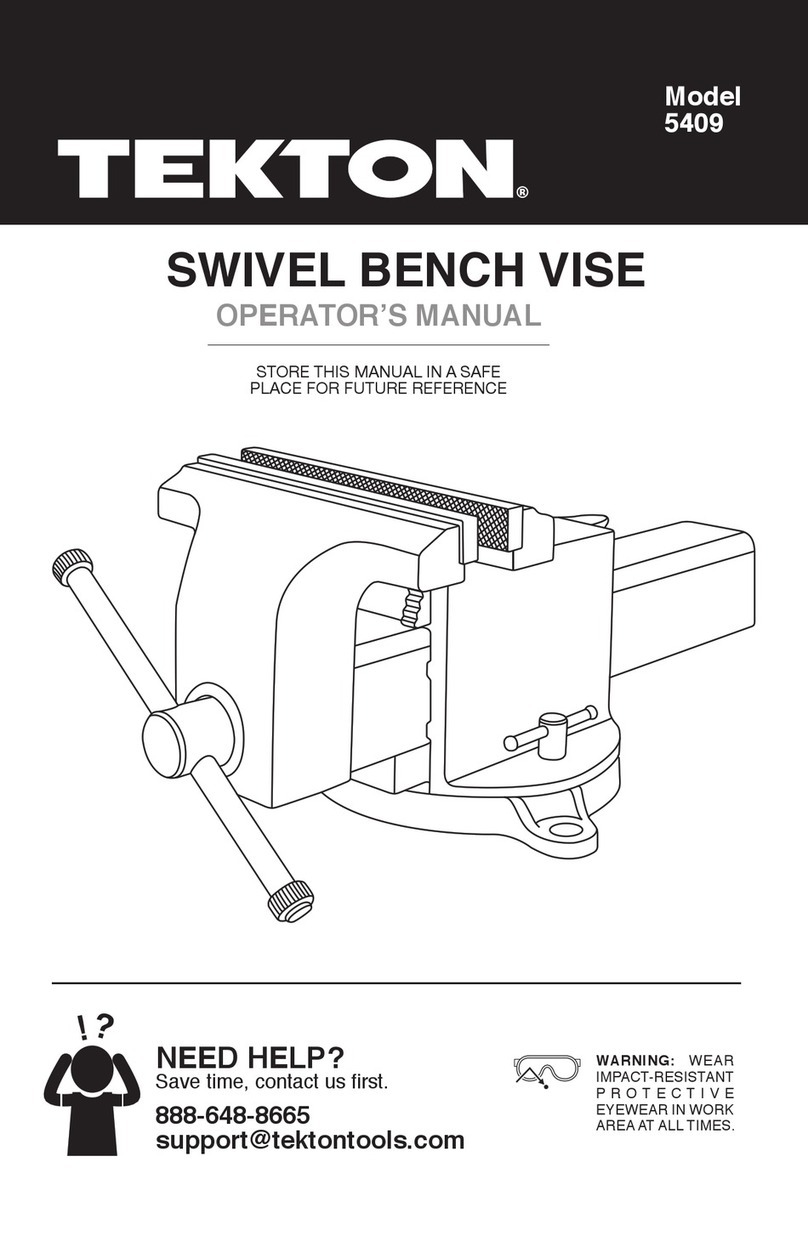

tekton 46875 User manual

WARNING: BEFORE USE, READ AND UNDERSTAND OPERATOR'S MANUAL. Wear impact-resistant protective

eyewear in work area at all times. This reel must only be mounted to a load bearing structural object such as a

stud, rafter, or floor which can support the combined weight of reel and hose and can withstand pulling forces on

hose when in use. Air hose is designed for use on regulated air compressor systems delivering less than 250 PSI.

DO NOT EXCEED 250 PSI. Be sure to restrain hose as it rewinds—do not allow hose to rewind at full speed.

Never exceed air pressure rating for any air tool. Read and follow all guidelines specified in the air tool owner’s

manual. Certain air tools, such as paint spray guns, sanders, grinders, and sandblasting equipment, present

specific dangers and hazards. Consult applicable material safety data sheet for precautions and possible respirator

recommendation.

OPERATOR’S MANUAL

STORE THIS MANUAL IN A SAFE

PLACE FOR FUTURE REFERENCE

®

AUTO REWIND AIR HOSE REEL

Items

46875, 46878

Save time, contact us first.

888-648-3371

NEED HELP?

!

?

Bend Restrictor

Hose Stopper

Model # 46875

• Air Hose Size: 3/8" x 50'

•Reel Air Inlet (F): 1/4" NPT

•Air Hose Outlet (M): 1/4" NPT

•Max Working Pressure: 250 PSI

•Max Burst Pressure: 1100 PSI

•Maximum Air Flow: 25 CFM

Model # 46878

• Air Hose Size: 1/2" x 50'

•Reel Air Inlet (F): 1/2" NPT

•Air Hose Outlet (M): 1/2" NPT

•Max Working Pressure: 250 PSI

•Max Burst Pressure: 1200 PSI

•Maximum Air Flow: 35 CFM

Guide Arm

Guide Arm

Air Inlet

Roller Guide

Drum

Locking Pawl

Support Leg

Support Leg

Base

For complete parts diagram, see

page 6-7, centerfold of book

page 2

Locking pawl

Locking gear

PULL

1

R

O

T

A

T

E

page 3

OPERATING AIR HOSE REEL

BEFORE MOUNTING AIR HOSE REEL, please take a few minutes to understand how it works. Practice operating it a

few times, pulling hose out and rewinding it back onto the drum. This will familiarize you with basic functions and can help

you understand where best to mount the air hose reel.

This air hose reel automatically rewinds air hose using an internal recoil spring. When hose is pulled from reel, it is pulled against

the tension of the recoil spring. The more hose is pulled out, the greater the tension built up in the recoil spring. NEVER LET GO

OF HOSE WHILE PULLING FROM REEL. Letting go will allow hose to rewind at uncontrolled speed, possibly damaging the

internal spring or roller guides.

1. Grasp air hose and pull slowly from reel. As hose is pulled from reel, the entire reel drum rotates. To prevent extra wear on air

hose, periodically check to be sure roller guides inside collar are rolling smoothly.

2. As reel drum rotates, the locking gear and pawl make a short series of six clicking sounds each 1/2 revolution. In one

revolution, there are a total of twelve locking positions.

3. TO LOCK REEL IN POSITION, slow down pulling motion as desired length of hose is reached. While pulling slowly, listen

for each short series of clicking sounds. As the pawl is clicking, stop pulling hose and decrease tension. The drum should lock

in position.

TO REWIND HOSE ONTO REEL, slowly pull hose out until the first series of clicks stops. This means the locking pawl has

cleared the locking gear. DO NOT LET GO OF HOSE! Slowly allow hose to rewind onto drum until hose stopper rests against

guide collar.

2

3

FLOOR

CEILING

WALL

page 4

MOUNTING HOSE REEL

Choosing a Location

DO NOT MOUNT HOSE REEL OUTDOORS OR ON VEHICLE. This hose reel is not designed to resist constant

exposure to weather or continuous vibration. Mount under cover in an area not directly exposed to weather.

Reel can be mounted on the floor, ceiling, or wall, wherever it is convenient. When choosing a location, remember that the

must be mounted reel to a load-bearing structural member capable of supporting combined weight of reel, hose, and

forces caused by pulling or maneuvering hose. Mounting reel near air compressor may be desirable since you can connect

the two with a shorter, less expensive length of hose. Also, air compressor controls will be conveniently nearby.

COMPRESSOR

WHIP HOSE

LEAD-IN HOSE LEAD-IN HOSE

TOOL

SHUT-OFF VALVE

RIGID PIPE

REGULATOR

MOISTURE TRAP

LUBRICATOR

AIR

HOSE

REEL

TYPICAL COMPRESSED AIR SYSTEM

page 5

TYPICAL INSTALLATION

WALL STUDS

MOUNTING PLATE

Example: 2x10 lumber

Lag bolt, lock washer,

and flat washer

4X 4X 4X

Machine bolt, two flat

washers, lock washer,

and nut

Machine bolt, lock washer,

flat washer, and anchor

TYPICAL FASTENERS AND HARDWARE COMBINATIONS

WOOD METAL MASONRY

INSTALLATION

Use included mounting

template to mark and drill the

hole locations.

MOUNTING TEMPLATE

Temporarily install the upper

fasteners leaving a 1/4" gap to

accommodate thickness of base.

1/4"

GAP

1. 2.

3. 4.

Guide base plate key holes over

the preinstalled fasteners.

Keep hose reel supported

at all times until all fasteners

are tight.

Install the lower fasteners

and tighten.

Remove the upper fasteners, and

reinstall with appropriate washers

and tighten all fasteners.

Keep hose reel supported

at all times until all fasteners

are tight.

KEYHOLE

SLOTS

1

2

6

5

4

12

5

14

13

10

7

910

8

11

11

3

30

99011

99016

page 6

44

42

39

40

43

41

PARTS LIST

1. Recoil Spring Cover

2. Recoil Spring

3. Recoil Spring Hub

4. Spring Cover Bolt

5. Nut (8)

6. Drum

7. Guide Arms (2)

8. Support Legs (2)

9. Base

10. Bolt (16)

11. Washer (16)

12. Nut (4)

13. Bolt (4)

14. Nut (4)

15. Guide Collar

16. Rollers (4)

17. Roller Pins (4)

18. Bolt (4)

19. Washer (4)

20. Rubber Bushing (4)

21. Nut (4)

22. Bolt (4)

23. Nut (4)

24. Air Inlet Axle

25. Air Inlet

26. Retaining Ring (2)

27. Retaining Ring

28. Air Outlet (To Hose)

29. Main Axle Bearing

30. Bolt

31. Locking Pawl

32. Tension Spring

33. Locking Pawl Axle

34. Retaining Ring

35. Locking Gear

36. Hose Clamp

37. Bolt

38. Nut

39. Hose Stopper

40. Bolt (2)

41. Washer (2)

42. Nut (2)

43. Air Hose

44. Bend Restrictor

35

10

25

8

7

32

21

15

20

26

29

24

31

36 37

38

27

22

19

18

16

14

28

46

23

13

47

11

33

34

22

17

ASSEMBLY DESCRIPTION 46845 46848

99011 3/8" Air Inlet Assembly •

99012 Locking Pawl Assembly •

•

99013 Guide Rollers and Pins •

•

99014 3/8" Hose Stopper Assembly •

99015 Main Spring •

•

99016 1/2" Air Inlet Assembly •

99017 1/2" Hose Stopper Assembly •

99043 3/8" O-Ring Kit •

99044 1/2" O-Ring Kit •

FITS THIS HOSE REEL

99012 99014

99017

99013 99043

99044

page 7

MAKING ADJUSTMENTS

Remove position bolts and nuts. Leave pivot

bolt in place. Adjust to one of three desired

positions. Reinstall fasteners and tighten.

1

2

3

12 3

page 8

Pivot Bolt

Position Bolt

Guide Collar

Air Hose

Adjusting the Guide Collar

Adjusting the Guide Arm

1 2

1. Pull out 3-4 feet of hose and secure the hose

reel drum.

Locking gear will disengage when bolts

are removed! Secure drum before

removing bolts.

2. Remove the bolts connecting the guide arms

to the support legs.

Locking gear will disengage when bolts

are removed! Secure drum before

removing bolts.

3. Rotate guide arm to one of two positions.

Replace bolts and tighten.

1

2

3

4

Reinstall bolts

as shown.

TWO PEOPLE ARE RECOMMENDED FOR THIS PROCESS. During the course of this adjustment, the locking gear

will disengage and become ineffective. Ask a second person to hold the drum to prevent it from spinning while

removing and reinstalling the guide arm bolts.

Adjusting Hose Stopper Position

The hose stopper determines the length of hose that remains outside of reel. To adjust stopper position:

1. First pull hose out past the desired position of hose stopper. Lock drum in position.

2. Loosen (but do not remove) both stopper bolts just enough so stopper can slide along hose.

3. Move stopper to desired position. Tighten stopper bolts until hose stopper cannot slide. Do not overtighten bolts.

Desired length

of hose

Loosen but do not

remove bolts

page 9

3. Unwrap one revolution of hose from

the reel.

4. Push the air hose through the roller

guide and reinstall hose stopper.

Keep drum locked at all times.

1. Pull out 2 feet of air hose and lock

drum. Remove air hose stopper.

2. Pull air hose back through the

roller guide.

Keep drum locked at all times.

3. Wrap one revolution of hose onto

the reel.

4. Push the air hose through the roller

guide and reinstall hose stopper.

Keep drum locked at all times.

1. Pull out 8 feet of air hose and lock

drum. Remove air hose stopper.

2. Pull air hose back through the

roller guide.

Keep drum locked at all times.

Adjusting Recoil Tension

Hose reel is shipped with spring tension properly set. Be aware that spring tension is calibrated to rewind entire length of air

hose. If you are working with only a portion of total air hose length or if you feel hose rewinds too quickly or too slowly, you

can easily adjust the tension of the main recoil spring.

DO NOT SET TOO MUCH TENSION IN SPRING. Damage to spring could result.

Decreasing Recoil Tension

Increasing Recoil Tension

U

N

W

R

A

P

2 FT

8 FT

W

R

A

P

12

34

12

34

ATTACHING INCOMING AIR

For consistent leak-free performance, air inlet is made of solid brass. Brass is a soft metal and extra care should be taken to

avoid cross threading. For a tight, leak-free connection, follow all instructions carefully.

Option 1

Wrap incoming air hose end with thread sealing tape. Thread air hose end into air inlet, taking care not to cross thread.

Tighten connection with wrench. Do not over-tighten.

Option 2

Locate included swivel nut connector. Wrap threaded end with thread sealing tape. Thread into air inlet, taking care not to

cross thread. Tighten connection with wrench. Do not over-tighten. Next, wrap end of incoming air hose with thread sealing

tape. Thread air hose into swivel end of connector, by turning swivel collar. Tighten connection with wrench. Do not

over-tighten.

To ensure optimum performance, check all connections for leaks. With air system pressurized, brush each

connection with soapy water. Inspect closely. Air bubbles indicate leaking air. Tighten any leaking fittings.

OPTION 2

OPTION 1

Lead-in

Hose

Lead-in

Hose

Swivel Nut

Connector

page 10

INCLUDED KIT

For easy installation and

best seal, thinly coat

O-rings with petroleum jelly.

Locking pawl

Replacing Locking Pawl

Sometimes with heavy use, the locking pawl can begin to wear causing poor engagement with locking gear teeth. This can

result in slipping or difficulty locking. It is easy to replace and can be done while hose reel is mounted.

1. Reel should be in fully retracted position ("home"), with hose stopper resting against guide roller collar. Be sure locking pawl

is not engaged with locking gear teeth, and that there is enough clearance between pawl and teeth to allow free and easy

removal and installation of locking pawl.

2. Unhook return spring from anchor point. Remove retaining ring with snap ring pliers. Remove old locking pawl and spring

from drum.

3. Attach new spring to locking pawl. Slide new locking pawl onto axle and secure with retaining ring. Hook return spring from

pawl to anchor point.

4. Verify function of locking pawl by pulling hose out and locking reel in position.

Install locking pawl

pointed toward

center of reel

Return spring Retaining ring

Locking pawl

3

2a

2b

page 11

Replacing Air Inlet O-rings

The O-ring seals inside the air inlet assembly wear over time. If leaking around air inlet

is observed, O-rings should be replaced. An O-ring replacement kit is shipped with this

hose reel. Store in a safe place for future use.

For complete parts diagram, see page 6-7, centerfold of book

1. Relieve air pressure and disconnect lead-in hose.

2. (2a) Remove retaining ring and (2b) slide swivel connector off from air

inlet axle.

3. Remove worn O-rings from air inlet axle and replace with new parts. Reassemble in

the order in which parts were removed and verify proper seal with soapy water.

1

1

345

2

Replacing Hose

If hose becomes damaged, it may be necessary to replace it. In most cases, air hose can be replaced while reel is

still mounted. Replace air hose with same diameter and length of original hose. Installing a longer or shorter

hose will require Adjusting Recoil Tension (page 9).

1. Shut off incoming air supply and disconnect the lead-in hose from the reel.

2. Pull air hose out of the reel until one wrap remains on the drum. Lock the drum in position. Before proceeding,

be sure drum is locked at a position that allows you to access the air hose clamp and air hose connection to

hub outlet.

BE AWARE THAT THE RECOIL SPRING IS UNDER MAXIMUM TENSION WITH DRUM IN THIS

POSITION. BE CAREFUL NOT TO ACCIDENTALLY DISENGAGE LOCKING PAWL. DRUM WILL

SPIN WITH UNCONTROLLED SPEED.

3. Remove the air hose clamp from the drum and disconnect air hose end from the hub outlet. Remove the air hose

from the reel. Save the spring guard and hose clamp for the new hose.

4. Feed the new hose through the roller guide, reinstall the spring guard, and connect the hose end to the reel hub

outlet. Do not use sealing tape on threads.

5. Reinstall the hose clamp and air hose stopper. Pull air hose to disengage the locking pawl and rewind the air

hose. Reconnect lead-in hose and turn on incoming air supply. Check all connections to verify there are no leaks.

© Copyright 2015

Michigan Industrial Tools

WWW.TEKTON.COM

Michigan Industrial Tools

3707 Roger B Chaffee SE

Grand Rapids, MI 49548

Printed in China

50 FT

Hub outlet Hub outlet

Remove

air hose

Install

air hose

This manual suits for next models

1

Table of contents

Other tekton Tools manuals