Telecast Adder 162 User manual

Adder™ 162/322

Audio/Intercom/Data Multiplexer

User Manual

Telecast Fiber Systems, Inc.

102 Grove Street

Worcester, MA 01605

Tel: 508-754-4858

Fax: 508-752-1520

www.telecast-fiber.com

2

3

Table of Contents

Introduction 5

Overview 5

Coaxial Cable Input and Output 5

Status Indicators 5

Battery Backup 5

Audio Input and Output 5

Data Input and Output 5

Representative System 6

Options 6

Unpacking 6

Optical Fiber 7

Installation of the Assembly 7

Line Power 7

Line Power Connection 7

Input Power Fuse 7

DC Current Requirements 9

Battery Charging 9

Electrical Hookups 9

Audio Connections 9

Digital Connections 10

Optical Connections 11

Optical Fiber Signals 11

Cable Fabrication 11

Fiber Ports 11

Multiple Fiber Versions 12

WDM Single Fiber Versions 12

Coaxial Cable Ports 12

Cable Runs 12

Fiber 13

Input and Output Module Connections 13

Removing and Replacing Modules 15

Optical Fiber or Coax Communication Selection 16

Switch Settings (older rev only) 16

Coax Length (older rev only) 16

Audible Alarm Settings 17

Local Power Alarm 17

Remote Power Alarm 17

4

Audio Signal Setup 18

Input Module Setup 19

Gain 19

Impedance 19

Grounding 19

Auxiliary Items 21

Signal Generator/Monitor 21

Status Indicators 22

Power Supply 22

Status 22

Received Signal Level 23

System Interconnections 24

Powering Up 25

Intercom Modules 25

Intercom Connections 27

4-wire Auxiliary (balanced) 27

Clear-Com 28

RTS Telex 29

Intercom Module Replacement 30

Cable Harness 30

Intercom Setup Switches 30

Theory of Operation 32

Data Connectors 32

Audio Circuits 34

Preventive Maintenance 36

Accessory List 36

Troubleshooting 37

Measuring Optical Power 37

Specifications 38

Repair 40

Warranty 41

5

Introduction

Overview

The Telecast AdderTM 162 (32 channels) and Adder 322 (64 channels) are modular, multi-

channel communications systems designed for the transmission of high-quality audio, data and

intercom functions. The units pre-amplify, digitize, multiplex, transmit and receive up to 64

channels of audio information, four data channels and three dual-channel intercoms over one or

two optical fibers or 2 coaxial cables. Audio path evaluation is achieved using a built-in audio

signal (tone) generator and level meter/monitor.

Modules contain eight connectors for mic (high or low impedance) or line level inputs, or eight

output connectors for signals de-multiplexed from the send/receive fiber.

The Adder 162 accepts up to four modules in any combination for a total of 32 channels in a

6RU, 10 inch high x 19 inch wide electronic equipment rack. The Adder 322 accepts up to eight

modules for a total of 64 channels in a 10RU, 17.5 inch high x 19 inch wide electronic

equipment rack.

Coaxial Cable Input and Output

Each assembly has a coaxial input and output on which all signals are multiplexed. There is no

redundancy in the coaxial system. On older versions, the coaxial input is activated by internal

DIP switches on the Main PC Board. The coaxial output is always active. On newer models, the

dip switches are gone and the units work on coax priority. That is to say that the system looks

for the coax link first and then, if it does not see one, switches to optical.

Status Indicators

The front panel of the Adder 162/322 contains LED status indicators that monitor audio signals,

the DC power source, and the communication link status.

Battery Backup

A Ni-Cad emergency battery backup is built into the assembly. Battery backup is limited to

approximately 20 minutes and should be considered short-term power loss protection. The

available Telecast power module (ADAP-AC-03 or Eel) provides continuous battery charging

during line power operation.

Audio Input and Output

Audio input levels are set up for each channel by switches on the front of each input module.

These switches set input gain from 0 to 40 dB, input resistance to 600 Ohm or 10 kOhm and a

+48 VDC bias voltage to power microphones either ON or OFF. A ground lift switch is also on

the front panel for use with each channel.

Audio outputs are at line level. There are no operator controls on the output modules.

Data Input and Output

The Model 162/322 assembly accepts and multiplexes four digital data signals and two remote

relay closures onto the output fiber. The receiving assembly accepts the transmission, restores

6

the digital signals and provides the switch closures. The number of data channels is fixed and

independent of the number of audio channels in the assembly.

Representative System

The flexibility offered by 64 channels of audio and the capability of having both input and output

modules in a single assembly can lead to many efficient and innovative hookups. A

representative system using the Telecast 322 in a 3-way split is shown in Figure 1.

Figure 1: Adder 322 with a 3-way Split

Options

Configure the 162/322 system by selecting the following options. Contact Telecast for details.

AI820 8-channel Input Module

AO820 8-channel Output Module

4-wire Intercom

Clear-Com 2-wire Intercom

RTS/Telex dual-channel Intercom

Multi-mode WDM (Wavelength Division Multiplexer)

Single-mode WDM

Unpacking

The Adder 162/322 minimum configuration consists of one input and one or more output

modules. Input (Model AI820) and output (Model AO820) modules are installed and tested by

Telecast prior to shipment, in accordance with customer specifications. In addition, microphone

impedance and bias is preset per customer order, as is preamplifier gain for each channel. In

addition to the Model 162/322 assembly with its Input and Output Modules, a system also

includes:

External power supplies (AC/DC adapters)

Protective covers for optical connectors

Hardware kits for rack mounting the units

7

Optical fiber

After unpacking, inspect the units for mechanical damage, and electrical connectors for bent or

damaged pins. Report any damage to the carrier and to Telecast Fiber Systems, Inc.

Leave the protective caps on the optical connectors until it is time to attach the fiber to the units.

Replace the caps onto the connectors whenever the fiber is disconnected.

Installation of the Assembly

Units are shipped ready for rack use. Some Adder 162/322 connections can be made at the

front or rear panel, which would have been determined when the order was placed. For bench

use, remove the rack mounting flanges by unscrewing them at three places along each flange.

Line Power

The external power supplies provided with each assembly require 120 VAC. Be sure that AC

outlets are within reach of their 6-foot power cords. If your Adder is equipped with intercoms that

require power (RTS or Clear-Com), you will need two such power supplies per frame.

Line Power Connection

Insert the 4-pin XLR connector from the Telecast power supply into the INPUT POWER

Switchcraft D4M receptacle located at the upper left corner or rear of the 162, and located at the

lower right corner or rear of the 322. Plug the supply into a 120 VAC line. See Figure 2 and

Figure 3 for the power connector locations and Table 1 for electrical connections.

Fuse XLR

Power

Figure 2: Input DC XLR Power Connector and Fuse

Table 1: XLR Power Connections

PIN SIGNAL

1 Ground

2 & 3 Unused

4 + Input VDC

Input Power Fuse

The SLO BLO power fuse in Figure 2 and Figure 3 is located next to the INPUT POWER

connector. Use a 6.25 Amp 5 x 20 mm approved fuse type for both Model 162 and Model 322.

Be sure to use the same fuse type if replacement is required.

8

Figure 3: Adder 322 and 162 rear panels

9

DC Current Requirements

Any 15 VDC external power supply used with the Adder 162 must provide 2.5 amperes

continuous current.

Any 15 VDC external power supply used with the Adder 322 must provide 3.5 amperes

continuous current.

Although the Adder 162/322 assembly will operate at 10 VDC, ≥13.8 VDC is required to charge

the internal backup battery. System operation below 15 VDC can cause battery charge

depletion.

Battery Charging

The internal battery is automatically charged whenever 13.8 VDC is provided at the INPUT

POWER connector shown in Figure 2 on page 3. Full charge takes 16 hours, and will power

Model 162 for 30 minutes and Model 322 for 15 minutes.

Electrical Hookups

Audio Connections

Audio I/O is via 3-pin XLR connectors with industry standard wire locations. See Table 2 and

Figure 4.

Table 2: XLR Audio I/O Cable Connections

PIN SIGNAL

1 Ground

2 Balanced I/O (-)

3 Balanced I/O (+)

The XLR connectors are located on the front panel of each module. On the input modules, XLR

connectors are female Neutrik type NC3FPR-H. On the output modules, XLR connectors are

male Neutrik type NC3MG-H. Refer to Figure 4.

INPUT (Female) OUTPUT (Male)

1221

3

Figure 4: XLR Connectors on Input and Output Modules

3

10

Digital Connections

The Model 162/322 assembly accepts and multiplexes four RS-232C or RS-422 digital data

signals and two remote relay closures. The 162/322 is also used to receive a transmission,

restore the digital signals and provide switch closures. The number of data channels is fixed and

independent of the number of audio channels in the assembly. Both data input and output are

accomplished on the same connector.

Digital signal connections are made via 9-pin D connectors; see Figure 5. The connection

specifications are listed in Table 3. A 110 Ohm terminating resistor placed across the balanced

inputs may be needed if input cable lengths are in excess of 6 feet. Serial communications can

be RS-232 at one end and RS-422 at the other, if desired.

Contact closure input is activated by pin 8 on contact to ground or to a TTL logic 0 signal level.

Contact closure output is established by an isolated, normally open, dry contact built onto the

Main PC Board.

51

69

12 34

DATA I/O

Figure 5: 9-pin D-connectors

Table 3: Digital Cable Connections

PIN Connectors 1 & 2 Connectors 3 & 4

1 RS-422 in (-) RS-422 in (-)

2 Contact out No Connection

3 Ground Ground

4 RS-232 out RS-232 out

5 RS-422 out (-) RS-422 out (-)

6 RS232/422 in (+) RS232/422 in (+)

7 Contact out No Connection

8 Contact in No Connection

9 RS-422 out (+) RS-422 out (+)

The four digital I/O connectors are AMP 747905-2, D subminiature female or equivalent.

11

Optical Connections

WARNING: Never look directly into the end of the optical fiber until it has been positively

determined to be safe. Eye damage could result.

Optical Fiber Signals

Each 162/322 system has multiple optical connections. As a minimum, a transmit output must

be connected via a suitable fiber to a receive input.

Fiber transmissions can be 100% redundant. A secondary fiber output operates with

independent drivers and is always active. If the active fiber link fails, an alarm is sounded and

the secondary link takes over.

Two additional, fiber outputs are available for local splits. This is useful when the same outputs

are received at multiple locations.

The Adder 162/322 is compatible with industry standard ST type connectors. It may be used

with installed backbone cables or with dedicated cables. Consult Telecast for information

regarding compatible fiber types.

Cable Fabrication

Assembled cables and connectors are available from Telecast Fiber Systems, Inc. For custom

cable fabrication, use type ST connectors such as Telecast part number CONN-ST-M.

Always follow the connector manufacturer’s directions when fastening a connector to the cable.

A Quick-crimp kit, part number CKIT-3M, is available from Telecast.

Always cover all unused fiber connectors.

Transmission Fiber Ports - Multiple Fiber Versions

TX1, TX2, TX3 and TX4

Fiber ports Tx1, Tx2, Tx3 and Tx4 shown in Figure 6 are fully redundant. All transmit ports are

always active and have independent output circuits.

Rx1 Rx2

Tx1 Tx2

Rx Tx

Tx4Tx3

FIBER

(Rx 1550) (Rx 1300)

(Tx 1300) (Tx 1550)

W

D

M

Coax

Figure 6: Fiber and Cable Ports

12

All ports carry digitized, multiplexed audio as well as digital and contact data. Each output has

the same capacity with distance capabilities as shown in Table 4. Unless otherwise specified, all

transmitters operate at 1300 nm except Tx2 which operates at 1550 nm.

Rx1 and Rx2

Fiber ports Rx1 and Rx2 accept the multiplexed optical signals from the output of another Model

162/322. The received signal is demuxed and sent to the output corresponding to the original

input on the transmitting assembly. These fiber input ports are internally switched with

preference to Rx1. If the active port fails to recognize a signal, the assembly switches to the

alternate port and an alarm sounds. An alarm also sounds if neither port has a signal present.

WDM Single Fiber Versions

The Rx ports in Figure 6 on page 7 are used to send and receive optical signals over a single

fiber on assemblies with Telecast’s Wavelength Division Multiplexer option (WDM). This is

accomplished by transmitting on one wavelength and receiving from the same fiber on an

alternate wavelength.

Since each unit is identical, Rx1 must be connected to Rx2 on the second unit to complete the

optical circuit. A redundant circuit from Rx2 on the first unit and Rx1 on the second unit can be

added using a second fiber.

The Tx1 and Tx2 ports are combined with the Rx1 and Rx2 ports by the WDM. Tx3 and Tx4

remain active and are still available for local splits.

Coaxial Cable Ports

Coaxial ports Rx and Tx carry the same data as the optical ports. The coax output is always

active. On older Adders, the coax input is active only when the optical receive inputs have been

disabled via SW1. Coax operation cannot be used as redundancy for the optical circuit.

Fiber Cable Runs

The installer is responsible for providing the fiber optic cable runs, available from Telecast Fiber

Systems, Inc. The Accessory List on page 31 shows cable and other items required for the

system. Be sure that the fiber types are compatible with the intended installation distances, as

shown in Table 4.

Table 4: Distance Limits by Fiber Type

Fiber Type Distance Limit

50/62.5/125 multimode 10 km

8/125 singlemode 20 km

All outputs and inputs of the standard unit are multimode (mm) and single mode (sm)

compatible. Tx2 is 1550 nm and all other transmissions are 1300 nm. When the WDM option is

ordered, the use of sm or mm must be specified.

If the WDM is installed, the fiber used must match that of the WDM to assure functionality.

13

Inspect and clean the fiber ends with clean, dry compressed air or with Kim-Wipes and isopropyl

alcohol. Fingerprints, or other dirt on the optical connector end surfaces, will reduce the

received optical signal level.

Coax

To use the system with coax instead of optical fiber, use Belden 8281, 75 Ohm or equivalent.

Refer to Optical Fiber or Coax Communication Selection on page 16 for the switch settings on

the Main PC Board which govern coaxial use with older Adder 162/322.

Input and Output Module Connections

Figure 7 shows an Input Module and an Output Module. The left ribbon on each module is the

signal conductor; the right ribbon provides power. Each ribbon plugs into a specific spot on the

Main PC Board; refer to Figure 8a on page 10.

Signal Power

Figure 7: Input (upper) and Output (lower) Modules for Adder Model 162/322

Module mounting slots are numbered from the upper part of the chassis to the lower part: A to D

on Model 162, and A to H on Model 322. The Model 162/322 Main PC Board has two sets of

signal and power ribbon connector terminations. See Figure 8.

Signal Ribbons (left side of main board) J11 to J8 are for signal ribbons A to D on Model

162/322. J7 to J4 are for signal ribbons E to H on Model 322.

Power Ribbons (right side of main board and auxiliary board) J24 to J21 are for power ribbons

A to D on Model 162/322. Power for modules E to H on Model 322 is supplied from an

additional power supply board located below the Main PC Board. See Figure 9 on page 14.

Other than module count, number of multiplexed signals, and size, the Models 162 and 322 are

identical in all respects.

14

Figure 8: Model 162 Main PC Board

Figure 9: Model 322 Auxiliary Power PC Board

ALARMS

ICOM

GAINS

DATA POWER

More Module

Power on 322’s

15

Removing and Replacing Modules

Figure 10 shows a Model 162 assembly and Figure 10 shows a Model 322 assembly.

Figure 10: Adder 162 and 322 - Modules

To change the configuration of your Adder 162/322 assembly:

1. Switch the power to the assembly OFF.

2. Loosen the two mounting screws at the left and right of the module.

3. Unplug the ribbon connectors at either end of the modules. Note that the connections

have spring locks that must be squeezed to be removed.

4. Change the module, and plug the respective signal and power connectors back into

their ports on the module. Tighten the mounting screws.

WARNING: Be sure to maintain the module location number from top to bottom in terms of

module location and connector position on the Main PC Board. An output module at

a given position must correspond to an input module at the same position at the

other end.

Pins on the ribbon connectors are very small in order to best use the very limited amount of

space in the Adder. Be careful not to bend pins when mating ribbon cables to their connectors.

16

Optical Fiber or Coax Communication Selection

Switch Settings

Switches on the Main PC Board control connectors between Adders over either fiber or coax.

Locate SW1 in the lower left corner of the Main PC Board (Figure 8a on page 10).

To receive from optical fiber, configure SW1 according to Figure 11.

Figure 11: Optical Fiber Receive Switch Setting

To receive from coax, configure SW1 according to Figure 12.

Figure 12: Coax Receive Switch Setting

Coax Length

Configure SW2 according to the length of coaxial cable being used. Refer to Figure 13.

Figure 13: Coax distance Settings

The maximum length of coaxial cable that can be used on any single run between assemblies is

1000 feet.

On newer versions, these switches do not exist and the units function in “Coax priority”. This

means that the systems first looks for a coaxial link. If one is not found, the system automatically

begins looking for an optical link. In addition, SW2 is also gone and coax lengths are handled by

an automatic coaxial length equalization circuit.

17

Audible Alarm Settings

An audible alarm is provided to indicate error conditions. This alarm can be deactivated by the

front panel ALARM ON/OFF-RESET switch. Refer to Figure 19 on page 22. In addition, the

REMOTE POWER and LOCAL POWER alarms can be disabled internally by SW6. Locate

SW6 in the upper right corner of the Main PC Board (Figure 8a on page 14).

Local Power Alarm

The LOCAL POWER ALARM indicates a failure in the external power input at this unit. To

configure the alarm for local power, configure SW6 according to Figure 14.

Figure 14: Alarm Switch — Local

Remote Power Alarm

The REMOTE POWER ALARM indicates a failure in the external power input at the remote unit

(i.e., the unit transmitting to this unit). To configure the alarm for remote power, configure SW6

according to Figure 15.

Figure 15: Alarm Switch — Remote

Alarms are latching. If an alarm occurs, the Audible alarm will sound until the front panel alarm

switch is set momentarily to OFF.

18

Audio Signal Setup

The switches for line or mic input levels, gain, and ground are positioned below the audio

connectors on the front panel of each input module. There are eight sets of switches, one set for

each channel. Channels are numbered left to right from 1 to 8. The panel switch markings for

channels 4 and 5 are shown in Figure 16.

The Model 162/322 system uses high frequency pre-emphasis on all audio channels. Maximum

level at 1 kHz with all gain switches off (unity gain) is +18 dBm. Maximum level at 20 kHz is

10dB lower, or +8 dBm.

The green LED indicates that a signal 30 dB below maximum, or -12 dBm or greater is present

at the channel input. The red LED indicates clipping, indicating that the A/D converter for the

channel is at or near overload and input gain or level must be reduced.

Figure 16: Input Audio Channel Switch Markings

Each channel setting should be carefully checked.

Output module gain is fixed. Maximum module output is +18 dBm, at 1 kHz, corresponding to

A/D clipping.

The LOz /HIz /48V INPUT switch (Figure 16) coupled with the input gain switches result in the

input signal levels shown in Table 5.

Table 5: Input signal levels

LOz, 600 Ohm balanced HIz, 10 kOhm balanced

Unity gain +18 dBm peak Unity gain +18 dBm peak

+10 dB +8 dBm peak +10 dB +6 dBV peak

+20 dB -2 dBm peak +20 dB -4 dBV peak

+30 dB -12 dBm peak +30 dB -14 dBV peak

+40 dB -22 dBm peak +40 dB -24 dBV peak

19

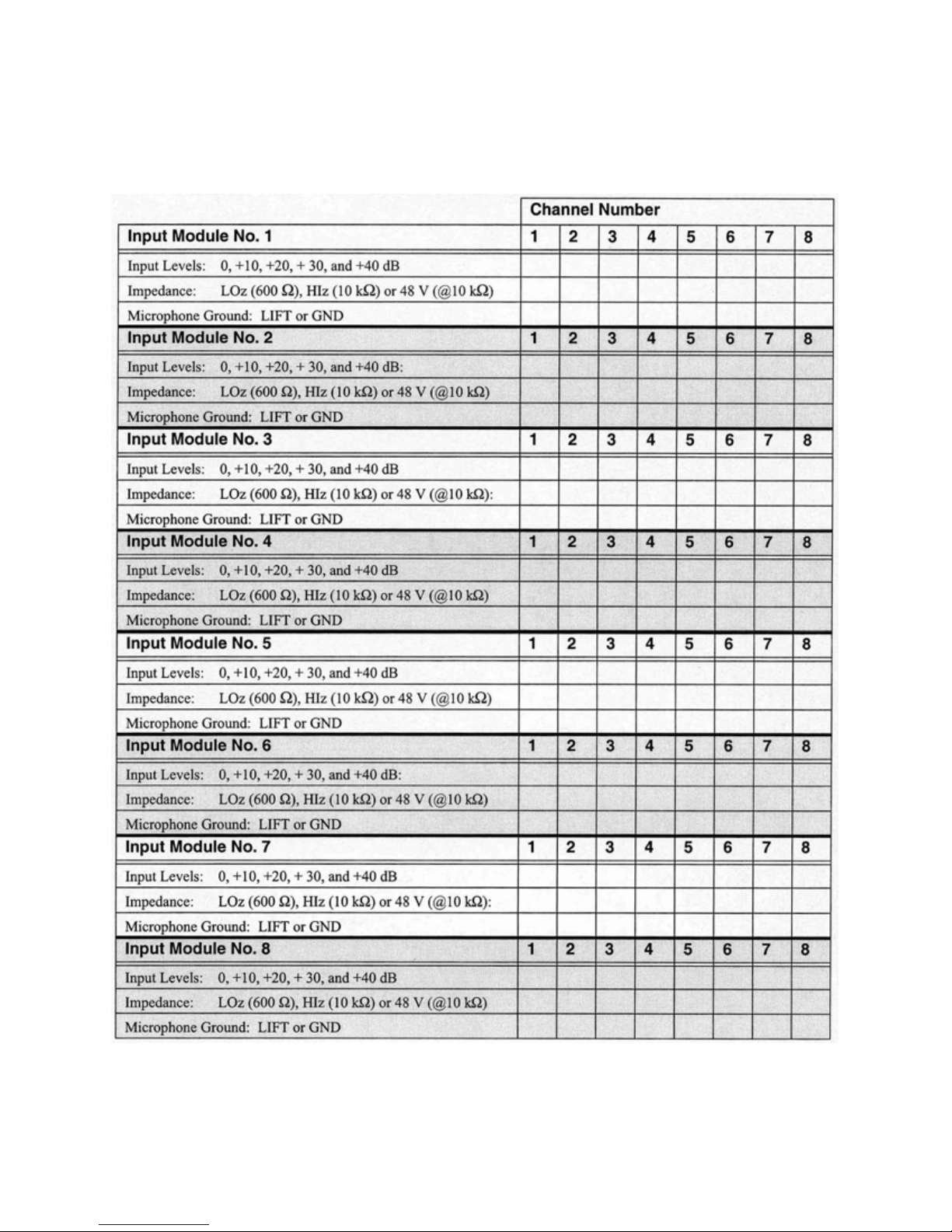

Input Module Setup

Use Table 6 to assist in setting up the front panel switches on each input module. You will be

setting up:

1. Input Gain: 0, +10, +20, + 30, and +40 dB

2. Input Impedance/Bias Voltage: LOz (600 Ohm), Hiz (10 kOhm) or 48V(at 10 kOhm)

3. Input Ground LIFT or GND

4. Gain

Determine the appropriate input gain for each channel and enter the value in Table 6. Refer to

Figure 17 for the front panel switch settings.

Note: Only one switch should be ON at a time as gain settings are NOT additive.

Table 6: Basic gain settings

Impedance

Determine the need for each channel’s input impedance at 600 Ohm or Hiz. Most systems

operate better in the Hiz mode.

If 48 V phantom power is needed, set the LOz/HIz/48 V switch to 48 V. With 48 V ON, the

impedance is always HIz. The phantom supply is limited to a maximum combined load of 60 mA

per 32 channels, which is about 2 mA per input channel with all channels in use. Source

impedance is 5000 Ohms. When fewer than the 32 loads are used, the current at each input

can be increased, limited by the 5000 ohm source resistance, up to a total of 60 mA for all

active loads. Always set unused phantom power switches to LOz or Hiz to be sure 48 VDC is

not applied where it is not needed.

Grounding - Determine the switch setting for Pin 1

When using 48 V phantom power, the PIN 1 switch on the front panel (Figure 16 on page 18)

must be set to GND. Do not set this to LIFT unless required to eliminate ground loops.

If phantom power is not being used, set this switch to the requirements of the channel’s signal

source. Make the appropriate entries in Table 6.

Double check your table and position each switch.

After your system is fully set up and operating, use the built-in signal generator to check for

adequacy of signal levels or for possible amplitude overload in any part of the audio path.

20

Table 7: Input Module Switch Settings

This manual suits for next models

1

Table of contents

Other Telecast Multiplexer manuals

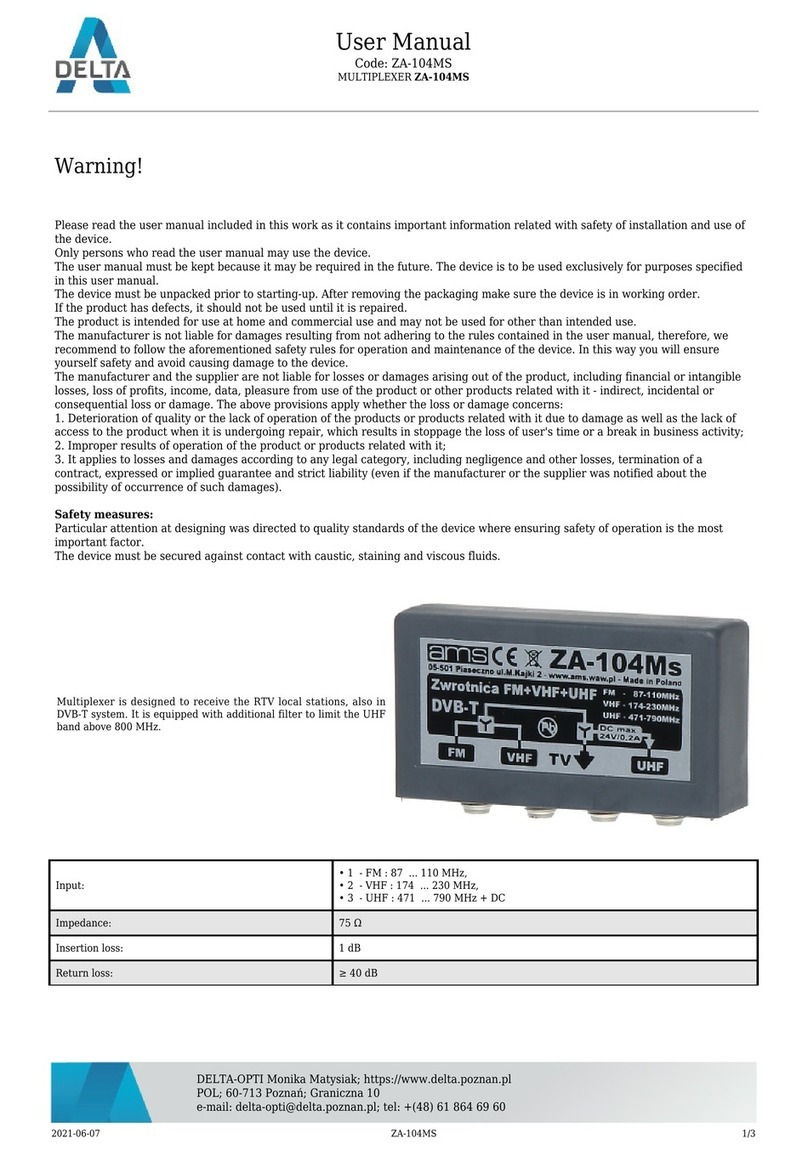

Popular Multiplexer manuals by other brands

Paradyne

Paradyne COMSPHERE 3611 installation instructions

Lightscape Networks

Lightscape Networks mSDM-1RD Installation, operation and maintenance manual

Tunstall

Tunstall Flamenco 77 0270 00 installation instructions

Ross

Ross MUX-8258 Series user guide

Keithley

Keithley 4225-RPM instructions

Lucent Technologies

Lucent Technologies Metropolis AMU 2m/4o Applications and Planning Guide