TELEDYNE API 452 User manual

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

i

Notice of Copyright

© 2015-2022 Teledyne Advanced Pollution Instrumentation. All rights reserved.

Revisions to this Manual are intended to clarify existing descriptions and are not intended to infer any changes

to customers under copy exact requirements.

Trademarks

All trademarks, registered trademarks, brand names or product names appearing in this document are the

property of their respective owners and are used herein for identification purposes only.

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

ii

Safety Messages

Important safety messages are provided throughout this manual for the purpose of

avoiding personal injury or instrument damage. Please read these messages

carefully. Each safety message is associated with a safety alert symbol and is

placed throughout this manual; the safety symbols are also located inside the

instrument. It is imperative that you pay close attention to these messages, the

descriptions of which are as follows:

WARNING: Electrical Shock Hazard

HAZARD: Strong oxidizer

GENERAL WARNING/CAUTION: Read the accompanying

message for specific information.

CAUTION: Hot Surface Warning

Do Not Touch: Touching some parts of the instrument without

protection or proper tools could result in damage to the part(s) and/or

the instrument.

Technician Symbol: All operations marked with this symbol are to be

performed by qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the

central safety grounding point for the instrument.

CAUTION

This product should only be installed, commissioned, and used strictly for the

purpose and in the manner described in this manual. If you improperly install,

commission, or use this instrument in any manner other than as instructed in this

manual or by our Technical Support team, unpredictable behavior could ensue with

possible hazardous consequences.

Such risks, whether during installation and commission or caused by improper

installation/commissioning/use, and their possible hazardous outcomes include but

are not limited to:

RISK

HAZARD

Liquid or dust/debris ingress

Electrical shock hazard

Improper or worn power cable

Electrical shock or fire hazard

Excessive pressure from improper

gas bottle connections

Explosion and projectile hazard

Sampling combustible gas(es)

Explosion and fire hazard

Improper lift & carry techniques

Personal injury

Note that the safety of a system that may incorporate this product is the end user’s

responsibility.

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

iii

Consignes de Sécurité

Des consignes de sécurité importantes sont fournies tout au long du présent

manuel dans le but d’éviter des blessures corporelles ou d’endommager les

instruments. Veuillez lire attentivement ces consignes. Chaque consigne de

sécurité est représentée par un pictogramme d’alerte de sécurité; ces pictogrammes

se retrouvent dans ce manuel et à l’intérieur des instruments. Les symboles

correspondent aux consignes suivantes :

AVERTISSEMENT : Risque de choc électrique

DANGER : Oxydant puissant

AVERTISSEMENT GÉNÉRAL / MISE EN GARDE : Lire la

consigne complémentaire pour des renseignements spécifiques

MISE EN GARDE : Surface chaude

Ne pas toucher : Toucher à certaines parties de l’instrument

sans protection ou sans les outils appropriés pourrait entraîner

des dommages aux pièces ou à l’instrument.

Pictogramme « technicien » : Toutes les opérations portant ce

symbole doivent être effectuées uniquement par du personnel

de maintenance qualifié.

Mise à la terre : Ce symbole à l’intérieur de l’instrument

détermine le point central de la mise à la terre sécuritaire de

l’instrument.

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

iv

MISE EN GARDE

Ce produit ne doit être installé, mis en service et utilisé qu’aux fins et de la

manière décrites dans le présent manuel. Si vous installez, mettez en service ou

utilisez cet instrument de manière incorrecte autre que celle indiquée dans ce

manuel ou sous la direction de notre équipe de soutien technique, un

comportement imprévisible pourrait entraîner des conséquences potentiellement

dangereuses.

Ce qui suit est une liste, non exhaustive, des risques et résultats dangereux

possibles associés avec une mauvaise utilisation, une mise en service incorrecte,

ou causés mauvaise commission.

RISQUE

DANGER

Pénétration de liquide ou de

poussière/débris

Risque de choc électrique

Câble d’alimentation incorrect,

endommagés ou usé

Choc électrique ou risque

d’incendie

Pression excessive due à des

connexions de bouteilles de gaz

incorrectes

Risque d’explosion et d’émission

de projectile

Échantillonnage de gaz

combustibles

Risque d’explosion et d’incendie

Techniques de manutention,

soulevage et de transport

inappropriées

Blessure corporelle

Notez que la sécurité d’un système qui peut incorporer ce produit est la

responsabilité de l’utilisateur final.

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

v

Warranty

WARRANTY POLICY (02024J)

Teledyne API (TAPI), a business unit of Teledyne Instruments, Inc., provides that:

Prior to shipment, TAPI equipment is thoroughly inspected and tested. Should equipment failure occur, TAPI

assures its customers that prompt service and support will be available. (For the instrument-specific warranty

period, please refer to the “Limited Warranty” section in the Terms and Conditions of Sale on our website at

http://www.teledyne-api.com.

COVERAGE

After the warranty period and throughout the equipment lifetime, TAPI stands ready to provide on-site or in-

plant service at reasonable rates similar to those of other manufacturers in the industry. All maintenance and

the first level of field troubleshooting are to be performed by the customer.

NON-TAPI MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by TAPI is warranted and will be repaired to the extent and

according to the current terms and conditions of the respective equipment manufacturer’s warranty.

Product Return

All units or components returned to Teledyne API should be properly packed for handling and returned freight

prepaid to the nearest designated Service Center. After the repair, the equipment will be returned, freight

prepaid.

The complete Terms and Conditions of Sale can be reviewed at http://www.teledyne-api.com.

CAUTION – Avoid Warranty Invalidation

Failure to comply with proper anti-Electro-Static Discharge (ESD) handling

and packing instructions and Return Merchandise Authorization (RMA)

procedures when returning parts for repair or calibration may void your

warranty. For anti-ESD handling and packing instructions please refer to the

manual, Fundamentals of ESD, PN 04786, in its “Packing Components for

Return to Teledyne API’s Customer Service” section. The manual can be

downloaded from our website at http://www.teledyne-api.com. RMA

procedures can also be found on our website.

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

vi

Table of Contents

NOTICE OF COPYRIGHT ........................................................................................................................... I

TRADEMARKS .............................................................................................................................................. I

SAFETY MESSAGES....................................................................................................................................II

CONSIGNES DE SÉCURITÉ..................................................................................................................... III

WARRANTY ..................................................................................................................................................V

TABLE OF CONTENTS ............................................................................................................................. VI

LIST OF FIGURES.....................................................................................................................................VII

LIST OF TABLES.......................................................................................................................................VII

1 PRODUCT DESCRIPTIONS ..................................................................................................................1-1

1.1 MODEL 452 PROCESS OZONE SENSOR ................................................................................................ 1-1

2 SPECIFICATIONS AND APPROVALS ................................................................................................2-1

2.1 MECHANICAL SPECIFICATIONS ........................................................................................................... 2-1

2.2 PERFORMANCE SPECIFICATIONS ......................................................................................................... 2-2

2.3 OPERATING LIMITS ............................................................................................................................. 2-2

2.4 ELECTRICAL SPECIFICATIONS ............................................................................................................. 2-2

2.5 CALIBRATION REFERENCE.................................................................................................................. 2-2

2.6 PRESSURE DROP ................................................................................................................................. 2-3

2.7 APPROVALS ........................................................................................................................................ 2-3

3 THEORY OF OPERATION ....................................................................................................................3-1

4 INSTALLATION ......................................................................................................................................4-1

4.1 UNPACKING ........................................................................................................................................ 4-1

4.2 MECHANICAL INSTALLATION ............................................................................................................. 4-1

4.3 ELECTRICAL CONNECTIONS................................................................................................................ 4-2

4.3.1 Power Supply........................................................................................................................... 4-2

4.3.2 Analog Output.......................................................................................................................... 4-2

4.3.3 Zero Calibration Input............................................................................................................. 4-3

4.3.4 Status Outputs.......................................................................................................................... 4-3

4.3.5 RS232/485 Interface ................................................................................................................ 4-3

4.4 GAS CONNECTIONS............................................................................................................................. 4-4

4.5 START-UP AND CALIBRATION PROCEDURE ........................................................................................ 4-4

5 COMMUNICATIONS..............................................................................................................................5-1

5.1.1 RS485/RS232 Commands ........................................................................................................ 5-1

5.1.2 Sample Serial Port Code ......................................................................................................... 5-2

6 MAINTENANCE: UV LAMP REPLACEMENT / ADJUSTMENT ...................................................6-1

7 SENSOR AND SYSTEM TROUBLESHOOTING ................................................................................7-1

7.1 STATUS LEDS..................................................................................................................................... 7-1

7.2 STATUS OUTPUTS ............................................................................................................................... 7-2

7.2.1 Sensor OK................................................................................................................................ 7-2

7.2.2 Invalid Reading........................................................................................................................ 7-2

7.2.3 Lamp Low ................................................................................................................................ 7-3

7.2.4 Cell Dirty ................................................................................................................................. 7-3

7.2.5 Status Output Summary Table ................................................................................................. 7-3

7.3 NO COMMUNICATION ......................................................................................................................... 7-3

7.4 TECHNICAL ASSISTANCE .................................................................................................................... 7-5

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

vii

List of Figures

FIGURE 2-1: MODEL 452 HIGH PURITY OZONE SENSOR ..................................................................................2-1

FIGURE 2-2: PRESSURE DROP VS.FLOW...........................................................................................................2-3

FIGURE 4-1: ELECTRICAL CONNECTIONS .........................................................................................................4-2

FIGURE 4-2: DIGITAL OUTPUT CONNECTIONS..................................................................................................4-3

FIGURE 6-1: COVER ASSEMBLY SCREWS ..........................................................................................................6-2

FIGURE 6-2: UV LAMP ORIENTATION...............................................................................................................6-2

FIGURE 6-3: VOLTAGE ADJUSTMENT LOCATIONS ............................................................................................6-3

List of Tables

TABLE 7-1: STATUS OUTPUTS ..........................................................................................................................7-2

TABLE 7-2: STATUS OUTPUT TRUTH TABLE ....................................................................................................7-3

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN88478

1-1

1 Product Descriptions

1.1 Model 452 Process Ozone Sensor

The Teledyne API Model 452 is a microprocessor-based sensor for measuring the concentration of

gaseous ozone in processes such as semiconductor wafer fabrication, water treatment, and ozone

research. The Model 452 can be used as a full flow process sensor or as a sensor to monitor a

small flow of gas diverted from a process stream.

The Model 452 features a standard 0-5 volt analog signal for reporting process concentration as

well as 4 digital status outputs for sensor diagnostics. A bi-directional serial interface is also

provided for computer control.

The Model 452 operates from an external +15 vdc power source.

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

2-1

2 Specifications and Approvals

Note: All specifications contained herein are subject to change without notice. Please contact

Teledyne API to obtain the current specifications.

2.1 Mechanical Specifications

Figure 2-1: Model 452 High Purity Ozone Sensor

Weight:

2.8 lbs. (1.27 kg)

Fittings*:

¼” stainless steel compression (tube) or ¼” VCR Fittings

(specified at time of order)

Wetted Materials:

316L Stainless Steel, PTFE, Sapphire

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

2-2

2.2 Performance Specifications

Accuracy:

Repeatability:

±1% of Full Scale.

1% of Full Scale

Response Time:

2 sec. to 95%

Zero Drift:

1% Full Scale/month (non –cumulative)

2.3 Operating Limits

Measurement Range*:

0-5, 0-10, 0-15, 0-20, 0-25% w/w

0-100, 0-200, 0-300, 0-400, 0-500 g/Nm3

Pressure Compensation:

Up to 3 Bar absolute

Operating Pressure*

Proof pressure:

7 – 30 psia or 25 – 60 psia

115 psia

Flow:

0.5-25.0 SLPM (See Figure 2-2)

Temperature range:

5 to 45 °C

Warm-Up Period:

30 minutes

2.4 Electrical Specifications

Power Input:

+15 volts ±1.0 volt (1.5 A maximum)

Analog Output:

0-5V Full Scale

Zero Cal:

Contact Closure Input

Status Indicators:

4 status LEDs

Digital Outputs:

Sensor OK, Invalid Reading, Lamp Low, Cell Dirty (Opto-isolated)

Serial Data Interface*:

RS232 or RS485, Half-Duplex, 9600 Baud

2.5 Calibration Reference

Span Calibration:

Traceable to Buffered KI laboratory calibration

Standard Temperature

and Pressure (g/Nm3

only):

0°C and 760 mmHg

*These specifications are configurable by the factory at ordering

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

2-3

2.6 Pressure Drop

Figure 2-2 below shows the approximate pressure drop from the inlet fitting to the outlet fitting as

a function of volumetric flow rate.

Figure 2-2: Pressure Drop vs. Flow

2.7 Approvals

This product is CE compliant and adheres to the Low Voltage and Electromagnetic Compatiblity

Directives.

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

3-1

3 Theory of Operation

The detection of ozone molecules is based on absorption of 254 nm UV light due to an internal

electronic resonance of the O3molecule. The Model 452 uses a mercury lamp constructed so that a

large majority of the light emitted is at the 254 nm wavelength. Light from the lamp shines

through an absorption cell through which the sample gas being measured is passed. The ratio of

the intensity of light passing through the gas to a reference measurement, which does not pass

through the gas, forms the ratio I/Io. This ratio forms the basis for the calculation of the ozone

concentration.

The Beer-Lambert equation, shown below, calculates the concentration of ozone from the ratio of

light intensities.

o

o

O

psi

CΙ

Ι

×

Ρ

×

Κ

Τ

×

×

−= ln

695

.14

273

1

3

α

Where:

I

= Intensity of light passed through the sample

Io

= Intensity of light through sample free of ozone

α

= Absorption coefficient

P

= Pressure

CO3

= Concentration of ozone

T

= Sample temperature in degrees Kelvin

psi

= Pressure in pounds per square inch (absolute)

l

= Path length

As can be seen the concentration of ozone depends on more than the intensity ratio. Temperature

and pressure influence the density of the sample. The density changes the number of ozone

molecules in the absorption cell, which impacts the amount of light, removed from the light beam.

These effects are addressed by directly measuring temperature and pressure and including their

actual values in the calculation. The absorption coefficient is a number that reflects the inherent

ability of ozone to absorb 254 nm light. Lastly, the absorption path length determines how many

molecules are present in the column of gas in the absorption cell.

The intensity of light is converted into a voltage by the detector/preamp module. The voltage is

converted into a number by a high resolution analog-to-digital converter. The digitized signal,

along with the other variables, is used by the CPU to compute the concentration of ozone using the

above formula.

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

4-1

4 Installation

4.1 Unpacking

Upon receiving the Model 452 please verify that no apparent shipping damage has occurred. If

damage has occurred, please advise shipper first, then Teledyne API.

4.2 Mechanical Installation

Mount the Model 452 to a stable platform using four #8-32UNC screws. See Figure 2-1 for

mounting-hole dimensions.

Please ensure the sensor is properly grounded during installation and prior to use. If the

instrument’s manifold is not fully grounded, the detectors may be influenced by electrical

interference, resulting in changes to the measured concentration output.

CAUTION – PREVENT DAMAGE TO INSTRUMENT

Do not allow the mounting screws to penetrate beyond 1/8 of an inch (3.2 mm) into

the bottom of the instrument.

CAUTION – PREVENT ELECTRICAL INTERFERENCE

If the mounting platform is non-conductive or not connected to earth ground, then a

separate connection to earth ground should be made using one of the mounting

screws. Failure to provide a proper earth ground connection may make the

Model 452 susceptible to electrical interference from external sources.

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

4-2

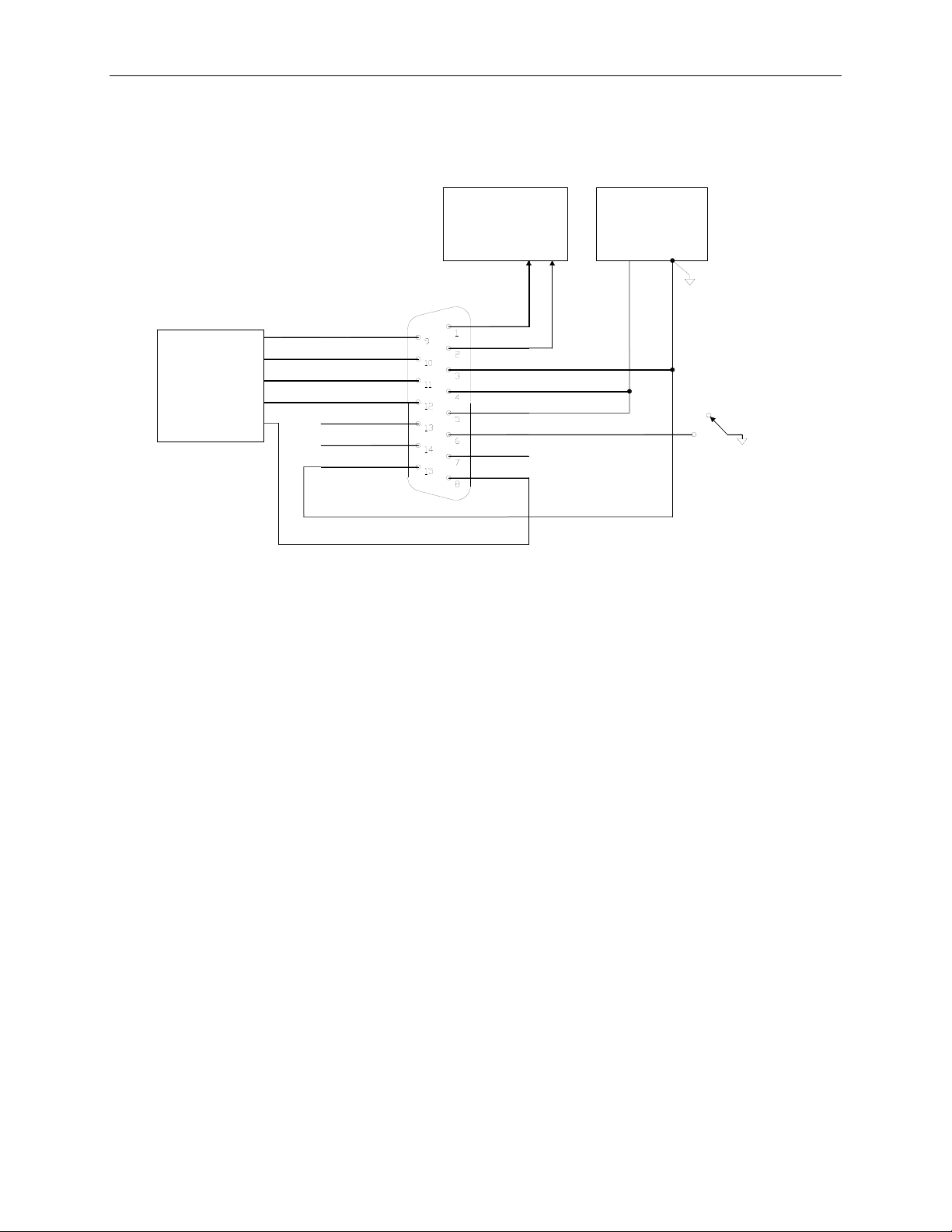

4.3 Electrical Connections

Electrical connections are made to the Model 452 using the 15 pin D-Sub male connector on the

top of the device. Figure 4-1 shows the pin-out of the 15-pin connector and typical connections.

Analog Out -

Analog Out +

Power Common

+15 Volt Supply

+15 Volt Supply

Digital In #1

Digital In #2

Digital Out #1

RS485-A

Power Common

RS485-B

Digital Out Common

Digital Out #4

Digital Out #3

Digital Out #2

Power Supply

Common

+15V

- +

Ozone Concentration

Meter

(0-5 VDC)

or Data Acqusition Device

Status Display

or

PLC

Zero Cal = Closed

Figure 4-1: Electrical Connections

4.3.1 Power Supply

The Model 452 requires a +15 VDC power source capable of supplying 1.5 A. DC power can be

connected through the male DB-15 connector or through the coaxial power jack. The coaxial

power jack is configured so that the ground connection is on the outside (shield) and the +15V

connection is on the center pin.

If power is to be supplied through the DB-15 connector, the positive terminal of the power supply

should be connected to pins 4 and 5 on the 15-pin connector and the common terminal should be

connected to pins 3 and 15.

If an AC Power Adapter is used to provide power, it should be connected to the coaxial power

connector adjacent to the DB-15 connector on the top of the Model 452.

4.3.2 Analog Output

The analog output is a 0-5 volt signal representing the ozone concentration measured by the

sensor. The output is scaled to the concentration range that the sensor has been set to measure.

Check the serial number label on the Model 452 to determine the concentration range.

For best performance, the analog output should be connected to a voltmeter or A/D converter with

a differential input and a minimum input impedance of 2KΩ.

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

4-3

4.3.3 Zero Calibration Input

The zero calibration input is located on Digital Input #1. To zero the Model 452, Digital Input #1

should be connected to the power common for at least 1 second. This can be accomplished using a

Normally Open switch or relay.

4.3.4 Status Outputs

The Model 452 has four digital status outputs for indicating error status and when operational

parameters have moved out of normal limits. These outputs are in the form of opto-isolated open-

collector transistors. They can be used to drive status LED’s on a display panel or interface to a

digital device such as a Programmable Logic Controller (PLC).

Figure 4-2 below shows the most common way of connecting the digital outputs to an external

device such as PLC. Note: Most devices, such as PLC’s, have internal provision for limiting the

current that the input will draw from an external device. When connecting to a unit that does not

have this feature, external dropping resistors must be used to limit the current through the

transistor output to 50mA or less.

See Sections 7.2 and 7.2.5 for details on using the Status Outputs for diagnosing sensor and

system-level malfunctions.

Figure 4-2: Digital Output Connections

4.3.5 RS232/485 Interface

The Model 452 features a bi-directional digital serial interface that can be used for sensor control

and data acquisition. The serial port is normally configured at the factory for either RS232 or

RS485 communications. Consult the serial number tag on your device for the port’s configuration.

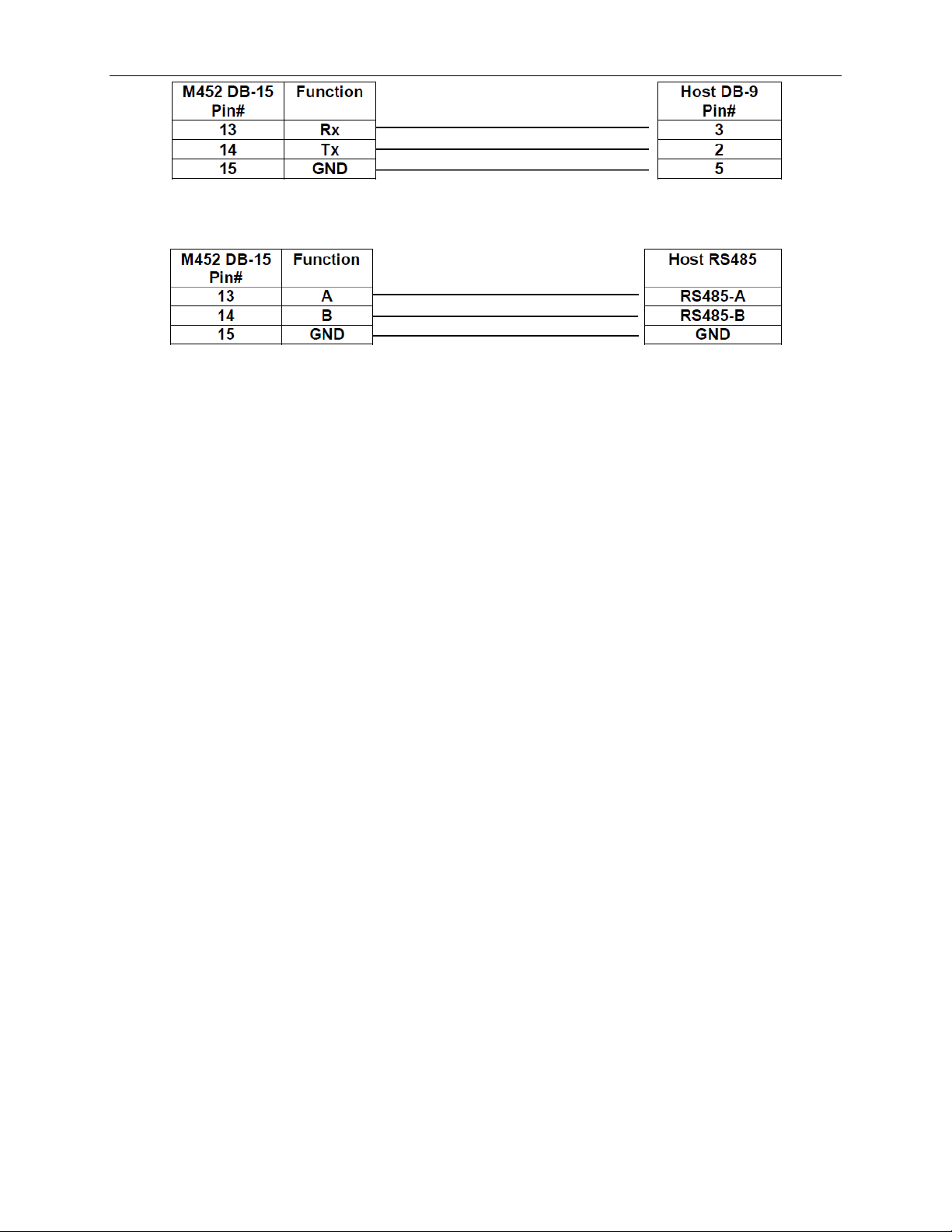

Figure 4-3 and Figure 4-4 show typical connections. Section 5 provides Communications details.

Controller serial port parameters are as follows:

Baud Rate

9600

Parity

None

Data Bits

8

Stop Bits

1

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

4-4

Figure 4-3. RS232 Connection

Figure 4-4. RS485 Connection

See Section 7.3 in the Sensor and System Troubleshooting section for verifying and configuring

the serial communications connector.

4.4 Gas Connections

Gas connections to the Model 452 are made by using either ¼” compression tube fittings) or ¼”

VCRface seal fittings (fitting option specified at time of purchase). The ¼” compression fittings

can be used with ¼” O.D. Stainless Steel or Teflontubing. The Model 452 is not sensitive to

flow direction; it does not matter which of the two fittings is used as the gas inlet.

To avoid contamination of the optical cell in the Model 452, ensure that all tubing upstream of the

Model 452 is properly cleaned and purged before the Model 452 is installed.

In order to achieve an acceptable response time and to avoid sample degradation, the system

should be set up so that a minimum flow rate of 0.1 SLPM is established through the Model 452.

If long tubing runs are used between the measurement point and the Model 452, then higher flow

rates should be used to avoid sample degredation. Appropriate tests should be conducted to

determine minimum flow requirements.

4.5 Start-Up and Calibration Procedure

1. Verify that the proper electrical connections have been made (See Section 4.3) and apply power to the

Model 452, allowing it to warm up for at least 30 minutes.

2. Purge the Model 452 with zero gas (usually oxygen) at a minimum flow rate of 0.1 SLPM for a

minimum of 5 minutes to purge.

3. Check that the Status Outputs are in their normal states and no errors are indicated (refer to Table 7-1).

4. Close the zero calibration input (See Section 4.3.3) for a minimum of 1 second to perform the automatic

zero calibration.

5. Re-check the Status Outputs to ensure that no errors are indicated.

6. Check the voltage on the analog output (See Section 4.3.2) and verify that it reads 0.000 ±0.010 volts.

The Model 452 is now ready for operation.

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

5-1

5 Communications

(If there is a need to troubleshoot, refer to Section 7.3, and to Figure 7-2 or Figure 7-3, according

to which CPU PCA your device is configured with.

5.1.1 RS485/RS232 Commands

All commands are valid for either RS232 or RS485 hardware configuration.

Calibration

Command:

d –

Calibrate Zero

1 byte 1 byte 1 byte

1 byte

<ADDRESS>

<command>

<CR>

<CHKSUM>

ADDRESS must match address of sensor. Range is 0-9 ASCII OR’d w/0x80 (hi bit set) = 0xB0-B9.

Applies to commands ONLY.

CHKSUM is the sum of all characters beginning with the address, ending with <cr>.

Always AND result with 0x7F, so high bit = 0. DO NOT send two’s complement.

Response:

OK<CR><CHKSUM> for an acknowledge

ERR<CR><CHKSUM> for an error

Data Request Command:

a – Send

Data:

1 byte 1 byte 1 byte

1 byte

<ADDRESS>

a

<CR>

<CHKSUM>

Response:

<address>,<Pressure>,<Cell_Temp>,<Meas_mv>,<Ref_mV>,<O3_wt%><CR><CHKSUM>

or:

ERR<CR><CHKSUM> for an error

Address range is ASCII numbers 0-9 (hi bit clear) = (0x30-39). Applies to responses ONLY.

Address Change Command:

i (x) –

Set Address

1 byte 1 byte 1 byte 1 byte 1 byte

0xAA i <New Address> <CR> <CHKSUM>

Address is 0xAA(Hex.) (Note high bit already set.) This is the general call address that all sensors

will receive.

<New Address> is binary value for new address (ie. 0x00 – 0x03)

Teledyne API Model 452 Ozone Sensor User Manual, 02852H DCN8478

5-2

Note:

Control input #2 on M452 (I2C port, bit 1) must be latched (input pulled to ground) prior to

initiating this command. This is required to inform the sensor that it is being addressed. This is the

only command that requires this action. Note that this control input (Pin 7 on the DB15 connector)

has an internal pull-up resistor and so does not require an external pull-up. Input should be released

when acknowledge is received.

Response:

OK<CR><CHKSUM> for an acknowledge

ERR<CR><CHKSUM> for an error

5.1.2 Sample Serial Port Code

The following is some example code in written in Visual Basic that demonstrates how these

commands could be sent to the instrument:

Dim check_sum, address, cmd_code As Byte

address = (&H30 + 0) Or &H80

‘ Address 0, converts to ASCII 0 and sets high

bit to 1‘ can substitute any allowable address

cmd_code = Asc("a")

check_sum = address + cmd_code + 13

‘ Sends ‘a’ command, can substitute ‘d’

command here

check_sum = check_sum And &H7F

‘ Set high bit to 0 for check_sum. This prevents‘

check_sum from being interpreted as an address

for ‘ other sensors on the bus.

Comm1.Output = Chr(address) &

Chr(cmd_code) & _ Chr(13) & Chr(check_sum)

Other manuals for 452

1

Table of contents

Other TELEDYNE API Accessories manuals