TELEDYNE API OPTI-Sense 5200 User manual

User Manual

OPTI-Sense 5200

with

Fault High, Zero Low, Customer-Supplied Power

© TELEDYNE API (TAPI)

9970 CARROLL CANYON ROAD

SAN DIEGO, CALIFORNIA 92131-1106

USA

Toll-free Phone:

+1 800-324-5190

Phone:

+1 858-657-9800

Fax:

+1 858-657-9816

Email:

api-sales@teledyne.com

Website:

http://www.teledyne-api.com/

Copyright 2022 094900000B DCN8470

Teledyne API 25 March 2022

094900000B DCN8470 Teledyne API OPTI-Sense 5200 i

NOTICE OF COPYRIGHT

© 2022 Teledyne API (TAPI). All rights reserved.

TRADEMARKS

All trademarks, registered trademarks, brand names or product names appearing in

this document are the property of their respective owners and are used herein for

identification purposes only.

ii Teledyne API OPTI-Sense 5200 094900000B DCN8470

SAFETY MESSAGES

Important safety messages are provided throughout this manual for the purpose of

avoiding personal injury or instrument damage. Please read these messages

carefully. Each safety message is associated with a safety alert symbol and is placed

throughout this manual; the safety symbols are also located inside the instrument. It

is imperative that you pay close attention to these messages, the descriptions of

which are as follows:

WARNING: Electrical Shock Hazard

HAZARD: Strong oxidizer

GENERAL WARNING/CAUTION: Read the accompanying message

for specific information.

CAUTION: Hot Surface Warning

Do Not Touch: Touching some parts of the instrument without

protection or proper tools could result in damage to the part(s)

and/or the instrument.

Technician Symbol: All operations marked with this symbol are to be

performed by qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the

central safety grounding point for the instrument.

CAUTION

This product should only be used for the purpose and in the manner

described in this manual. If you use this product in a manner other

than that for which it was intended, unpredictable behavior could

ensue with possible hazardous consequences.

NEVER use any combustible/explosive gas with this product!

For Technical Assistance regarding the use and maintenance of this instrument or

any other Teledyne API product, contact Teledyne API’s Technical Support

Department:

Telephone: +1 800-324-5190

Email: api-techsupport@teledyne.com

or access any of the service options on our website at http://www.teledyne-api.com/

094900000B DCN8470 Teledyne API OPTI-Sense 5200 iii

CONSIGNES DE SÉCURITÉ

Des consignes de sécurité importantes sont fournies tout au long du présent manuel

dans le but d’éviter des blessures corporelles ou d’endommager les instruments.

Veuillez lire attentivement ces consignes. Chaque consigne de sécurité est

représentée par un pictogramme d’alerte de sécurité; ces pictogrammes se retrouvent

dans ce manuel et à l’intérieur des instruments. Les symboles correspondent aux

consignes suivantes :

AVERTISSEMENT : Risque de choc électrique

DANGER : Oxydant puissant

AVERTISSEMENT GÉNÉRAL / MISE EN GARDE : Lire la

consigne complémentaire pour des renseignements

spécifiques

MISE EN GARDE : Surface chaude

Ne pas toucher : Toucher à certaines parties de l’instrument

sans protection ou sans les outils appropriés pourrait entraîner

des dommages aux pièces ou à l’instrument.

Pictogramme « technicien » : Toutes les opérations portant ce

symbole doivent être effectuées uniquement par du personnel

de maintenance qualifié.

Mise à la terre : Ce symbole à l’intérieur de l’instrument

détermine le point central de la mise à la terre sécuritaire de

l’instrument.

MISE EN GARDE

Cet produit doit être utilisé aux fins décrites et de la manière

décrite dans ce manuel. Si vous utilisez cet produit d’une autre

manière que celle pour laquelle il a été prévu, l’instrument

pourrait se comporter de façon imprévisible et entraîner des

conséquences dangereuses.

NE JAMAIS utilizer de gaz explosive ou combustible avec cet

produit!

iv Teledyne API OPTI-Sense 5200 094900000B DCN8470

WARRANTY

WARRANTY POLICY (02024J)

Teledyne API (TAPI), a business unit of Teledyne Instruments, Inc., provides that:

Prior to shipment, TAPI equipment is thoroughly inspected and tested. Should

equipment failure occur, TAPI assures its customers that prompt service and support

will be available. (For the instrument-specific warranty period, please refer to the

“Limited Warranty” section in the Terms and Conditions of Sale on our website at

the following link: http://www.teledyne-api.com/terms_and_conditions.asp).

COVERAGE

After the warranty period and throughout the equipment lifetime, TAPI stands ready

to provide on-site or in-plant service at reasonable rates similar to those of other

manufacturers in the industry. All maintenance and the first level of field

troubleshooting are to be performed by the customer.

NON-TAPI MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by TAPI is warranted and will be

repaired to the extent and according to the current terms and conditions of the

respective equipment manufacturer’s warranty.

PRODUCT RETURN

All units or components returned to Teledyne API should be properly packed for

handling and returned freight prepaid to the nearest designated Service Center. After

the repair, the equipment will be returned, freight prepaid.

The complete Terms and Conditions of Sale can be reviewed at

http://www.teledyne-api.com/terms_and_conditions.asp

CAUTION – Avoid Warranty Invalidation

Failure to comply with proper anti

-Electro-Static Discharge (ESD)

handling and packing instructions and Return Merchandise

Authorization (RMA) procedures when returning parts for repair or

calibration may void your warranty. For anti

-ESD handling and

packi

ng instructions please refer to the manual, Fundamentals of

ESD, PN 04786, in its

“Packing Components for Return to Teledyne

API’s Customer Service”

section. The manual can be downloaded

from our website at

http://www.teledyne-api.com. RMA procedures

can also be found on our website

.

094900000B DCN8470 Teledyne API OPTI-Sense 5200 v

ABOUT THIS MANUAL

Note We recommend that all users read this manual in its entirety

before operating the instrument.

CONVENTIONS USED

In addition to the safety symbols as presented in the Safety Messages page, this

manual provides special notices related to the careful and effective use of the

instrument and related, pertinent information.

ATTENTION COULD DAMAGE INSTRUMENT AND VOID WARRANTY

This special notice provides information to avoid damage

to your instrument and possibly invalidate the warranty.

Important IMPACT ON READINGS OR DATA

Provides information about that which could either affect

accuracy of instrument readings or cause loss of data.

Note Provides information pertinent to the proper care,

operation or maintenance of the instrument or its parts.

vi Teledyne API OPTI-Sense 5200 094900000B DCN8470

TABLE OF CONTENTS

Safety Messages...................................................................................................................................... ii

Warranty.................................................................................................................................................. iv

Table of Contents.................................................................................................................................... vi

List of Figures.......................................................................................................................................... vi

List of Tables........................................................................................................................................... vi

1. INTRODUCTION, CAUTIONS, AND SPECIFICATIONS .........................................................................7

Cautions ............................................................................................................................................7

Specifications ....................................................................................................................................8

Features ............................................................................................................................................8

2. MECHANICAL INSTALLATION................................................................................................................9

3. ELECTRICAL CONNECTIONS ..............................................................................................................11

RS-232 Connector ..........................................................................................................................11

I/O Connector..................................................................................................................................11

Fault DO Specifications .......................................................................................................12

Over-Voltage Protection.......................................................................................................12

4. SYSTEM OPERATION ...........................................................................................................................13

Zeroing the OPTI-Sense .................................................................................................................13

5. INSTRUMENT ERROR CODES.............................................................................................................14

6. TECHNICAL ASSISTANCE....................................................................................................................15

LIST OF FIGURES

Figure 2-1. Mechanical Dimensions.............................................................................................................. 9

Figure 2-2. Inlet (right) and Outlet (left) Connectors................................................................................... 10

LIST OF TABLES

Table 1-1. Specifications............................................................................................................................... 8

Table 3-1. I/O Connector Pinout ................................................................................................................. 11

Table 5-1. Instrument Error Codes ............................................................................................................. 14

094900000B DCN8470 Teledyne API OPTI-Sense 5200 7

1. INTRODUCTION, CAUTIONS, AND SPECIFICATIONS

The Teledyne API Opti-Sense 5200 is a state-of-the-art Non Dispersive InfraRed (NDIR)-

based sensor that is designed to monitor SIF4 (Silicon Tetrafluoride) concentration,

typically at sub-atmospheric pressure.

The OPTI-Sense unit is designed to be mounted vertically. Horizontal mounting is also

acceptable. Two KF16 fittings are provided to effectuate the pneumatic connections.

Electrical connections are on the rear panel of the instrument. Power and control signals

are applied through the DB15 connector. The RS-232 connector should be connected to a

laptop computer if the graphical user interface (GUI) will be used.

The OPTI-Sense 5200 can be used qualitatively three minutes after power up. For accurate

quantitative results, allow the unit to warm up for thirty minutes. The OPTI-Sense should

be allowed to warm up overnight for applications in which low drift is critical. Purge and

zero the instrument after the warm-up period is completed.

CAUTIONS

Please review these instructions carefully to ensure proper installation, operation and care

of the system to minimize the risk of personal injury or product damage due to improper

handling.

HAZARD: Toxic, Corrosive Gas

•SIF4 (Silicon Tetrafluoride) is a toxic, corrosive, nonflammable

gas packaged at pressure up to 1000 psig. It has a sharp

suffocating odor. The gas is colorless but fumes white in moist

air. Hydrolyzes to very corrosive hydrofluoric acid on contact

with moisture. Can cause severe chemical burns if inhaled or

upon skin contact. When entering released area, wear self-

contained breathing apparatus (SCBA). Fully protective suits

are required in large releases.

•Install appropriate safety monitoring equipment wherever SIF4

is used.

•Materials in contact with SIF4 should be suitable for such use.

316L Stainless, Barium Fluoride (BaF2), Teflon™, Chemraz™

are recommended.

WARNING: Electrical Shock Hazard

When performing any maintenance to the unit, make sure all DC

power is disconnected from the unit

CAUTION: Risk of Damage to Instrument

Use only TAPI-recommended spare parts. Substitution parts could

result in damage to the equipment, may create hazardous

conditions, and will void the warranty.

8 Teledyne API OPTI-Sense 5200 094900000B DCN8470

SPECIFICATIONS

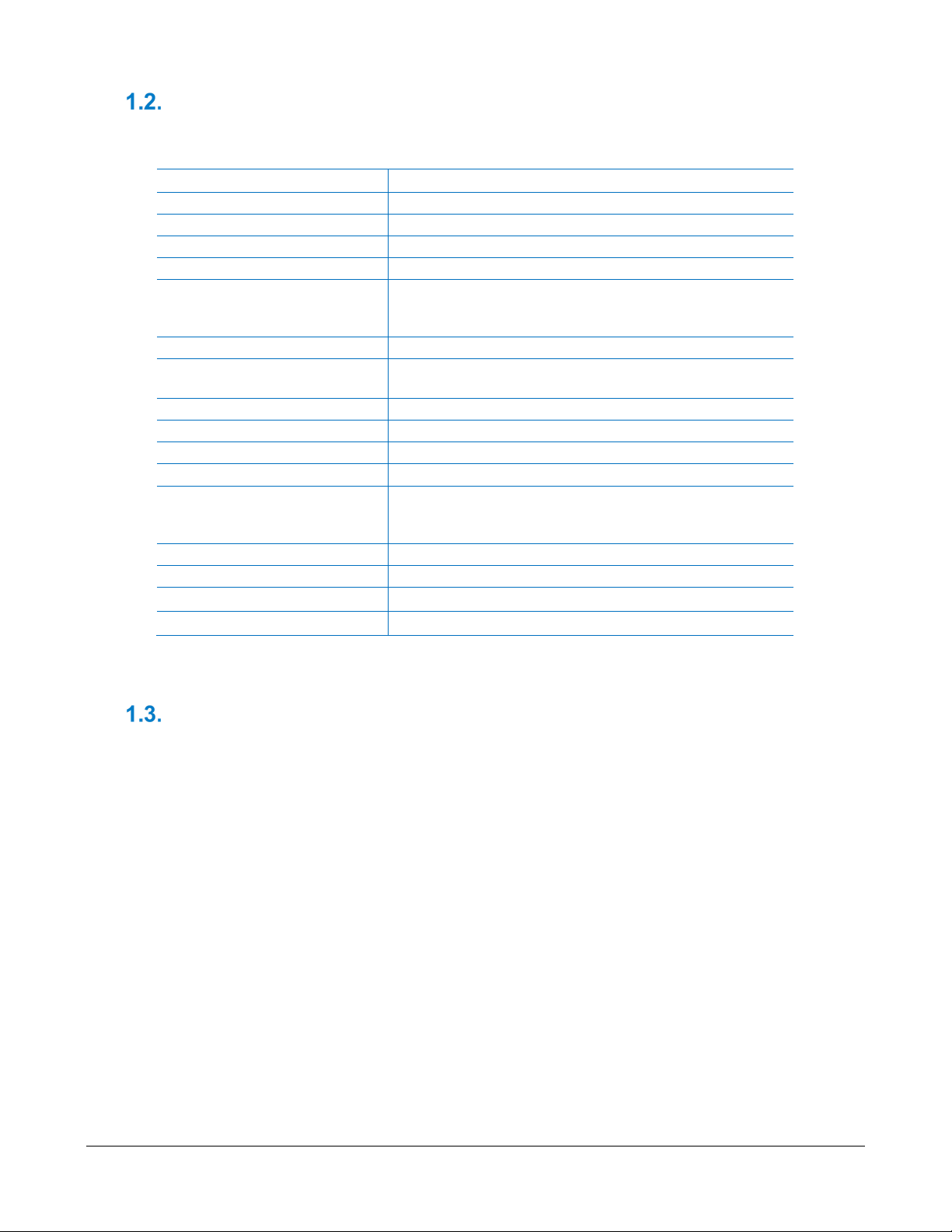

Table 1-1. Specifications

Parameter

Description

Measuring Principle

Non Dispersive IR absorption

Application

Measurement of SiF4 Absorbance

Dimensions (W x H x D)

4.72” x 8.66” x 3.15” (120 mm x 220 mm x 80 mm)

Light Source

Infrared light source

Response Time

(time to respond to step

function of SIF4)

< 2 seconds to 90% of step

Reading Update

1 reading/second

Analog scaling/Filter type

1-10 VDC corresponds to (0.0-0.2) units of absorbance,

< 10Watts, factory set

Leak Testing

Vacuum Leak-Tight Cell

Gas Connection

KF16-300 Series stainless steel

Pressure Range

200mT-5000mT

Temperature Range

5 – 45

°

C

Power Input

15 VDC Customer Supplied, 350 mA max during normal

operation

24VDC Customer Supplied

Weight

7 Lbs. (3.17 kg)

Digital Interface

RS-232, with GUI Interface

Software

Embedded (standard) Labview GUI interface

Compliance

CE approved

FEATURES

•Zero by Voltage Command

•Fault Digital Output (DO) indicates instrument errors.

•1-10 Volt Analog Output

•Overvoltage Protection

094900000B DCN8470 Teledyne API OPTI-Sense 5200 9

2. MECHANICAL INSTALLATION

ATTENTION

Ensure adequate space to access connectors and to

remove cover when necessary for servicing.

Ensure adequate clearance to allow free air flow for

cooling, and to avoid high heat-generating equipment.

Sensor dimensions are shown in Figure 2-1.

Figure 2-1. Mechanical Dimensions

10 Teledyne API OPTI-Sense 5200 094900000B DCN8470

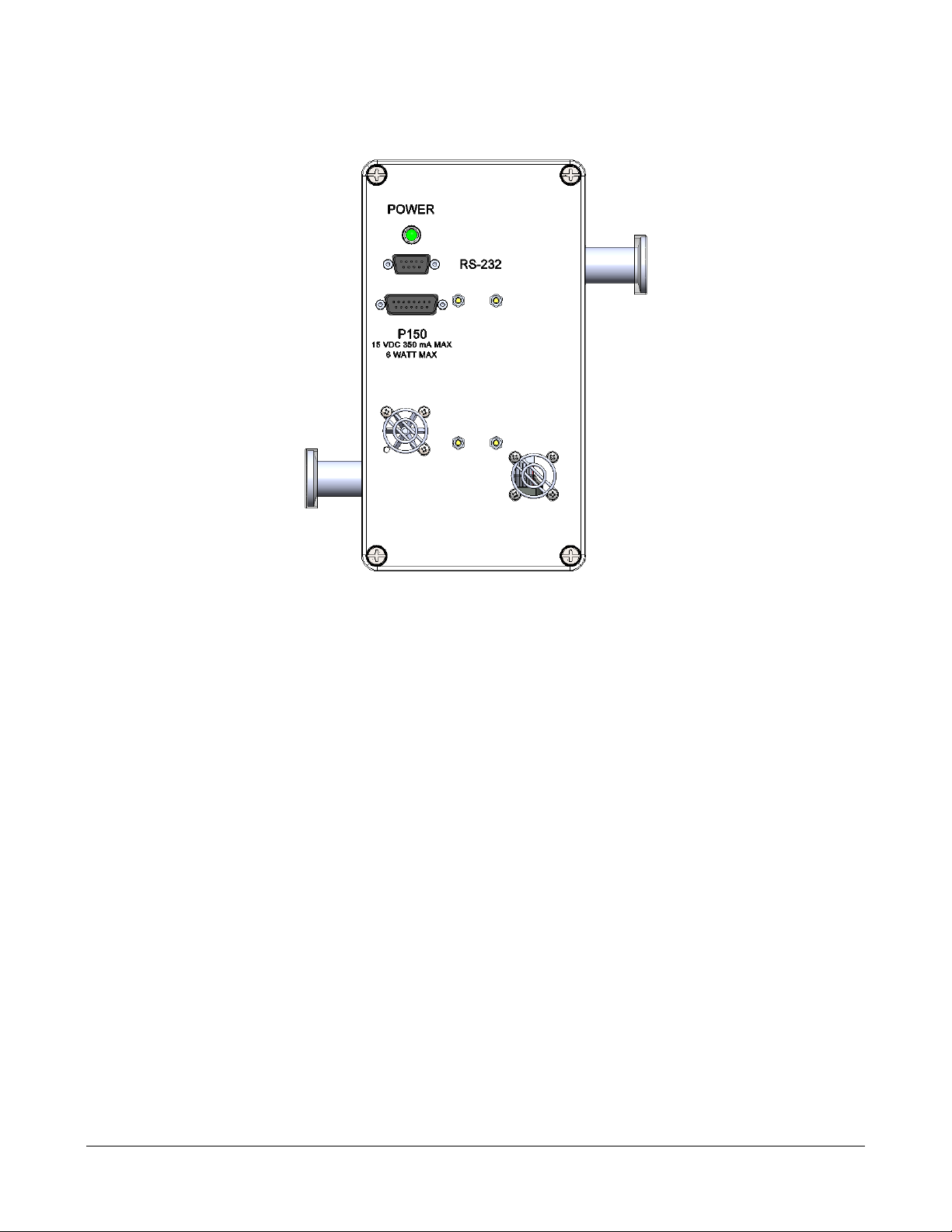

The OPTI-Sense unit is designed to be mounted vertically. Figure 2-2 below shows the

front view of the OPTI-Sense unit, with KF16 inlet connector on the upper right and outlet

connector on the lower left. Horizontal mounting is also acceptable.

Figure 2-2. Inlet (right) and Outlet (left) Connectors

The flow of gas through the unit should be interrupted when there is a possibility of

particulate matter soiling the windows or lodging onto the cell surfaces. Particulate matter

or films deposited onto the cell surfaces will render the measurement inaccurate and the

unit inoperable.

It is strongly recommended that the OPTI-sense unit be periodically purged and zeroed

using reference gas (see Section 4).

094900000B DCN8470 Teledyne API OPTI-Sense 5200 11

3. ELECTRICAL CONNECTIONS

Refer to Figure 2-2 for this section. The status light is a steady green when instrument

power is on. DB9 connector is for RS-232 communications and the DB15 connector is for

the input/outputs (I/O).

Opti-Sense is marked with the appropriate power rating required for the unit to work and

function as designed. Note the supply voltage and current, which are shown on the label.

RS-232 CONNECTOR

If the OPTI-Sense Graphical User Interface (GUI) software is used, the RS-232 output

should be connected to the COM1 port of the computer running the GUI software.

I/O CONNECTOR

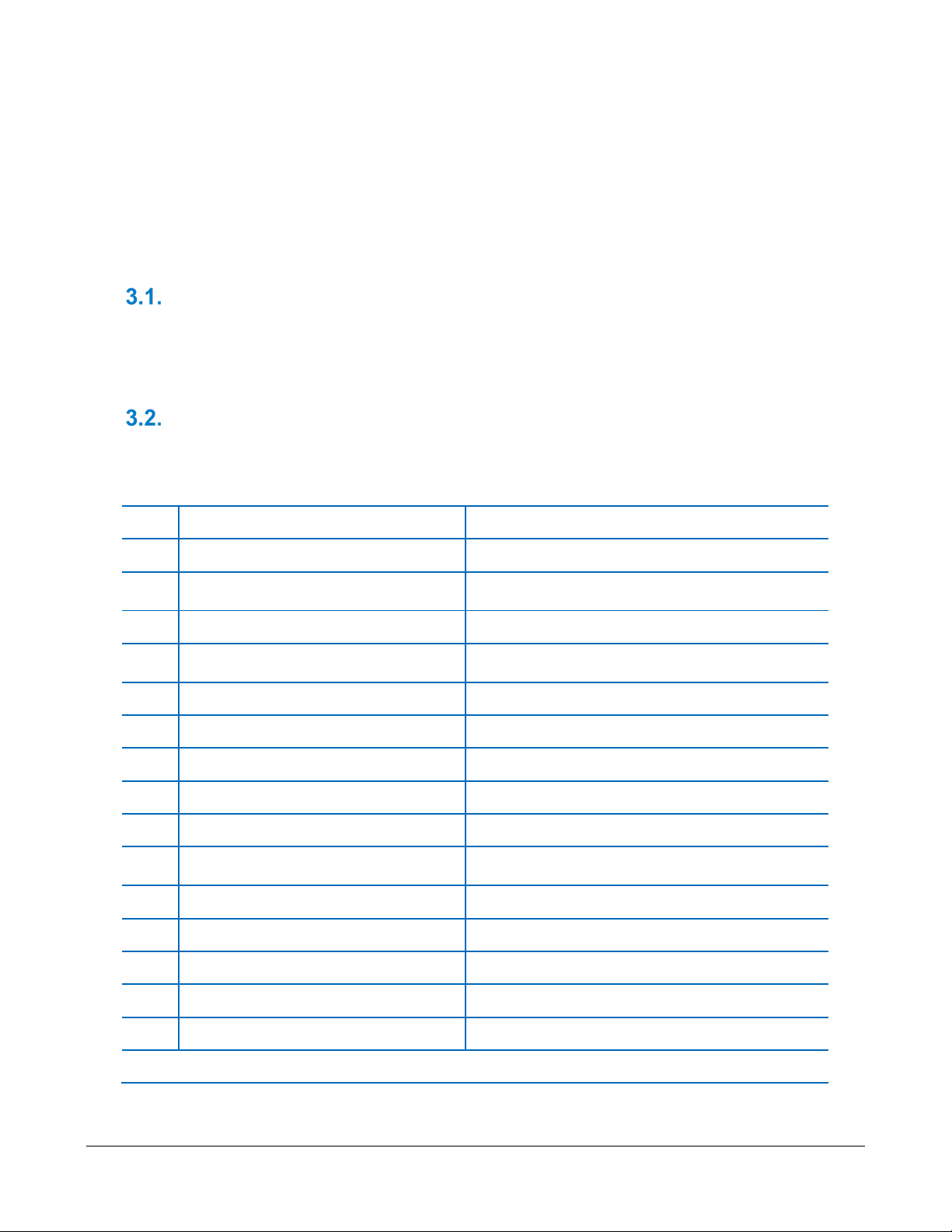

Table 3-1, below, shows the I/O connector pinout.

Table 3-1. I/O Connector Pinout

Pin

Connection

Notes

1N/C

2Analog Signal Out

1-10 Volt Range

Scale is factory programmable.

324 VDC Return See note below.

4Digital Input (DI) for Zero Command

Normally high.

Pull low for 200 ms to zero.

5N/C

6N/C

715 VDC Power Input 350 mA max during normal operation.

824 VDC Power Input

9Analog Signal Out Return See note below.

10 Fault Digital Output (DO)

HIGH indicates fault.

LOW indicates no fault.

11 Return for Zero Signal See note below.

12 N/C

13 15 VDC Return See note below.

14 15 VDC Return See note below.

15 Fault DO Return See note below.

Note: Pins 3,9,11,13,14,15 are shorted internally.

12 Teledyne API OPTI-Sense 5200 094900000B DCN8470

FAULT DO SPECIFICATIONS

The Fault DO is configured normally low; the output is high when an error has been

detected.

For most error conditions, the Fault DO will continue to indicate a fault until the unit is

successfully re-zeroed or rebooted. However, some errors are inherently intermittent in

nature, and are cleared automatically when they no longer affect instrument data. For

example, the three minute instrument warm-up period is indicated as an error to allow

detection of accidental power disruption; the Fault DO will indicate no fault when the

warm-up period is over.

•Operating Voltage (Power, pin 8): 24VDC ± 10%

•Output circuit:

oOutput HIGH Voltage: 24 VDC ± 10%, 203 Ωoutput resistance.

oOutput LOW Voltage: 4.9 ± 0.1 VDC, 203 Ωoutput resistance.

OVER-VOLTAGE PROTECTION

Maximum Ratings For DB15 Input Lines

•Forward voltage: 30V

•Reverse voltage: 50V

DB15 output lines are short-circuit protected.

094900000B DCN8470 Teledyne API OPTI-Sense 5200 13

4. SYSTEM OPERATION

The unit is designed to be left powered on at all times. Refer to the zeroing instructions

presented next in Section 4.1.

ZEROING THE OPTI-SENSE

The unit should be fully warmed up and purged of SiF4 before zeroing. Nitrogen, Argon,

Oxygen or vacuum purge are acceptable. Note that the unit will not zero during the three-

minute warm-up time and will report an error if a zeroing request is received during the

warm-up period. (This error can be cleared by zeroing the unit once the warm-up period

is over.) The zero signal command is configured active low; the line must be held low for

at least 200 ms.

•Operating Voltage (HIGH): 24VDC ± 10%

•Operating Voltage (LOW): 0VDC Nominal, 4VDC Max.

Zeroing will take approximately five seconds during normal operation.

Zeroing the OPTI-sense unit is essential to establish a stable baseline reading. TAPI

recommends zeroing the unit as often as possible. In applications were baseline drift is

critical, zeroing before every measurement cycle might be required.

Internal volume of the unit is approximately 40 cc, a minimum of 10 volumes exchanges

is recommended before zeroing the OPTI-sense. Please note that internal volume of tubing

connected to the unit should be considered when calculating purge time and flow rate.

Note that the OPTI-Sense has analog output range 1-10 volt. After the sensor is zeroed,

the analog output will read one volt.

14 Teledyne API OPTI-Sense 5200 094900000B DCN8470

5. INSTRUMENT ERROR CODES

Table 5-1 shows the instrument error codes, their causes, and corrective action.

Table 5-1. Instrument Error Codes

Error

Code

Cause Corrective Action

2

Too much light - out of design range. The

instrument may have been zeroed while

SiF4 was present.

Purge and zero the instrument.

3 No light detected.

Purge and zero the instrument. If error persists after

zeroing:

•Do not open the unit without prior permission

from TAPI.

•Contact TAPI immediately for service

instructions. It may be possible to repair your

unit in situ.

•If you do remove the unit, check the KF16

ports for powder contamination. Powder

contamination indicates presence of particulate

matter or a deposited film. Make sure that

provisions are in place to prevent particulate

matter or film deposition onto the surfaces of

the absorption cell.

4

Too much light - signal cannot be

measured. The instrument may have been

zeroed while SiF4 was present.

Purge and zero the instrument.

5 Instrument warming up.

Will clear automatically three minutes after the

instrument boots up.

6

A zeroing request was invalid because the

instrument was warming up. The instrument

did not honor the zeroing request.

Wait for the three minute warm-up period to complete,

then re-zero the instrument.

7

Insufficient light.

Same as for Error Code 3.

8 Timing error.

Purge and zero the instrument. Contact TAPI if the

problem occurs repeatedly.

9 Missed reading.

Purge and zero the instrument. Contact TAPI if the

problem occurs repeatedly.

094900000B DCN8470 Teledyne API OPTI-Sense 5200 15

6. TECHNICAL ASSISTANCE

Please contact our Technical Support department for any technical assistance needed:

Teledyne API Technical Support

9970 Carroll Canyon Road

San Diego, California 92131-1106 USA

Toll-free Phone: +1 800-324-5190

Phone: +1 858-657-9800

Fax:

+1 858-657-9816

Email: api-techsupport@teledyne.com

Website:

http://www.teledyne-api.com/

Table of contents

Other TELEDYNE API Accessories manuals