January, 2018 Page 4

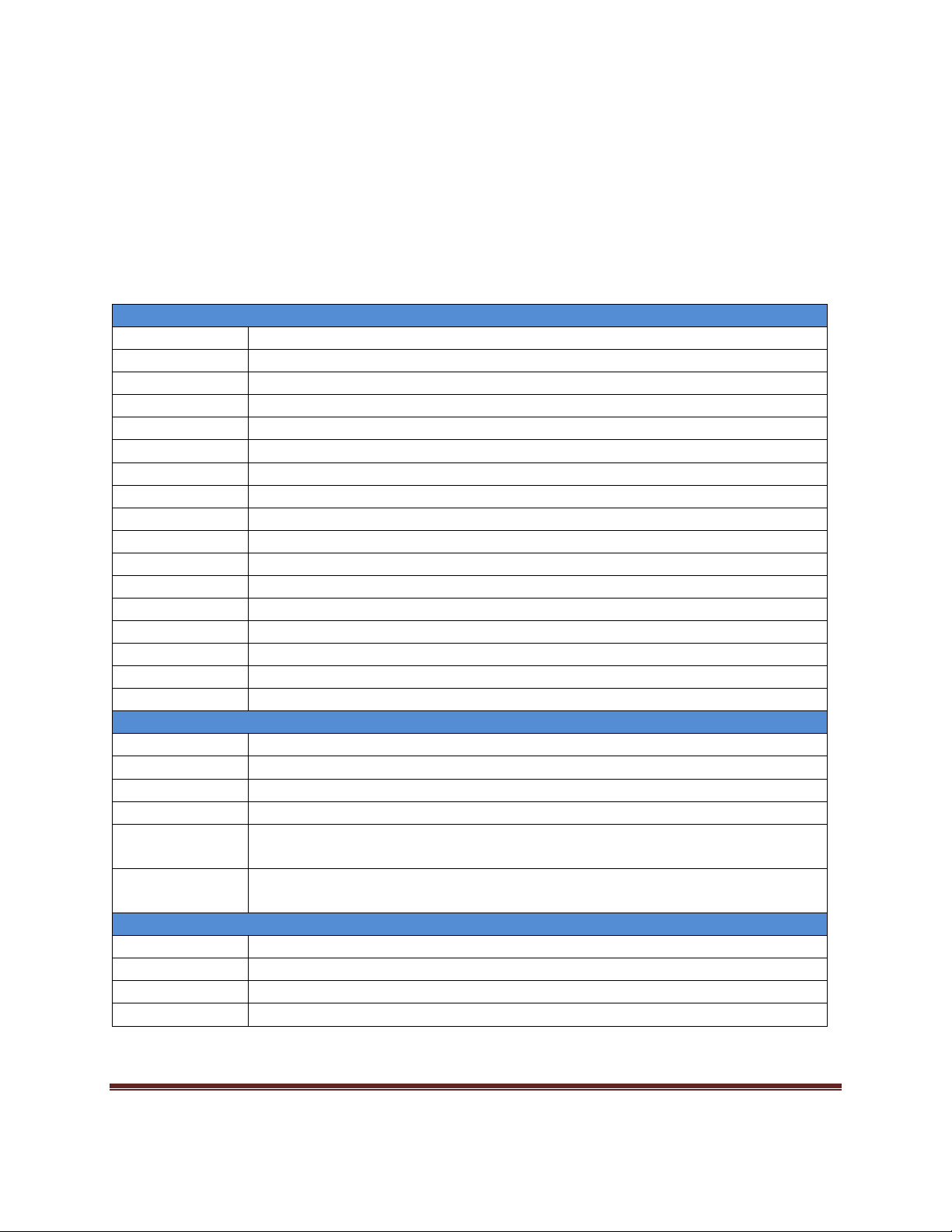

4.1.5 Data: Tools .......................................................................................................................... 21

4.2 Control ........................................................................................................................................22

4.3 Configuration .............................................................................................................................. 23

4.3.1 Configuration: General........................................................................................................ 23

4.3.2 Configuration: Inputs .......................................................................................................... 24

4.3.2.1 Configuration: Inputs: Analog .........................................................................................24

4.3.2.2 Configuration: Inputs: Modbus....................................................................................... 25

4.3.2.3 Configuration: Inputs: Digital..........................................................................................25

4.3.2.4 Configuration: Inputs: Temperature...............................................................................25

4.3.3 Configuration: Outputs ....................................................................................................... 25

4.3.3.1 Configuration: Outputs: Computed ................................................................................ 25

4.3.3.1.1 Configuration: Outputs: Computed: Raw Velocity ...................................................25

4.3.3.1.2 Configuration: Outputs: Computed: Velocity ...........................................................25

4.3.3.1.3 Configuration: Outputs: Computed: Actual Volumetric Flow................................... 26

4.3.3.1.4 Configuration: Outputs: Computed: Standard Volumetric Flow .............................. 26

4.3.3.2 Configuration: Outputs: Analog ......................................................................................27

4.3.4 Configuration: Calibrations ................................................................................................. 27

4.3.4.1 Configuration: Calibrations: Timing ................................................................................27

4.3.4.2 Configuration: Calibrations: Evaluations......................................................................... 28

4.4 Administrator.............................................................................................................................. 29

5 Operation ............................................................................................................................................29

5.1 Calibration and Adjustment........................................................................................................29

5.2 Interference Check...................................................................................................................... 30

5.3 Creating a Correction Curve........................................................................................................ 30

5.4 Long-Term Shutdown.................................................................................................................. 31

6 Maintenance ....................................................................................................................................... 32

6.1 Scheduled Preventative Maintenance Chart ..............................................................................32

6.2 Pitot Tube Cleaning Procedure ...................................................................................................32

6.3 Sample Line Cleaning Procedure ................................................................................................32

6.4 Filter Media Replacement Procedure.........................................................................................33