TelePost LP-100 User manual

1

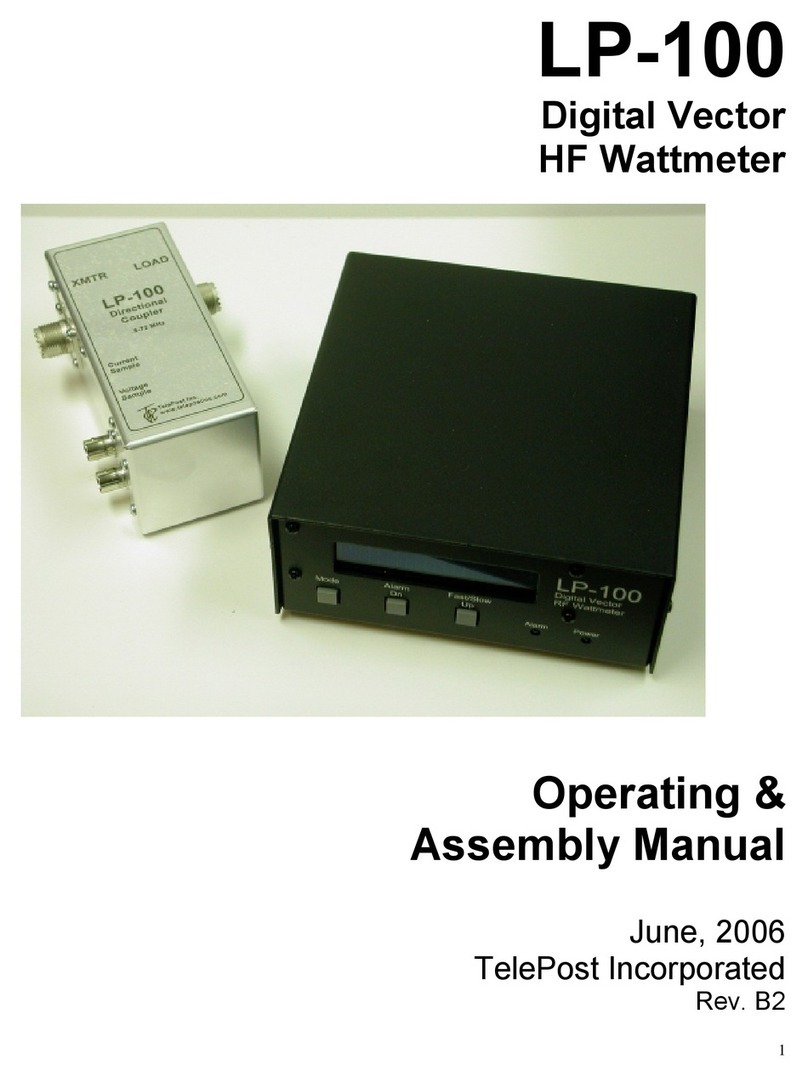

LP-100

Digital Vector

HFWattmeter

Operating &

AssemblyManual

April 2007

TelePost Incorporated

Rev. C20

2

Compliance Statements…

FederalCommunicationsCommission

Statement(USA)

Thisdevice complieswithPart15 oftheFCC Rules. Operation issubjecttothefollowing two

conditions:(1)thisdevice maynotcauseharmfulinterference,and (2)thisdevice mustacceptany

interferencereceived, including interferencethatmaycauseundesiredoperation.

EuropeanUnionDeclaration ofConformity

TelePostInc. declaresthattheproduct:

ProductName:DigitalVectorRFWattmeter

ModelNumber:LP-100

Conformstothefollowing ProductSpecifications:

EN55022:1998Class B

following theprovisionsoftheElectromagneticCompatibilityDirective89/336/EEC,testedandverified

3-17-2006 atFCC accreditedlaboratory.

IndustryCanadaComplianceStatement

CanadaDigitalApparatusEMIStandard

ThisClass Bdigitalapparatusmeetsall therequirementsoftheCanadianInterference-Causing

EquipmentRegulations.

Cetappareil numeriquedelaclasseBrespectetouteslesexigencesdu Reglementsurlematerial

brouilleurdu Canada.

CopyrightandTrademarkDisclosures

LP-100 isatrademarkofTelePostInc. Windows®isaregistered trademarkof Microsoft Corporation.Teflon®isa

registered trademark of E.I. du Pontde Nemoursand Company.PICmicro®isaregistered trademarkof MicroChip

TechnologyInc.

Materialinthisdocument copyrighted ©2007 TelePost Inc. Allrightsreserved.Allfirmwareand softwareused inthe LP-

100, LP-100 VCPand LP-100 Plotprogramscopyrighted ©2004-2007 TelePostInc.Allrightsreserved. MicroCode

Loaderisacopyrighted programfromMecanique, http://www.mecanique.co.uk/.

3

TableofContents

Introduction............................................................................................................4

PartsList.................................................................................................................5

AssemblyInstructions............................................................................................8

InitialCheckout....................................................................................................16

Setup/Calibration..................................................................................................18

Operation..............................................................................................................22

CircuitDescription ...............................................................................................26

Schematic............................................................................................................28

Troubleshooting ...................................................................................................30

Software................................................................................................................32

SpecificationsandCALTable.............................................................................34

Warranty..............................................................................................................35

AppendixA..........................................................................................................36

4

Introduction

TheLP-100isdesignedasan accurateinstrumentformonitoringstationperformance. It providesanumberofuniquefeaturesnotseen

beforeinahamradiowattmeter.

Themost obviousof theseisthevectordisplay.Thisdisplayshowsthecompleximpedanceoftheloadintwoways. Thetoplineof the

displayshowsimpedanceinpolarform…i.e.,magnitudeandphaseoftheimpedance.Thebottomlineshowstherealandimaginary

componentsofimpedance…i.e., R+jX.Theparametersaredisplayedinarangeof0.1to999.9ohms.Phaseisdisplayedin0.1

degreeincrementsfrom0-180 degrees.

Featuresinclude…

•PLEDdisplaywithbargraphsforpowerandSWR, alongwithnumericalreadout forboth

•ProfessionaldBm/ ReturnLoss display

•50 mWto2500Wwithfourautorangingscales

•Powerdisplayresolution of0.01to1Wdependingon scale

•Frequencycoverageof 1.8-54MHz,withautomaticband-by-bandcompensation

•Z, R,|X|displayfrom0-999.9ohmseach

•Separatecouplerwith50ohmportsforuncluttereddesktop

•Peak-hold numerical powerreadoutwith"hang"characteristicforpowerandSWR

•SWRaccuracy<.15(5%)fromabout.1Wto2500W, .05 typical

•Poweraccuracyis5%typical atanyrated powerlevelorfrequencyfrom.5Wto2500Waftercalibration,usable to0.05W

•Canbeeasilymatched in thefield toexternal standardtowithin0.1%on eachband

•Powerdisplayisactual powerdeliveredtotheload(FwdminusRefpower).

•SWRAlarmsystemwithsetpointsforOff, 1.5,2.0.2.5and3.0.

•WindowsfreewareVirtual Control Panel forsoftware/ remotecontrol

•Supportwithin TRX-Managerfordirect remotemonitoring

•Advanced charting capabilityforSWR, RL, Z, R, Xandphaseanglevs.frequency

•Built-inbootloadertoallowforfirmwareupgradestobedownloadedand installed.

•Callsignscreen savertoextend lifeof display

•Directinput forbenchtesting &field strengthmeasurements, -15 to+33dBm.

•ConformstoFCCPart 15A&B, ICAS andCEradiated emission limits,tested andverified byaccredited lab

Thismanualwilladdress theassemblyof theLP-100,initialcheckout,calibrationandoperation.You maywishtoread throughthe

circuitdescriptionandstudytheschematicbeforebeginning assemblytofamiliarizeyourselfwiththeproject. It ishighlyrecommended

thatyouthoroughlyread throughthe Assembly section beforeevenunpacking theLP-100kit.

RoHSStatement

TheEUadoptedaset of standardsforthe“ReductionofHazardousSubstances”inJuly2006.Thereisconsiderableconfusionover

whichdevicesandcompaniesareaffectedbythenewrules.It isouropinion thathome-builtkitsareexemptfromthislegislation,and

theremaywellbeafurtherexemption undertheheading“Measurement Equipment”fortheLP-100.Also,sinceTelePostdoesnothave

apresenceinEurope,wedo notimporttoorexportfromamemberState, asstipulatedintherules.

Regardless oftheseexemptions,everyefforthasbeenmadetoprovide100%RoHScompliantparts,PCBsandSMTassembly

processesontheLP-100.Werecommend theuseof standardPb/SnalloysoldersforassemblyofLP-100kits,mainlyforperformance

reasons.Thisisperfectlyacceptableundertherulesfor“ownusebuiltequipment(hobbyist)”.Useoflead-free solderisalso

permissible,sincethePCBsarelead-free, butbeawarethat specialequipmentandtechniquesarerequiredtouselead-free solder,

and PCBreworkhasamuchhigherchanceofdamagingthePCB.

Inlayman’sterms,theLP-100isaslead-free aspossiblewithoutcompromisingperformanceorlong-termreliability,andbuildersin

memberStatesarefree toassembleanLP-100withwhateversoldertheywish.

HardwareUpgrades

Starting withserial#101, theLP-100usesan upgradedPICprocessor, withtwicethememoryofthepreviouschip.Thisallowsfor

yearsoffirmwaredevelopmentandaddedfeatures.AnyownerofanearlierLP-100isentitledtoafree upgradetothenewprocessor,

but willneedtodo anadditionalcalibrationtotakeadvantageofthenewcapabilities.AsaconveniencetoanyLP-100 owner,TelePost

will do thechipswapandafree recalibrationiftheownerreturnstheLP-100toTelePostathisshipping expense, and paysforreturn

shipping($12 forFedexGroundinsured).Alternatively,TelePostcanshipanewprocessortotheownerinexchangefortheoldone, or

forasmall chargeiftheownerwishestokeeptheoldprocessorasabackup.Inthiscase,itisuptotheownertorecalibratehismeter,

and tosaveandre-programhisCALtableintothenewchip. Fordetailsonchipswapping, send an emailto larry@telepostinc.com.

5

PartsList- Subject tochangewithout notice.

Pre-installedSMTparts

QTY PartNo. Description

4C9,10,12,13 0.01uF50V

2R4,18 Resistor26.71%.25W

2R5, 12 Resistor49.91%.5W

2R6,21 Resistor56.21%.25W

2R9, 27 Resistor56.21%.5W

2R10,20 Resistor4221%.25W

1R24 Resistor1741%.25W

1R30 Resistor1201%.25W

1R33 Resistor32.41%.25W

1R35 Resistor751%.25W

1D8 HSMS-2805 dualSchottky diode

1U1 AD8302

1U9 AD8367

1U10 Gali-74MMIC

1T1 ADP-2-1Transformer

Partstobeinstalled–mainchassis

QTY PartNo. Description

14 C1,2,5,6,7,11,14,20,22,32,33,40,42,43 0.1uF50Vmarked104

3C3,27,41 10uF50V

1C4 0.33uF50Vmarked334

8C8,21,28,29,30,34,38,39 0.01uF50Vmarked103

7C15,16,17,18,19,31,35 1uF50Vmarked105

2C23,24 0.001marked102

2C25,26 0.002marked202

1C36 330pF50Vmarked331

1D2 Rt.Ang. LEDRed

1D3 Rt.Ang. LEDGreen

1D4 1N4001

1D5 1N4148

1RC1 ribbon cableassembly

2J1,P1 16-pinDILheaderfordisplay

2J2,7 BNC jack,rt. angle

1J3 Powerjack2.5mm

1J4 DB9PCBmount

1J6 DualRCAPCBmount

2JP1,2 2-pinSILheader

2Shortingjumper

4L1,2,3,7 470 uH, 100 mAmoldedchoke(largebrown)(yel-viol-br-silver)

or1mH, 100mAmoldedchoke(largegreen)(br-blk-red-gold)

2 L4,6 470uH,30mAmoldedchoke(small greenorbrown)(yel-viol-br-gold)

1L5 1 mH,30 mAmoldedchoke(mediumgreen)(br-blk-red-silver)

or1mH, 100mAmoldedchoke(largegreen)(br-blk-red-gold)

1Q1 2N4401

1 LCD-1 PLEDdisplay20x2

2R1,13 1M1%1/8wbr-blk-blk-yel-br

3R2,41,42 10k5%1/8wbr-blk-or

3R3,16,17 1k5%1/4wbr-blk-red(maybe1/8wdepending onboardversion)

5R7,11,14,34,36 1k5%1/8Wbr-blk-red

1R8 20kpot

1R15 22k5%1/8Wred-red-or

6

QTY PartNo. Description

2R19,29 4.75%1/4Wyel-viol-gold

1R22 150k1%1/8Wbr-grn-blk-or-br

2R23,25 10k1%1/8wbr-blk-blk-red-br

1R26 6.34k1%1/8Wblu-or-yel-br-br

1R31 100 5%1/8Wbr-blk-br

1R32 174 1%1/8or1/4Wbr-viol-yel-blk-br

1R37 57.61%1/8or1/4Wgrn-viol-blu-gold-br(bluebody)

1R39 120 5%1Wbr-red-blk-blk-br(brownorrust coloredbody)

1RL1 OmronG5V-2-H1-DC5

1S1 CEM-1212CPiezotransducer

3SW1,2, 3 4mm tactileswitch,rt. Angle

3Switchkeycaps

1T2 ToroidcoreFT37-61

1U2 LM7805

1U3 18F2620

1U4 TLC-271ACP

1 U5 MAX6225BEPA

1U6 MAX232N

1U7 LM34DZ

1 U8 MCP3304

1Y1 Resonator10 MHz

1#28 wireforxfmr (2)6”(15.24cm)lengths–twocolors

1PwrCable2.5mm

1Enclosure MainEnclosure(top&bottom)

1PCB MainPCBw/pre-installedSMTparts

1Heatsink Heatsinkfor7805regulator

2ICSocket 8-pinsockets

2 ICSocket 16-pinsockets(Socket notusedfortherelay)

1ICSocket 28-pinsocket

4RubberFeet Square

Partstobeinstalled–coupler

QTY PartNo. Description

1Enclosure Coupler

1PCB Coupler

2T1,2 ToroidcoresFT140-61

2UHFConnector SO-239

2BNC Connector UG1094/U

2BNC cable 6'(1.83m)M/M–RG58U

4R3, 4,9,10 75 ohm1%1W(2512SMT)

8R1, 2,5-8,11,12 301 ohm1%1W(2512SMT)

2Nylonbushings Onewith3/16”(4.76mm)hole, onewith¼”(6.35mm)hole,3/16”(4.76mm)&1/8”

(3.18mm)onserial#safter200)

6AdhesiveTeflon®tape 2 long and 4shortpieces(2long&2short onserial#safter200)

1TerminalStrip 2lug terminalstrip

1#20 wireforxfmrs (2)45”(1.14m)lengths

1RG-142B/UTeflon®coax (1)2”(5.08cm)length

1RG-316UTeflon®coax (1)2”(5.08cm)length

4RubberFeet Round

1AdhesiveLabel CouplerTop Label

7

Hardware

QTY PartNo. Description

1 4-40x1.5”(3.81cm)threadedstandoff(.625”(1.59cm)onserial#safter200)

1 4-40x0.75”(1.91cm)machinescrew(serial#safter200)

14 #4 self-tappingscrews–1/4”(6.35mm)–plated(forcoupler)

14 #4 lockwashers(9forcoupler,3formainchassis)

(11 forcoupler,3formainchassisstarting about serial#350)

1#4 splitlockwasherforcouplerPCB

10 4-40x3/8”(9.53mm)machinescrews–plated(8forSO-239s,2forDB9)

(plus1forattaching voltagexfmrstandoffstarting about serial#350)

54-40x1/4”(6.35mm)machinescrews–plated(3forcoupler,1forheatsink)

(1fewerstartingaboutserial#350)

9 4-40nuts–large(forcoupler)

44-40nuts–small(1forcouplerPCB,3formainchassis)

16 4-40x3/16”(4.76mm)machinescrews–black(formainchassis)

84-40x¼”(6.35mm)threadedstandoffs(formainchassis)

6#4 x¼” (6.35mm)self-tapping screws–black(formainenclosure)

1#4 x3/8”(9.53mm)self-tappingscrew–black(forRCAconnector)

1#4 SolderLug(2onserial#safter200)

You shouldcheckall partsbeforestartingtoallowyou tostarttheprocess ofobtainingreplacement partsassoonaspossible.It isalso

agoodideatosort thepartsinadvance…egg cartonsarehandyforthis(passivepartsonly).Michael’scraftsstoresalsohavenice

plasticcaseswithdividersatlowprices. Note: partssubject tochangewithoutnotice.Forinstance,thereareacouplecaseswherea

resistoriscalledoutfor1/8Wwherethesuppliedonemightbe¼W,asinR33 &R37. Also,theoriginalpartforR39 wasacompact1W

resistorwherethecurrentpartislarger. Thisisduetosketchyavailabilityoftheearlierparts.ThePCBlayoutwillberevisedinthe

futureifitbecomesclearthattheoriginalpartswillnolongerbeavailable.Inthecaseofthelargerresistors,justformtheleadsunder

thepartasshownbelowif thishappens.Thiscan alsohappenwithlead spacingoncaps.

8

Assembly

Importantwarnings–readthisbeforestartingassembly

You shouldvisuallyinspectallthesolderpads/traceswithamagnifierforanyetchingproblems.Thisisdonebeforeshipping,butI

recommendthebuilderdoasecond inspectionaswell. Wealsonowdo 100%continuitychecks ofall padsbeforeshipment, and I

recommendthebuilderdothisaswell.Thisisaresultofacouplebadboardsfoundinproduction run#3. Thesetwostepswilltake

about15minutes,butcouldsavealotof work. Todothecontinuitycheck,turntheboardupsidedown,andconnectonelead ofyour

DMM tothegroundplane. Toucheachpadonthebottomthat isnotathermalgroundpad(onewitha“+”shapedconnectiontothe

groundplane).Noneof thenormalpadsshouldhavecontinuitytoground except fortwonearT1,theSMTxfmr,whichprovidesaDC

pathtogroundforthosepads. NOTE:thedozensoflittle“vias”tiethetoptothebottomgroundplanes,andthesedo notneedtobe

checkedastheyaresupposedtobegrounded.

AlloftheSMTcomponentsarepre-installedonthemainboardforyourconvenience. SMTpartsaresuppliedwherevernecessaryfor

performanceoravailabilityreasons. CAUTION: Beverycarefulhandlingthisboardtoavoiddamagetotheinstalledparts. Anti-static

measuresarehighlyrecommended,suchasuseof ananti-staticmat,groundedsolderingironandwrist band.

You maywishtoclean thefluxfromtheboardafterassembly,althoughitisnotnecessarywithmost modernsolders. Atoothbrushand

alcoholaregood forthis. Onlyuserosincoresolder.Useofacidcoresoldervoidsthewarranty.Lead-free solderisOK,andtheboards

areRoHScompliant, butitwillbemoredifficulttoremovepartswithout damagingtheboardshouldyouhaveto.

Overview

BelowisapartslayoutofthemainPCB.Thesemarkingsmatchthesilk-screening onthePCB, butarerepeatedhereforclarity. You

can alsocrossoutthepartsonthisgraphicastheyareinstalled. Note: DONOTusethismanualforassemblyofkitswithserial

numbersbefore#101.UseLP-100 ManualRev. BlistedontheLP-100webpageat www.telepostinc.com/lp100.html instead.Some

picturesinthismanualareof boardsorcomponentsfromearlierproduction runs.Thesemaybeslightlydifferentthanlaterversions.

Forinstance, L8, R28,C44, andC45weredeletedon laterversions,andC27andJ8werechanged.

9

Assemblycont’d

Irecommendapproachingassemblyinthefollowingorder…

Install all ICsockets

Install resistors

Install capacitors

Install connectorsandswitches

Install 7805regulator

Install chokesselectivelyasoutlinedintheinstructions

Thisallowstheboardtoremainflat duringmostoftheconstruction.Followingthisorderwill alsofacilitateinitialcheckout.Thechokes

will beselectivelyinstalledtoallowforcheckoutof varioussectionsofthecircuit.

Checkout will followthisorder…

Verifyproper+5vdcbeforepoweringanydevices

Install L2, PICandPLEDandcheckdisplayforproperPICoperation

Install L1, L3,U5,U7and U8andverifyproperoperationofADC

Install L5andU4andverifyproperpowerdetection

Install L7andverifyproperfrequency counteroperation

Install U6and verifyproperserialportoperation

Theabovechecks willrequireonlyaDVMand theSetupscreensexcept forthepowerdisplaycheck.Tocheck thepowerdisplay,you

will needatransmitterandcompletedcoupler.Iwill list expectedcurrentdraininredateachstepsothatyoucanverifythat nothingis

shortedineachsection.Acurrentlimitedorfusedpowersupplywith0.25ampmaximumfuseshouldbeusedduringcheckout.

TocalibratethepowerreadingsoftheLP-100willrequireaminimumofanaccurate50-ohmdummyload and ameanstomeasurerf

power. Youwillneedadiodepeakdetectororacalibratedoscilloscopetomeasurerfvoltageacross theload. Analternativewouldbe

an accuratereferencewattmeter.

Tocalibratetheimpedancegainandphasedetectorsyouwillalsoneeda25ohmdummyload.Thiscanbeeasilymadeupout of

inexpensive3W,5%metaloxideresistors, suchasusedinmyLP-200ortheElecraftDL-1.Alternatively,youcanuseapairof50ohm

dummyloadswithcoaxadapterstoallowthemtobeparalleledtoprovide25 ohms.Thiscalibrationcanbedonewithaslittleas5Wof

power. Thisadjustment isnot imperative, asthedefaultvalueisquiteacceptable.

SWRcalibrationrequiressettingoffset andslopeadjustmentsfortheAD8302gaindetector.Calibration oftheAD8302 phasedetector

requiresadelaylineofknownelectricallength. Youcangetprettyclosebyusing ahighqualitypieceof polydielectricRG-58,and

calculatetheelectricallengthindegreesusingthefollowingformula…

Phase=(360*L*F)/(984*VF)

WhereDelayisindegrees, Lisinfeet and FinMHz. VFwouldbe0.66forpolydielectric.Aconvenientlengthisabout6’(1.83m),

whichwouldprovideadelayof~45degrees(thecenteroftherange)at14MHz. Youwillfindmoreaboutcalibrationinthe Calibration

section.I amcontemplatinganinexpensivecalibration kitinthe$25 range,whichwouldincludeaswitchabledummyload PCBand

pre-cutdelayline.IwillalsocalibrateanyassembledLP-100kitfree ofchargeif you payforreturnshipping.

You willneedthefollowingtoolstocompleteassembly…

Adjustablesolderingiron–800degreesmaximum

60/40alloysolder….020”(0.51mm)diameterrecommendedforthermalpads

Needle-nosepliers

Wirecutters

SmallPhilipshead screwdriver

Razorknife

DigitalMultimeter

NOTE:TheLP-100iswhatIwouldcall anintermediatelevelkit. Ifcareistaken,you shouldhavenodifficultybuildingit. Iwouldpegthe

assemblytimeat about8hourstotal,plussomereadingthrough themanualinadvance,and sometimeforcalibration. Takeyourtime,

and double-checkyourwork. Achangewasmadeafterserial#100tomakethethermalpadstoground easiertosolder. Theboardis

nowalsoRoHScompliant.Thisshouldnot poseanyproblem.Infact,I findthenewerboardseasiertosolder.

10

Assemblycont’d

Step-by-step assemblyinstructionsformainboard.

Belowisapictureof theassembledPCB.TheSMTpartscomepre-installed.

Itisrecommendedthat you print thismanualtoallowforeasy referencewhilebuilding,andtoallowyou tocheck offthestepsasyou

completethem. Therewillalsobeatableofcalibrationvaluesyou canenterasyoudothecalibration. Thiswill enableyoutoreturnto

theoriginalsettingsshouldyouneedtointhefuture.

Makesureyourworkareaisstatic-free toavoiddamagetothepre-installedSMTparts.Itisalsoadvisabletowearananti-staticwrist

band.Refertothepartsplacement graphiconpage6ortheabovepictureforquestionsregardingpartsplacement. Youcan zoominto

thepdfversionof thisdocumentforeasierpartsidentificationifneeded.

qInstall all ICsockets,keeping theboardflatasyougotoavoidgaps.

qInstall resistors. Toavoidmessiness whentrimmingleads,Iwoulddo about 6at atime.Ifyouareunsureofthecolorsusedby

someofthemanufacturersforthecolorcode,measurethevaluewithaDMM.

qInstall all .01uFcaps(marked103),ingroupsof about6.

qInstall all .1uFcaps(marked104).Thisshouldbedoneinat leasttwobatches.Onsomeruns,thesepartshaveformedleads.You

can straightentheleadsarejust snap thepartinasdesigned.

qInstall remainingcaps,leaving the10uFcapsforlast. Observepolarityonelectrolytics. Referringtothecomponentplacement

guideandpicturemayhelpwithpartsplacement,forinstanceforC27whichwaschangedtoanelectrolytic.

qInstall greenand redLEDs. NOTE: Donotinstallthesetightagainsttheboard.Becauseof manufacturingtolerancesonthese

parts,theymaynotlineupwiththefrontpanelholeswheninstalledtight againsttheboard.Itisdesirabletoleaveabout 1/16”of

spacing belowtheLEDs,sothat theycanbebentforwardtolineup ifnecessary.

11

Assemblycont’d

qInstall miscellaneouspartssuchasresonator,Piezotransducer,transistor,diodes, etc. NOTE:Removetheprotectivecoveringon

thetransducerbeforeusing.Also, the“+”lead goestothesidewiththejumper,pertheplacement guide.Theoutsideleadsofthe

resonatorareinterchangeable. Donot install chokesyet.

qInstall connectorsandswitches, except forJ4,theDB9connector. Youwill probablyhavetopropsectionsof theboardupto

ensurethat thepartsareflushwiththeboard.Install theheaderonthePLEDPCB.Theheaderisinstalledon thebacksideofthe

PLEDPCBwiththelongpinspointing awayfromtheboard.

qInstall 7805regulator.Attachheatsinktotheregulatorbeforeinstallingon PCB,using 4-40x¼” (6.35mm)”machinescrewand

smallhexnut.Itdoesn’t matterwhichsidethenutison.

qInstall T2nearC43. Thisxfmrismadeupof 10bifilarturnsof#28 enameledwirewoundonaFT37-61core.Wireissuppliedin

redand greentomakewiringasnap.Bifilarmeansthatthetwowiresarewoundasapair. See diagramaboveforwiring.It does

notmatterifthewiresareparallelortwisted. Aturnisdefinedasapassthroughthecenterofthecore. Youwillwindupwiththree

leads,whichwillbeinsertedintothethree holesindicatedonthesilk-screen. Thelead withtwowiresgoestothecenterholeinthe

PCB. Makesurethattheenamelisremovedfromtheleadsbeforesolderingtoensuregoodcontact.

qInstall L4andL6.Theremainingchokeswillbeinstalledaspartoftheinitialcheckoutoftheboard,inordertoenablepoweringup

ofcircuitsindividually.Thesemaybebrownorgreen, butaresmallerthantheotherchokes. NOTE:Ifyoucheckthechokeswitha

meterliketheAADE,thereadingsmaybelow. Thisisbecausethechokesuseferritecores,andtheLvarieswithfrequency. The

littlemeterstendtotestatverylowfrequencies.

qThejumpersforthePTT connectorcan bewirednow.Thenormalwiringisshownonthecomponent placementdiagramatthe

beginningofthischapter,andbelow.Thisprovidesforanormallyclosedconnection betweenthecenterconductorsofthetwo

RCAconnectors. Thiswillworkformost rig/ampcombinations.FormoreoptionsforPTTwiring,check out theSteppIRTuning

Relaysectionof mywebpage.

qAttachJ4,theDB-9connectortothePCBusing4-40x3/8”(9.53mm)screws,lockwashersandsmallhexnuts.Thelockwashers

and nutsgoon thebottomoftheboard.Solderthepinsaftertighteningthescrewstoavoidstressingthepinsaftersoldering.

qYou caninstall RL1atthistime.Thecorrectpositioningiswiththetwoseparatedpinstowardthebackoftheboard,next tothe

snubberdiode,D5.Thenotchinthetopisalsopositionednext tothediode.See thecomponent placementillustration.I usedto

supplyasocketforthis,but havedecidedthatthere’sreallynoneedforit, andthere’sariskoftherelayworkinglooseduring

shipment.

12

Assemblycont’d

Initialcheckoutofmainboard.

qStep1.Makesurethatyourbenchisclean andthePCBisnotsitting on anycutoffcomponentleads.Connectsuppliedpower

cabletoasupplyof12-15VDC. Thedashedwhitelead on thesuppliedpowercableisthe+lead (centerpin). Makesureyouhave

ajumperinstalledatJP2.Using yourDMM,check for5.0VDC at pin3ofU2.Thevoltageshouldbewithin0.25Vof 5.0VDC. ~7

mA.

qRemovepowerand installL2,U7,Y1andthePIC.TemporarilyconnectthePLEDdisplay. Becarefultomakesurethereisnothing

on yourbenchwhichcouldshortout anythingonthePLEDPCB. Theribboncableshouldbeorientedasshownintheinterior

photobelow.Makesurethattheribbon connectorsarecenteredon theheadersat bothends.

qStep2.Powertheboardupagain,andverifythatyouareseeing the“splash”screenwithversionandcopyright information,

followedbythemainLP-100 screen. Themainscreenshouldlooklikethescreenon thephotoatthetop ofthe“Operation”section

ofthismanual.Ifyoudon’tsee thedisplay,adjustthesettingof R8.Thepropersettingisjustat thepointwherethedisplay

reachesmaximumbrightness.Thiswill ensurethatthebrightnessdropstotheproperlevelwhenthefirststepofthescreensaver

timerisreached. Afineradjustmentcanbemadeafterthescreen-saverstarts.ThecorrectvoltageforthePLEDat thejunctionof

R8andR15 is3.0Vatfullbrightness whiledisplayingthemainscreen.It willdrop to2.4–2.5Vinthescreensavermode. ~35

mA

qStep3.InstallL1,L3, U5,andU8. ~82mA.TemporarilyentertheSetupmodebybrieflypressingtheMode(SW1)and Alarm

(SW2)buttonsalmost simultaneously. TheModebutton shouldbepressedslightlyahead oftheAlarmbutton. NOTE: Startingwith

firmwareversion1.1.44, entering(orexiting)SetupisaccomplishedbyholdingtheModebuttonforabout aseconduntil thescreen

changes. You shouldnowsee thefirstCalibratescreen, shownbelowforfirmwarepriorto1.1.47.Thesecond screenisfor

firmware1.1.47andafter. ThisscreenshowsthereferencevoltagegeneratedbyU1(thegain/phasedetector),theReceived

SignalStrengthIndicatorvoltagefromU9(theAGCchip)and temperatureindegreesFand C(fromthetempsensor, U7). Note:

theRSSIreadingshowninthisphotoiswithRFpowerapplied. Theresting voltagewithnoRFisgenerallybetween.150and.250.

NewerfirmwaredisplaysTempindegreesCorFdepending ontheselection.

qStep4.InstallL5,L7, U4andU6andcheck thecurrent. ~160 mA. Ifalliswell, settheboardasideuntil thecouplerassemblyis

completedtoallowcheckoutofthepowerdetectorcircuitand frequency counter.

13

Assemblycont’d

Step-by-step assemblyinstructionsforthecoupler.

Refertothedrawingandpicturesduringassemblyofthecoupler.Thetop pictureiscourtesyofDario,N5QVF,andthelowerrightone

iscourtesy ofStan, W5EWA. Thesequenceof picturesbelowisfromJackK8ZOA.Jackdevelopedacleverwaytoensureproper

winding ofthecores,bothforspacing andcoverageofthewindings.Detailsof Jack’swindingmethodologyisfoundbelow.

14

Assemblycont’d

Constructionofthecouplerconsistsofonlyafewsteps. Themaincomponentsarethetransmissionline,toroidaltransformersand the

attenuatorPCB.Themost criticalstepisthewindingofthetransformers. Theyarewoundwith26turnseachof#20 enameledwire.

Thecoresarewound inoppositedirections,i.e. theyshouldbemirrorimagesof eachother. Thewindingsshouldbeevenlyspaced

over~60%ofthecore, asshownlater.ThecoresaresupportedbynylonbushingswithTeflon tapeoverthem,whichareinsertedinto

thecorecentersafterwinding.If thewiresarewoundtightly,thecoresshouldfit snugly,butshouldnothavetobeforced.Thecores

shouldbewoundbyhand,don’t useanytoolsonthecoresorwiresastheymaybreak.

HerearesomedetailsofthewindingaidthatJack,K8ZOAdeveloped. He

createdtheruleusingExcel,using thefollowingmethod.

Start withafreshExcelworkbook.Clickontheupperleftcell,andselect

underline. Rightclickandselectcopy,thenhighlightcells2thru25inrow1,

rightclickand select paste. You shouldnowhaveastackof25 linesinrow1.

Adjustrowheight for0.10" (2.54mm)betweenlines, whichcorrespondstoa

rowheightof7.2.Dothisbyhighlightingthe25rows,selectFormat>Row>

Heightinthetoolbar,andsetrowheightto7.2. Thisgives60%coverage

whichmatchesthesmallTeflontapesizegap.Copythecellsandpasteextra

copiessothat you willhaveatleasttwotouseafterprinting.

Thereducedsizescreencapturetotherightshowswhatthescreenshould

looklikebeforeprinting.Print thescreen, cuttotherulesout and tapetothe

cores. Useawhitelaundrymarkerorgreasepenciltomarkthelinesonthe

toroids.Jackrecommendstheuseofatightfitting corktoholdthewindings

inplaceasyou proceed, and tohelpflattenthewireagainstthecoreonthe

inside.

ThebushingwiththelargerholeismountedbetweentheSO-239

connectors,andsupportedbytheRG-142 Teflon®coax. Thispieceof coax

formstheprimarywinding ofthecurrent samplingtransformer.Theother

transformerissupportedbya0.625”(1.59cm)standoffand1.0”(2.54cm)

screwwhichformstheprimaryofthevoltagesampling transformer. Oneend

ofthisstandoffisgrounded,andtheotherconnectstotheattenuatorPCB.

Thetransformersecondariesarewiredasshowninthedrawing.Itis

importantthatthecoresbepositionedasshown,andthewiresberoutedas

shown.Improperrouting orcoreorientationwillaffectperformance,

especiallyabove25 MHz.

qInstall thetwoSO-239UHFconnectorsusing 4-40x3/8”(9.53mm)machinescrews, #4lockwashersand large#4hexnutsfor7of

themountingholes. Theremaining hole,uses4-40 x3/8”(9.53mm)hardwareandasolderlug asshown. Thesoldercupsonthe

SO-239sshouldbefacingupward.

qSoldertwoshortpigtailsabout 1.5”(3.81cm)longintothecenterpinofthetwoBNCs. You can usecut endsfromotherpartsfor

this.InstallthetwoBNCconnectorsusingthesuppliedspecialhardware,including solderlugs, asshown.

15

Assemblycont’d

qPreparethetwopiecesofcoaxasshowninthediagram.Makesurethattheshieldwiresdon’tshortouttothecenterconductoron

eitherend. RG-142isdoublesilvershielded.Leavealittleshieldshowing on oneend asshowninthepics above,and thenwrap a

short pigtailof wirearoundit.It issafetoapplyareasonableamountof heattotheTefloncoaxwithoutworryabout melting the

insulation.

qWind26turnsof#20enameledwireon eachoftheFT140-61 cores.. Thecoreswillbewoundinoppositedirections,sothatthe

finishedtoroidswillbemirrorimagesofeachother.Awinding isdefinedasthewirepassing throughthecenterofthecore. If you

countwindingson theoutsideedgeofthecore,yourcount will beoneshortoftheactualnumberof turns.Mis-countingbyoneturn

will giveyou apowerreadingerrorof8%,andcauseotherproblemsaswell.Thecurrentsamplingxfmrisinstalledbetweenthe

SO-239 connectors, andwill besupportedbytheshortpieceof Teflon®coax. Thevoltagesamplingxfmrissupportedbythelong

standoff.Leave1”(2.54cm)longpigtailsonthexfmrsexcept forthelead that exitsfromthebackofthevoltagexfmr (lowerright

lead inthelowerright picturebelow),whichshouldbe3”(7.62cm)long (shownexitingtheframeinthepicture). Scrapetheenamel

offtheendsof theshortleads. Arazorknifeorsandpaperisgoodforthis. Note:It isbesttoscrapetheenameloff, asthesupplied

wiremayormaynotbeheatstrippable.Wind thewiretightly.Useyourfingerstokeepthewindingsformed closetothecoreson

theinside.

qBeforeslippingthenylonbushingsintothewoundcores,takethetwolongpiecesof Teflon®tape, peelthepaperoffofthe

adhesiveside, andwrapeachofthenylonbushingswiththeTeflon®tape. Thentaketheshortpieces,removethepaper,andstick

theminthecoresbetweenthewindings.Thiswillmakeforatight fitinsidethetoroidcores,andwillalsoservetokeepthe

windingsproperlypositionedaround thecores. Beforeslidingthecoresinplace,makesurethattheinsideofthewindingsisflat

againstthecores.BecarefulwhenpushingthecoresinplacenottodislodgetheTeflon®tape. See thepicturebelow.Note: The

pictureshowsthevoltagexfmr withtheolderbushingwith¼”(6.35mm)hole. Thelatest versionis1/8”(3.18mm).Theoldpicture

alsoshowsaslightlydifferentmixofTeflon®tape.

16

Assemblycont’d

qSolderthe12SMTresistorsontotheattenuatorboardasshown. Don’t beafraidoftheseparts.TheseareVERYbigpartsasSMT

goes. Theresistorvaluesareprintedontheresistors.Useafinetiponthesoldering iron,andtinONEofthePCBpadsforeach

resistorwithasmallamountof solderbeforeattempting tosoldertheresistors. Holdtheresistorsinplacewithatweezers, and

applyalittleheattotheedgebetweeneachpad and theboarduntilthesolderflowsbetweentheresistorand pad.It ishelpfulto

slidetheresistoroverthepadasit meltsontothesolderdrop,sothattheotherend exposesalittleofthepadontheotherside.

Soldertheothersideinplacebyapplyingheatand soldertotheedgewheretheresistorsitsonthepad.Thengobacktothe

tackedpadandtouchupifnecessary.Applyingalittlefluxtotheboardahead oftimewillhelptoholdthepartsinplaceand aidin

solderflow.Toverifytheproperinstallationoftheresistors, useanohmmetertocheck theresistanceof eachbarestripline

connectiontoground.Themounting holeisgrounded, aswellasthelong stripalongthetopedge. Eachpointshouldbeabout83

to84ohms.Ifnot,check yoursoldering.

qInstall thePCBontothesideofthecouplerabovetheBNCsas

shown.Theboardmountswiththeholenearthebottomedge.

Bend and solderthepigtailsfromtheBNCstothetwostriplines

nearthemounting hole.Use4-40x¼”(6.35mm)machinescrew,

thesmall splitlockwasherandsmall hexnuttomounttheboard.

qSolderonetheshortpieceof RG-316Upreparedearliertothe

solderterminalonthebottomofthecoupler,withthecoaxshield

connectingtothegroundedlug, and thecentertothelug that

connectstothecurrent samplingxfmr.

qSolderthecenterconductorfromtheotherend ofthecoaxtotheremainingPCBstriplinepad,andtheshieldtotheground lugon

thecenter-most BNC.

qSlidethecurrentsamplingtransformerovertheshort pieceofRG-142asshowninthediagrams,beingcarefultoposition the

windingsandthecoaxshieldasshown.Thisisatightfit, butifyoutakeyourtimeandrotatethecoaxasyoupress itintoplace,

you shouldn’thaveanytrouble.Thereseemstobealittlevariationinthediameterof theRG-142,soyou mayfind thatyou needto

filetheinsideof thebushingalittletoallowagoodfit.Thiscanbedonewithasmallrattailfile, arolledpieceof sandpaperora

reamer. Analternative,suggestedbyK8SIXistousea#10drillbit todrill theholeout alittle.

qThexfmrshouldbeorientedlevel,withthewindingsfacing up beforesoldering.Solderthecoaxon theshieldend intotheSO-239

connector,andtheshieldwiretothesolderlug ontheXMTRconnector. Cutthewirefromtheoutsideleft ofthetransformer

secondarytolengthand solderittothelugontheXMTRconnector. Theotherend ofthecoaxwillbesolderedalong withthelong

wirefromthevoltagexfmr inanupcomingstep.

qInstall the2-lug terminalstrip,thencutandsolderthewirecomingfromtheinsiderightsideof thexfmr totheinsulatedlugonthe

terminalstrip.

qPreparethevoltagexfmrasshowninthephotosonthebottomofpage13, using the0.625”(1.59cm)standoff,4-40x0.75”

(1.91cm)screw,lockwasherandsolderlug.Thelong lead shouldexitthecoreon thesidewiththestandoffasshowninthe

overhead pictureofthecoupler. Afterapprox. serial#350,alockwasherwasaddedbetweenthestandoffand nylon bushing.

qBend thesolderlug outatclosetoa90 degree angle,andsolderasmalllengthofdiscardedcomponentlead toit.

qAttachtheassemblytothesideofthecouplerusing4-40 x3/8”(9.53mm)hardware. Thesolderlug and pigtailshouldbefacing the

PCB.Itisimportantthatthisassemblybeattachedfirmlyoryouwill see erraticoperation.Alockwashershouldbeplacedbetween

thecouplerwallandstandoff,andonebetweenthescrewhead andoutsideof thecoupler.

qPrepareand soldertheshort end ofthetoroidwinding sothatitconnectstothesolderlugon theright-mostBNC.If thecoreis

mountedcorrectly,thiswireshouldcomeofftheright sideofthecorefromtheinside.Solderthepigtailfromthestandofftothe

striplinepad on theend ofthePCB.Leaveasmallbend inthislead toallowforflexing whenthetopisattachedtothecouplerand

thewallsarepulledapart.

qThelongwirecomingofftheoutsideleftsideof thecoregoestotheoutput SO-239as

shown.Theend ofthewireshouldbeplacedinsidetheSO-239centerconnector

alongsidetheRG-142centerconductor,orloopedaroundtheSO-239center

conductorasshowninthephotos.Besuretoscrapetheend toallowgood solderingin

eithercase.Beforesoldering thesewirestotheSO-239, thewallsof thecouplerneed

tobepre-tensionedsothattherewon’tbeanystress ontheRG-142whenthetopis

attachedtothecoupler.Todo this,Iusea2”(5.08cm)longstandoffplacedbetween

thewallsabovethexfmr toseparatethewallsslightly.Asuitablesubstitutewouldbea

2”(5.08cm)longpieceofwooddowel.Thewireshouldberoutedabout1/8”(3.18mm)

fromthecurrentxfmrasshown.Forbestphaseaccuracy at50MHz, alittlecoupling to

thecurrent xfmrsecondaryisdesirable. Removethespacer.

17

Assemblycont’d

qMakesurethatall connectionsaresolderedwell,andthat thecoresarelevel.Slipthetoponandattachwith(14)4-40 x¼”

(6.35mm)sheetmetalscrews. Applypressuretheendsof thecovertoprevent gapsfromformingasthescrewsaretightened.

qClean andwipethetopofthecoupler.Carefullylineupthetoplabelandapplystartingatoneend andsmoothingasyougoto

prevent theformation ofbubbles.

Final Checkoutand Assembly

Beforegoingthrough theSetup screens,itisnecessarytoverifythattheremainingbasiccircuitsareworking. PoweruptheLP-100,

and verifythat thecurrentdrawiscorrect.(160 mA ). ConnecttheCurrent and Voltageportsofthecontrollerandcouplertogether

usingthesupplied6’(1.83m)coaxcables. Youmaywanttobundlethecablesusingelectricaltapetomakeforaneaterinstallation.

Onecableshouldbemarkedwithcoloredtapeatbothendssothatthecablesarealwaysconnectedconsistentlyinthefuture.I also

marktheCurrentjacks on bothendssothatthecoloredcablealwaysconnectstoCurrent. Thispreventscrossingof thecables, and

alsoeliminateserrorsduetocablevariations.

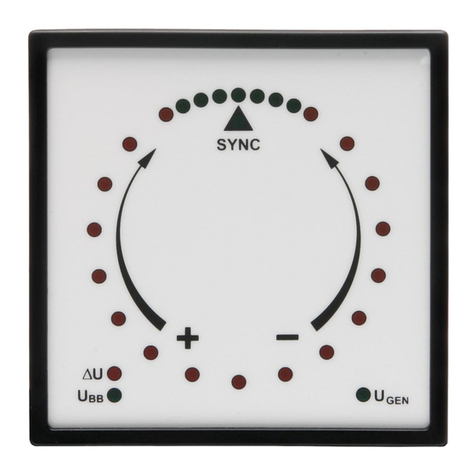

Connect a50ohmdummyloadtotheLOADport. SelecttheFast modeforthedisplay(press Fast/Slowbuttonuntilyou see alower

case“w”afterthepowervalue),and applyasmallamountofpower. ThePowerand SWRbargraphsshoulddeflectupward,andthe

numericalreadoutsshoulddisplayanumberveryclosetotheexpectedvalue. Switchtothevectordisplay(press Modebuttononce),

and youshouldsee valuescloseto50ohmsforZand R, and closetozeroforphase.

Next, enterSetupmodeasdescribedinInitialSetup, and scrolltotheGain/PhaseZeroscreen. AdvancetotheGain/PhaseZero

screenbypressingModetwice. You shouldsee theband indicatedinthelowerleftcornerduringtransmission.Thisshouldmatchthe

band you aretransmitting on.TheBandindicatorshouldremainonthelastusedbandaftertransmission.

UsingtheAlarmSet button, settheAlarmfor“1.5”.Removethedummyload andtransmitintothecoupleratlowpower.TheRedAlarm

LEDshouldlighton thefrontpanel,andtherelayshouldclick. IfyouhaveJP1inplace,thePiezotransducershouldalsosound.Note:

thetransducerwillsoundprettyloud sinceit’snotinsideacaseatthispoint.Reconnectingthedummyloadwillcancelthealarmaftera

second orso. You can double-check thePTT connectionswithanohmmeteratthistime. Thecenterconductorsof theRCAconnectors

wouldbenormallyshortedtogether,andopenwhenthealarm sounds.

You arenowreadytoinstallthecontrollerboardinthecase. First, looselyinstallthe4-40x¼” (6.35mm)threadedstandoffsonthe

bottomofthecaseusing4-40x¼”(6.35mm)black machinescrews.Next, slidetheboardintotherearholesasyoudropthefront

downtowardthebottom.Becarefulnottoscrapethebottomoftheboardon thefrontpanelasyou slideit.

Oncetheboardisinplace,alignthefrontholeswiththeswitchesandLEDs,andscrewtheboarddownwithfourmore4-40 x¼”

(6.35mm)blackscrews.Tightenthebottomscrews. Theswitchcapswillbeinstalledaftercalibration,incaseaproblemshowsupthat

requiresremovaloftheboardfromthecase. Thecapscan bescratchedduringremovaliftheyareinstalled.

Install thefourremaining4-40x¼”(6.35mm)

standoffson thefront ofthePLEDPCB,using

four4-40x¼”(6.35mm)black machinescrews,

and tighten.Mount thePLEDPCBtothefront

usingtheremaining black machinescrews,and

install theribboncablebetweenthetwoPCBsas

showninthepicture. Don’tforgettoremovethe

protectivefilmfromthePLEDdisplaysurface

beforemounting. Again,makesurethat the

ribbon jacklinesupproperlywiththeheaderpins.

Thetop coverwillbeinstalledaftercalibration.

Connections…

Power: 11-15VDC,centerpin+,2.5mm.Thelead withthewhitestripeon thesuppliedcableis+

PTT: LoopthePTTbetweenyouramplifierandrigthrough theLP-100usingRCAconnectors

RS-232:Connectstocomputer…standardM-FstraightthroughDB9serialcable.

Current/Voltage:ConnecttocorrespondingjacksonthecouplerusingsuppliedRG-58Ucables.

18

Setup/Calibration

Note: Thissectionassumesyouareusingfirmwareversion1.1.1orlater,andof coursetheupgradePICprocessor.Ifyouownakit

fromthefirst productionrun(serial#100 orolder), thenitishighlyrecommendedthatyouupgradetothenewprocessorbefore

calibrationtoavoidhavingtocalibratetwice. Thisisanochargeupgrade(except forshippingcost).

EntertheSetup modeagainasdescribedinInitialCheckout.Belowyou willsee apictureof eachSetupscreenalongwithabrief

synopsisofwhatit doesandwhat thecontrolsadjust.Remember,forfirmware1.1.45orlater, it isasingle,long,Modebuttonpress.

Referencescreen.Displaysthereferencevoltagefromthegain/phasedetector,aswellastheRSSI

voltage(ReceivedSignal StrengthIndicator) fromtheAGCchipused in thefrequencycounterpreamp.

Thisvoltageisproportionaltothelog oftheRFinput powertotheLP-100. Thescreen alsoshows

temperatureinDegF &C. Therearenoadjustmentsforthisscreen.

Thisscreenallowsyou toentertheactual impedanceof yourdummyload. Thiswillresultinamore

accuratecalibration if yourdummyloadisotherthanexactly50.0ohms.

Thisadjustmentisused tocalibratethezeropoint (oroffset)ofthemagnitudeandphasedetectors. The

adjustmentissemi-automaticinthatyoudon’thavetomakeanyadjustments. Theprocess requiresyouto

brieflytransmit intoan accurate50ohmdummyloadon eachbandinsequence,andtopress theAlarm/Dn

button tosavethecorrectionforeachband.

Thisadjustmentisused tocalibratetheslopeofthephasedetector. Itissimplydonebyinsertingalinewith

knowndelayintotheCurrentinputoftheLP-100, andtransmittingintoahighquality50ohmdummyload.

The controlsarethen adjusted sothat thedisplaycorrectlyshowsthelinedelay. IfcoaxofknownVelocity

Factorisused, thelinelengthindegreescanbesimplycalculated.

Thisadjustmentisused tocalibratetheslopeofthegaindetector. It isaccomplished bytransmittingintoa

25 ohmloadandsettingtheTrimforareadingof25.0(orwhatevertheactual loadresistanceisifit’snot

exactly25.0).

Allowsadjustmentoftheaccuracyoftheop-ampdetectorandADC toprovidecorrect conversion valuesat

lowpowerlevels. Thescreen showstheoutputvoltageofthedetector, and theTrimlevelissetby

adjustingforzerovoltagewithnoRFpowerapplied.

AdjustsoverallpoweraccuracyoftheLP-100. Thisadjustmentaffectsallfrequenciesequally, and ismade

bycomparing theLP-100powerreadingwithan accuratereference. Acceptablereferencemeasurement

devicescan beinexpensivelymade,andwill bedescribed later.

Sameasabove,but adjuststhedisplayedpowerreadingon aband-by-band basis. Thebuilt-infrequency

counterdetectsthebandyou’reon, andstorestheCALconstantforeachbandautomaticallyfor12bands

from160mthrough4m.Thecounterworksfrom50 mWto2500W.

Thisscreenisused tomatchthereadingsofthelowpowerandhighpowerADC inputs.It isdoneata

powerlevelbelow320W, whichisthepoint at whichthelowpowerinputreachesmaximum.Itspurposeis

toallowcompensatingforanyerrorinthe1%precisiondividerpartsused inthehighpowerinput. NOTE:

MovedupbetweenOffsetandMasteron ver.1.1.47candlater.

ThisscreenallowssettingtheSWRAlarmpowerthresholdandPowerdisplaytype. Thealarmthresholdis

usedmainlyin contesting stationswithmultipletransmitterstoprevent falsealarmswhen energyfrom

anothertransmitterispicked upbyan antenna. Thechoicesare0,0.1,1.0, 10.0and100.0W. Thepower

Thisscreenallowsselection ofthecorrect cablecompensatingtabletomatchtheconnecting cablesyou

areusing.EarlyLP-100susedRG-174U,but achangewasmadetoRG-58Ustartingwit serial #101.

Startingwithserial#400, thismenuwaschangedtoaserial numberselection, andcoversanyhardware

changebetweenversionsinsteadofjust cables. Inthecaseof the5th run, itcoversthechangeinresponse

of aslightlydifferentmodelpowercombiner.

19

Setup/Calibration Cont’d

AllowseditingoftheGain/PhaseZeroCALvalues,whicharenormallygatheredautomatically. Thisis

useful forrestoringaccidentallychangedvalues.TheDnbutton adjustsgaintrim,andtheUpbuttonadjusts

phasetrim.

Allowssettingof maximumbargraph scalevaluesforallthree autoranging scales. TheDnbutton selects

Low,MidorHigh range,andtheUpbutton allowsscrollingthroughthe variousmaxpoweroptions.The

displayedrangeincludes0.4dBovershoot (~10%)abovetheindicatedvalue. Note: Theserangesdonot

affect thenumerical readout, whichhasnolimits. Defaultsare15W, 100W, and 1500W.

Thisscreenisused toset thewidthofthebargraphin theFastmode. Itisuseful foroptimizingthe

bargraphresolution foramplifiertuning, forinstance. Thedisplayedrangegoesfromthemaximumsetin

thepreviousscreen,toaminimumwhichistheselected numberofdBbelowthatmaximum. Default is6dB.

The nameof thisscreenwaschanged toFastBargraphRange.

Thisscreenallowssettingofthenumberofsamplesusedtoaveragethenumerical readout inFastmode.

The rangeis2to32samples. Thedefaultis8samples.

ThisscreenallowssettingthepeakholdtimeintheSlow(peak)mode.Therangeis0.25to5seconds.The

defaultof 3secondsisgood fornormalSSBorCWoperation.Thefastest settingcan beusefulforamplifier

tuning,especiallywhen a“pulser” isused.

Thisscreenisused toset the“User”SWRAlarmsetpoint. It can besetbetween1.0and5.0in stepsof 0.1.

Impedance Calibration

Calibration isdoneinacoupleofsteps. Firsttheimpedancemeasurementsystemiscalibrated,andthenpowerleveliscalibrated. The

requiredtoolsforthiscalibrationareahighquality50ohmdummyload,ahighqualitypowermeterorothermethod ofdetermining

powerasdescribedinthetext and ashortcoaxiallineofknownelectricallength.Asecond dummyload isalsodesirableforcalibrating

theslopeofthegaindetectorforimpedance,butnotabsolutelynecessaryasthisadjustmentseemstovaryonlyslightlyfrommeterto

meter.Inormallydo calibrationat 100W, butveryclosetofullaccuracycan behad withpoweraslowas5W,andsomewhatreduced

accuracyisattainabledownto<1W.

I amworkingona“calibrator”designwhichwoulduseinexpensive1%thickfilmresistorsor5%metaloxideresistorstoprovide

switchable50/25 ohmimpedancewitha10Wrating.It wouldincludeadiodepeakdetectorformeasuringpowerwithacalibratedtable

ofvoltagevs.power.Iamalsotesting amethodofusinga6’longlengthof RG-59Uwhich,whenterminatedwitha50ohmdummy

load, producesaknowncompleximpedance. ThisprovidesamoreaccuratewayofsettingtheGainandPhaseslopeadjustments,and

takesintoaccountcouplervariationsasopposedtothedelaylinemethod.Ihavecharacterizedreadilyavailableandinexpensive

cablesavailablefromJameco, RadioShackand Mouser,and willprovidepartnumbers.ThecablesareBNC-to-BNC,andmayrequire

UHFadaptersifyoudon’talreadyhavethem. Thesearealsoavailablefromtheabovesuppliers.

Thefirst calibrationscreenisthe“DummyLoadZ”screen, whichallowsfortheentryofyourdummyload’sactualimpedance. This

makescalibrationmoreaccuratewhenyourloadisnotexactly50ohms. UsetheDn/Upbuttonstosetthedisplaytomatchyourload’s

actualimpedance.Ifyoudon’thaveagoodwaytomeasureyourdummyload, you can measuretheresistanceatDC using aDMM.If

you knowtheload tobelow-inductancethrough 6m,thiswillgiveareasonableapproximation.Ifyou arelookingforahighquality

dummyload,checkoutwww.ridgeequipment.com. Theyhavesomeexcellent surplusloadsforaslittleas$10.

Thenext screenistheGain/PhaseZeroscreen. Thisallowsforband-by-bandbalancingof thegainandphasedetectors.Todo this,

connectyourdummyload totheANTconnectoron theLP-100coupler.Startingwiththelowestbandyoucan transmiton,keythe

transmitter.Press theAlarm/Dnbuttontocalculateandsavethecorrectiondata,thenunkeythetransmitter.You shouldsee theTrim

valueschangeonthedisplay.Dothisinorderforallthebands.(TheFast/Slow/Upbuttonresetsthetrimvaluesforthedisplayedband

tothedefaultvalueof127,andtheEditGain/PhTrimsscreenallowseditingthesevaluesaftercapturingifneeded).

Thenext adjustmentscreenisPhaseSlope. Thisadjustmentsetstheslopeofthetransfercurveofthephasedetectorsothatthe

measurementlimitsarecorrect. TheaboveZeroadjustmentensuresthatzerodegreesreadsclosetozero. Thisadjustmentensures

thathigherphasedelaysdisplayaccurately. Togethertheydefinetheslopeofthephasedetectioncurve.

20

Setup/Calibration Cont’d

AsmentionedintheOverview, adjustingthePhaseSlopeissimplyamatterofmatchingthereadingtoaknowndelaylinevalue.Again,

theformulafordeterminingdelayindegreesis…

Phase Delay(Degrees)=(360*L*F)/(984*VF)

WhereLisinfeet andFinMHz. VFwouldgenerallybe0.66 forpolyethylenedielectric. FoamdielectricsaregenerallyhaveaVFof

about.80.Check forthecorrectvalueofthecoaxtype/brandyouareusing.A6’lengthwithpolydielectricwillprovideadelayofnear

45 degreesat 14MHz. Thisisagood rangetouse, asitplacesthephasedisplayat about midrange.

InsertthedelaylineintotheCurrentcablebetweenthecontrollerandcoupler,using aBNCbarrelconnector. Witha50ohmload,the

phaseshouldread closetothecalculatedvalueindegrees. Ifnot,usetheDn/Upbuttonstoadjustthereadingtothecorrectvalue.

Leaving thissettingatthedefault1.000will resultinamaximumphaseerrorofafewdegreesovermostofthefrequency range.

ThelastimpedanceadjustmentscreeniscalledGainSlope. Thissetstheslopeofthegaindetectorsothat itislinearwithincreasingZ.

Theadjustmentrequiresaloadotherthan 50 ohms,Aconvenientvalueis25ohms, whichcan becreatedeasilybyparallelingtwo50

ohmloadsusinga“T”connector.Itisimportantwhenmaking thisadjustmentthatthereisnocoaxbetweenthe25 ohmloadandthe

coupler“Load”connector, otherwisethelinewill transformthe25 ohmresistiveloadtosomemixedR+jXvalue. Theeasiestwaytodo

thisistoscrewaUHFTee connectordirectlytotheLoadconnector, andthenuseadaptersorlengthsof50ohmcoaxtoconnecttothe

two50ohmloads.Withthetransmittersetto20m,applypowerand see what theimpedancereadsonthisscreen.Ifthedisplayed

valueisslightlyhigherorlowerthantheactualvalue, adjusttheDn/Upbuttonstomatchtheload’sactualZ(orresistanceon aDMM).If

a25ohmloadreads100ohms,you havethecurrent andvoltagecablescrossed.Correctthisandstartcalibrationoverfromthetop.

Remembertoreturntoa50ohmload afterthistest.Theexpectedtrimvalueshouldbeintherange-.0004to+.0004,andwillusually

beevencloserthan that.Leavingthisadjustmentat0.0000willresultinamaximumerrorof afewtenthsofanohm.

PowerCalibration

Beforestartingcalibration, itshouldbepointedoutthatcalibrationisnotabsolutelynecessary.Incalibratinghundredsoftheassembled

versionsoftheLP-100, itwasfoundthatthemaximumerror, asread onaHP-436Apowermeter,was+/-1.5%beforecalibrationon

160-10m.Theerroron 6mcanbemorelike+/-5-10%beforecalibration. Ofcourse,thereismoreconsistency incouplerconstruction

on theassembledunitsthantherewouldbewithdozensof different builders,butit wouldbeunlikelythattheerrorwouldbemorethan

about5%ifcareistakentofollowtheinstructionson thecouplerassembly.

Thefirsttestrequiresno test equipment. WhileintheSetup>Offset screen, adjusttheDn/Upbuttonsforazeroreading ofthe

displayedvoltagewithnoRFpowerapplied.Thisnullsouttheresidualoffset voltageoftheop-ampdetector.

Thenext screenallowsfortheadjustmentofMasterpowersensitivity.Thisvaluewillnormallybenear1.BoththeMasterandFine

poweradjustmentshavearangeof+/-12.5%in0.1%increments.

TheFinesensitivityadjustment ismadewhiletransmittingintotheLP-100.Theadjustmentsaffectthetrimvaluesfortheband being

displayed.Thefrequency displayfollowsthetransmitfrequency automaticallywhenyoutransmit.

BeforeadjustingeithertheMstrorFinetrims,itisnecessarytoprovidean accuratemeansofmeasuringpowerthatisindependent of

theLP-100.ThesimplestapproachtothisistoborrowahighqualitymeterlikeaBirdorAlphatouseasareference, andconnectit

betweentheLP-100anddummyload withaUHFmale-maleadapter.Anevenbetterapproach,whichiswhatisusedforthefactory

calibration, usesacalibrated30 dBattenuatorfeeding alaboratorypowermeter(HP436AorBoonton4200inmycase). Thepower

meteriscalibratedagainstanNIST(NationalInstituteof StandardsandTechnology)traceablereferencecalibration signal.

Themost accuratesimplemethodfordoingthiswithcommon toolsistouseahigh qualitydummyloadwithadiodepeakvoltage

detectorandDMM.Hereisthesetup…

Other manuals for LP-100

1

Table of contents

Other TelePost Measuring Instrument manuals