Telequipment DM64 User manual

PAHAMQELIAJP

+ +KO?EHHKO?KLA

OPKN=CA %cUBA@I31

I=JQ=H

I

WHOHTXLSPHQWi

}

Eqfp klq mlppf\ib ql p_obbk [ii efde sliq[dbp* pl _[ob pelria \b q[hbk

klq ql qlr_e efde sliq[db q[dp, =ipl tebob mlppf\ib qeb fkpqorjbkq

pelria \b rkmirddba =J@ ptfq_eba lcc arofkd pbosf_fkd, = >HAA@AN

L=PD BKN PDA ADP EOJKP LNKRE@A@*pl [cqbo ptfq_efkd lcc

[ka \bclob qlr_efkd [kv fkqbok[i m[oqp*qeb ADP pelria \b afp_e[odba

\v qbjmlo[ofiv peloqfkd qeb [mmolmof[qb mlfkqp ql _e[ppfp* &clo

fkpq[k_b qeb ?NP _[qelab mfk[ka L@= _lkkb_qlo tebob [mmif_[\ib',

RVFLOORVFRSH

VWRUDJH WaSH GP97

FOR SERVICING AND SPARES ENQUIRIES

SEE THE INFORMATION AT START OF CHAPTER 5.

TEKTRONIX U.K.LTD.,

313 Cg_rd Rn_c,

Sntsgf_sd,

Lnmcnm, N14 6JJ

Emfk_mc.

}U(\'ICe

osi=

t/q

R

eJ

yf(1'

3fOO?

TEKTRONIX, INC.,

o._.

Bnw 500,

Bd_udqsnm,

Oqdfnm (97005)

U.S.A.

Irrtd 11 (2876)

Nnudladq 1976

{Cnoxqhfgs (1974) ax

TEKTRONIX U.K. LTD.

LX'01/

Hl_=k,,,

STORE

}I

AJD=J?A i%JPACN=PA

H

-J

·

SINGLE

REP SHOTRESET

TRIO LEVEL}}.4)]. ]

STABILITY

?K=NOA

y±±,±,,±,±±7',±,±±,cy

PNEC

HIAC

K"P

,.

POSITION J

S

PR

-

cibHK

PR

OLQH

"

.Ji PNECDB

,.

%J?DKL =Hi

oy

1

+}

yy+=o

Q

q,77

SUM..J}

=

@?

c

POSITION

q

,,+

-

=?

KcBMKJ £J%

KQP

,.

'N

EJRi77=P

Kri JKNI=H

CH2

INTRODUCTION

The OM64 is an all solid-state, dual trace, storage oscilloscope. It uses a bistable CRT to provide

a large, bright display. Stored waveforms may be viewed for up to one hour.

In the non store mode, it performs as a conventional oscilloscope.

The design of this instrument is subject to continuous development and improvement, conse-

quently this instrument may incorporate minor changes in detail from the information contained

herein, which would, in the main, affect the Components List and the reader should pay particular

attention to the notes at the beginning of chapter 5.

To minimize the risk of damaging the storage screen, the following precautions should be

observed.

Because an undeflected bright spot on the CRT screen can burn the storage target, the

BRILLlANCE control should be kept to the minimum required to produce a clear, well-defined

display. Care must be observed in the degree of writing-beam intensity used, particularly when using

slow sweep rates.

When attempting to store fast-rising or fast-falling portions of waveforms viewed at relatively

slow sweep rates, the high trace intensity required (due to the intensity difference between the

horizontal and the vertical segments) could cause storage target damage.

Avoid repeated use of the same base line position on the screen.

Do not leave a display on the CRT screen (either writing or stored) when the display is not

needed.

Do not leave STORE switches pushed in when the storage mode is not needed.

To obviate the risk of damage during transit and facilitate packaging, the owner is requested to

remove the po~er supply plug and NOT send the following items unless they are suspect, should this

Instrument be returned to TELEQUIPMENT for servicing.

Manual

Probes

Power Supply Lead

Plug Assemblies

I

CONTENTS

I

Page CHAPTER Page

I

CHAPTER

SPECIFICATION 4MAINTENANCE

&

CALIBRATION (cont.)

I

Cathode Ray Tube (CRT) 1/2 Horizontal amplifier 4/5

Cpoling 1/3 Preliminary procedure 4/2

I

Horizontal system 1/1 Probe' 4/2

Outputs, Front panel 1/2 Storage Circuit 4/6

Power Requirements 1/3 Sweep

&

Trigger 4/2

Size 1/3 Single Shot 4/5

I

Temperature limits 1/3 Vertical Amplifier

Trigger 1/2 D.C.

&

L.F. setting 4/3

Vertical System 1/1 Pulseresponse 4/5

Weight 1/3 Supply variation 4/2

I

X-V mode 4/5

General 4/1

2OPERATING INSTRUCTIONS Checks

I

Gain 4/1

Controls and Connectors Sweep Speed 4/1

Connectors, input

&

output 2/2 Mechanical 4/1

CRT

...

2/1 Accessto interior 4/1

J

Horizontal display 2/1 CRT

Sweep 2/1 Removal ... 4/1

Trig Mode 2/1 Fitting 4/1

Vertical display 2/2 Location of Pre~et controls 4/1

J

Operation 2/3

Pre-operational checks 2/3

5 COMPONENT LIST

J

3CIRCUIT DESCRIPTIONS Assemblies 5/16

Component 5/2

Attenuators 3/1 Mechanical 5/14

J

Block Diagram 3/1

CRT 3/3

EHT Supplies 3/5 6 CIRCUIT DIAGRAMS Figure

Horizontal amplifier 3/3

J

Power supplies 3/6 Attenuator 2

Sweep Block Diagram 1

Generator 3/3 Component reference

Trigger 3/2 PC Nos 110

&

112 11

J

Unblanking amplifier 3/3 PC No 111 12

Vertical amplifier 3/1 Power supply 10

Storage

9

J

Timebase ... 6

4 MAINTENANCE

&

CALIBRATION Trigger 5

Unblanking amplifier 6

Calibration 4/1 ·X· amplifier 6

J

Attenuator 4/4 ·V· amp. Input

&

Channel switching 3

Calibrator 4/6 Output

&

Trigger pre-amp. 4

CRT

...

4/3 Time/Div ...

7

J

------

CHAPTER I

SPECIFICATION

3 dB bandwidth

D.C. Coupled

A.C. Coupled

Risetime

Bandwidth (- 3 dB)

Phase error

Deflection factors

Calibrated (12 ranges 1-2-5 sequence)

Gain Xl0

Uncalibrated - with variable

Sweep generator

Sweep rates

Calibrated (23 ranges 1-2-5 sequences)

Uncalibrated (with variable)

Repetitive

1

Single Shot

J

External horizontal amplifier

3 dB bandwidth

Risetime

Deflection factors

Input impedance

Maximum input - D.C., peak A.C. or sum of

Channel 1

Channel 2 (normal or inverted)

Channels 1

&

2

Alternate

Chopped (at 150 kHz approx.)

Summed

X-V

I

xl0

:_ _ xl

D.e. - 10 MHz D.C. - 8 MHz

----

2 Hz - 10 MHz 2 Hz - 8 MHz

35 ns nominal 44 ns nominal

CH 1 is vertical input, CH2 selected via timebase switch

as horizontal input

D.C. - 1 MHz

Less than 10 at 10 kHz

10 mV - 50 V/div ± 5%

1 mV/div - 5 V/div

Complete cover between sequence and to 125 V/d iv

2 s - 100 ns/div ± 5% (without expansion)

400 ms-l00ns/div ±8% (with X5 expansion)

Complete cover between sequence and to 5 s/div

Selected by switch

D.C. - 1 MHz

350 n~

200 mV/div or 1 V/divapprox.

100

i< 1

and 30 pF approx.

400 V

Coupling

Source A.C. or D.C.

CH 1, CH2, alternate or external

Internal

Amplitude - Automatic

Trigger level 0.25 div 40Hz to 1 MHz

I

Alternate

0.25div D.C. to 1 MHz

I

1.0 div

rising to 0.5 div at 5 MHz

1 div from 1 MHz to> 10 MHz

External

Amplitude

Impedance 250mV peakto peak

100 krl parallel with 30 pF

External intensity modulation

Coupling

Amplitude, peak A.C. to Cathode

50 V maximum

20 V for perceptible modulation at average brilliance

10 nF and 10 krl

1 hour

Manual or automatic at end of sweep

0.25 s. approx.

Time constant

Store Mode

Erasure

Erase time

Writing rate

Enhance off

on

Variable enhancement

25 div/ms

250 div/ms

25 - 250 div/ms

Calibrator, peak to peak

Accuracy

Sweep sawtooth

Coupling

Amplitude peak to peak

Minimum load

Gate out

Coupling

Amplitude, peak to peak

500 mV square wave at supply frequency

2%

D.C.

10 V approx.

47 krl

D.C.

500 mV approx.

100 - 125 V in 5 V steps

200 - 250 V in 10 V steps

48 - 400 Hz

100 VA approx.

Frequency

Consumption

Height

Width

Depth

24 cm

21 cm

37

cm

Operating

Non-operati ng - 5 to +40oC approx.

-25

to +70oC approx.

CHAPTER 2

OPERATING INSTRUCTIONS

2.1 FUNCTION OF CONTROLS

AND CONNECTORS

Controls are situated on the front panel except

when specified

2.1.1 CRT

BRILLIANCE

FOCUS

ASTIG/

POWER ON·OFF

BEAM LOCATE

ERASE

MANUAL

varies the intensity of the display.

controls the definition of the display.

is used in conjunction with FOCUS

for best overall definition.

when pressed a spot will appear in the

non-store area 2 mm approx to the

left of the start of the trace. This

facility is provided for vertically posi·

tioning the trace without storing it.

when pushed in the trace can be

stored for up to one hour.

Note: Change of mode causes the

Store to be cleared and the stored

traces destroyed.

when pushed in, the writing speed is

increased.

controls the writing speed up to

X10

approx.

Note: This facility reduces the

contrast and hence storage time.

this facility is provided for storing a

recurrent signal at high writing speeds.

when depressed, the stored trace is

removed.

when switched to AUTO, the stored

trace is automatically erased at the

end of each sweep and the timebase

armed for the next input signal.

TRACE ROTATION situated on the rear panel. Rotates

the trace(s) about the horizontal axis

of the CRT and used to align the

trace(s) with the horizontal graticule

divisions.

2.1.2 HORIZONTAL DISPLAY

POSITION varies the location of the trace(s) in

the horizontal axis, when not in the

X·Y mode.

acts as a more sensitive position

control as well as the X5 horizontal

gain switch. When pulled out in the

X5 position, all sweep speed calibra-

tions must be divided by 5. In the

X-V mode, FINE inoperative, X5 gain

operative.

2.1.3 SWEEP

TIME/DIV

2.1.4

TRIG

MODE

TV F 'md TV L

controls the speed of the main sweep.

The sweep rates indicated are only

valid if VAR IABLE is fully clockwise

and FINE position is pushed in for

X1 gain. If FINE position is pulled

out and VAR IABLE is at CAL. the

calibrations should be divided by a

factor of 5 to ascertai n the sweep

speed.

enables speeds between that indicated

by TIME/DIV and the next lower

speed to be selected. The control also

selects X-V operation when the knob

is pushed in.

selects that point on the signal wave-

form at which the sweep starts. In the

AUTO position. ref 2.1.4 below, the

trigger oscillates recurrently at a low

repetition rate in the absence of a

triggering signal; when a suitable

signal is applied. the circuit is auto-

matically triggered at the mean level

of the input waveform.

controls the sensitivity of the sweep

generator; turned fully anti-clockwise

prevents the sweep from running,

while fully clockwise causes the

sweep to free ru n.

assist in viewing or photographing a

non-recurrent signal. If a recurrent

signal is applied to the oscilloscope.

in the SINGLE-SHOT mode, the

sweep will run once each time RESET

is pressed. when

not

in the X-V mode.

When a recurring signal is applied. the

timebase should be locked by using

STABILITY and LEVEL.

facilitates triggering from TV field

(frame) or line pulses; the LEVE L

control may require adjustment for

best results. Polarity relates to the

sense of video modulation.

should be depressed for synchroniza·

tion from high·frequency signals.

LEVE L can be adjusted for a locked

sweep.

provide triggering from the positive

or negative-going slope of a wave-

form.

obtained by releasing DC and AC

buttons.

enable the sweep to be triggered

either internally from the vertical

amplifier or externally.

relate to the coupling of the trigger

circuit. For very low input frequency

DC should be selected.

2.1.5 VERTICAL DISPLAY

OFF-ON release of these buttons,switches off

the channel concerned. If both

channels are switched off, a straight

line trace results which cannot be

shifted by the POSITION controls,

except when in the X-V mode.

selects triggering from either or both

channels. When alternately triggering

from both channels both INT TRIG

buttons should be released; the

displays should be partially super-

imposed.

provide three display modes for the

vertical channels.

In the CHOP mode, the channels are

alternately switched on and off at a

frequency of about 150 kHZ; this

mode is suitable at the lower sweep

speeds. In the AL T mode, each

channel is alternately displayed for

the duration of a sweep; this

mode is preferable at higher sweep

speeds.

In the SUM mode, the display is the

addition of the individual signals.

CHl POSITION is used to shift the

trace, CH2 POSITION is a Fine shift

in the SUM mode.

If INVERT is depressed,the resultant

display is the difference between the

two input signals.

displaces each trace in the vertical

direction except when both channels

are off.

In the X-V mode irrespective of

button settings CH1 provides a verti-

cal shift and CH2 a horizontal shift.

the setting of this button determines

whether the CH2 signal isdisplayed in

the same polarity asthe input signal

or inverted. The inverted setting is

used to display the difference

between two signals in the SUM mode.

provides twelve steps of attenuation

of each channel's input signal.

Calibrated sensitivities are only valid

when VARIABLE is fully clockwise.

enables all deflection sensitivities

between that selectedby the VOLTS/

DIV switch and the next below to be

covered. The control must be fully

clockwise for acalibrated display; for

Xl0 gain the knob should be pushed

in.

selects the input signal coupling. In

the DC position, the signal from the

INPUT connector is coupled directly

to the attenuator.

In the AC position a capacitor is

inserted in series.

In the GND position the input to the

attenuator is grounded and socket

disconnected; this position enables

the 0 V D.C. level of a trace to be

ascertained.

2.1.6 INPUT AND OUTPUT CONNECTORS

1. INPUTS

BNC

2. OUTPUTS

CAL

connectors are linked to the vertical

channel attenuators via the DC-GND-

AC switch described above.

there is a BNC connector in the

sweep section of the front-panel.

This enableseither external triggering

signals to be applied, or in the EXT

condition of the VARIABLE speedit

provides the EXT X input. The con-

nector is D.C. coupled to both trigger

and horizontal amplifier circuits. An

external blocking capacitor may be re-

quired to removethe D.C.component.

Input resistanceis 100 kU

A X5 amplification of the horizontal

display is obtained by pulling out

FINE position. If a dual-trace display

is required on EXT X, the vertical

display mode must be set to CHOP,

the AL T and SUM modeswill provide

only one trace.

at thE; rear of the instrument and

connected via an isolating capacitor

to the CRT cathode. A negative-going

signal is thus necessary to intensify

the trace while a positive-going signal

will blank it.

socket provides a waveform for

checking the calibration of the vertical

channels.

The repetition rate is at supply

frequency.

provides a fast-edged positive-going

rectangular pulse lasting for the

duration of the sweep.

The gate out signal or 0.5 V peak to

peak 1 kHz squarewave is used for

calibrating probes asfollows.

1. Connect the probe to INPUT 1.

2. Set VOLTS/DIV to

.1 (X10),

10 mV (Xl001.

3. Turn VARIABLE fUlly clockwise.

~

,

,

,

I

I

I

SAWTOOTH

ill

4. Set TIME/DIV to 1 ms.

5. Connect probe tip to the GATE

OUT.

6. Adjust the probe trimmer for a

square corner on the leading edge

of the display as follows:

In the HZ1 B probe, a screwdriver

adjustment is provided through a hole

in the probe body.

The GE81 000 is calibrated asfollows:

1. Slacken the narrower of the two

knurled rings at the BNC connec-

tor end of the probe cable.

2. Rotate the adjacent broader ring

until a square corner is obtained.

3. Tighten the narrow ring without

disturbing the broad ring.

If a 1kHz squarewave is used, the

amplitude should be about 500 mV

and a few cycles of the waveform

should be displayed. The above

calibration procedure should be

followed with X10 probe tip applied

to the squarewave generator output.

The compensation should be checked

if the probe is transferred to INPUT 2.

provides a positive-going ramp wave-

form when the sweep is running. A

recurring sawtooth is produced when

the STABI L1TY is fully clockwise for

the sweep generator to free-run. The

resistance of an applied load should

exceed 47 k,Q to avoid loading the

sweep generator.

th is is connected to the chassis of the

instrument.

2.2.1 Before connecting the instrument to the supply, check

that the rear voltage-selector plug is indicating the local

supply voltage or the nearest value to it. Check also that the

fuse fitted is 1 A for 100-125 V operation or 500 mA for

200-250 V.

NOTE:-

The 3-core supply lead is alternatively colour coded

as follows:

Brown

Black

Earth

(Chassis)

Green/Yellow

Green

Blue

White

1. CRT

BRILLIANCE

FOCUS

ASTIG

STORAGE

TRACE ROTATION

Mid Position

Central

Fully anti-clockwise

Off

As set

2. HORIZONTAL DISPLAY

POSI TI ON Central

FINE Central and pushed in

3. SWEEP

STABILITY

TIME/DIV

VARIABLE

LEVEL

TRIG MODE

SINGLE SHOT

Fully clockwise

5

ms

Fully clockwise

Any position

A 11buttons out

REP.

4. VERTICAL DISPLAY CH1 & CH2

OFF-ON ON

INT TRIG 1

CHOP AL T-SUM CHOP

POSITION Central

INVERT-NORMAL NORMAL

VOL TS/DIV 0.2 V

VARIABLE Fully clockwise

DC-GND-AC GND

1. Plug into the supply and switch on by the ASTIG. LUM.

2. Allow a few minutes for warm up then adjust CRT and

POSITION controls for a two-trace display.

3. Adjust TRACE ROTATION if necessary to make the

traces horizontal.

4. Apply the supply frequency squarewave from the CAL

500 mV peak to peak socket to both INPUT connectors

via co axial leads and switch both DC-GND AC to DC.

5. Rotate STABILITY anti-clockwise to lock display.

6. If the supply frequency is 50 Hz, 2.5 cycles of the

calibrator waveform will be displayed. each display being

2.5 div in amplitude.

CHAPTER 3

CIRCUIT DESCRIPTIONS

3.1.1 This chapter wi

11

assist the reader to comprehend the

circuitry of the OM64. By referring to the Block Oiagram

reference Figure 1 the reader will seethe interfaces of the

various circuits and signal paths, which will be dealt with in

detaiI later.

3.1.2 The signal is fed via the Attenuator to the Vertical Am-

plifier. Its description covers the function of the 'Y' input

pre-amplifiersand Output amplifier, Channelswitching multi-

vibrator and trigger pre-amplifier. The output isfed to the 'Y'

plates of the CRT with a portion of it beingfed to the trigger

network.

3.1.3 The Trigger circuit provides pulsesof suitable amplitude

and polarity to trigger the timebase from internally or ex-

ternally derived waveforms.

3.1.4 The Timebase description deals with the AL T pulse and

Sweep generators, Gating and Hold-off bistables. This stage

determines the start and finish of eachsweepand generatesa

sawtooth waveform for the horizontal amplifier.

3.1.5 The Horizontal amplifier description coversthe

'X'

output,

which amplifies the sawtooth waveform or an external

'X'

signal and appliesit in push-pull to the

'X'

platesof the CRT.

3.1.6 The Unblanking amplifier description coversthe Chop and

Sweep retrace blanking amplifiers. The output being fed to

the CRT g2 electrode.

3.1.7 The Calibrator and E.H.T. are included with the descrip-

tion on the Power supplies, the function of the former is to

provide a calibrated peak to peak squarewaveat power·line

frequency for the purpose of checking the vertical amplifier

and timebase calibration.

3.1.8 The CRT description covers the store and non store

switching, manual and auto erase generators, enhance

generator and collimation correction for the storagesection

of the CRT Also included is a brief description of the

mannerin which the CRT actually storesinformation.

The signals to be observedare connected to the instrument

via BNC sockets and switch S901, referenceFigure 2. Two

identical attenuators each comprising four frequency-

compensated resistive dividers with ratios of 100:1, 10:1,

5:1 and 2:1. Theseare switched singly or in tandem; C902,

C905, C908 and C912 serveto standardize the input time

constants; C904, C907, C911 and C914 compensate the

respective dividers.

3.3 VERTICAL AMPLIFIER

('Y'-AMPLI FIER)

The circuits of channel 1 (CH1) and channel 2 (CH2) are

identical with zenerdiodes 0604, 0611 providing stabilized

positive and negative voltages and diodes 0607, 0608 the

shift voltages CH1 is described below reference Figure 3.

Where references are made to CH2, CH2 will be quoted.

3.3.1 The output from the attenuator is fed to the gate of

TR601 via a protection circuit C601, C602, R601, R602a,

R602b, and R603 which prevents excessive voltage

damagingthe input FET.

3.3.2 TR601 and TR602 form a paraphaseamplifier with their

sources long-tailed through TR628. R624 provides variable

gain control. Compensation is provided by R625 for trace

movement causedby varying R624. R622 compensatesfor

supply voltagevariation in conjunction with R626, R630,

R632 and 0604. Neutralization is effected by C604.

3.3.3 The output from the FET input stageis taken via emitter

followers TR603 and TR604 to a gain stage TR605 and

TR606. In the emitter circuit R617 setsthe X1 channelgain

and R618 the X10. The collector outputs are connected to

the switching stage,TR609 and TR611, via emitter followers,

TR607 and TR608, which provide in push-pull the channel

trigger signal. The Miller capacities of the above gain stage

areneutralized by C603 and C609.

In CH2 the emitter followers TR624 and TR625 provide the

horizontal signalin the X-V mode.

3.3.4 TR609 and TR611 form a long-tailed pair with C606 and

R614 providing H.F. compensation. Their output feeds a

shunt feedback amplifier TR612 and TR613. The feedback

resistors are split into pairs, R644, R650 and R658 R661;

with H.F. compensation being provided by C621, R656,

C619, R655, connected between the junctions of the above

pairs of resistors.

3.3.5 The output from TR612, TR613 is fed to the emitter

input of the output stage,TR752 and TR753, which drives

the 'Y' platesof the CRT Fig.8.

A portion of the output is taken via a balanceddivider, R771,

R773 and R772, R774 to switch, S751,which switcheseither

the above portion of the-signalor the channelsignalfrom the

emitter followers, TR607 and TR608, to a long-tailed pair

TR755, TR757, which drive the Trigger circuit.

3.3.6 The CH2 output from TR624. TR625 also drives a

separate long-tailed pair. TR754, TR756 which acts as a

horizontal pre-amplifier in the X-Y mode. The X-V gainsare

equalized with R787. The outputs from TR754, TR756

collectors drive the diode switching matrix in the horizontal

output amplifier.

3.3.7 Channel switching is carried out by TR614 and TR615,

which act asa bistable in the ALT mode and a free-running

multivibrator in the CHOP mode the current being provided

via a long-tail TR616.

3.3.8 In the AL T mode a negative-goingpulse coinciding with

the start of the sweep flyback is fed, via 0606 or 0609, to

the above bistable causing it to switch. When TR614 is

conducting, it passescurrent from the switching stage,TR609

and TR611, allowing the CH1signalto passto the shunt feed-

back amplifier, TR612 and TR613. At the sametime TR615

is off, its collector rises to 16 V approximately taking the

emitters of CH2 switching stage,TR626 and TR627 with it

and so cutting off the current. Oiodes 0610 and 0612

prevent the base-emitterjunctions from breaking down in the

reversecondition.

3.3.9 In the CHOP mode, R664 and R648 are returned to H.T.

via R639 and R649, forming an astable multi vibrator. The

frequency is mainly determined by R664, R648, C613, C622,

R647, R663, R639 and R649.

3.3.10 In the SUM mode, the current supplied via TR616 is

switched off, so both TR614 and TR615 are non-conducting.

Both switching stages,TR609, TR611 and TR626, TR627

are required to be on, so extra current is bled from the 115 V

line via R637 and R638. Current flows through the switching

stages,via R646 and R662 through R673 to earth. Hence

these signals are added at the basesof TR612 and TR613.

CH2 signal can be inverted by switch, S604, to provide

addition or subtraction of the two signals.Also in the SUM

mode, CHl POSITION becomesa coarseshift control. CH2

POSITION being the very fine shift control.

3.3.11 The table below shows the state of the switched

components for all switch combinations; followed by a

resumeon the part of circuit activated.

Condition A denotes R637, R638 connected to

+

110 V.

Condition B denotesTR616 conducting.

Condition C denotes R673 connected to junction R646/R662.

ALTernate CHOP SUM

x-y

I

CHl CH2 A B C ABCA B C A B C

ON OFF NO YES NO NO YES NO NO YES NO NO NO NO

OFF ON NO YES NO NO YES NO NO YES NO NO NO NO

ON ON NO YES NO NO YES NO YES NO YES NOiNO,NO

OFF OFF NO YES NO NO YES NO NO YES NO N°iNOINO

1. CHl On, CH2 Off.

TR614, TR609 and TR611 are conducting, this feeds the

output of TR609 and TR611 to the basesof TR612 and

TR613; TR626 and TR627 being reversed biased by the

potential at TR615 collector.

TR615, TR626 and TR627 are conducting,so only the output

of TR626 and TR627 may passto the basesof TR612 and

TR613; TR609 and TR611 being reversed biased by the

potential at TR614 collector.

TR614 and TR615 are connected to form a bistable circuit.

At the end of each sweep,a negative-goingpulse appearsat

the junction 0606/0609 which reversesthe state of the

bistable. Hence TR614 and TR615 conduct alternately and

allow the outputs of CHl and CH2 alternately to reachthe

basesof TR612 and TR613.

-1

R648 and R664 are returned to H.T. via R639 and R649 to

form an astable multivibrator, which free runs at 150 kHz

approx. Thus the outputs of CHl and CH2 are successively

switched into TR612 and TR613 at 150 kHz. At each

transition a pulse is fed from the emitters of TR614 and

TR615 via C642 to the unblanking amplifier Fig.6, which

blanks the CRT beam and thus provides automatic transient

blanking in the chopped mode.

The tail of the multivibrator and R633 are disconnected;

TR614 and TR615 are non-conducting; R673 is connected

to ground providing a current path for both channels

simultaneously; TR609, TR611, TR626 and TR627 are

conducting; extra current being fed to their collectors, via

R637 and R638 from the

+

110 V line, to maintain correct

conditions. CHl and CH2 may be used as a summing or

differential (with INVERT pressed)amplifier. In this mode,

the CHl POSITION control provides a coarseshift, and CH2

POSITION control provides a very fine shift control

(reference3.3.10).

TR614 and TR615 are non conducting, preventing outputs

from either CH1 or CH2 from reaching TR612 and TR613.

When the X-Y switch is selected,the circuit is connected for

X-Y operation asfollows, regardlessof any vertical amplifier

mode switching. R641 is returned to ground, ensuring CH1

signal is connected to TR612 and TR613; TR626 and TR627

are biased off, TR616 is non-conducting and the junction

R646/R662 is returned to HT.

The basesof trigger input amplifiers TR2 and TR3, reference

Figure 5, are fed with internal or external trigger signalsvia

switch, S4,whi'chselectsthe sourcefrom either the collectors

of TR753 and TR754 in the vertical amplifier or TRl the

external trigger amplifier. S2selectsthe polarity of the signal

on which the triggering occurs.

3.4.1 Whenswitched in by S3aorS3b, R15,the LEVEL control

varies the basepotentials of TR2 and TR3 in antiphase.This

alters the quiescentvoltage on the baseof TR4 and O.C. level

of signalrequired to trip TR4 and TR5.

3.4.2 When S3a and S3b are open in the AUTO position, feed-

back is applied from TR4 collector via R27 and R9 to TR2

baseand from TR5 collector via R26 and R23 to TR3 base.

This feedback causesTR2, TR3, TR4 andTR5 to oscillate,in

the absenceof a trigger input, at a low frequency primarily

determined by Cll, R26 and R27. Input signalsare A.C.

coupled only and override the above oscillation, causingthe

circuit to lock to the input frequency. The trigger sensitivity

is set by R34, this adjusts the hysteresisof TR4 and TR5.

R17 is setto provide symmetrical operation of TR2 and TR3.

3.4.3 When Sla and b are in the NORMAL position, TR4

and TR5 form a Schmitt trigger. The constant amplitude

rectangular-wave output at the collector of TR5 is

differentiated by C15 and R38. The resulting bidirectional

pulses are applied to the series clipper 01, which provides

the collector of TR68 in the sweep circuit with negative-

going trigger pulses.

In the TV positions of Sla and b, R25 is disconnected from

the emitter of TR4; TR4 converts into a sync separator with

C12 being switched across R31. TR5 changes into an inverter

with decoupling capacitor C16 being switched across the

emitter resistors R36, R25 and R34. In the TV F position of

Sl a, the differentiating time-constant of C15 and R38 is

increased by the addition of R39.

3.4.4 With Slc set to HF, R32 is added in series with R34

across C14; this converts TR4 and TR5 into a free-running

oscillator whose frequency is adjusted, by R15 the LEVEL

control, to synchronise with the H.F. trigger input.

The sweep genArator, reference Figure 6, consists of a Miller

integrator TR71 and emitter follower TR72; and also

bistables, a gating bistable TR66, TR68 and hold-off

bistable TR73, TR74, connected between the Miller output

and input.

3.5.1 Initially, for an incoming trigger pulse to fire the sweep

the following conditions apply:-

Diodes 067, 068 and TR69 are conducting and clamp the

drain of TR71 at

+

2.5 V approx. The hold-off bistable is

held with TR73 off, TR74 on and the gating bistable with

TR66 on, TR68 off.

3.5.2 A negative-going trigger pulse causes TR66 to switch off,

TR68 on, and 066 to conduct. Hence current flowing through

R84 diverts from 067, 068 to 066. This open circuits 067,

068 and releases the gate of TR71. TR71 drain starts to rise,

due to Miller action, taking TR72 base and emitter with it

and cutting off TR69. This rising sawtooth voltage passes

through 071 until eventually TR73 base becomes sufficiently

positive to switch the bistable over. Hence TR74 switches off,

TR73 on and the negative voltage step at TR73 collector

causes TR68 to switch off and TR66 on. TR68 collector

goes positive, switching 066 off, 067 and 068 on; starting

the flyback.

3.5.3 Current flows through R84, 067 and 068 into the timing

capacitor Ctto commence flyback. When TR72 emitter has

fallen sufficiently taking TR69 emitter with it then TR69

conducts and clamps Ctat the initial start potential. This

potential is determined by the resistor ratios R85, R86, R94

and R95.

3.5.4 During the flyback period, 071 is off due to the charge

on the hold off capacitor Ch' This charge leaks away through

R104, R105, R106, R107 and Rl12 until eventually TR73

switches off, TR74 on; the initial conditions (3.5.1 above)

are restored.

3.5.5 When the sweep is switched to single-shot mode, TR73

base is prevented from switching at the end of the flyback

and clamped by diode 072. The bistable is switched over by

pressing RESET, this applies a negative-going pulse to TR73

base and causes the collector current to switch off and TR74

to conduct. The circuit is then ready for the next incoming

trigger pulse to fire the sweep.

3.6 HORIZONTAL AMPLIFIER

(X-AMPLIFIER)

The horizontal amplifier reference Figure 6, consists of a

pre-amplifier TR76, followed by a cascode connected long·

tailed pair output stage, TRn, TR78, TR79 and TR81.

3.6.1 The pre'amplifier TR76 is a shunt feedback stage in

which the sweep and shift voltages are mixed via Rl03,

R121 on its base. In the EXT X position;TRl is connected in

place of a sweep signal, which converts the high impedance

external input into a low impedance suitable for mixing with

the shift voltage at TR76 base. The TR76 collector output is

fed to the base of TR78 via 076. TR78 and TR79 form the

bottom half of a cascode amplifier, their collectors driving

the emitters of TRn and TR81; tail current being supplied

via TR82.

3.6.2 Gain control is provided in the Xl condition by R132,

in the X5 position by R131. The output from TRn and

TR81 collectors driving the CRT

X

plates.

3.6.3 In the sweep and EXT X positions 076 and 081 are

conducting; 077 and 082 are not conducting, the signal

being fed to the base of TR78 with 075 and 079 not

conducting. 074 and 078 are conducting shorting the

collectors of the X-V pre'amplifier TR751 and TR752.

3.6.4 In the X-V mode 074 and 078 are not conducting, 075

and 079 are conducting allowing the push pull output from

CH2 to be fed to the bases of TR78 and TR79. Also 076 and

081 are not conducting; 077 and 082 are conducting

shorting out the signal on TR76 collector.

The amplifiers for unblanking comprise TR65, TR67 and for

chopped blanking TR62 and TR64, reference Figure 6.

3.7.1 In the absence of a sweep TR66 conducts, causing current

to flow through TR65 making the TR65 collector, the TR67

emitter and the CRT Mod Plate electrode negative with

respect to the CRT A 1 electrode so blanking the trace.

3.7.2 When the sweep starts TR66 switches off; TR65 current

ceases; hence its collector goes to h.t. causing TR67 emitter

and CRT Mod Plate to follow. The potentials of A1and Mod

Plate electrodes are equalized so unblanking the trace.

3.7.3 Chopped blanking pulses are fed from the vertical

amplifier via C642 to the cascode circuit TR62 and TR64,

which amplifies the pulse. The collector of TR64 falls;

allowing 064 to conduct and pass blanking pulses, via TR67

to the CRT Mod Plate electrode to blank the trace.

The CRT is of the direct viewing bistable storage type and

contains special storage electrodes additional to a

conventional CRT To make the circuitry comprehensible

two figures are included in this manual. Figure 8 shows the

conventional mode circuit. Figure 9 the storage.

3.8.1 The storage circuit provides the voltage levels necessary to

operate the flood guns, collimation electrodes, target back-

plate, and erase generators. Additional circuitry includes the

enhance generator, which permits faster single sweeps to be

stored and the integrate switch which permits a stored image

of a number of repetitive sweeps, each of which are too fast

to store alone as a single sweep.

Fig. 1 a block diagram includes the storage circuit.

3.8.2 Storage Basic Operating Principles

The storage target backplate (STB) collects the secondary

electrons emitted by the insulator surface, when the insulator

is bombarded with high energy electrons from the writing gun.

This stored positive charge on the insulator is then used to

control the flow of flood gun electrons to a phosphor screen,

in order to produce a visual image.

3.8.3 The flood guns provide low energy electrons directed in a

large cone towards the screen, the collimation electrodes

shape the electron beam to provide uniform coverage of the

STB.

3.8.4 The operating level of the tube, that is the storage or non-

storage mode, is determined by the potential difference

between the STB and the flood gun cathodes.

3.8.5 In the storage mode, the following states are required to

exist in sequence.

1. Ready to write. The insulator surface of the STB tends to

discharge down towards the flood gun cathodes, such that

the flood gun landing energy is not sufficient to illuminate

the phosphor in the target.

The target is now ready to write.

2. Writing. The storage target is scanned by high energy

electrons from the writing cathode. These electrons cause

secondary emission to occur over the scanned area and the

bombarded surface charges sufficiently positive to switch

over to a higher voltage stable state and remains in this

state after the writing gun excitation is removed.

3. Viewing. In this written state, the potential difference

between the flood gun cathodes and the STB has

increased due to the positive charge on the insulator. The

flood gun electrons now penetrate the written area and

illuminate the phosphor. This visual display will persist as

long as the flood beam is allowed to continue to land on

the insulator surface.

At high sweep rates, the writing beam energy is not

sufficient to cause the insulator to switch to the upper

voltage stable state, so when flood gun electrons land on

the target they discharge the insu lator down to the flood

gun cathode potential.

Hence, storage is a function of writing speed.

4. Erasure. When the stored display is no longer required, a

positive pulse is applied to raise the whole STB voltage

above the writing threshold, so that the whole area is

written with flood gun electrons The pulse then goes

negative and as the voltage gradually returns towards zero,

the target is charged towards the ready to write threshold

and the whole procedure can be repeated.

3.8.6 Circuit Description:

The circuit, reference Figure 9, comprises three triggered

monostable pulse generators; enhance TR100l, TR1002,

manual erase TR1003, TR1004 and auto erase TR1007,

TR1009. The outputs from these circuits are connected, via

the erase amplifier TR1005, TR1006, to the CRT STB

electrode. Additionally O.C. supplies are provided for the

collimation electrodes CEl to CE5.

3.8.7 In the NORMAL (non-store) condition of the CRT, the

base of TR1005 is connected to a fixed potential. TR1005,

TR1006 are connected as a single stage shunt feedback

amplifier; the O.C. output level sets the STB potential at

approximately 75 V.

3.8.8 When switched to STORE mode, the base of TR1005 is

connected to a resistive mixing circuit comprising, the O.C.

level adjustment Rl026, via Rl028, the erase generator out-

put from TR 1004 via R1029 and the enhance generator out-

put from TR1002 via Rl031. The STB electrode resides at a

potential of approximately 150 V.

Note:

These potentials will vary from instrument to

instrument.

3.8.9 The ENHANCE and AUTO ERASE monostables are

triggered by a pulse from the sweep generator that occurs at

the start of the flyback period. This pulse is shaped by

TR1000 and applied via Cl00l and Cl014, to the respective

monostables.

The MANUAL ERASE is applied via S1004a. A negative

pulse is applied to the base of TR1003 causing it to switch

off, TR1004 to switch on and bottom. The circuit will switch

back after a period determined approximately by Cl007 ana

Rl017; the collector of TR1004 will then rise until it is

clamped by 01007. When TR1004 switches on, it also

discharges Cl008. Hence at the end of the pulse period

Cl008 will charge towards -100 V line until clamped by

01008 at -14 V.

3.8.10 The waveform at TR1005 base is the sum of the O.C.

level, a negative-going rectangular pulse of approximately

14 V amplitude from the TR1004 collector followed by an

exponential decay back to -14 V approximately from the

negative side of Cl008.

3.8.11 This signal is inverted and amplified by the shunt feed-

back stage TR1005, TR1006 and applied to the STB

electrode of the CRT. At the same time, the emitter of

TR1006 drives the bootstrap emitter follower TR1008 via

the zener diode 01014. The signal voltage passes through

Cl013 cutting off 01009 so disconnecting the +300 V line.

The collector of TR1006 rises due to bootstrap action taking

the collimation electrodes CE4, CE5 positive. This is done to

maintain correct collimation of the flood beam during the

erase period.

3.8.12 The AUTO ERASE generator is triggered by a negative

pulse occurring at the start of the sweep flyback. The

sequence of eJents for auto-erasure is to first put the time-

base into the single sweep mode. This is done automatically

when switching to auto-erase, then the sweep flyback

switches the auto-erase generator to produce a negative-going

rectangular pulse. The leading edge of the pulse fires the erase

generator to erase the display and at the end of the pulse

period, when erasure is complete the back edge of the pulse

resets the sweep; ready for the next input signal to trigger it.

The negative pulse from Cl014 switches TR1007 off,

TR1009 on; the circuit recovery rate being determined

approximately by Cl015, Rl045. The output from the

TR 1009 collector is differentiated and the positive edge

removed by 01024. The negative edge from 01024 is then

used to fire the erase generator TR1003, TR1004. The

positive output from TR1009 collector is used to reset the

sweep so that it fires on the next input signal.

3.8.13 The ENHANCE generator is also fired by a pulse

occurring at the start of the flyback; a variable width

rectangular pulse is produced which is fed to the base of

TR 1005, so raising the potential of the STB. This increases

the writing speed of the CRT and also the background level,

so reducing the contrast of the stored image. If the Manual

or Auto Erase generators are also operating, then the enhance

pulse sits on top of the erase pulse amplitude and assists in

clearing the stored information.

3.8.14 To increase the writing speed still further with a

recurrent waveform, the flood gun cathode can be open

circuited by the INTEGRATE switch S1003. This switches

off the collimated flood beam and allows successive sweeps

to build up the stored charge on the insulator until the

insulator is able to switch to its higher voltage stable

condition. Then if the INTEGRATE switch is released; the

flood beam switches on, permitting the stored image to be

viewed.

3.9.1 The negative supply voltage, reference Figure 8, for the

CRT cathode is supplied by a class 'C' oscillator circuit

consisting of TR302, transformer T301 and a current sensing

amplifier TR301 and TR303. The oscillator runs at

approximately 40 kHz with the secondary of the transformer

being rectified by 0302 and C303 serving as a reservoir

capacitor. This produces a voltage of -3.2 kV relative to

chassis.

3.9.2 The potential divider chain between the - 3.2 kV and the

+

110 V lines provides the necessary voltages for the CRT

writing gun electrodes and senses the output of the regulator

circuit. Any change in the regulator output induces a current

change in the potential divider chain. This current change is

amplified by the current amplifiers TR301 and TR303 to

control the automatic self bias for the class 'C' amplifier

TR302. This is developed across C301 to vary the conduction

angle of the class 'C' amplifier and maintain a constant voltage

output.

3.9.3 The zener diodes 0306 and 0304 maintain constant

voltages across the Focus circuit, so as to make the current in

the potential divider chain independent of the Focus control,

which is achieved by controlling the photo-energy incident

on the photo-transistor PT R304 from the light source LP 301.

3.9.4 TR307, R315 and R319 form a clipper circuit which clips

the negative-going portion of the E.H.T. oscillator at the

collector of TR307. This clipped signal is then peak to peak

rectified by 0306

&

0308 and superimposed onto the

3.2 kV line to control the bias on the grid of the CRT. R319

varies the clipping level and hence alters the brightness of the

trace.

3.10.1 The power supply circuit is shown in Fig. 10. All the

rectifiers used are silicon semiconductors thus ensuring a

minimum of delay for the rectified voltagesto obtain their

maximum value. A power transformer T401 provides all the

required voltages from its secondaries.The primary may be

adjusted, by a meansof a link input voltage selector panel,

for operation on alternating voltages from 100-125 V and

190-240 V at 50-60 Hz.

3.10.2 One secondary winding, 14-0-14 V, is full waverectified

twice and supplies

±

12.5 V and

±

14 V. Another full wave

rectifier provides O.C. for the CRT flood gun heater. One

half of the winding provides power for the graticule

illumination bulbs.

3.10.3 A secondwinding, 100-0-100V, alsowith two full wave

rectifiers supply

±

100 V.

3.10.4 Two additional floating windings drive bridgerectifiers to

supply the

+

180V and

+

300 V lines

3.10.5 All lines are R-Csmoothed, to provide low ripple supply

voltagesfor the relevantcircuit boards

3.10.6 The 500 mV peak to peaksquarewavecalibrator output

is developed acrossR407 by using the 14 V A.C. output

from the transformer to switch 0416 alternately on and off.

0416 is in series with R408 and R411 to a 6.2 V zener

diode. R411 sets the current through the chain and

consequently the voltage developedacrossR407.

4.1.1 The entire solid-state design of the instrument should

render frequent re-adjustment of the internal preset controls

unnecessary; however, to ensure full measurement accuracy,

it is desirable to make an occasional check, reference 4.3.2,

4.3.3. on the vertical amplifier sensitivity and timebase sweep

speed.The internally generated 500 mV peak to peak calibra-

tion waveform may conveniently be used for these checks.

4.1.2 Should a more complete calibration be required, such as in

the event of transistor replacement, reference should be made

to the appropriate procedure in the Calibration paragraph of

this Chapter.

Before it is assumed that a fault condition exists, control

settings should be verified with referenceto the Pre-Operation-

al checks,paragraph 2.2.

Attenuator trimmers are accessible from the left hand side,

front, after the covershavebeen removed. PC.110 and PC.111

which carry the circuits for the timebase, power supplies and

storage are situated on the right hand side; PC.115, the

vertical amplifier is on the left hand side and PC.123, the

E.H.T. is below the rear of the CRT. The boards are marked

with a legendto facilitate component identification.

The cabinet sidesare removed asfollows:

1. Disconnect the power supply.

2. Loosen the two handle-clamp securing~cre.·'s.

3. Easethe top of each .:::ieoutwarrls.

4. Unhook the bottom of e?'"h siti.: fro

1""1

the locating

slots. The chassis base cover plate is secured by six

fixing screws, one at each corner and one half-way

along eachside.

1. Remove both cabinet sides,asdescribed above.

2. Removethe rear cover (four screws).

3. Unplug the 14 pin CRT baseconnector.

4. Unplug the five pin connectors (top, rear PC.111).

5. Removethe three screwsholding the mumetal screen.

6. Unplug the trace rotation coil connector (rear PC.115L

7. Removethe CRT and screenfrom the instrument by

moving them towards the rear to clear the front panel;

moving the forward end of the CRT to the left. The

CRT and screen may be removed with the cableform

attached.

8. Remove adhesivetape and rear location moulding from

the CRT.

9. Removethe CRT from the screen.

4.2.4

CRT FITTING

Reversethe order detailed above 4.2.3. Ensure that the CRT

forward end is located in the rubber moulding behind the

front panel. If the trace rotation control does not provide an

adequate range of adjustment reversethe trace rotation plug.

4.3.1 The following procedure enablesa full calibration of the

instrument to be accomplished. If any operations are carried

out in isolation, regard should be paid to the risk of inter-

action with other adjustments also to control settings and

waveforms applied in earlier steps.

The following tools and equipment shall be required:

1. Calibrator, Telequipment Type C1A or Item 2.

2. Time Marker Generator and an accurate voltage source.

3. Signal Generator.

4. Terminator, 50~. If alternative to 1 above is used,a

suitable matching terminator should be used.

5. Variac with a

±

10%facility.

6. Avometer.

7. Oscilloscope with 100 mV/Div sensitivity.

8. Voltmeter with range;;"3.5 kV.

9. X1 Probe.

10. X10 Probe.

11. Non capacitive trimming tool.

12. Screwdrivers with various width blades.

4.3.2

SWEEP SPEED CHECK

1. Switch CH1 and CH2 on.

2. Set VOL TS/DIV to 100 mV.

3. Turn VARIABLE fully clockwise and releasefor

XL

4. Set DC·GND-AC to DC.

5. PushFINEforX1.

6. Set TIME/DIV to 10 ms.

7. Turn VARIABLE (speed)fully clockwise.

8. Connect INPUT 1

&

2 to CAL.

9. Adjust STABILITY for locked display.

10. Check SweepSpeed

=

1 cycle/2 divs. for 50 Hzsupply

3 cycles/5 divs. for 60 Hz supply

for 400 Hz supply set TIME/DIV to 1 ms

check SweepSpeed

=

2 cycles/5 divs.

4.3.3

GAIN CHECK

1. Repeat 1 through 5 above.

2. Connect CAL to INPUT 1.

3. Adjust CH1 POSITION, Trigger andSweepcontrols for

convenient display.

4. Check amplitude

=

5 divs. if incorrect adjust R617.

5. Connect CAL to INPUT 2.

6. Adjust CH2 POSITION, Trigger and Sweep controls

for convenient display.

7. Check amplitude

=

5 divs., if incorrect adjust R691.

NOTE: VARIABLES must remain fully clockwise.

4.3.4 PROBES

Reference2.1.6, sub-para2, GATE OUT.

4.3.5 PRELIMINARY PROCEDURE

1. With the instrument disconnected from the power supply,

removethe cabinet sidesasdetailed in 4.2.2.

2. Insert the voltage-selector plug in the rear panel with the

arrow indicating the nominal voltage of the local A.C.

supply or the nearestvalueto it.

3. Connect the Oscilloscope's power cable to a Variac. The

coresof the cableare alternatively colour-coded asfollows.

---:-:-:-:-n-- ~ NE~::AL

Black

-I

White

---------------------------

EARTH

(Chassis)

Green/Yellow

Green

4. Setall presetpots to mid position.

5. Set front-panel controls asfollows:

POSITION (CHl

&

2) Central

OFF-ON (CHl

&

2) OFF

ALL VARIABLES fully clockwise

STABILITY fully clockwise

POSITION (horizontal) Mid position

FINE Central and pushedin

All pushbuttons Out

6. Connect voltmeter; negative to CRT pin 2, positive to

earth.

7. Connect the Variac to the power supply, switch on power

supply and allow oscilloscope to warm up.

8. Adjust the Variac to give the same voltage as that

indicated by the voltage-selector plug.

9. Adjust BRILLlANCE for reasonablesetting.

10. Adjust FOCUS and ASTIG.

11. Adjust R308 to givevoltmeter readingof -3200V.

12. Turn BRILLIANCE fully clockwise.

13. Adjust R328 for maximum brilliance.

NOTE When R328 is correctly adjusted,the BRILLlANCE

control should give continuous variation over its range.

Over adjustment of R328 simply causesexcessivespot

swelling with no real increasein the trace brilliance. Also

the EHT may change,asindicated by avometer.

14. Adjust BRILLIANCE for reasonablesetting.

15. DepressBEAM LOCATE and observespot appearsappro-

ximately 2mm to the left of the trace start.

1.0 To setauto and trigger sensitivity R17 and R34.

1.1 Set VARIABLE (speed)to EXT X.

1.2 Releaseall Buttons.

1.3 PressEXT TRIG.

1.4 Set CHl and CH2 DC-GND-ACto GND.

1.5 Connect TEST Oscilloscope to TR3 collector tag

62.PCll0. (ReferenceFig 11)

1.6 Set Oscilloscopeto 0.1 volts/div and 20 ms/dil/.

1.7 Turn R34 fully anti-clockwise.

1.8 Adjust R17 to the centre of the rangeover which a

continuous oscillation, at 1 MHz approximately, is

observedon the Test Oscilloscope.

1.9 Turn R34 slightly clockwise.

1.10 ResetR17to the centre of the oscillation range.

1.11 Repeat 1.7 through 1.9 until the oscillation develops

into atriangular waveform at 20 Hzapprox.

1.12 Adjust R17and R34 to give a symmetrical waveform

of 70 mV peakto peak.

2.0 To set gatepotential: R93.

2.1 Connect Test Oscilloscopeto Tag21, PCll0.

2.2 Turn STABILITY fully anti-clockwise.

2.3 Turn VARIABLE (speed)fully clockwise.

2.4 Adjust R93 for 2 V negativepotential with respectto

GND.

3.0 To setsweeplength: Rl06.

3.1 Connect Test Oscilloscopeto Tag23, PCll0.

3.2 Turn STABILITY fully clockwise.

3.3 Adjust R106 for a total sweepamplitude of 10 V.

3.4 Disconnect Test Oscilloscope.

3.5 ReleaseEXT TRIG.

3.6 Set CHOP-SUM-ALT to AL T.

4.3.7 VERTICAL AMPLIFIER (supply variation compensation)

1.0 To setCH1 supply variation: CH1 on, CH2 off.

1.1 Set VOLTS/DIV to 10 mY.

1.2 Set DC-GND-ACto DC.

1.3 Connect Calibrator to INPUT 1.

1.4 Set calibrator to 5

m\l

peakto peak, 1 kHz squarewave.

1.5 PressVARIABLEforXl0gain.

1.6 Set POSITION to centre of range.

1.7 Adjust R642 until trace appears.

1.8 Set R618 for 5 div deflection approximately.

1.9 Adjust STABI L1TY for free-run trace.

1.10 Set DC-GND-ACto GND.

1.11 Adjust R642 to centralizetrace.

1.12 Reducesupply voltageby 10%.

1.13 Note direction. if trace movesin the vertical axis;

1.14 Adjust R622 slightly to move trace in the direction

noted in 1.13 above.

1.15 Increasesupply to normal.

1.16 Adjust R642 to :;entralize trace.

.17 Rel'eat 1.12 th'ough 1.16 until trace movement is

reduced to a minl 1um, when the Variac setting is varied

between

±

10%,

2.0 To set CH2 supply variation: CHl off, CH2 on.

2.1 SetVOLTS/DIVtol0mV.

2.2 Set DC-GND-AC to DC.

2.3 Connect Calibrator to INPUT 2.

2.4 Set Calibrator to 5 mV peakto peak 1 kHz squarewave.

2.5 PressVARIABLEforX10gain.

2.6 Set POSITION to centre of range.

2.7 Adjust R669 until trace appears.

2.8 Set R693 for a5 div deflection approximately.

2.9 Adjust STABILITY for free-run trace.

2.10 Removesignalby earthing input.

2.11 Adjust R669 to centralize trace.

2.12 Reducesupply voltage by 10%.

2.13 Note direction, if trace moves in the vertical axis;

2.14 Adjust R697 slightly to move trace in the direction

noted in 2.13 above.

2.15 Increasesupply to normal.

2.16 Adjust R669 to centralize trace.

2.17 Repeat 2.12 through 2.16 until trace movement is

reducedto a minimum, when the Variac setting is varied

between

±

10%.

2.18 Disconnect Calibrator.

3.0 To check supply fluctuation.

3.1 Switch CH1on and check CH2 is on.

3.2 Alter Variac setting rapidly between

±

5%.

3.3 Checkthat both tracesdo not bounce more than 1mm.

If bounce isexcessiverepeatOp. 1.0

&

2.0 above.

4.3.8 CRT (Geometry)

1.0 To set geometry R1065.

1.1 Connect Signal Generator to INPUT 1.

1.2 Set Signal Generator to at least 100 kHz sinewave.

1.3 Switch CH2 off.

1,4 SetTIME/DIV for closespacedraster,10sinewaves/div

approximately.

1.5 PushFINE for Xl gain.

1.6 SetCHl VOLTS/DIVto 10mV.

1.7 Adjust Signal Generator's amplitude to provide a raster

with top and bottom edgesjust visible in the display area.

1.8 Adjust Rl065 for minimum curvature at the edgesof

the raster.

1.9 Disconnect the Signal Generator.

4.3.9 VERTICAL AMPLIFIER (D.C. and L.F. setting)

1.0 To setCH1 VARIABLE and POSITION balance:R625

and R642.

1.1 Check CHl on, CH2 off.

1.2 Set VARIABLE fully clockwise.

1.3 Set VOLTS/DIV to 10 mV.

1,4 Set DC-GND-AC to GND.

1.5 Adjust POSITION to align trace with graticule centre

line.

1.6 PushVARIABLE forXl0gain.

1.7 Adjust R642 to centralize trace.

1.8 ReleaseVARIABLE for Xl gain.

1.9 Repeat 1.5 through 1.8 until no trace movement

occurswhen operating VARIABLE.

1.10 PushVARIABLE forXl0gain.

1.11 Turn VARIABLE fully anti-clockwise.

1.12 Adjust R625 to centralize trace.

1.13 Turn VARIABLE fully clockwise.

1.14 Repeat 1.11 through 1.13 until there isno movement

when VARIABLE isturned through its range.

2.0 To setCH2 POSITION balance: R669.

2.1 Switch CH2 on.

2.2 Pushboth VARIABLES for Xl0 gain.

2.3 Set both DC-GND-ACto GND.

2.4 Turn both VARIABLES fully clockwise.

2.5 Set CHOP-SUM-ALT to AL T.

2.6 Centralize both traces.

2.7 Set CHOP-SUM-ALT to SUM.

2.8 Adjust R669 to centralize trace.

2.9 Repeat 2.5 through 2.8 until no trace movement

occurs.

3.0 To setCH2 VARIABLE balance: R701.

3.1 CH1off. CheckCH2 ison.

3.2 Set VARIABLE fully clockwise.

3.3 Set VOLTS/DIV to 10 mV.

3.4 Set DC-GND-ACto GND.

3.5 Adjust POSITION to align trace with graticule centre

line.

3.6 PushVARIABLE for X10 gain.

3.7 Turn VARIABLE fully anti-clockwise.

3.8 Adjust R701 ta centralize trace.

3.9 Repeat 3.6 through 3.8 until there is no movement

when VAR IABLE isturned through its range.

4.0 To setCH1 X1 gain: R617.

4.1 Switch CH1 on, CH2 off.

4.2 Set VOLTS/DIV to 10 mV.

4.3 ReleaseVARIABLE for Xl gain.

4.4 PressINT TRIG 1.

4.5 Set TIME/DIV to 1 ms.

4.6 Set DC-GND-ACto DC.

4.7 Conr,ect Calibrator to INPUT 1.

4.8 Set Calibrator to 50 mV peak to peak 1 kHz square-

wave.

5.0 To setCH1 X10 gain: R618.

5.1 Set Calibrator to 5 mV peak to peak.

5.2 PushVARIABLE for Xl0 gain.

5.3 Adjust R618 to give5 div amplitude.

Other Telequipment Test Equipment manuals

Popular Test Equipment manuals by other brands

Sonel

Sonel UV-260 Corona Camera operating manual

Dickey-John

Dickey-John mini GAC Operator's manual

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS PCSTestr35 quick guide

MTP

MTP MTP-1032 instruction manual

CTR Group

CTR Group PRATIKA User and maintenance guide

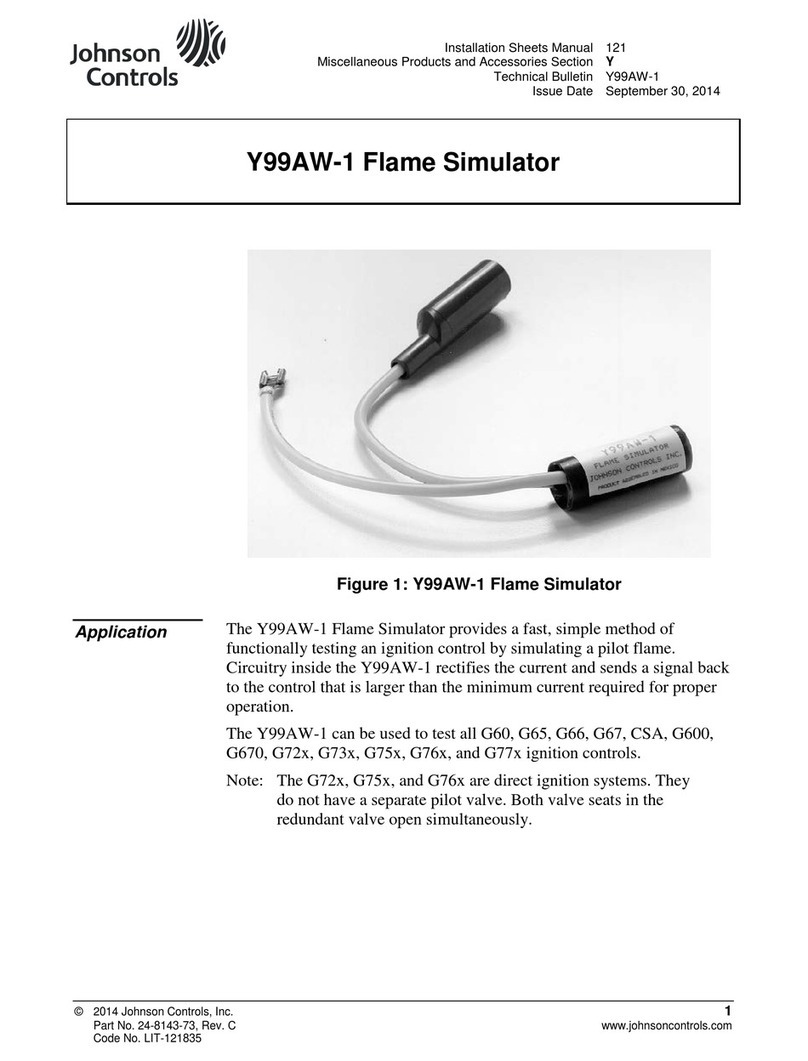

Johnson Controls

Johnson Controls Y99AW-1 Installation Sheets Manual