Telesis XPRESS EP/TLM User manual

XPRESS™ EP /TLM Laser Marking System

Doc. No. 40213 – 1 of 6

System Overview

The XPRESS EP/TLM is an advanced, fiber-coupled diode

end-pumped laser marking system. The laser beam quality and

Q-switched pulse characteristics are optimized for applications

that require high beam quality and stability. This system is a very

good choice for general-purpose laser marking, scribing,

trimming, and other material processing applications.

The XPRESS-series unique L-shaped design features a continuous

wave (CW)/Q-switched Nd:YVO4end-pumped laser with a

remote fiber-coupled diode pumping source. With average diode

life of greater than 20,000 working hours the XPRESS EP offers

the user “best-in-class” reliability.

The robust mechanical and optical design allows the Telesis

XPRESS EP to operate in industrial conditions with respect to

shock, vibration, and dust.

The XPRESS EP/TLM laser marking system offers these

advantages:

•Reliable, long, maintenance-free performance

•Compact size and modular construction

•Remote, fiber-coupled pumping diode

•Exceptional beam quality and stable output power

•Active (thermo-electrical) temperature control of the

laser crystal and pumping diode

•Active AO Q-switching

•Air cooling

•Visible red diode for dry run / positioning

•Large digital display for marker status, settings, and

error condition monitoring

•Standard 115/230VAC operation

•DoD-compliant Unique Identification (UID) marking

System Configuration

The XPRESS EP/TLM basic package consists of the following:

•TLM-Series Laser Controller – contains pumping diode,

RF driver, and other electrical components

•Fiber Optic / Umbilical Assembly

•XPRESS EP Laser Marking Head – contains sealed

resonator, beam expander, turning mirror, galvanometer

assembly, visible red light positioning laser

•Software – Merlin II LS Laser Marking Software

•System Computer – supplied by Telesis or by customer

The modular design allows for major components to be easily

replaced and returned to Telesis if in need of repair.

Laser System Options

•Desktop computer or Notebook computer with powered

cardbus-to-PCI expansion enclosure

•Externally-mounted focus-finder diode

•Tool post w/ manual hand crank for z-axis adjustment

•Pushbutton station (start/abort)

•I/O Options:

TTL via PCI-DIO24 Card (Kit #53920)

Opto-isolated via Merlin DCIO Module (Kit #53928)

TMC090 Controller (for auxiliary axes; additional I/O)

•Programmable X-, Y, or Z-axis (TMC090 required)

•Rotary drive fixture (TMC090 required)

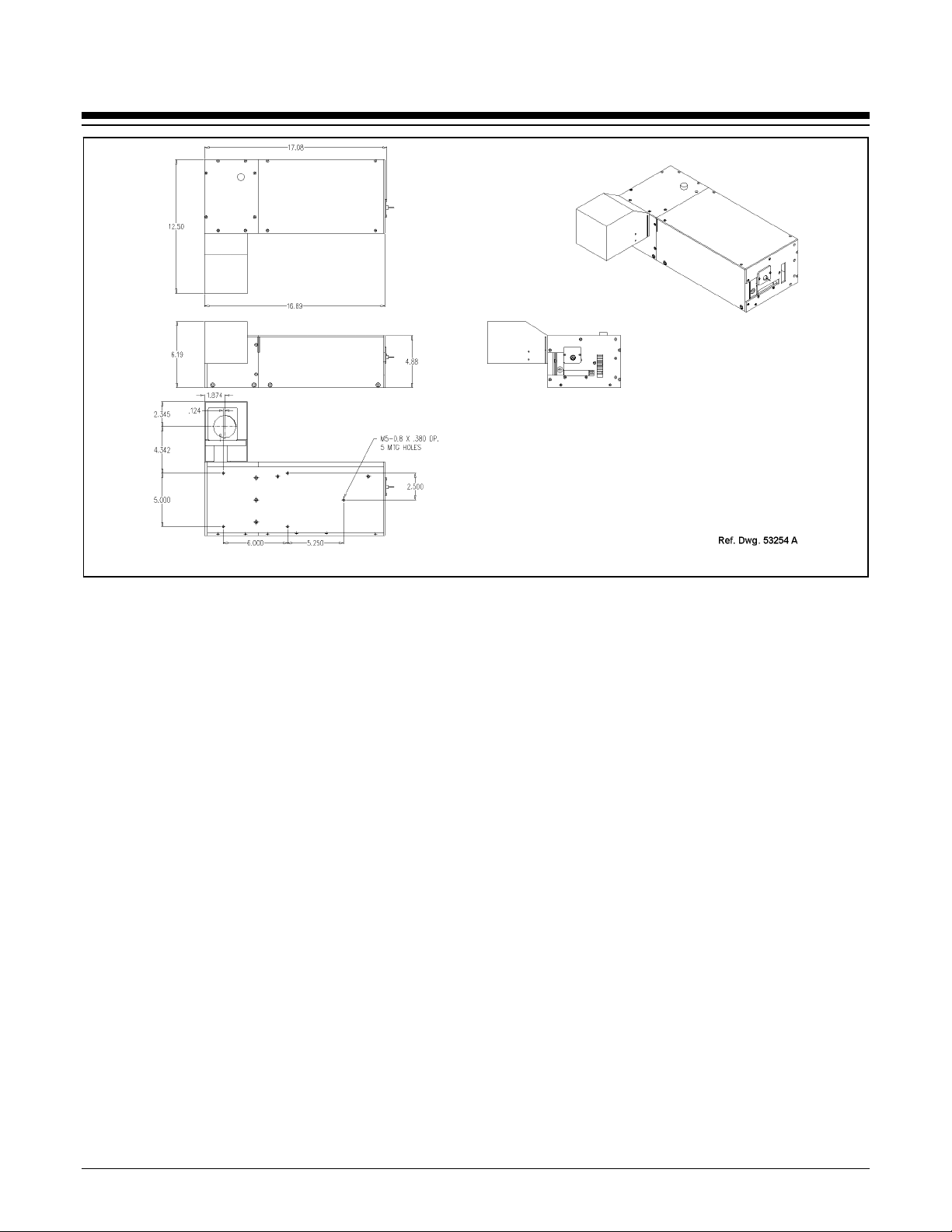

XPRESS EP/TLM Laser Marking System General Arrangment

XPRESS™ EP /TLM Laser Marking System

Doc. No. 40213 – 2 of 6

System Setup

Complete installation procedures are provided in the

XPRESS EP/TLM Installation/Maintenance Manual. The

following procedures are listed for reference only to provide a

general overview of the installation process.

1. Equipment should remain powered down and in OFF

position until mounting is complete.

2. Place computer, monitor, keyboard, and laser controller in

desired location. Locate controller as close as practical to

laser marking head. Standard cable length is 1.75 meters

(5.74 feet) long between the laser marking head and the

laser controller. An optional 4.75-meter (15.58-ft.) fiber

optic cable is also available.

3. Place the laser marking head on selected mounting.

a. Do not bend or kink fiber optic cable. The fiber

optic cable will tolerate approximately 300 mm

(12 in.) diameter bend without damage.

b. Allow a minimum distance of 150 mm (6 in.) at

rear of the laser marking head. This will provide

sufficient room for a proper bend radius of fiber optic

cable.

c. Do not block or obstruct exhaust fan. Note location

of exhaust fan on right side of the laser marking head.

This fan must have adequate clearance to ensure

proper cooling.

4. Mount laser marking head using any three of five factory-

tapped M5-0.8 mounting holes provided.

a. Locate five pre-drilled M5-0.8 mounting holes. The

one nearest the galvanometer output is referred to as

the "origin". All other mounting hole dimensions are

referenced to this hole. Refer to the Mounting and

Dimension Details drawing more information.

b. Telesis recommends using a minimum of three (3)

attach points for mounting the laser marking head,

one of which should be the origin mounting hole.

c. Mounting bolts must not extend into laser marking

head more than 9.5 mm (.38 in.) to avoid

interference with internal components.

d. The leading edge of customer-supplied mounting

fixture should extend no greater than 25.4 mm (1 in.)

from origin mounting hole to allow clearance for

beam output lens.

e. As viewed from front of the laser marking head in

upright position, center of output beam is 11.0287 cm

(4.342 in.) from origin mounting hole.

5. Secure the laser marking head to mounting fixture using

M5-0.80 bolts and lock washers. Do not over tighten bolts.

6. Ensure laser controller power switch (front panel) is OFF.

7. Select proper fuse arrangement, then connect power cable.

8. Connect fiber-optic cable to laser marking head. Connect

remaining cables, as applicable.

9. Refer to XPRESS EP/TLM Operation Supplement for proper

startup procedure. Refer to laser marking system Operation

Manual for complete information on using system software.

XPRESS EP Laser Marking Head Dimensions and Mounting Details

XPRESS™ EP /TLM Laser Marking System

Doc. No. 40213 – 3 of 6

XPRESS EP/TLM System Specifications

Compliance............................CDRH

Laser Type.............................fiber-coupled, diode end-pumped,

Q-switched, Nd:YVO4

Wavelength (laser output)......1,064 nanometers (nm)

CW Average Power ..............7 watts at 1,064 (nm)

Expected Diode Lifetime.......greater than 20,000 hours

Long Term Output

Power Stability ...................less than ± 2%

Max. Power Consumption .....less than 500 watts

Input Power ...........................95 to 250 VAC, 6 amps, 50/60 Hz

single phase

Supply Voltage Fluctuation ...± 10%, maximum; clean ground line

Oper. Environment ................Indoor only; Installation Category II,

Pollution Degree 2 Environment

Oper. Temperature.................18° to 35°C (65° to 95°F)

Recommended Temp.............20° to 25°C (68° to 77°F)

Oper. Relative Humidity........10% to 85% non-condensing

XPRESS EP Laser Marking Head

The XPRESS-series lasers have a unique, space-saving “L”

shaped footprint. Designed for easy maintenance, the galvo head

is mounted at a 90° angle to the laser rail. A heat exhaust fan is

located on the back side of the unit.

The laser marking head encloses the sealed laser resonator, the

beam expander, the turning mirror, the red light dry

run/positioning laser and the galvanometer assembly.

Laser Marking Head Specifications

Dimensions (L x D x H) ........43.38 x 31.75 x 15.72 cm

(17.08 x 12.50 x 6.19 in.)

Mounting Weight..................approx. 13.6 Kg (30 lbs.)

Mounting Holes .....................five factory-tapped M5-0.80

Positioning.............................visible red diode beam (650 nm)

Field Resolution.....................16 bit (65535 data points)

Galvanometer Repeatability ..less than 22 micro radian

Marking Field Size ...............lens-dependent, see chart

Fiber-Optic Cable Length......1.75 m (5.74 ft.) – standard

4.75 m (15.58 ft.) – optional

Cooling ..................................air cooled, active thermo-electric

Marking Field Size

The size of the marking field is dependent on lens type.

See below.

Sealed Laser Resonator

The laser resonator is assembled and sealed in the clean room

environment to prevent optical contamination. The laser resonator

contains an electro-mechanical safety shutter. Under power, the

safety shutter allows 1064nm laser beam to pass through the

galvanometer steering mirrors. If the shutter is closed during

normal operation (or power is removed from the system via a

power off/stop condition) it will inhibit the 1064nm laser beam.

Visible Red Positioning Beam

The laser marking head produces a visible red diode that may be

viewed on the work surface without the need for protective safety

goggles. This provides a safe and convenient aid for laser setup

and part programming. Since the red beam is located after the

shutter, the positioning beam may be used with the shutter opened

or closed. Additionally, the visible red beam may be used with the

lasing beam during the marking cycle. Note that protective

eyewear should always be worn when the laser is in operation.

Flat Field Lens, Final Objective Lens, (F-Theta Lens)

The final object lens is key to the marking performance of the

system. This is the final coated optical lens that the beam will pass

through before it strikes the marking target. This lens is called a

flat field lens because when the beam is focused, the focus lies in a

plane perpendicular to the optical axis of the lens. To protect the

final objective lens from dust and debris, a clear protective cover

is inserted between the work area and the lens.

The following chart outlines the available lenses, the resulting

image field provided by the lens, and the working clearance (in

millimeters and inches).

Lens

Image Field

(mm) (in.)

Working

Clearance

(mm) (in.)

100 mm 65 x 65 2.56 x 2.56 97.0 3.82

160 mm 110 x110 4.33 x 4.33 175.0 6.89

Spot Size (line width)

In all cases, laser marked spot size is dependent on a variety of

factors including lens selection, focus, laser power, and the

material being marked. The following chart is provided for

reference only.

Lens Spot Size (line width)

100 mm 25 microns (.0010 in.)

160 mm 40 microns (.0015 in.)

XPRESS™ EP /TLM Laser Marking System

Doc. No. 40213 – 4 of 6

TLM-Series Laser Controller

The pumping diode is enclosed in the laser controller, while the laser

resonator with the crystal is located in the laser marking head. The

pumping beam from the diode (approx. 808 nm) is delivered through

a fiber optic cable directly into the laser resonator.

The laser controller also contains the active thermo-electrical cooling

system for the pumping diode, the RF driver, galvanometer power

supplies, driver control circuits, appropriate fusing, and a

115/230VAC IEC320 connector, and a front panel control module.

Engineered for the greatest reliability and for ease of maintenance,

the pumping diode within the laser controller is an easily replaceable

sealed module with expected lifetime of greater than 20,000

operating hours.

Operator Control Panel

The front panel includes the system key switch, laser off push

button, manual safety shutter control, function indicators, and LCD

display. The display allows monitoring of the diode current, the

crystal and diode temperatures, system status, and error conditions.

TLM-Series Laser Controller Console

Laser Controller Specifications

Dimensions (W x H x D)....... 42x 14 x 50cm

(16.5 x 5.5 x 19.5 in.)

Surrounding Envelope ........... 50x 14 x 56cm

(19.5 x 5.5 x 22.0in.)

Weight ...................................approx. 10 Kg (22 lbs.)

Cooling ..................................air cooled, active thermo-electric

Fiber Optic Cable Assembly

The fiber optic cable is permanently attached directly to the

pumping diode within the laser controller and cannot be removed.

The standard optical fiber is 1.75 meters (5.74 feet) long. An

optional 4.75-meter (15.58-ft.) fiber optic cable is also available.

System PC

The laser system requires an IBM-compatible computer for

running the Merlin®II LS Laser Marking Software. The PC may

be a desktop or a notebook computer and may be supplied by

Telesis or by the customer. If the PC is supplied by Telesis,

warranty for the computer, computer keyboard, monitor, and

peripherals default to the original equipment manufacturer.

Galvo control cards are included, along with interconnect cabling.

The laser software is installed and the entire unit is tested as a

laser marking system.

The minimum computer requirements are as follows:

•Windows® 2000 or Windows® XP

•Telesis Merlin®II LS Laser Marking Software

•Pentium®III, 128 MB RAM (minimum)

•Multi-gigabyte, HDD

•CD-ROM and 3.5 in. External Disk Drives

•SVGA Color Monitor, Mouse, and Keyboard

•Laser/Galvo Controller Board

•Video Card

•One available RS-232 Serial Port

•Two available USB Ports

•Two available PCI Slots *

Note: If a notebook computer is used, expansion

must be used to provide the PCI slots.

XPRESS™ EP /TLM Laser Marking System

Doc. No. 40213 – 5 of 6

System Software

Telesis’ powerful WIN32 Merlin®II LS Laser Marking Software is

a PC-based operating software package that comes standard with

the laser marking system. It is a graphical user interface that

makes marking pattern design quick and easy. The WYSIWYG

(what-you-see-is-what-you-get) interface provides a to-scale

image of the pattern as it is created. Just “click and drag” for

immediate adjustment to field size, location, or orientation.

The Merlin®II LS includes tools to create and edit text (at any

angle), arc text, rectangles, circles, ellipses, and lines. Multiple

fields may be grouped and saved as a block to form a logo.

Existing DXF CAD files can also be imported for marking. Non-

printable fields can be created to clearly display a graphical

representation of the part being marked.

Overview of Merlin-II LS User Interface

Merlin®II LS Laser Marking Software Specifications

Operating System ..................Windows®2000 or Windows®XP

Desktop PC or Notebook PC

Font Generation .....................True Type Fonts

Barcodes and Matrix..............2D Data Matrix, PDF417, BC 39,

Interleaved 2 of 5, UPCA/UPCE BC

128, Maxi Code, Code 93, QR Code

and others

Graphic Formats ....................Raster and Vector: BMP, GIF, JPG,

WMF, EMF, PLT, DXF

Serialization...........................Automatic and Manual Input

Host Interface Capable

Linear Marking......................Scalable with Letter Spacing

Control

Arc Text Marking ..................Scalable and Adjustable

Drawing Tools .......................Line, Rectangle, Circle, Ellipse

Remote Communications

The communication capability of the marking system software

allows you to control the laser from remote I/O devices. Remote

communications can be performed by connecting to a Host computer,

an optional I/O card, or an optional TMC090 Auxiliary Controller.

The rear panel of the controller also provides a connector to

monitor output signals that report the status of the shutter, laser

emission, and fault conditions.

Host Communications. Remote communications may be

executed from a host computer using RS-232 or Ethernet

(TCP/IP) connections to the system computer (i.e., the PC

running the Telesis laser marking software). The software

provides parameters to define the data transmitted to and from

the host. For more information on using and configuring these

parameters, refer to the Operation Manual supplied with the

laser marking software.

I/O Card. Telesis offers an optional I/O card that allows for an

additional six input and six output signals. The I/O card is

available in the following kits. For more information on using

the optional I/O card, refer to the Telesis Optional I/O Card

Installation Supplement supplied in each of these kits.

Kit #53920 This kit is available for all Telesis laser

systems. It includes the I/O Card, SIPs resistor

packs (pre-installed), the software driver CD,

and installation documentation.

This kit does not provide opto-isolated signals.

If this kit is used, it is the responsibility of the

installer/integrator to provide opto-isolation

between remote I/O devices and the I/O card.

Refer to the OEM User’s Guide for signal

limitations.

Note: Telesis does not endorse direct

connection of I/O signals to the I/O

card. Direct connections to high

current/high voltage devices will

damage the card.

Kit #53928 This kit is available for all laser systems that

use the Merlin-II LS Laser Marking Software.

It includes Kit #53920 (above), plus the Telesis

I/O Interface Module and two cable assemblies.

This kit provides opto-isolated signals between

remote I/O devices and the I/O card through the

Telesis I/O Interface Module. Additional opto-

isolator board assemblies or opto-isolated I/O

rack assemblies are not required when the

interface module is used.

TMC090 Controller. Telesis offers an optional TMC090

Controller for all laser systems that use the Merlin-II LS Laser

Marking Software. The TMC090 Controller provides an

interface for connecting six input and six output signals to and

from the laser marking system, and for connecting the optional

auxiliary axes: vertical (Z) axis, rotational (Theta) axis, and

linear (L1 and L2) axes. For details, refer to the TMC090

Installation/Maintenance Manual supplied with the controller.

XPRESS™ EP /TLM Laser Marking System

Doc. No. 40213 – 6 of 6

Communications Protocol

Two types of host interface are supported (RS-232 or TCP/IP) and

two communication protocols are provided through the Merlin-II

LS marking system software (Programmable and Extended).

Programmable Protocol. Programmable protocol provides one-

way (receive only) communication with no error checking or

acknowledgment of the transmitted data. You may use

Programmable protocol to extract a continuous portion of a

message string to print. This can be used with a host computer or a

bar code scanner. Note that XON/XOFF Protocol applies even

when Programmable Protocol is selected.

The Programmable Protocol Message Type identifies the type of

message sent from the host. It determines how the marker uses the

data it extracts from the host message string when Programmable

Protocol is used.

49 Message type 49 ("1") overwrites the content of the first

text-based field in the pattern with the data extracted from

the host message. Note that if the field contains message

flags, they will be overwritten, not updated.

72 Message type 72 ("H") updates the Offset X/Y

parameters with the data extracted from the host message.

Syntax for the transmitted string is ±X.X,±Y.Y where ± is a

positive or negative sign, X.X represents the X-axis offset

distance, and Y.Y represents the Y-axis offset distance.

80 Message type 80 ("P") indicates the data extracted from

the host message is the name of the pattern to be loaded.

81 Message type 81 ("Q") updates the text in the first query

text buffer (buffer 0) with the data extracted from the host

message.

86 Message type 86 ("V") updates the text in the first

variable text field in the pattern with the data extracted from

the host message.

118 Message type 118 ("v") updates the first text field

encountered in the pattern that contains a variable text flag

that matches the specified string length.

If the host is providing the Message Type within the transmitted

text string, enter "0" in the Message Type parameter text box

displayed on the Programmable tab of the Host/Setup window.

0 Message type 0 (zero) indicates that the host will provide

the message type, field number (if applicable), and data (if

applicable). This option allows more flexibility by

delegating the message type selection to the host on a

message-by-message basis. It also allows you to direct data

to specific fields and/or query text buffers.

The host can use Message Type 0 to provide data to the

marking system. The marking system will insert data

transmitted with the message into the appropriate location.

Communications Protocol (continued)

Extended Protocol. Extended protocol provides two-way

communication with error checking. It is designed to provide

secure communications with an intelligent host device using pre-

defined message formats and response formats. It also provides

error checking using a block check code to detect faults in the

transmitted messages and to verify the data is properly received.

The Extended Protocol Message Type determines how the marker

uses the data it extracts from the host message string or from the

marking system software, as applicable.

1 Message Type "1" can provide data to a text string in the

pattern or poll the pattern for data.

E Message Type "E" allows the host to take the machine

offline. It also provides the option of displaying an error

message box with the provided data string.

V Message Type "V" can provide data to a variable text string

in the pattern or poll the pattern for data.

P Message Type "P" can load a pattern or poll the system for

the current pattern name.

O Message Type "O" places the marker online. This allows a

host computer to reset. For example, this may be used to

recover from a power outage when the marker is

unattended.

G Message Type "G" initiates a print cycle.

Q Message Type "Q" can provide data to the system query text

buffer or poll the system for data.

H Message Type "H" can provide data to the system X/Y

Offset parameters or poll the system for data.

S Message Type "S" is used to poll the system for the machine

status. The machine status is returned to the host in an eight-

character hexadecimal mask.

I Message Type "I" is used to poll the system for the I/O

status.

Table of contents

Popular Measuring Instrument manuals by other brands

Tektronix

Tektronix RSA5100B series Declassification and security instructions

CEM

CEM SMART System 5 Operation manual

Test Equipment Depot

Test Equipment Depot BST-CM273 instruction manual

Agilent Technologies

Agilent Technologies 490 user manual

OHAUS

OHAUS ST Series instruction manual

Fluke

Fluke 5606 user guide