Teletek electronics Loop Tester User manual

1

TECHNICAL AND

OPERATION

MANUAL

Loop Tester

Attention:

This manual contains information on limitations regarding product use and

function and information on the limitations as to liability of the manufacturer.

The entire manual should be carefully read.

The information in this manual is a subject to change without notice!

Loop Tester –Technical and Operation Manual

2

Table of Contents

1. Introduction......................................................................................................................................................3

1.1. General Description..........................................................................................................................3

1.2. Technical Specification.....................................................................................................................3

1.3. Supplied Equipment in the Kit...........................................................................................................3

1.4. Preparing the joint connections.........................................................................................................3

2. Control and Operation Elements ......................................................................................................................4

2.1. Control Unit......................................................................................................................................4

2.2. Buttons’ Functionality........................................................................................................................4

3. Connection Diagrams.......................................................................................................................................4

3.1. Loop Connection..............................................................................................................................4

3.2. Topology Diagrams ..........................................................................................................................5

4. Operation with the Loop Tester........................................................................................................................6

4.1. Switching on the Tester....................................................................................................................6

4.2. Choosing a Language.......................................................................................................................6

4.3. Reading a Topology of a Loop/Line ..................................................................................................6

4.3.1 Reading of Unaddressed Loop/Line (New installations)......................................................6

4.3.2 Reading of Addressed Loop/Line (Present installations).....................................................6

4.4. Perform Cable Tests.........................................................................................................................7

4.4.1 Auto Cable Test.................................................................................................................7

4.4.2 Single Cable Test...............................................................................................................8

4.4.3 Searching for Cable Faults.................................................................................................8

4.5 Perform Loop Tests...........................................................................................................................9

4.5.1 Loop State.........................................................................................................................9

4.5.2 Loop Tools.......................................................................................................................10

4.5.3 Bisection Method for Faults Searching .............................................................................10

4.5.4 Reading Device Parameters.............................................................................................10

4.5.5 Searching Short / Break Faults.........................................................................................11

4.5.6 Searching of Devices in Fire Alarm Mode.........................................................................12

4.5.7 Searching for Branch Position..........................................................................................12

4.5.8 Turn ON/OFF Device LEDs/Sound...................................................................................12

4.5.9 Checking the Operation Current.......................................................................................13

4.6 Addressing Devices Menus .............................................................................................................13

4.6.1 Autoaddressing by ID Number..........................................................................................13

4.6.2 Autoaddressing by Isolator Module...................................................................................14

4.6.3 Selfaddressing of Devices................................................................................................14

4.6.4 Changing the Address of a Device ...................................................................................14

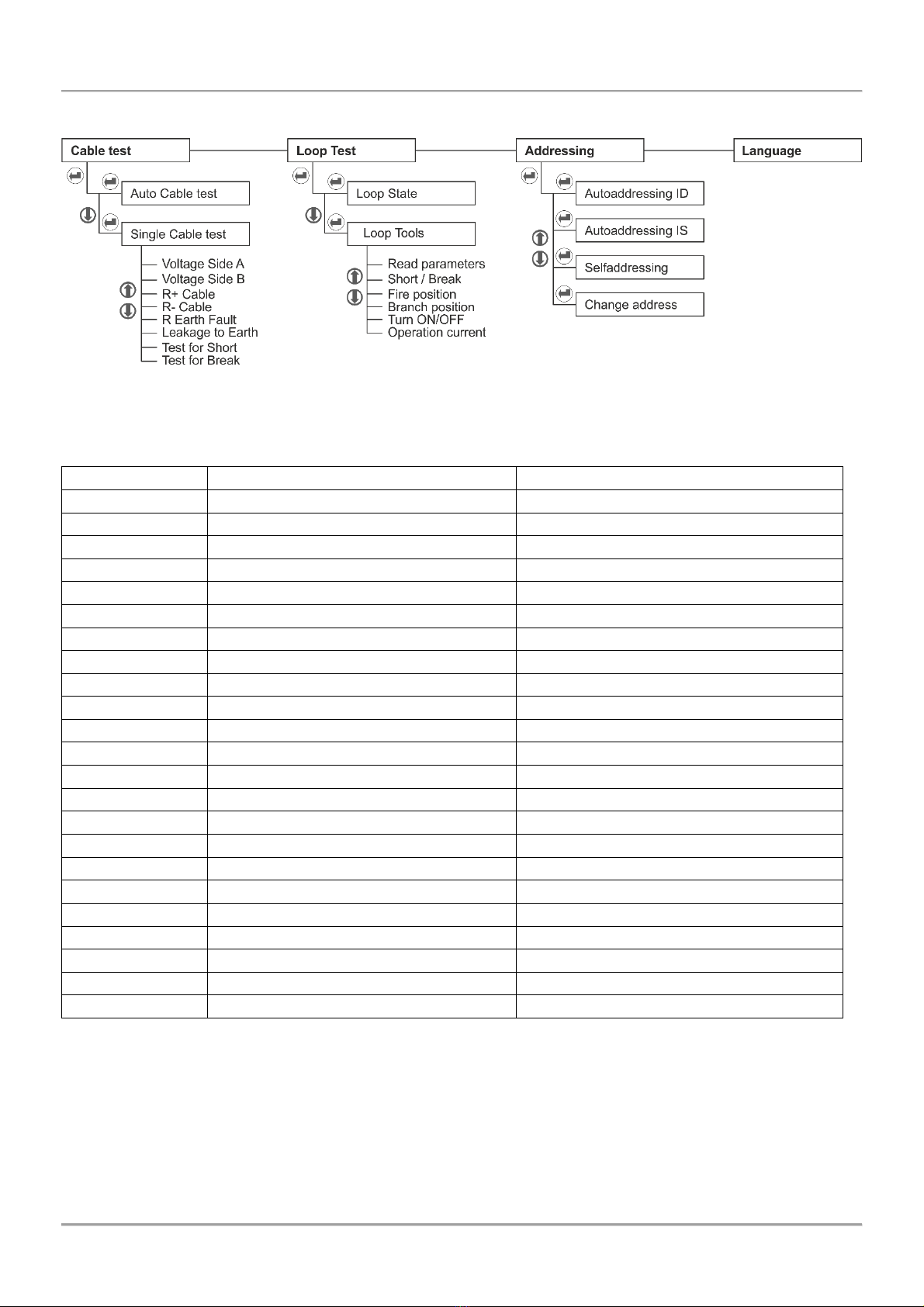

5. Quick Menu Structure....................................................................................................................................15

Appendix –SensoIRIS Devices..........................................................................................................................15

Loop Tester –Technical and Operation Manual

3

1. Introduction

1.1. General Description

The Loop Tester is a diagnostic tool specially designed for operation with addressable devices SensoIRIS series.

The device is suitable for testing the continuity and the technical characteristics of the fire cable and also the

operability of the loop and the connected devices.

The Loop Tester can operate with only one loop line. The switching between the loops of the panel is very easy

using the supplied clamp terminal blocks.

The time for test may vary according the length of the loop and the number of the connected devices.

Important notes:

•During the test the loop line must be disconnected from the control panel!

•DO NOT connect the fire control panel and the Loop Tester to the loop line simultaneously!

•The cable tests have to be done without connected devices to the loop line! If the cable tests are

made with connected devices, you must consider that the measured results would not be exact.

•For exact results in searching short circuits faults, breaks in the loop line and existing branches is

mandatory all devices in the loop/line to be with built-in isolator module –see the corresponding

table for SensoIRIS addressable devices in the Appendix.

•In case of installed devices without isolators in present operating fire alarm systems, you have to

consider that they will be displayed as separate branches in the system. When you have to search

for branches in a system including devices without connected isolator, we recommend to remove

them temporally before starting mentioned above test procedures.

1.2. Technical Specification

•Main Power Supply: AC/DC Switching Adapter; input 100-240VAC, 50/60Hz, 1.5A; output 15VDC, 4A, 60W

•Range of the addresses: 1 ÷ 250

•Multilanguage Menus: YES

•Dimensions: 225 x 102 x 65 mm

•Weight: 340g

•Housing material, color: ABS, white

•Nominal Operating Temperature: -5°C ÷ 40°C

•Storage temperature: -20°C ÷ +70°C

•Related Humidity: ≤93% @ +40°C

1.3. Supplied Equipment in the Kit

•Loop Tester Unit –1 pc

•Power supply adapter –1 pc

•2-Cage clamp connector terminal block with levers –4 pcs

•Conductor wire, red, 120mm, 1.5mm2–2 pcs

•Conductor wire, black, 120mm, 1.5mm2–2 pcs

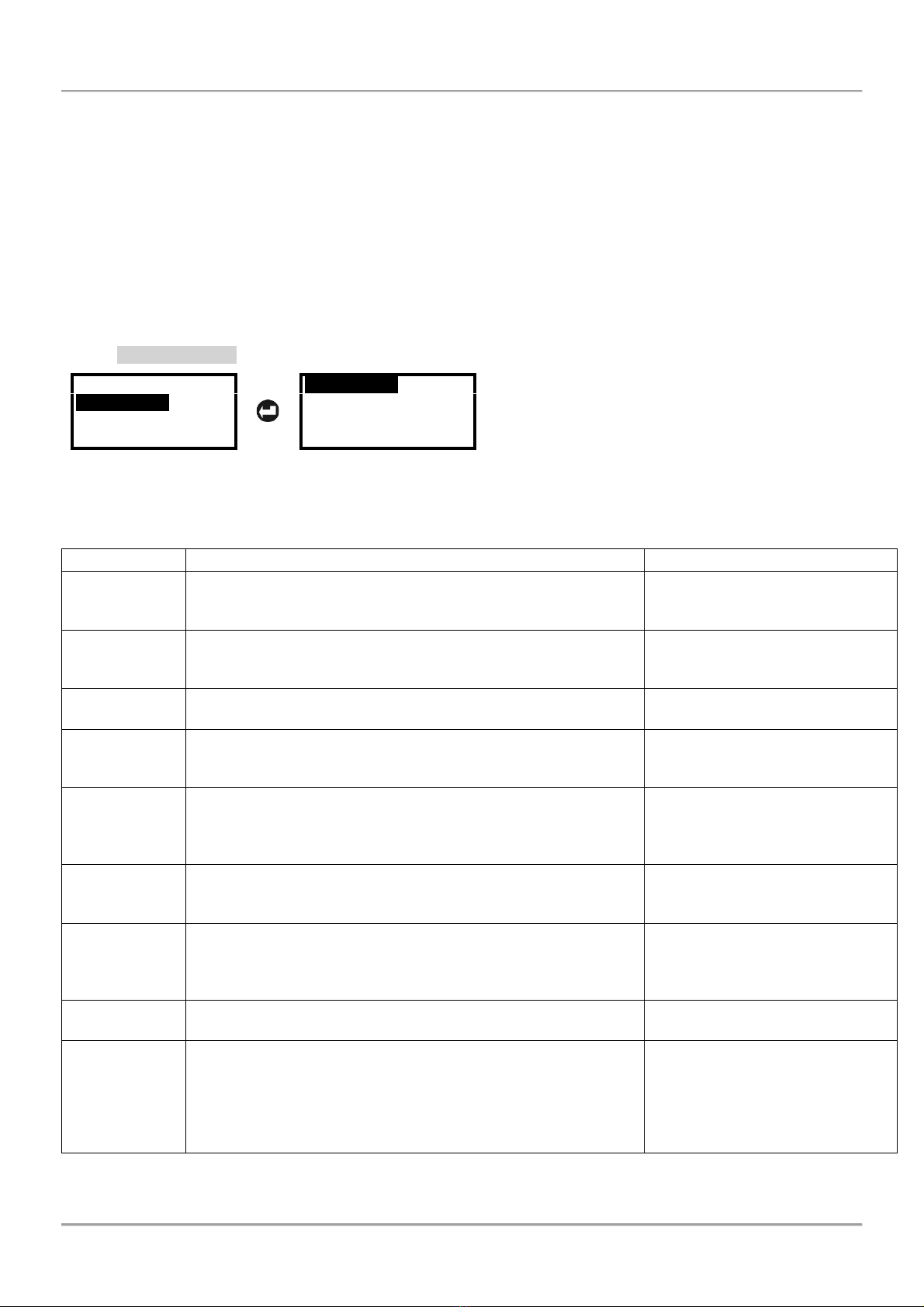

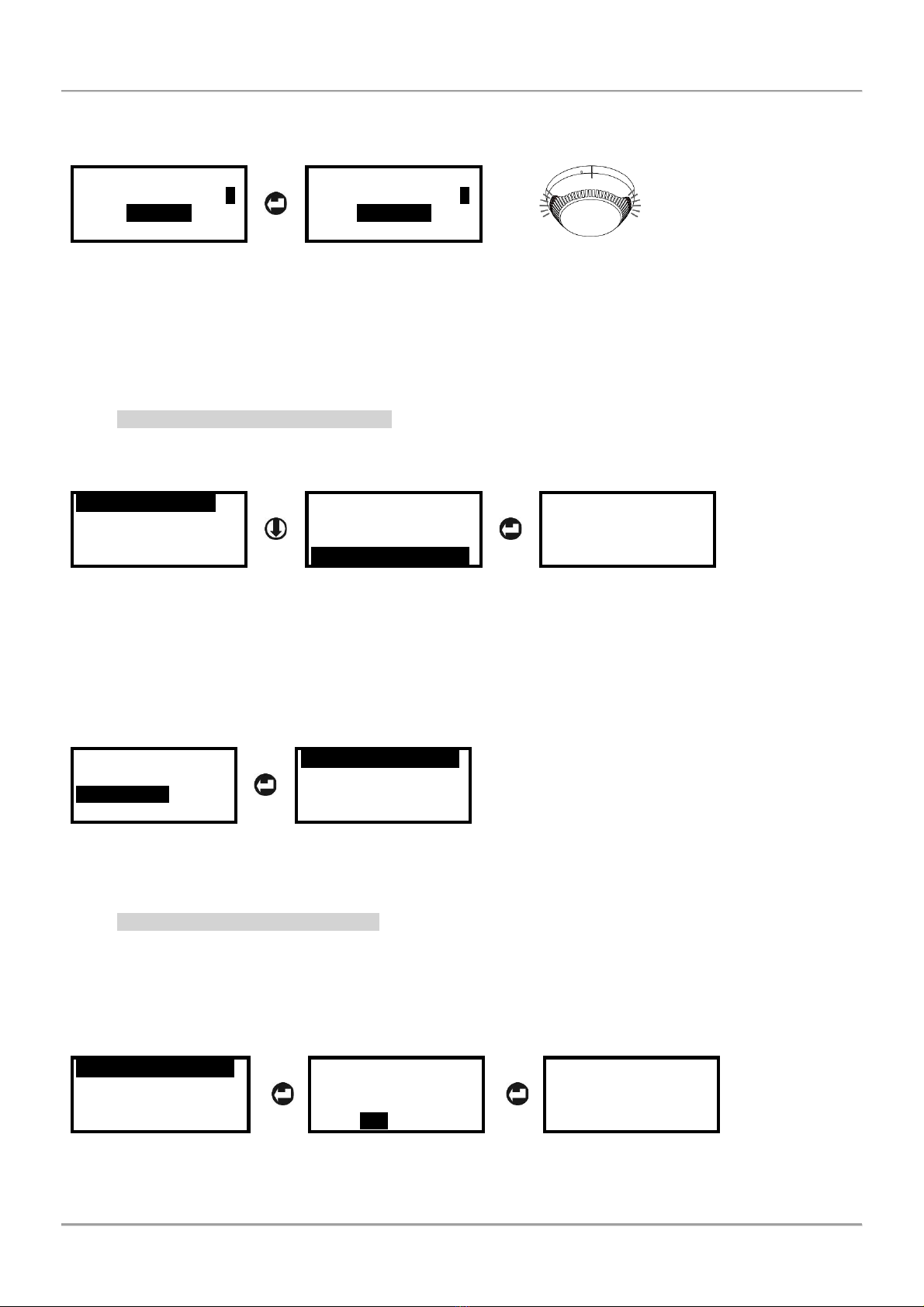

1.4. Preparing the joint connections

The Loop Tester is delivered with a set of wires (2 red and 2 black) and clamp terminals for easier connection to the

loop line. You can prepare the joint connections in advance and then follow the description in item 3. Connection

diagrams. Use conductor wires with cross-section from 0.14 to 4.00 mm².

Strip the wire to 11 mm length.

Lift the lever to open the clamp block.

Insert the stripped wire.

Push the lever backwards to close

the clamp block.

Loop Tester –Technical and Operation Manual

4

2. Control and Operation Elements

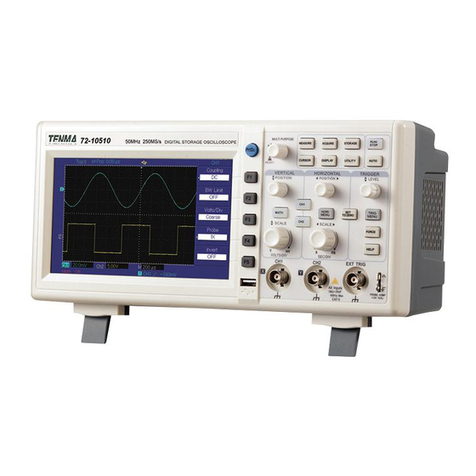

2.1. Control Unit

View from above

1 –Terminal block for connection to the loop line.

2 –LCD text display.

3 –Operation control buttons.

4 –Socket for switching the external power supply adapter.

5 –ON/OFF power switch.

6 –Micro USB port for firmware and software updates.

View at the bottom

2.2. Buttons’ Functionality

Button

Function

Description

Enter

- Confirmation of set parameters.

- Starting a test or addressing procedure.

- Turn ON/OFF of device LED indication.

Up

- Scrolling up the menus.

Modify

- Increasing the numeric digit with one unit.

Down

- Scrolling down the menus.

Right (Move)

- Moving the cursor on left/right.

Esc

- Reject the set parameters.

- Exit (one step back) from a sub- or main menu.

- Cancelation of test or addressing procedure.

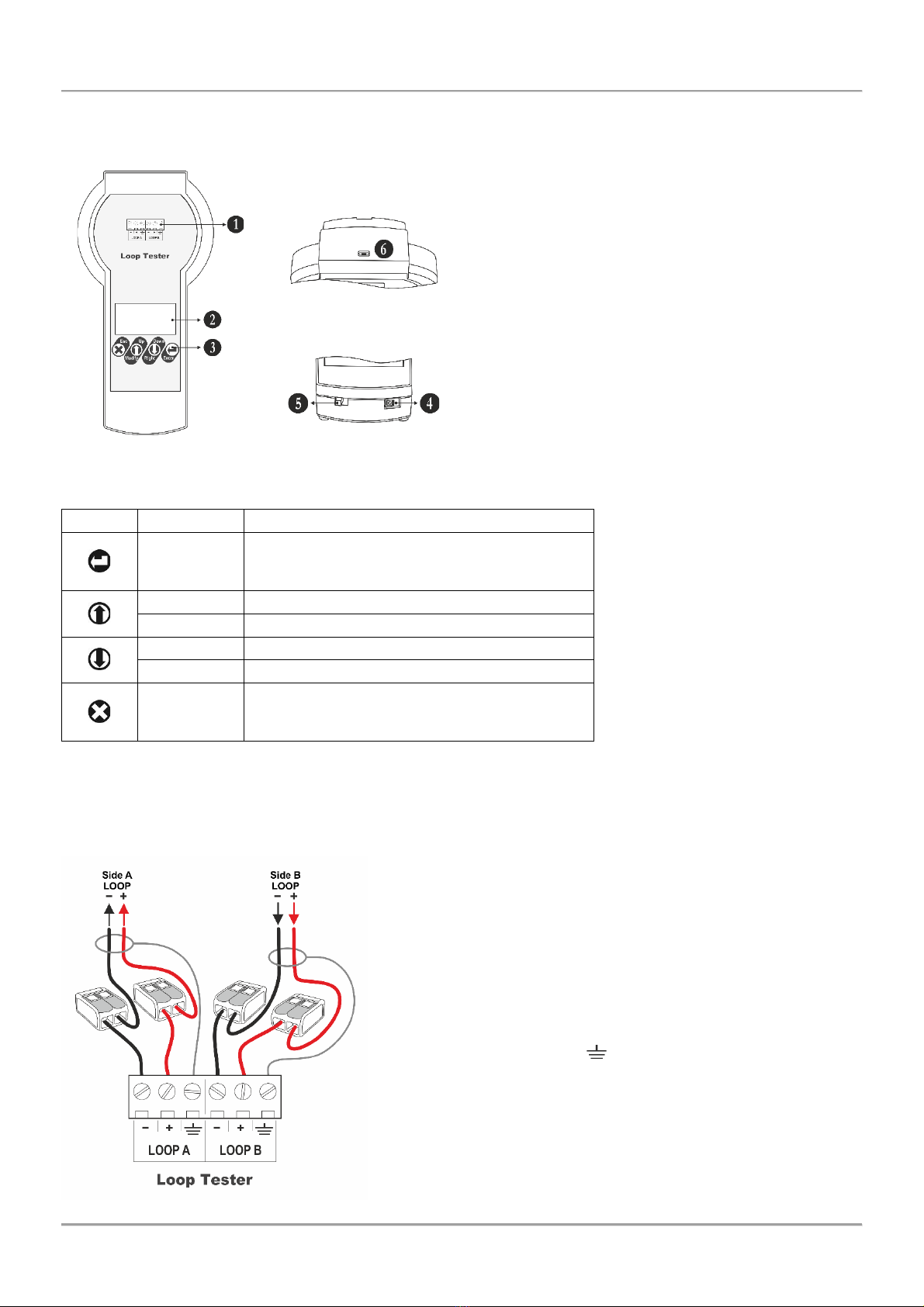

3. Connection Diagrams

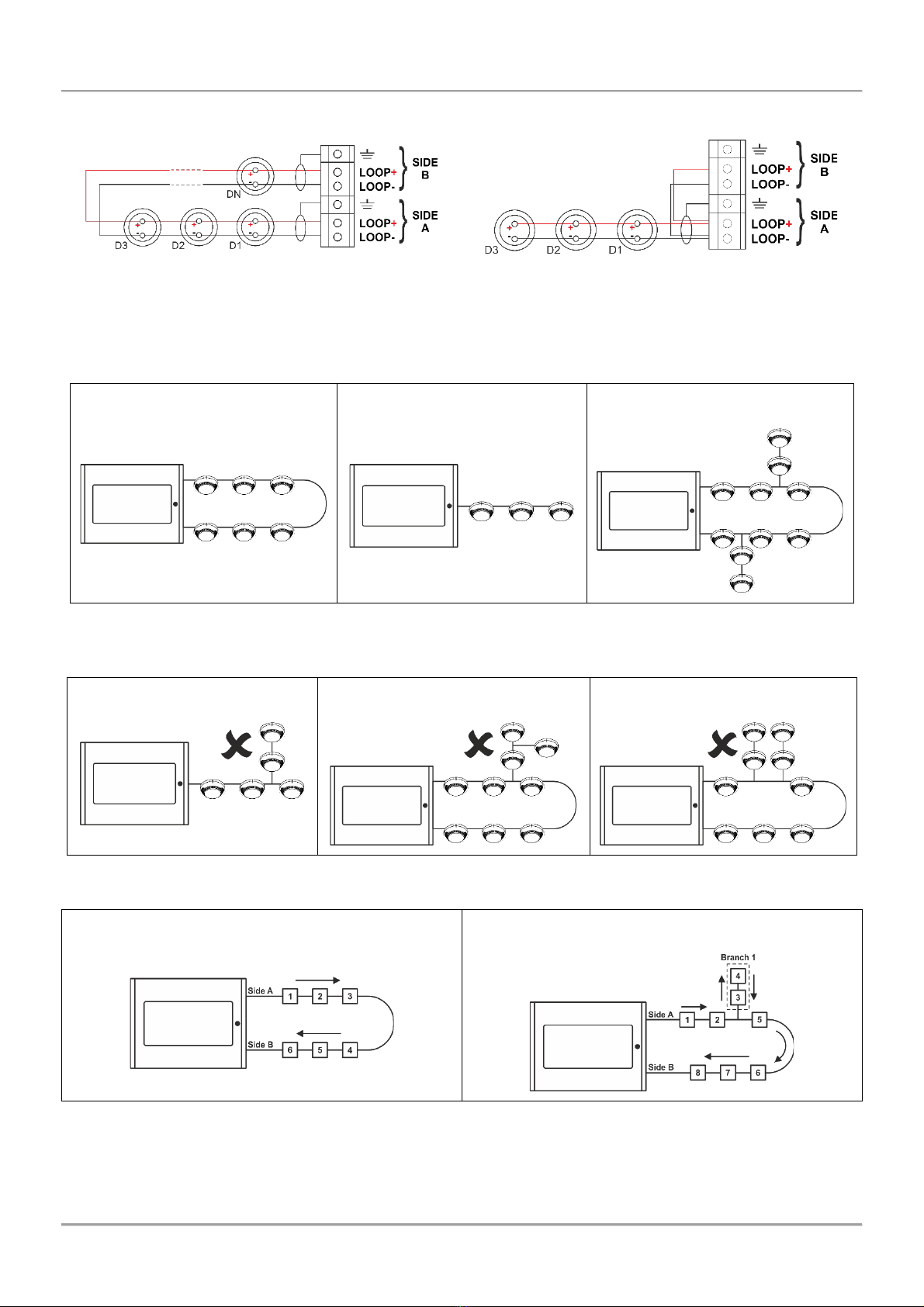

3.1. Loop Connection

Attention:

The loop line must be disconnected from the control panel before

connection to the Loop Tester!

DO NOT connect the fire control panel and the Loop Tester to the

loop line simultaneously!

Connect the four ready joint connections (clamp terminal + wire) to the

terminal row of the Loop Tester as strictly observe the polarity.

Connect the loop ends (side A and side B) to the respective clamps

connected to the terminal row of the Tester. Connect the shield ends

of the loop wires to the GND ( ) terminals of the Tester.

In case of a connection to a single line, connect to the Loop Side A

terminals of the tester, and use bridge connections along to Loop side

B terminals.

Loop Tester –Technical and Operation Manual

5

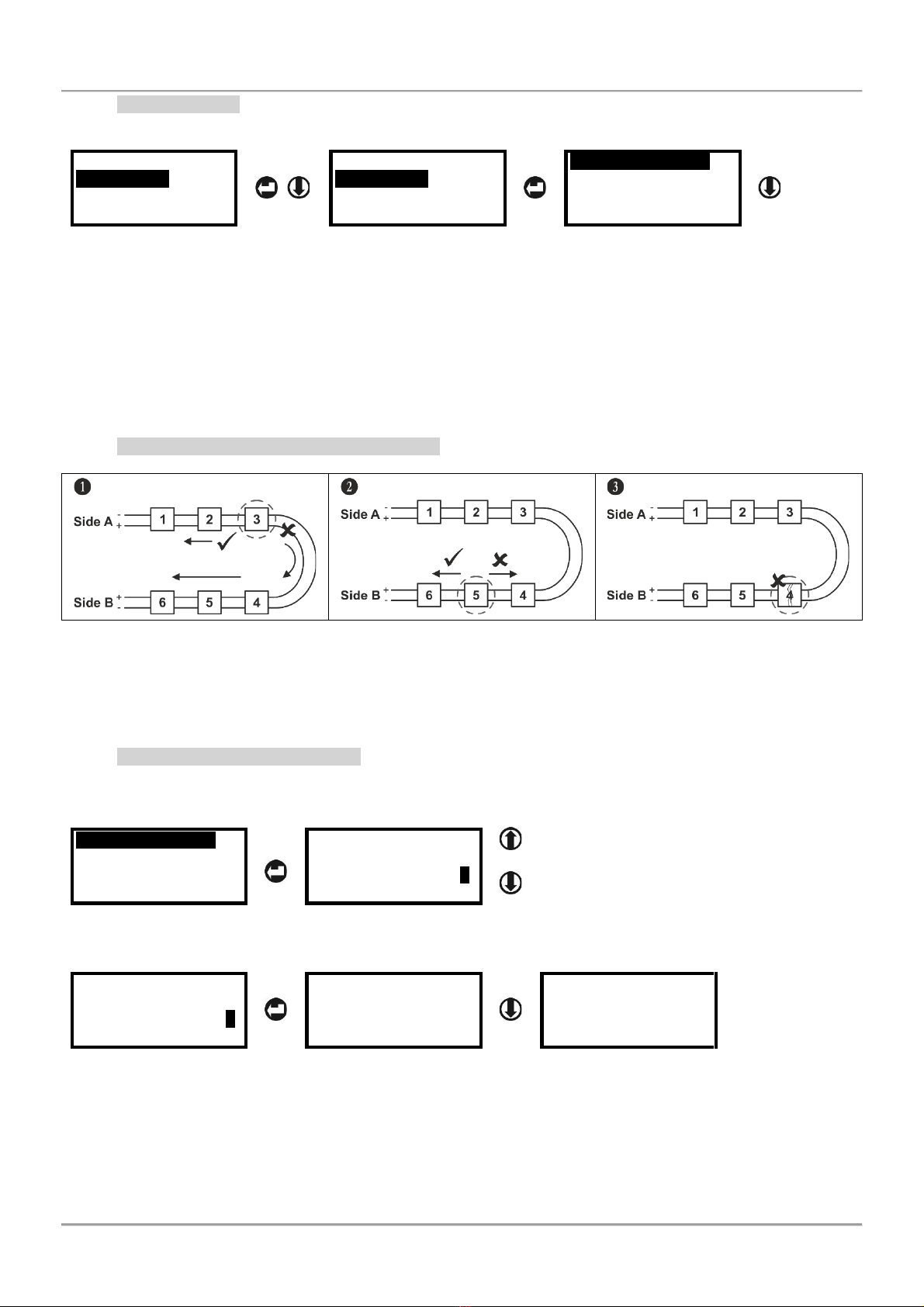

The following pictures represent a loop and single line connection to the Loop Tester terminal rows.

Loop connection

Single Line Connection

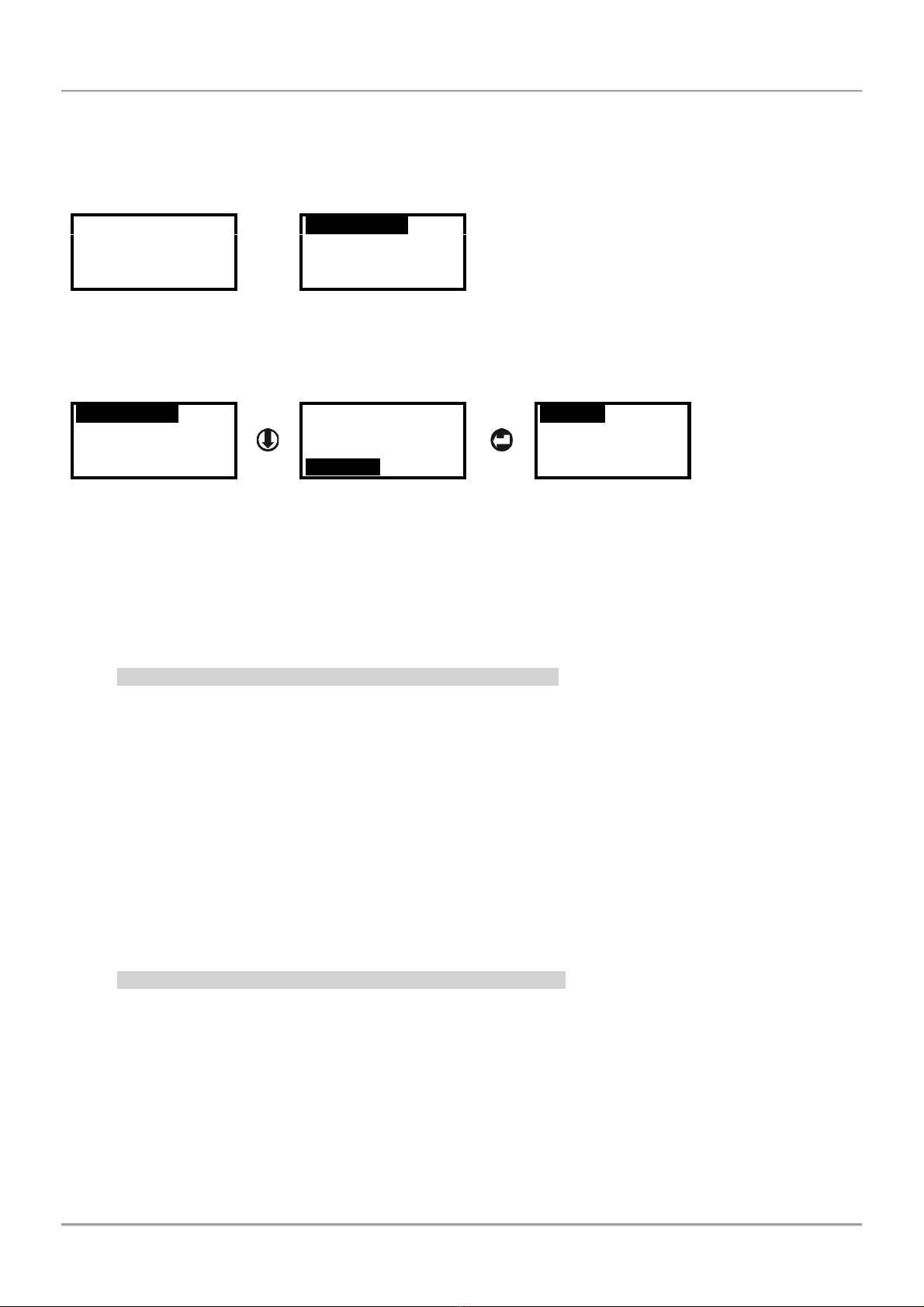

3.2. Topology Diagrams

The following topology types are allowed to be used for connection of SensoIRIS series addressable devices:

Loop

Single line

Loop with branches

The following topology types are not allowed to be used for connection of SensoIRIS series addressable devices. In

case of such connection found in the connection loop/line during addressing procedeure by isolator (see item 4.6.2),

the Loop Tester will display an error message “Branch in Branch” and will abort the operation.

Branch on a single line

Sub-branch of a branch on a loop

Branches without separation

In case of starting a test procedure of an unaddressed loop, the Loop Tester will set sequential addresses to the

devices according their order in the loop:

Addressing order in a loop

Addressing order in a loop with branch

Loop Tester –Technical and Operation Manual

6

4. Operation with the Loop Tester

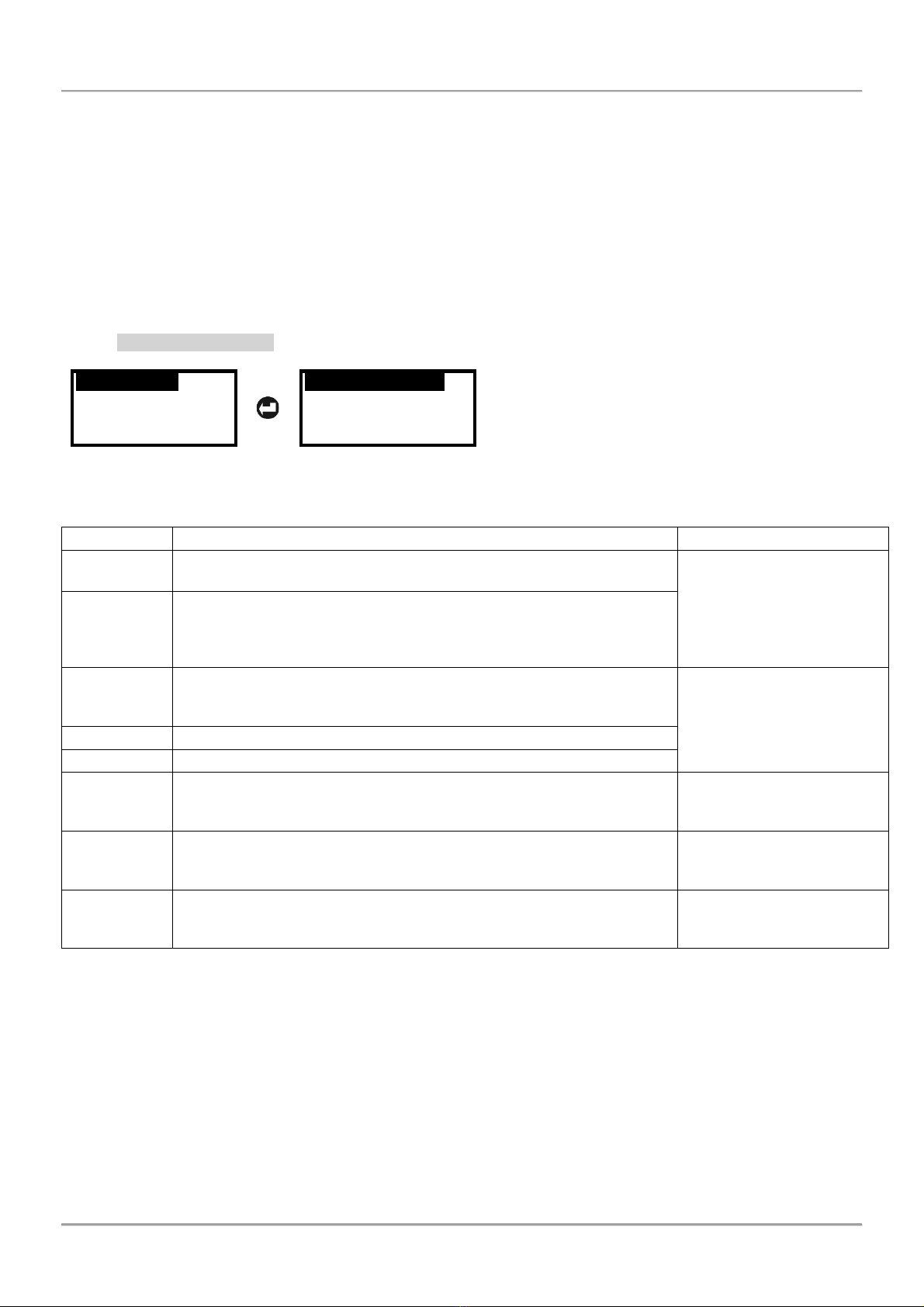

4.1. Switching on the Tester

Power on the Loop Tester with the switch (item 2.1, position 5) moving in ON position. The display will show for a

while the software version of the device and then will display the main operation menus.

SW ver: 1.2

Cable tests

Loop Tests

Addressing

Language

4.2. Choosing a Language

The default set language is English. To set other available language for the setting menus, use the down arrow

button to select Language menu and press ENTER button.

Cable tests

Loop Tests

Addressing

Language

Cable tests

Loop Tests

Addressing

Language

English

Български

Italiano

Español

Use the arrows to select the language and confirm the choice with ENTER button. The menus will automatically

switch to the new set language.

4.3. Reading a Topology of a Loop/Line

The Loop Tester operation (test and addressing procedures) always starts from Loop Side A to Loop Side B –see

item 3.1. A list with avaliable devices in the loop/single line is reviewed in menu Loop Tests –Loop State (see item

4.5.1). The devices are displayed as a list according their set address in the system.

4.3.1 Reading of Unaddressed Loop/Line (New installations)

The advantage of the Loop Tester is that it is possible to read and test the characteristics of the fire cable,

connections in a loop or a line, and the mounted addressable devices for the site in advance, before connection to

the fire alarm control panel. In new installations the connected devices have no set addresses and the technician

has to address them first to perform the loop testing.

To perform testing of a new installation (unaddressed devices) follow the steps:

1. Connect the loop/line wires to the Loop Tester terminals as described in item 3.1.

2. Switch on the Loop Tester.

3. Enter in menu “Loop Test” and choose sub-menu “Loop Tools”. Select a test and press ENTER.

4. Select the option “Unaddressed loop” and confirm. Starting the procedure, the Loop Tester will set

sequential addresses to the devices according their order in the loop.

Note: You can run the addressing procedure again and change the set addresses later, when the loop is finally

connected to the fire alarm control panel.

4.3.2 Reading of Addressed Loop/Line (Present installations)

Attention: When you use the Loop Tester for diagnostic of present and already operating fire alarm

installation, it is strongly recommended first to save the existing configuration using specialised ProsTE

programming software!

To perform testing of a present installation (addressed devices) follow the steps:

1. Read the panel configuration with ProsTE software and save it as *TDF data file.

2. Power off the fire panel.

3. Disconnect the loop wires from the loop expander terminals.

4. Connect the loop/line wires to the Loop Tester terminals as described in item 3.1.

5. Switch on the Loop Tester.

6. Enter in menu “Loop Test” and choose sub-menu “Loop Tools”. Select a test and press ENTER.

7. Select the option “Addressed loop” and confirm.

Loop Tester –Technical and Operation Manual

7

4.4. Perform Cable Tests

This is a menu for performing test of the fire cable used in the installation. The test can be fully automatic or

manually selected separate single tests for different electrical values. It is recommended to run first the automatic

test for reviewing the general state of the cable and then, if it is necessary, to proceed with single tests.

The performed tests are for searching breaks, short circuits or earth fault of installed cable, which can disturb the

operability of the loop line.

Attention: The tests must be performed with no connected devices to the cable. If there are connected

devices, they have to be disabled or dismounted before running the desired tests.

Select Cable test menu and confirm with the ENTER button. Then choose auto or single cable test.

4.4.1 Auto Cable Test

Cable tests

Loop Tests

Addressing

Language

Auto Cable test

Single Cable test

Select this sub-menu to perform fully automatic test of the electrical characteristics of the cable. While the test is

running on, the message “Please Wait” is shown on the display. The time for test may vary according the length of

the cable.

The results from the test are shown as a list with values and can be reviewed (scrolling up/down) with arrow buttons:

Value

Description

Range limits/Messages

Ua

Measured voltage from the Loop side A. The side A is powered on and

then the voltage is measured at the same side of the loop.

15-32V

Ub

Measured voltage from the Loop side B. The side A is powered on,

then the side B is powered on and the voltage is measured at side B of

the loop. The measurement gives an idea for the voltage drops (from

side A to side B), electrical current value and cable resistance.

R+

The resistance of the positive cable wire. In case “Too High” message

is displayed that means there is a break in the cable or a bad contact

in the joint connections.

< 250 Ohm –Normal

250 - 400 Ohm –High

> 400 Ohm –Too High

(see item 4.4.3)

R-

The resistance of the negative cable wire. Same as described for “R+”.

Re

The resistance of the earth cable. Same as described for “R+”.

Earth Fault

Shows the presence of earth fault problem (or leakage to earth) of the

positive or negative wire of the cable* (see item 4.4.3).

None –No fault

Yes –Earth fault detected

in the cable

Short in cbl.

Shows the presence of short-circuit fault between the positive or

negative wire of the cable* (see item 4.4.3).

None –No fault

Yes –Short-circuit fault

with the cable

Break in cbl.

Shows the presence of breaking in the cable* (see item 4.4.3).

None –No fault

Yes –Break fault with the

cable

* Note: Use the bisection method for finding and location of the exact place of the fault. The method is described in

item 4.5.3.

Loop Tester –Technical and Operation Manual

8

4.4.2 Single Cable Test

Cable tests

Loop Tests

Addressing

Language

Auto Cable test

Single Cable test

Voltage side A

Voltage side B

R+ Cable

R- Cable

In “Single Cable test” sub-menu, all cable tests (see the table in item 4.4.1) are manually selected and performed

according the current needs of the technician. You can scroll with up and down arrow buttons to review the rest of

the possible test. The selected test is started with pressing ENTER button. To reject a started test press ESC button.

To escape from the “Cable Tests” menus press ESC button several times.

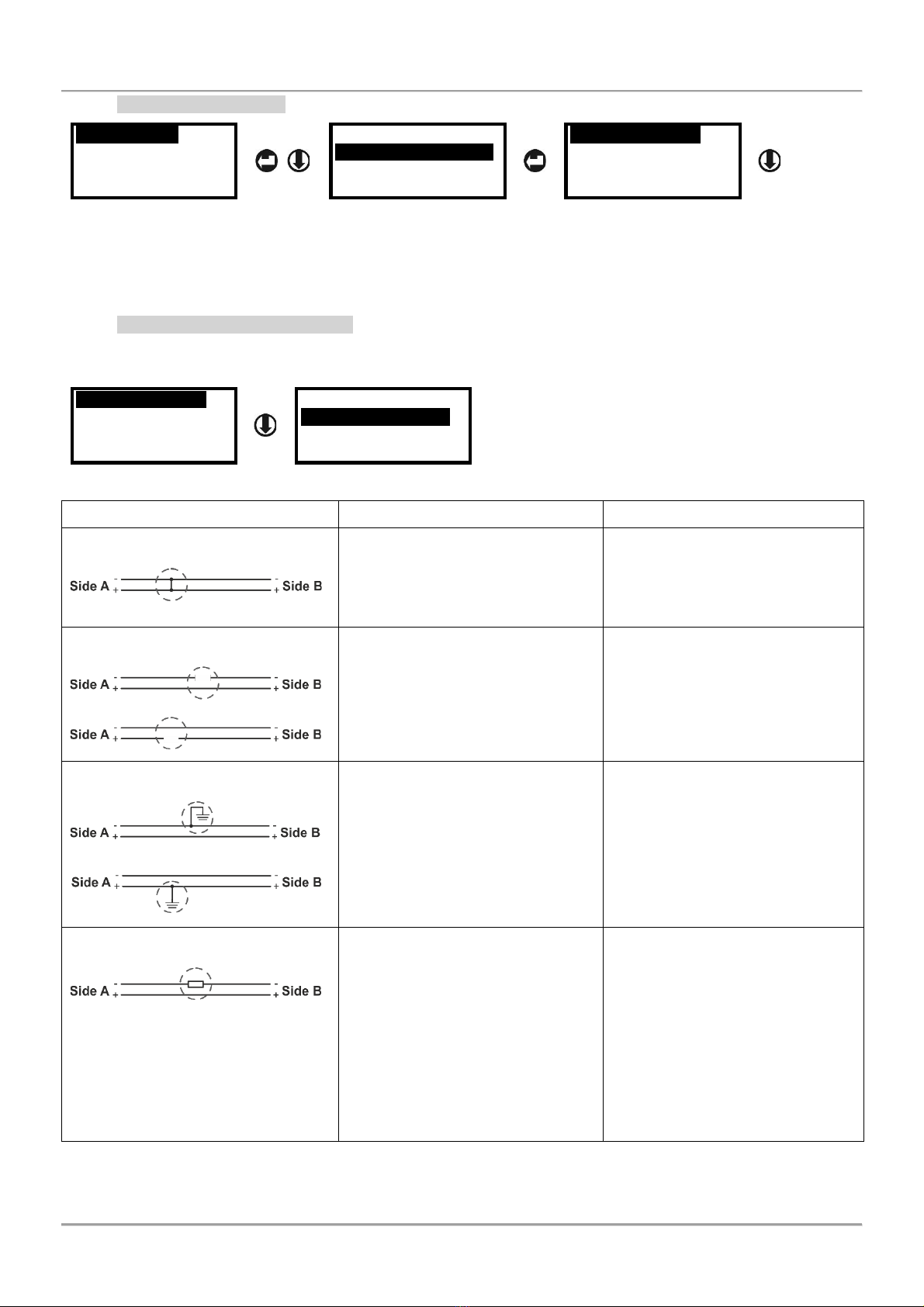

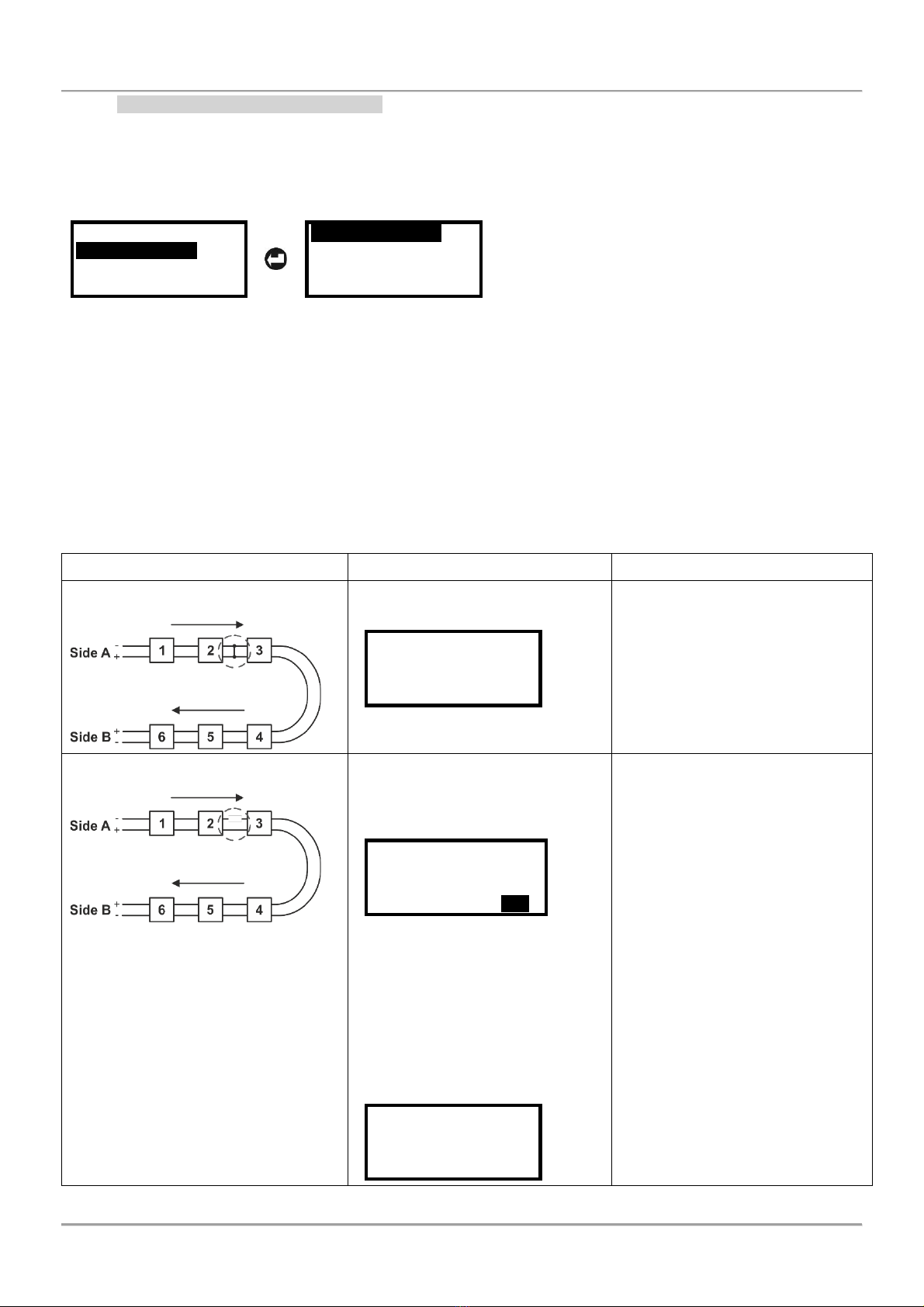

4.4.3 Searching for Cable Faults

If an error message is displayed in “Auto Cable Test” menu, you can run the separate single test again and locate

the exact place of the fault. Select a test using the arrows and run it with ENTER button.

Voltage side A

Voltage side B

R+ Cable

R- Cable

R Earth Cable

Leakage to Earth

Test for Short

Test for Break

Fault Diagram

Description

Solution

Short-circuit in the cable

Run singe test “Test for Short”

again to confirm the presence

short-circuit in the cable. In case of

fault the tester will display message

“Short in Cable”.

To locate the place of the short-

circuit fault use Bisection method

as dividing the cable in equal parts

(1/2, 1/4, 1/8, etc), until finding the

faulty section. See also item 4.5.3.

Break in the cable

Run singe test “Test for Break”

again to confirm the presence

break in the positive or negative

cable wire. In case of fault the

tester will display message “Break

in Cable”.

To locate the place of the break

use Bisection method as dividing

the cable in equal parts (1/2, 1/4,

1/8, etc), until finding the faulty

section. See also item 4.5.3.

Earth fault in the cable

Run singe test “Leakage to Earth”

again to confirm the presence earth

fault in the positive or negative

cable wire. In case of fault the

tester will display message “Earth

fault”.

Search the earth fault as inspect

the grounding components in the

cable line, corrupted shield of the

cable, etc.

You can also use and the Bisection

method described in item 4.5.3.

Too High resistance

According the result in the Auto

Cable Test menu run the single test

for:

“R+ Cable”

“R- Cable”

“R Earth Cable”

In case of unusual high resistance

found the tester will display

message “R+/R-/Re=Too High”.

The error message “Too High” is

displayed when the detected

resistance in the positive cable

wire (R+), negative cable wire (R-)

or earth cable (Re) is higher than

400 Ohm. In such cases, it is

recommended to check the cable

and the joint connections

(terminals, base contacts). Check

also the cable length –it might be

too long.

Loop Tester –Technical and Operation Manual

9

4.5 Perform Loop Tests

This is a menu for performing test of the loop and the connected devices. It is recommended to run first the “Loop

state” automatic test for reviewing the general state of the loop and a list of the connected devices. The general

review will help you at the beginning to orientate for current faults, possible breaks or short-circuits in the loop, the

number of connected devices and troubles with them.

Attention: To perform more precise tests it is obligatory to use the built-in isolator module for all modules

and call points connected to the loop. It is recommended to use detectors and sounders with bult-in isolator

module (see the table in the Appendix). In installations where, detectors and sounders without built-in

isolators are already being used, the results for searching branches and localization of short-circuits and

break in the loop can be uncertain. In this case it is recommended for more precise results in searching of

errors to be performed and the bisection method (see item 4.5.3).

4.5.1 Loop State

Cable tests

Loop Tests

Addressing

Language

Loop State

Loop Tools

Select “Loop State” menu and press ENTER. The message “Please wait” and a process bar are shown during

analysing the current loop state. The time for reading data can vary according the length and the number of

connected devices.

The general information is displayed as a list with short messages for the state and can be reviewed (scrolling

up/down) with arrow buttons:

Parameter

Description

State Messages

Short Side A

Shows the presence of short circuit at Loop Side A. In case of

fault “Yes” message, you can perform a detailed search using

menu “Loop Tools” – “Short / Break” (see item 4.5.5).

None –No fault

Yes –Short circuit detected at

side A.

Short Side B

Shows the presence of short circuit at Loop Side B. In case of

fault “Yes” message, you can perform a detailed search using

menu “Loop Tools” –“Short / Break” (see item 4.5.5).

None –No fault

Yes –Short circuit detected at

side B.

Earth Fault

Shows the presence of earth fault in the loop.

None –No fault

Yes –Earth fault detected.

Loop Break

Shows the presence of break in the loop. In case of fault “Yes”

message, you can perform a detailed search using menu “Loop

Tools” – “Short / Break” (see item 4.5.5).

None –No fault

Yes –Loop break detected.

Noaddr. Dev.

Shows the presence of devices with no set address in the loop.

Note: A possible reason for presence of devices with no set

address is performing the Loop State test for an unaddressed

loop.

None –No unaddressed devices

XXX –Number of found

unaddressed devices

Dbl. address

Shows the presence of devices with double address in the loop.

None –No double addresses

XXX –Number of found double

addresses

Num devices

Shows the current number of the addressed devices in the

loop.

Note: The number of unaddressed devices and devices with

double address are not included into this number.

XXX –Number of addressed

devices

Op. curr.

Shows the operating current of the loop. This is average

consumption of the connected devices.

Up to 500mA

Devices Table

Shows a list of the available devices and their set address in the

system. Note: The found devices with double address are listed

at the bottom of the table. The presented numbers for them are

not real addresses. In this case is recommended to perform an

addressing procedure for the loop and run the Loop State test

again.

-

Loop Tester –Technical and Operation Manual

10

4.5.2 Loop Tools

In this menu are available some test for finding troubles in existing loop installation.

Cable tests

Loop Tests

Addressing

Language

Loop State

Loop Tools

Read parameters

Short / Break

Fire position

Branch position

In the “Loop Tools” menu are included the following operations for precise finding of troubles and devices in the loop

configuration. You can scroll with up and down arrow buttons to review the rest of the available operations:

•Read parameters

•Short / Break

•Fire position

•Branch position

•Turn ON/OFF

•Operation current

4.5.3 Bisection Method for Faults Searching

1. Divide the loop into two separate equal lines. Measure the voltage at each line.

2. Divide the faulty line in the center. Restore the earlier connection in the correct line. Measure again the voltage at

each line. Thus, you will be able to locate the fault section.

3. Proceed in this way of dividing the faulty section in the center reducing the possible area with fault.

4.5.4 Reading Device Parameters

The “Read parameters” menu is for reviewing the type and some specific information for a device. Select “Read

parameters” and press ENTER button. Then using the arrows enter an address number - the buttons functionality is

described in item 2.2.

Read parameters

Short / Break

Fire position

Branch position

Read parameters

Enter Address 001

- Increasing values with one unit.

- Move the cursor between digits.

To read the parameters for the device of the selected address press ENTER button. The screen displays the

following general information:

Read parameters

Enter Address 001

Type:

Address:

S.No:

SW version:

Address:

S.No:

SW version:

Day Night

•Type –The name of the device –refer to the table in the Appendix for more details.

•Address –The current set address of the device.

•S.No –The serial number of the device, unique 10 digits number.

•SW version –The software version of the device.

•Day/Night –This parameter is available for reviewing only for detectors. In the field is displayed the set

levels for Day and Night operation modes (Low/Normal/Medium/High).

To escape from the “Read parameters” menu, single press ESC button.

Loop Tester –Technical and Operation Manual

11

4.5.5 Searching Short / Break Faults

Attention: To perform accurate tests for finding of Short and Break position in the loop is mandatory all of

the devices in the loop to have a built-in isolator module!

The “Short / Break” menu is for searching the exact place of short-circuit or a break in the loop.

Read parameters

Short / Break

Fire position

Branch position

Addressed loop

Unaddressed loop

According the organization of the system configuration there are two approaches to start test:

•Addressed loop –Use this option, when the devices in the loop are with already set address numbers.

The searching will follow the set addresses in the loop and will display the faults according their order.

•Unaddressed loop –Use this option, when all or some devices are undressed. Before starting the test,

the tester will erase the current addresses and will set new to all devices according the ID number.

After choosing an approach to proceed the tester starts consistent tests for short-circuit and break faults. The test is

started with pressing the ENTER button. During analysing, a message “Please wait” and a process bar are displayed

on the screen. The time for analysing can vary according the length of the loop and the number of faults.

The results are displayed with text messages pointing the place of the fault. Below is presented a quick table for

possible faults.

Fault Diagram

Description and Display

Solution

Short-circuit in the loop

A short-circuit is detected between

devices 2 and 3 in the loop.

Short at:

Dev.Type 002

Dev.Type 003

Locate the place of the displayed

devices and check the cable

section between them.

Tip: You can locate the exact place

of a device as turning ON its LEDs

(or sound signal for sounders) –

see item 4.5.8.

Break in the loop

A break in the loop is detected

between devices 2 and 3 in the

loop. The tester will locate the place

searching from both sides A and B.

Break between:

002 dev from SideA

004 dev from SideB

Find location >>>

The displayed numbers are the

counted devices from the two sides

of the found break. To find the

exact location of the break fault,

press ENTER button and confirm

with “Yes” command to continue.

When the test is over, the screen

displays the address of the device

after which the break is detected.

Break after:

Dev.Type 002

Locate the place of the displayed

devices and check the cable

section between them. The break

in the loop may be caused and

from bad connections to the device

terminals (bad joint contacts to the

base terminals for detectors and

sounders also).

Tip: You can locate the exact place

of a device as turning ON its LEDs

(or sound signal for sounders) –

see item 4.5.8.

Loop Tester –Technical and Operation Manual

12

4.5.6 Searching of Devices in Fire Alarm Mode

In this menu the technician can review if there an activated manual call points in the system. The test can be

performed for checking the correct operation of the connected call point to loop. Select “Fire position” and press

ENTER button. During the analysing process a message “Please wait” and a processing bar are displayed on the

screen. If there are activated manual call points, they will be displayed with their address number.

Read parameters

Short / Break

Fire position

Branch position

Devices in fire:

MCP150 008

MCP150 055

To escape from the “Fire position” menu, single press ESC button.

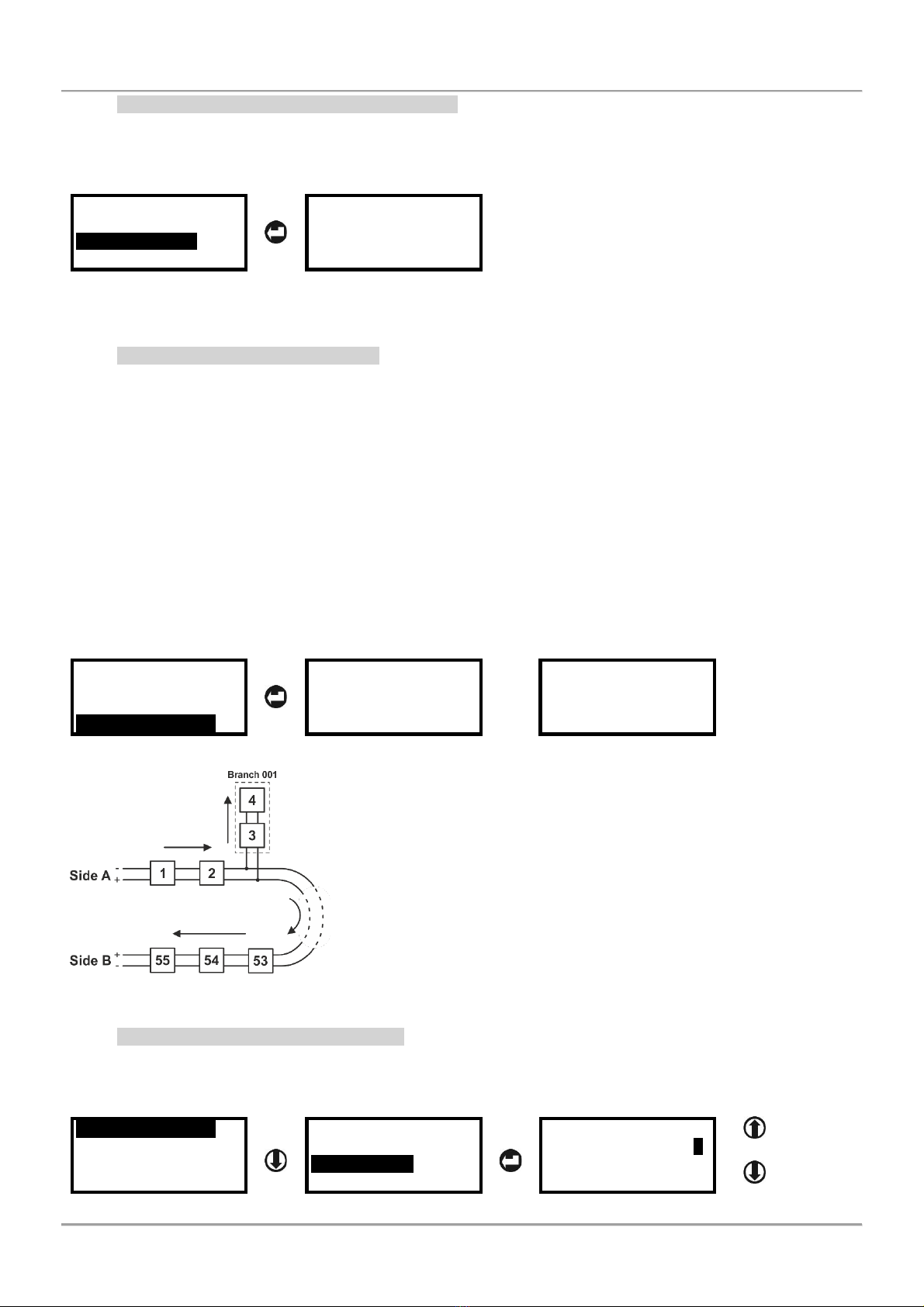

4.5.7 Searching for Branch Position

The branch is a sub-loop to the main loop. The connection topology diagrams are presented in item 3.2.

Attention: To perform accurate localization of the Branch position in the loop is mandatory all of the devices

in the loop to have a built-in isolator module!

In case of presence of devices without isolator, after performing this test they will be reported with type and

address and the branch search will be cancelled. For this reason, the devices without isolator, if present at

the site, must be removed in advance, before performing branch searching.

The presence of Short circuit and Break in the loop will generate an error message and the branch

searching process will be aborted.

Select “Branch position” and press ENTER button. During the analysing process a message “Please wait” and a

processing bar are displayed on the screen. The tester starts searching and during the test will show the total

number of addressed devices found in the loop (note that if a device is removed temporally it will not be included into

this number). At the last row is presented the real time searching as the tester goes through the loop devices.

At the final results screen are displayed the total number of found branches followed by the location where the first

one starts and the number of included devices into it. If there is more than branch into the loop, the list can be

reviewed with the arrow buttons.

Read parameters

Short / Break

Fire position

Branch position

Analysing...

Total devices in

Loop: 055

Started dev.: 001

Numb branches 001

001 Branch at:

M140 IS 003

Dev.in branch:002

Example for representing the described configuration above:

The Branch 001 is started with detector with set address 003, and

includes 2 devices in total (addresses 003 and 004).

You can locate the exact place of all devices included into the branch as

turning ON their LEDs (or sound signal for sounders), starting with the

first one displayed with the tester –see also item 4.5.8.

Note: In real installation the addresses may not be in consecutive order

as displayed in the example. It is recommended when searching for

branches to refer also to the electrical schematic diagrams of the built

fire alarm installation at the site.

4.5.8 Turn ON/OFF Device LEDs/Sound

This is a menu for location of exact place of a device in a fire installation with switching ON its LEDs (or sound signal

for sounders). From the main “Loop tools” menu use down arrow to select the “Turn ON/OFF” sub-menu and press

ENTER button.

Read parameters

Short / Break

Fire position

Branch position

Fire position

Branch position

Turn ON/OFF

Operating current

Turn ON/OFF

Enter address 000

Increasing values

with one unit.

Move the cursor

between digits.

Loop Tester –Technical and Operation Manual

13

Use the arrow buttons to select and address of a device and press ENTER button. A field “Turn ON” is appeared on

the screen. Press ENTER button again to activate the LED indication of the device. The field is changed to “Turn

OFF” and the LEDs of the device are switched on*.

Turn ON/OFF

Enter address 001

Turn ON

Turn ON/OFF

Enter address 001

Turn OFF

To switch off the LED indication press the ENTER button again –the field is changed to “Turn ON”. To select new

address for check, press ESC button –the field “Turn ON” is removed and the section for entering and address

starts blinking waiting new number to be entered.

*Note: For sounders with strobe, together with the LEDindication is switched on and a sound signal. For sounders

without strobe option is turned on only sound signal.

To escape from the “Turn ON/OFF” menu, single press ESC button.

4.5.9 Checking the Operation Current

This is a menu for checking the operation current in the loop –the average consumption of the connected devices in

the loop. The maximum current consumption of the devices in the loop is Imax = 500mA. If the consumption

exceeds this value an over-load protection would be turned on.

Read parameters

Short / Break

Fire position

Branch position

Fire position

Branch position

Turn ON/OFF

Operating current

Op.curr.= 120 mA

To escape from the “Operating current” menu, single press ESC button.

4.6 Addressing Devices Menus

In the “Addressing” section are accessible menus for different type of addressing devices in the loop. The menus are

common with those available in IRIS/SIMPO fire alarm panels. The menus allow performing two auto addressing

procedures by ID number or by isolator module (IS). The self-addressing procedure is used for quick adding of new

devices to free addresses. The last menu is for quick changing the current address of a device.

Cable tests

Loop Tests

Addressing

Language

Autoaddressing ID

Autoaddressing IS

Selfaddressing

Change address

Attention: Performing the auto addressing procedures by ID number and by Isolator module, will erase all

currently set address numbers of the devices in the loop.

4.6.1 Autoaddressing by ID Number

The addressing procedure follows the order of the ID numbers of the devices connected to the line. The order is

according the device type starting with the smallest ID number in the loop: modules, sounders, detectors and manual

call points. It is possible to address devices with and without built-in isolator modules. No restrictions for addressing

detectors into branches.

Select “Autoaddressing ID” menu and press ENTER button. To start the procedure, select “Yes” option and press

ENTER again.

Autoaddressing ID

Autoaddressing IS

Selfaddressing

Change address

Autoaddressing ID

Are you sure?

No

Yes

Autoaddressing ID

Successful

Number addressed

Devices: XXX

After successful addressing a message “Successful” will appear on the screen followed from the total number of

addressed devices. The order of addressing can be reviewed in “Loop State” menu –see item 4.5.1.

To escape from the “Autoaddressing ID” menu, press ESC button.

Loop Tester –Technical and Operation Manual

14

4.6.2 Autoaddressing by Isolator Module

This way requires all of the devices connected to the line to have a built-in or connected to the loop isolator module.

The tester starts the addressing of devices according their place following the order in the loop from side A to side B

–see item 3.1. There are some restrictions for addressing the detectors included into branches –see item 3.2.

Select “Autoaddressing IS” menu and press ENTER button. To start the procedure, select “Yes” option and press

ENTER again. During the addressing procedure, the screen displays the current number of found addressed devices

and the number of found branches.

Autoaddressing ID

Autoaddressing IS

Selfaddressing

Change address

Autoaddressing IS

Are you sure?

No

Yes

Successful

Addressed

Devices: 055

Nmb.branches: 001

After successful addressing a message “Successful” will appear on the screen followed from the total number of

addressed devices and the total number of found branches. The order of addressed devices can be reviewed in

“Loop State” menu – see item 4.5.1. The branch position can be reviewed in “Loop Tools” menus – see item 4.5.7.

Note: The addressing can be unsuccessful in case of found devices without isolator in the loop. In this case a fault

message “Branch in branch” will display on the screen and the addressing is aborted. It is recommended before

starting addressing by isolator module first to remove the devices without isolator module from the loop.

To escape from the “Autoaddressing IS” menu, press ESC button.

4.6.3 Selfaddressing of Devices

During this addressing procedure, the devices are added one by one to the loop (currently the detectors and

sounders are not mounted to the bases; the call points and modules are not connected to the loop).

Select “Selfaddressing” menu and press ENTER button. The tester will starts checking the current configuration as

during the process a message “Please wait” and a processing bar are displayed on the screen. When the reading is

complete the screen displays the total number of found addresses and the next free address in the system.

Autoaddressing ID

Autoaddressing IS

Selfaddressing

Change address

Selfaddressing

Dev. in loop: 055

Next address: 056

Ent. to start

Selfaddressing

Dev. in loop: 055

Next address: 056

ESC to stop

Press ENTER button to begin selfaddressing. Start to mount detectors one by-one. The tester will set the displayed

address number to the mounted device and automatically proceeds with next free address in the system. Every

device will confirm the new set address: with LED indication and/or with sound signal for sounders.

When all the new devices are added press ESC button to stop the procedure.

4.6.4 Changing the Address of a Device

In this menu the technician can change the current address of a device.

Select “Change address” menu and press ENTER button. The tester will starts checking the current configuration as

during the process a message “Please wait” is displayed on the screen. When the reading is complete the screen

displays two fields for setting the current address and the new address for the device. Use arrow buttons to set

address for changing and press ENTER button. The field “Set new addr” becomes active. Set the new address and

press ENTER to confirm.

Autoaddressing ID

Autoaddressing IS

Selfaddressing

Change address

Change address

Current addr: 001

Set new addr:

Change address

Current addr: 001

Set new addr: 009

After successful changing a message “Successful” will appear on the last row of the screen.

If “Busy new address” message is displayed on the last row that means the selected new address is already used in

the system configuration. In that case press ESC button to start the procedure again.

If “No device at:” message followed from an address number is displayed, that means no real device is found on the

current set address. In that case press ESC button to start the procedure again.

Loop Tester –Technical and Operation Manual

15

5. Quick Menu Structure

Appendix – SensoIRIS Devices

Device Name

Description

Isolator Module Available

S130

Optical-smoke detector

No

S130 IS

Optical-smoke detector

Yes (built-in)

T110

Temperature detector

No

T110 IS

Temperature detector

Yes (built-in)

M140

Combined detector

No

M140 IS

Combined detector

Yes (built-in)

MCP150

Manual call point

Yes (must be connected during installation)

WSOU

Sounder

No

WSOU IS

Sounder

Yes (built-in)

WSST / WS

Sounder and strobe

No

WSST IS / WS IS

Sounder and strobe

Yes (built-in)

BSOU

Base with sounder

No

BSOU IS

Base with sounder

Yes (built-in)

BSST

Base with sounder and strobe

No

BSST IS

Base with sounder and strobe

Yes (built-in)

MIO 04

Module with 4 outputs

Yes (must be connected during installation)

MIO 40

Module with 4 inputs

Yes (must be connected during installation)

MIO 22

Module with 2 inputs/2 outputs

Yes (must be connected during installation)

MIO 22M

Module with 2 inputs/2 monitored outputs

Yes (must be connected during installation)

MOUT

Module with 1 output

Yes (must be connected during installation)

MOUT-240

Module 240V interface with 1 output

Yes (must be connected during installation)

MINP M

Mini module with 1 monitored input

No

MC-Z

Conventional zone module

Yes (must be connected during installation)

Table of contents

Popular Test Equipment manuals by other brands

Heathkit

Heathkit VC-3 instruction manual

Bante Instruments

Bante Instruments PHscan30L instruction manual

NeuroTek

NeuroTek Elite Series quick start guide

Wolfgang Warmbier

Wolfgang Warmbier METRISO 3000 operating instructions

Hioki

Hioki 3665-20 manual

Tool it

Tool it NBT100 TEST PROCEDURES / OPERATING INSTRUCTIONS