BELL SYSTEM PRACTICES

AT&TCo

Standard

SECTION 582-211-700

Issue 3, April

1979

"DATASPEED*"

40

OPERATOR CONSOLES

KD AND RO

DlSASSEMBL

Y/REASSEMBLY, ADJUSTMENT, AND PARTS

CONTENTS PAGE

1.

GENERAL.

. . . . . . . . . . . . . . . . . . . . 1

TOOLS

REQUIRED.

. . . . . . . . . . . . . 2

2.

DISASSEMBLy/REASSEMBLy.....

2

KDOPCON.....................

2

A. Rem.oval

..................

.

B.

Replacement

...............

.

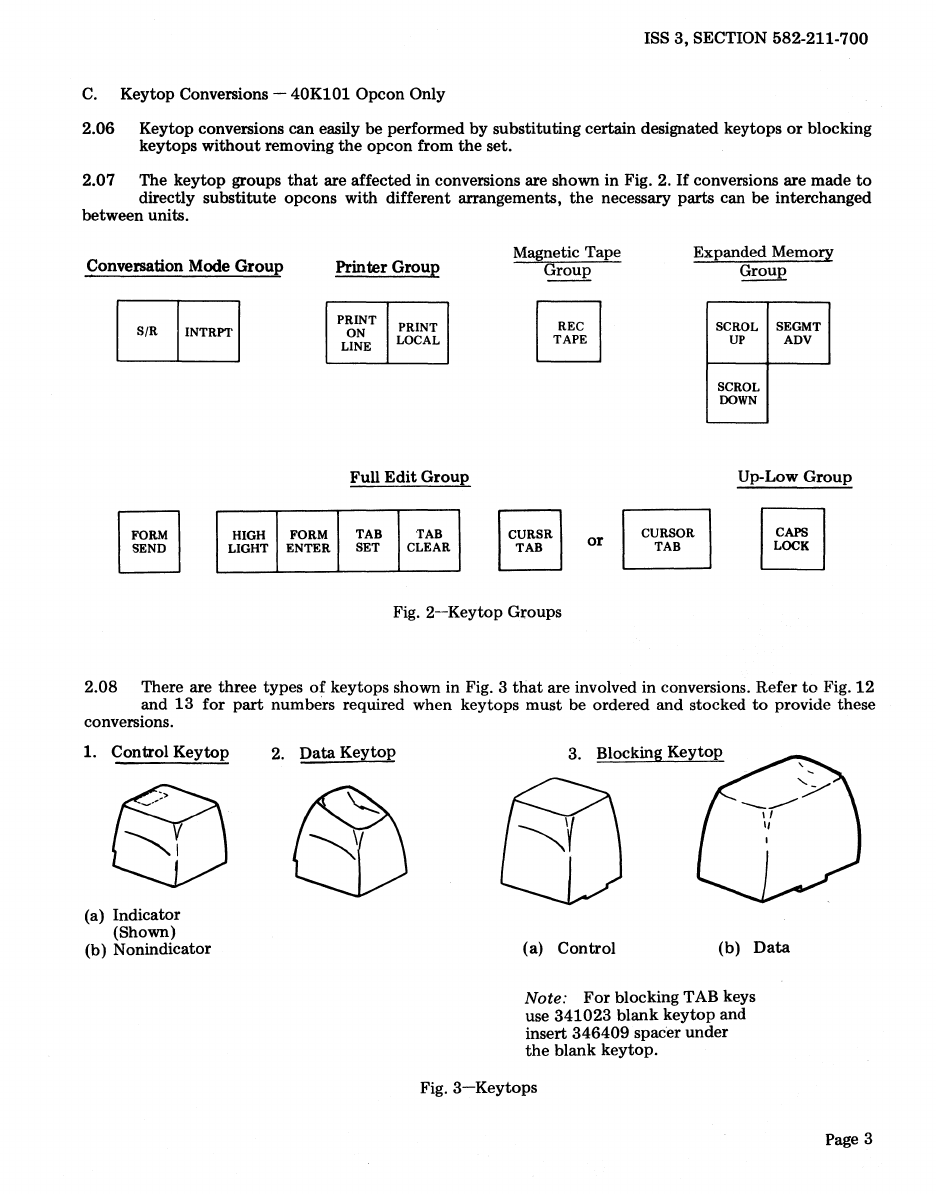

C.

Key

top

Conversions -

40K101

Opcon

Only

.........

.

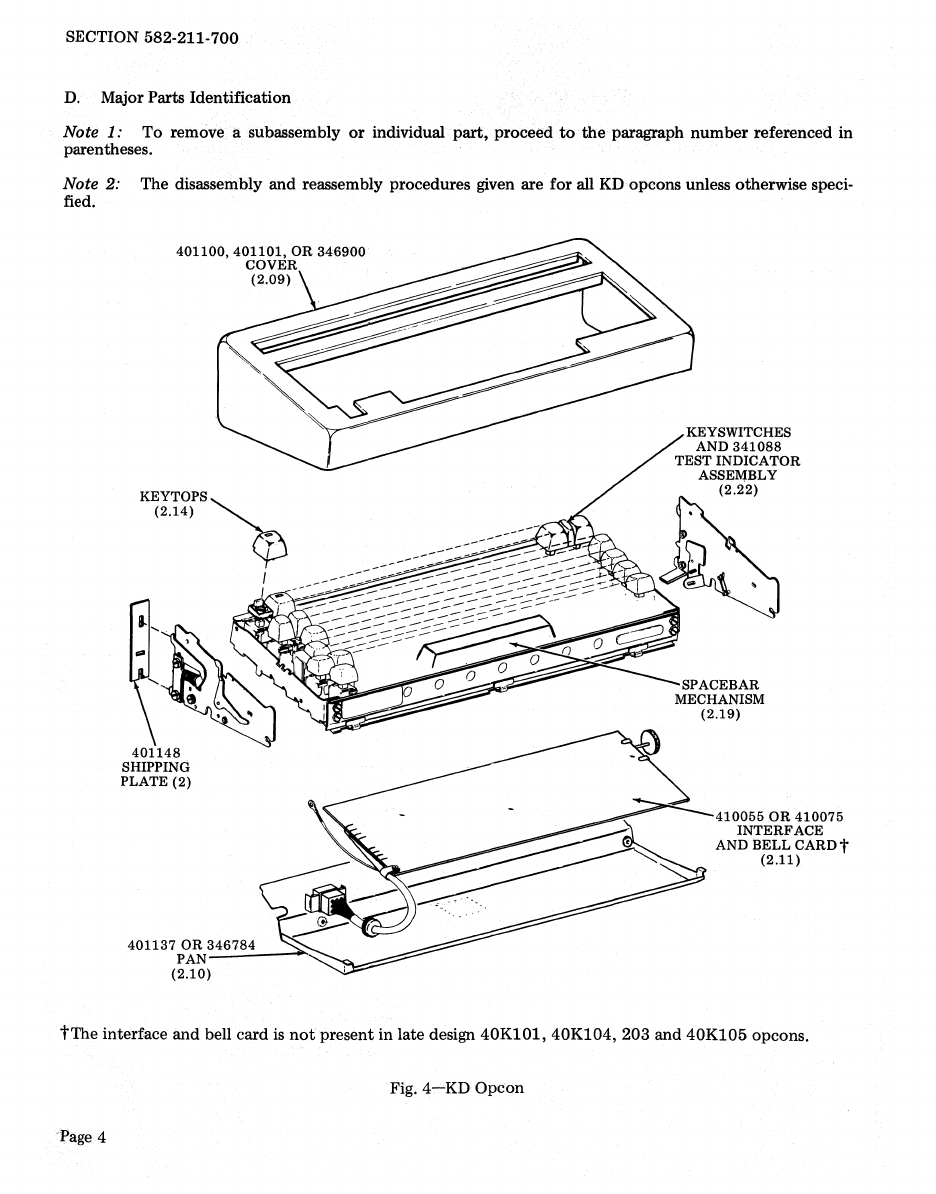

D. Major Parts Identification

.....

.

E. Disassembly/Reassembly

......

.

2

2

3

4

5

RO

OPCON.....................

11

A. Removal and Replacement . . . . .

11

B.

Key

top

Conversions . . . . . . . . . .

11

C.

Major Parts

Identification.

. . . . . 11

D.

Disassembly/Reassembly.......

12

3. ADJUSTMENT. . . . . . . . . . . . . . . . . .

16

COVER TO KEYTOP

ADJUSTMENT........

..........

16

4. PARTS

.........................

17

NUMERICAL INDEX

............

.

31

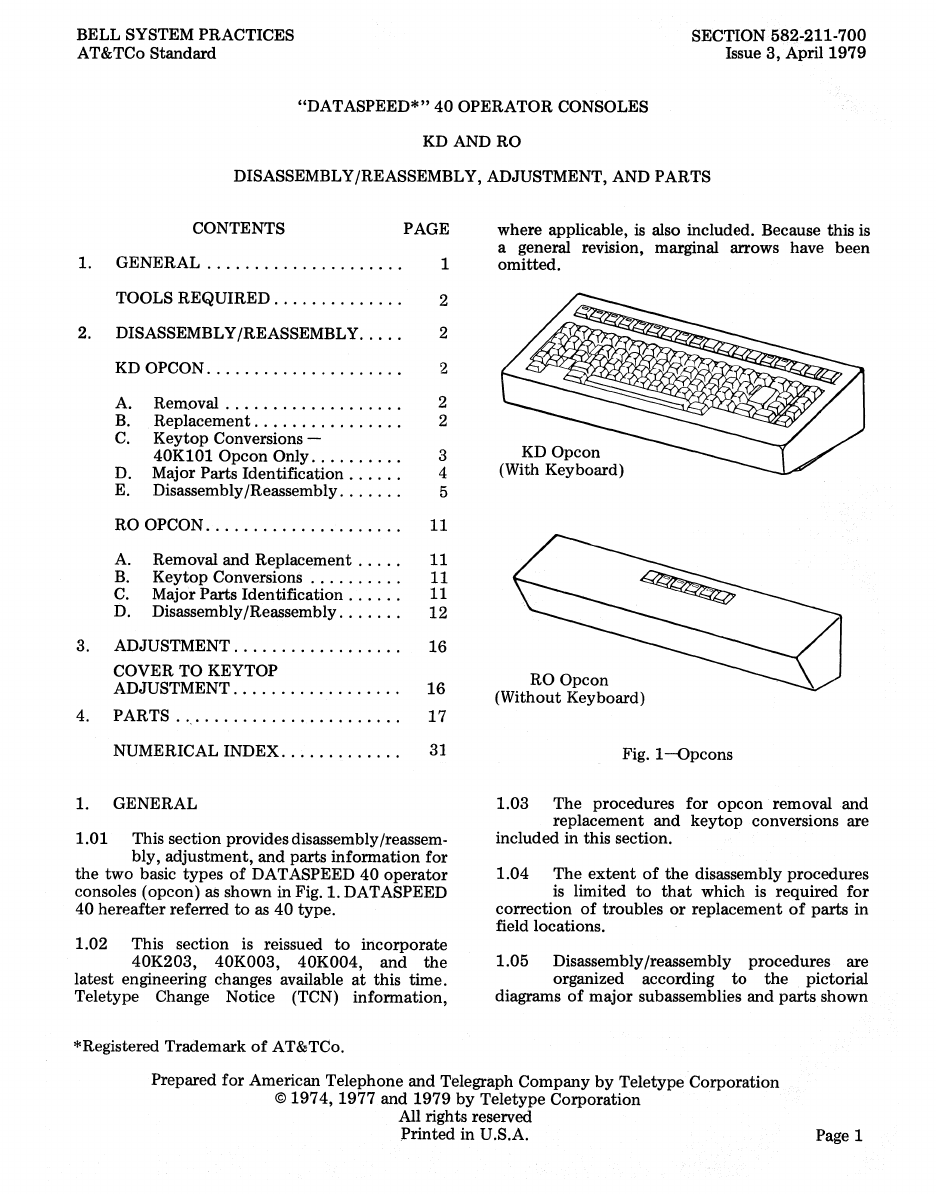

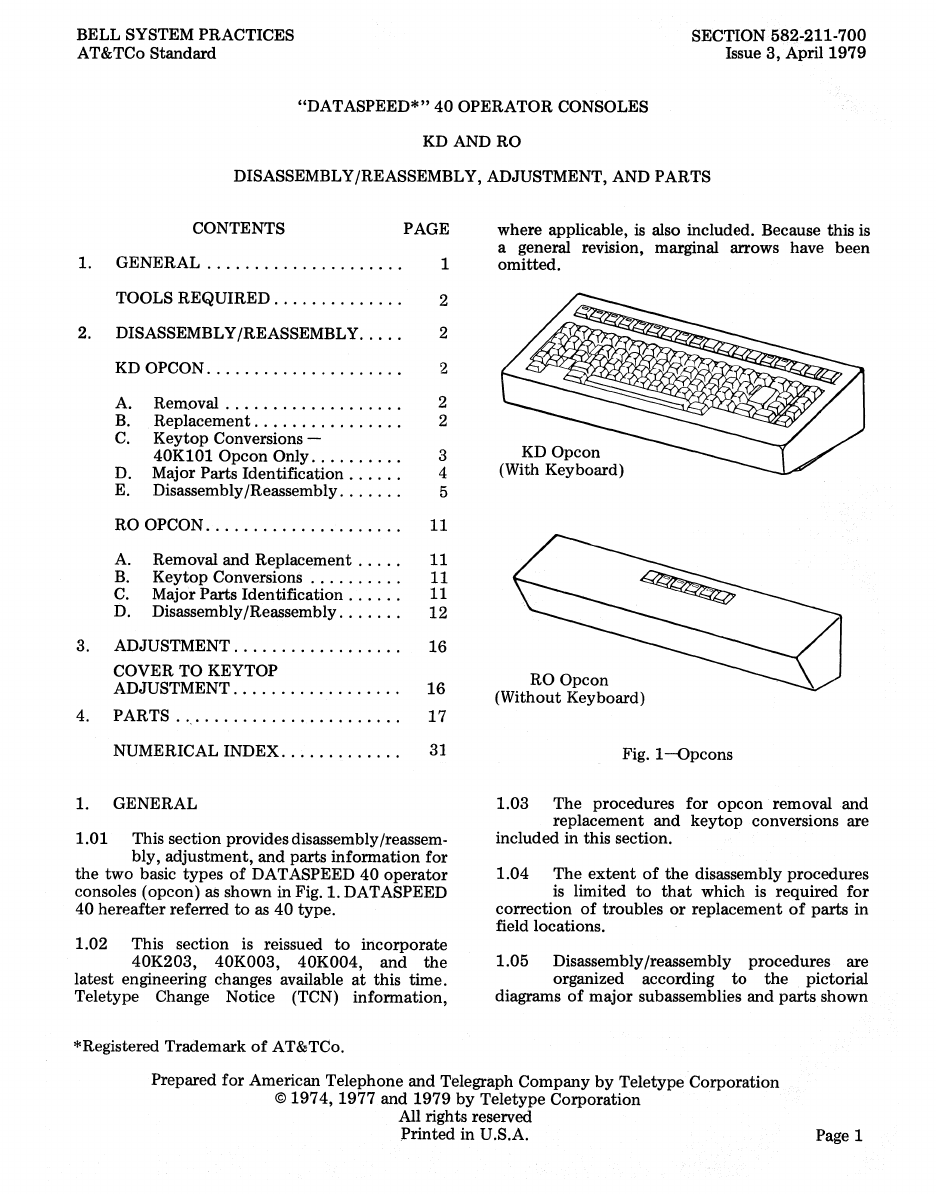

1. GENERAL

1.01

This section providesdisassembly/reassem-

bly, adjustment, and parts information

for

the

two

basic

types

of

DATASPEED

40

operator

consoles (opcon) as shown in Fig. 1. DATASPEED

40

hereafter

referred

to

as

40

type.

1.02 This section is reissued

to

incorporate

40K203, 40K003, 40K004,

and

the

latest engineering changes available

at

this time.

Teletype Change Notice (TCN) information,

*Registered Trademark

of

AT&TCo.

where applicable,

is

also included. Because this is

a general revision, marginal arrows have been

omitted.

KD Opcon

(With Keyboard)

RO Opcon

(Without Keyboard)

Fig.

1-opcons

1.03

The

procedures

for

opcon

removal and

replacement

and

key

top

conversions are

included in this section.

1.04

The

extent

of

the

disassembly procedures

is limited

to

that

which is required

for

correction

of

troubles

or

replacement

of

parts

in

field locations.

1.05

Disassembly/reassembly procedures are

organized according

to

the

pictorial

diagrams

of

major

subassemblies and

parts

shown

Prepared

for

American Telephone and Telegraph

Company

by

Teletype Corporation

©

1974,1977

and

1979

by

Teletype Corporation

All rights reserved

Printed

in U.S.A. Page 1