2. 13 Refer to the appropriate wiring diagrams

packed with the teletypewriter set.

2. 14 Connect the signal line leads (supplied

by customer) to the terminals on the

terminal board at the rear of the call control

unit as indicated in the wiring diagram.

2. 15 Connect power cord to an ac source, 115

volt 60 Hz.

2.16 CheckDASHPOT ORIFICE(Spacing Area)

adjustment, since altitude may have

some effect on dashpot operation. See Section

57

4-122-700TC.

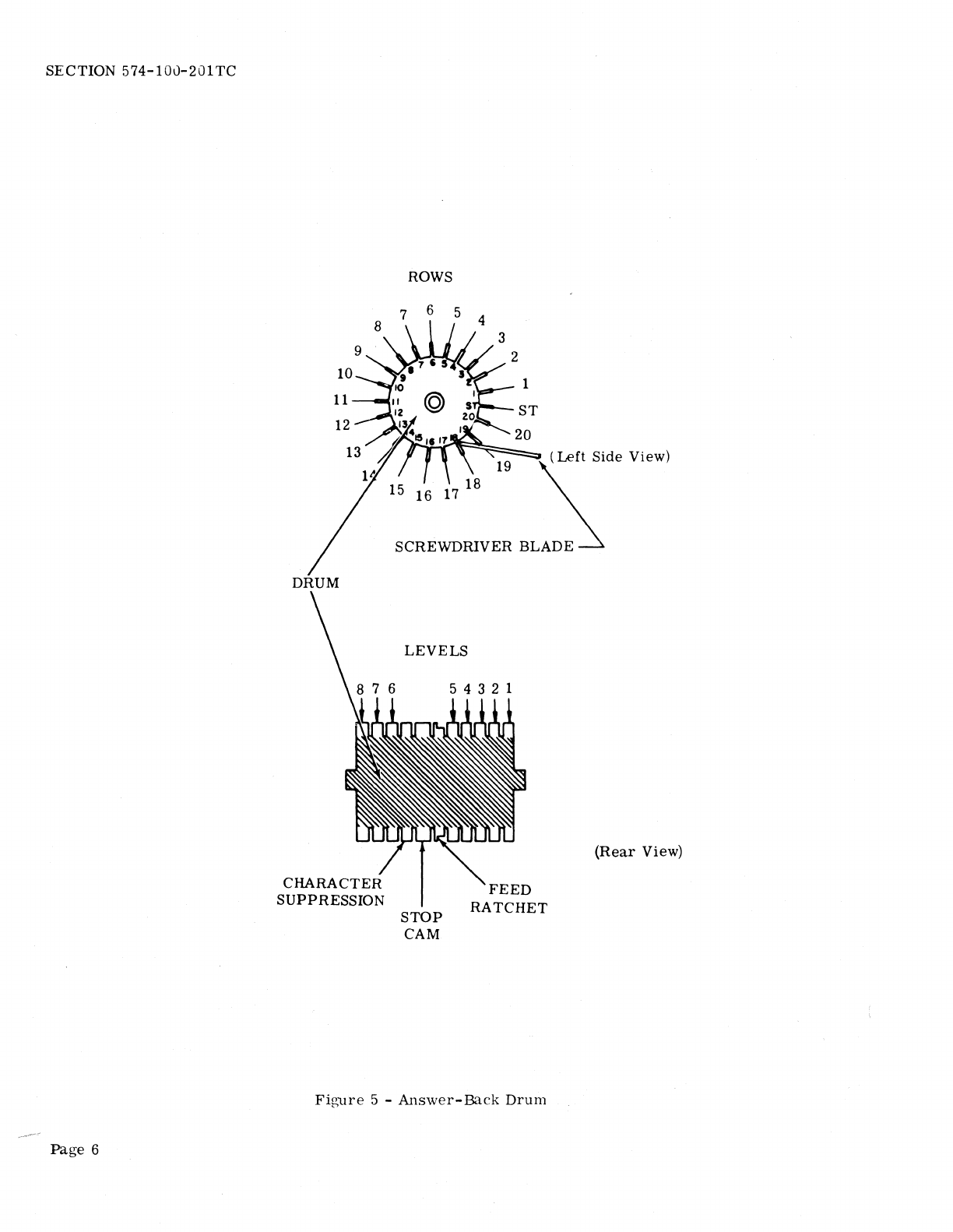

2.17 Sets equipped with an answer-back mech-

anism must be tested for proper response

to a predetermined call character suchas WRU.

The following procedure is recommended for

performing this test.

(a) Use a predetermined call character such

as WRU, to call in the newly installed set.

(b) The set should establish the connection

and automatically transmit the answer-

back message.

Note: Set will not respond if the suppres-

sion tine has been removed from the last

row. See 2. 07 (b).

(c) If proper response is not obtained, check

and correct the answer-back area adjust-

ments (Section 574-122-700TC), beginning

with those of the following list.

DRUM POSITION

TRIP LEVER CLEARANCE

FEED PAWL POSITION

FEED LEVER POSITION

"HERE-IS" BELLCRANK POSITIONING

TRIP BAIL POSITIONING

CHARACTER SUPPRESSION CONTACT

WIRE GAP

2. 18 The 33 Teletypewriter Sets are shipped

from the factory with the automatic car-

riage return-line feed feature in the typing unit

ISS 6, SEC'l'ION 574-100-201 TC

disabled by means of clips. The clips mount

over slots in the TP180950 front tie bar. To

enable this feature on friction feed sets remove

the clip over slot A. To enable this feature on

sprocket feed sets remove the two clips, in slot

A and slot L.

Note: Slot A is not stamped on the function

casting. Refer to 574-122-700TC for orien-

tation.

2. 19 Connect the signal line leads (supplied

by customer) to the terminals on the

terminal board at the rear of the call control

unit as indicated in the wiring diagram.

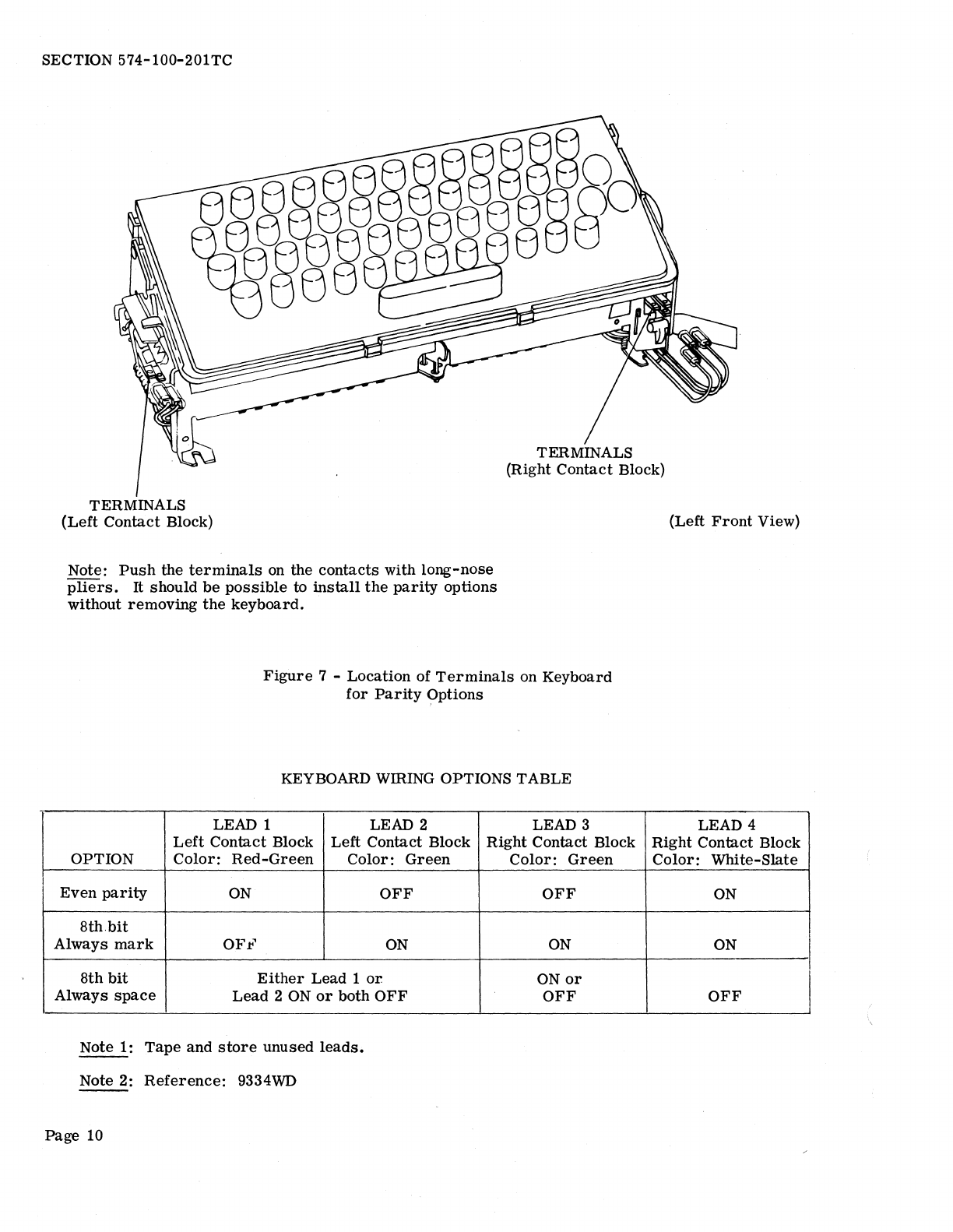

2. 20 The 33 Teletypewriter Sets are shipped

from the factory with the even parity

option installed in the keyboard. The customer

may:

(a) Retain even parity, or

(b) Wire the keyboard for the 8th bit always

marking, or

(c) Wire the keyboard for the 8th bit always

spacing.

The wiring options are installed by connecting

wires to terminals at the right front of the key-

board and at the left contact block (see Figure 7).

The options are shown in the Keyboard Wiring

Options Table.

2. 21 Low Tape Contact Adjustments (for units-

so equipped): -

(a) Operating Arm Adjustment (Figure 8):

Replace cover. With tape spindle in

place, there should be 5/16 inch to 7/16 inch

clearance between operating arm and tape

spindle. To adjust, bend operating arm.

(b) Operating Arm Clearance (Figure 9):

Remove cover. The operating arm

should have a minimum of 1/8 inch clearance

Page 9