MANUAL

373, 2-1

PART

2

--

INSTALLATION

A.

VARIABLE

FEATURES

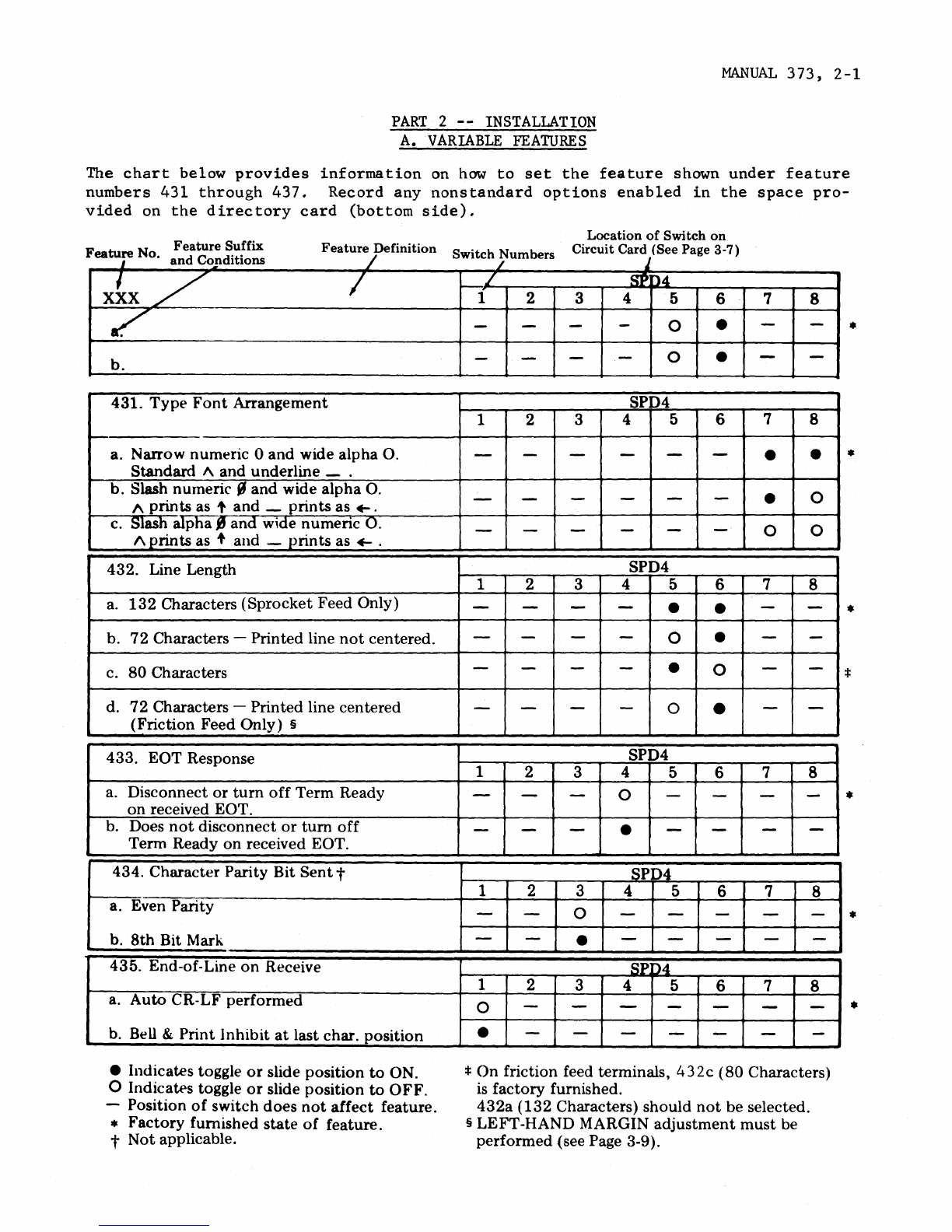

The

chart

below

provides

information

on

how

to

set

the

feature

shown

under

feature

numbers 431

through

437.

Record

any

nonstandard

options

enabled

in

the

space

pro-

vided

on

the

directory

card

(bottom

side).

Feature

No

Feature

Suffix

i .

and

Conditions

Feature

Definition

S

't

h N b

/

WI

C / urn ers

Location

of

Switch

on

Circuit Card (See Page 3-7)

X~X

/ I

~

b.

431.

Type

Font

Arrangement

a. Narrow numeric 0

and

wide alpha O.

Standard

1\

and underline _ .

b. Slash numeric S

and

wide

alpha

O.

" prints as ,

and

_

prints

as

+-.

c. Slash alpha

~

and

wide

numenc

O.

1\

prints

as , and -

prints

as

~

.

432. Line Length

a.

132

Characters

(Sprocket

Feed Only)

b.

72

Characters -Printed line

not

centered.

c.

80

Characters

d.

72

Characters -Printed line centered

(Friction Feed Only) §

433. EOT Response

a. Disconnect

or

turn

off

Term Ready

on

received EOT.

b. Does

not

disconnect

or

tum

off

Term Ready

on

received EOT.

434. Character Parity Bit

Sent

t

a. Even Parity

b.

8th

Bit

Mark

435. End-of-Line

on

Receive

a.

Auto

CR-LF performed

b.

Bell & Print

Inhibit

at

last char. position

• Indicates toggle

or

slide position

to

ON.

o

Indica~s

toggle

or

slide position

to

OFF.

-Position

of

switch

does

not

affect

feature.

•

Factory

furnished

state

of

feature.

t Not applicable.

j

L

SP:

D4

1 2 3 4 5 6 7 8

----0 • - -

----0 • --

SPD4

1 2 3 4 5 6 7 8

------• •

----- - • 0

------0 0

SPD4

1 2 3 4 5 6 7 8

-- - -• • --

----0 • --

--- - • 0 --

----0 • --

SPD4

1 2 3 4 5 6 7 8

---0 ----

-- - • - - --

SPD4

1 2 3 4 5 6 7 8

--0 ---- -

--• --- - -

SP:

D4

1 2 3 4 5 6 7 8

0 ---- - --

• ---- - --

:I:

On

friction feed terminals, 432c

(80

Characters)

is

factory furnished.

432a

(132

Characters) should

not

be selected.

§

LEFT

-HAND MARGIN

adjustment

must

be

performed

(see Page 3-9).

•

•

•

•

•

•