BELL SYSTEM PRACTICES

AT&TCo Standard SECTION 582-202-200

Issue

2,

December

1980

INTEGRATED SYNCHRONOUS "DATASPEED*" 40

RECEIVE-ONLY PRINTER (ROP) STATION

INSTALLATION

CONTENTS PAGE

1.

GENERAL.

. . . . . . . . . . . . . . . . . . . . 1

2.

TECHNICALDATA..............

3

3.

UNPACKING...................

6

PEDESTAL............

....

.....

6

TRACTOR FEED

PRINTER CABINET . . . . . . . . . . . . . 6

FORMS ACCESS

PRINTER

CABINET.

. . . . . . . . . . . . 7

4. PREOPTIONING DISASSEMBLY . . . 8

5. FIELD OPTIONS AND

DESCRIPTIONS. . . . . . . . . . . . . . . . .

10

PRINTER OPTIONS.

..

. . . . . . . . . . .

10

CONTROLLER

OPTIONS.

. . . . . . . .

13

GROUND

OPTION.

. . . . . . . . . . . . . . 21

6.

OPTION

ACTIVATION.

. . . . . . . . . . 22

TRANSMITTING CODES. . . . . . . . . .

29

ACTIVATING PRINTER

OPTIONS......................

33

ACTIVATING CONTROLLER

OPTIONS......................

48

ACrIVATING DATA SET

OPTIONS......................

59

7. FINAL ASSEMBLY. . . . . . . . . . . . . .

64

1.

GENERAL

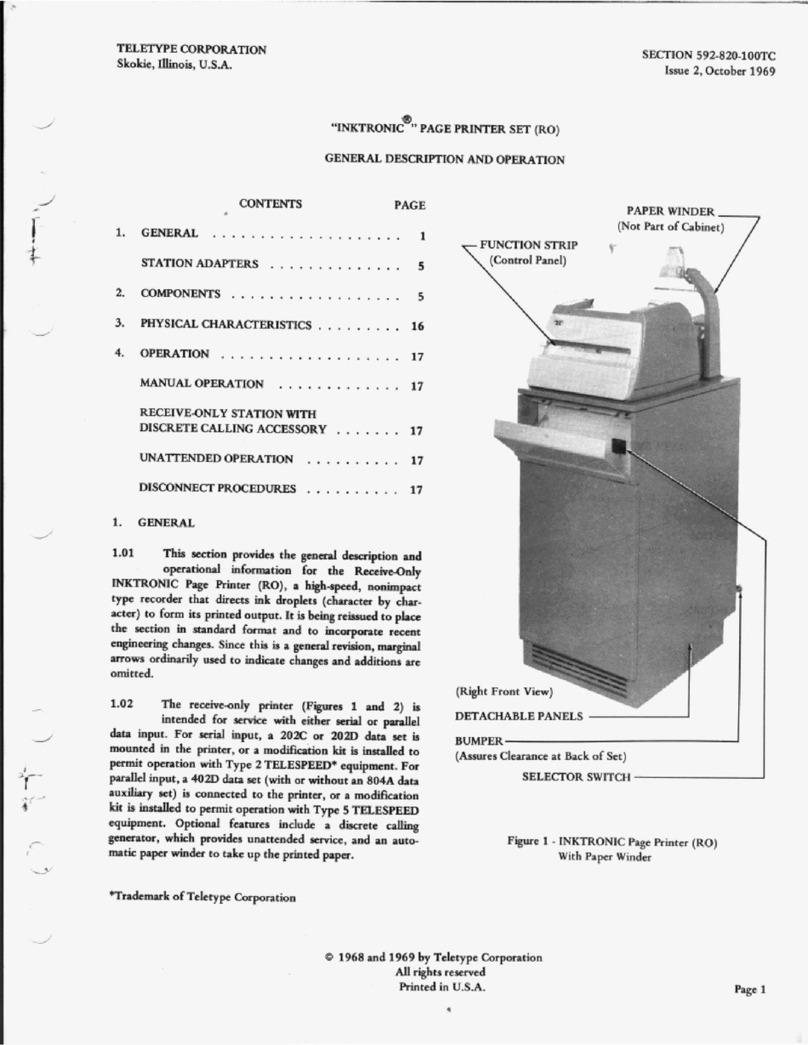

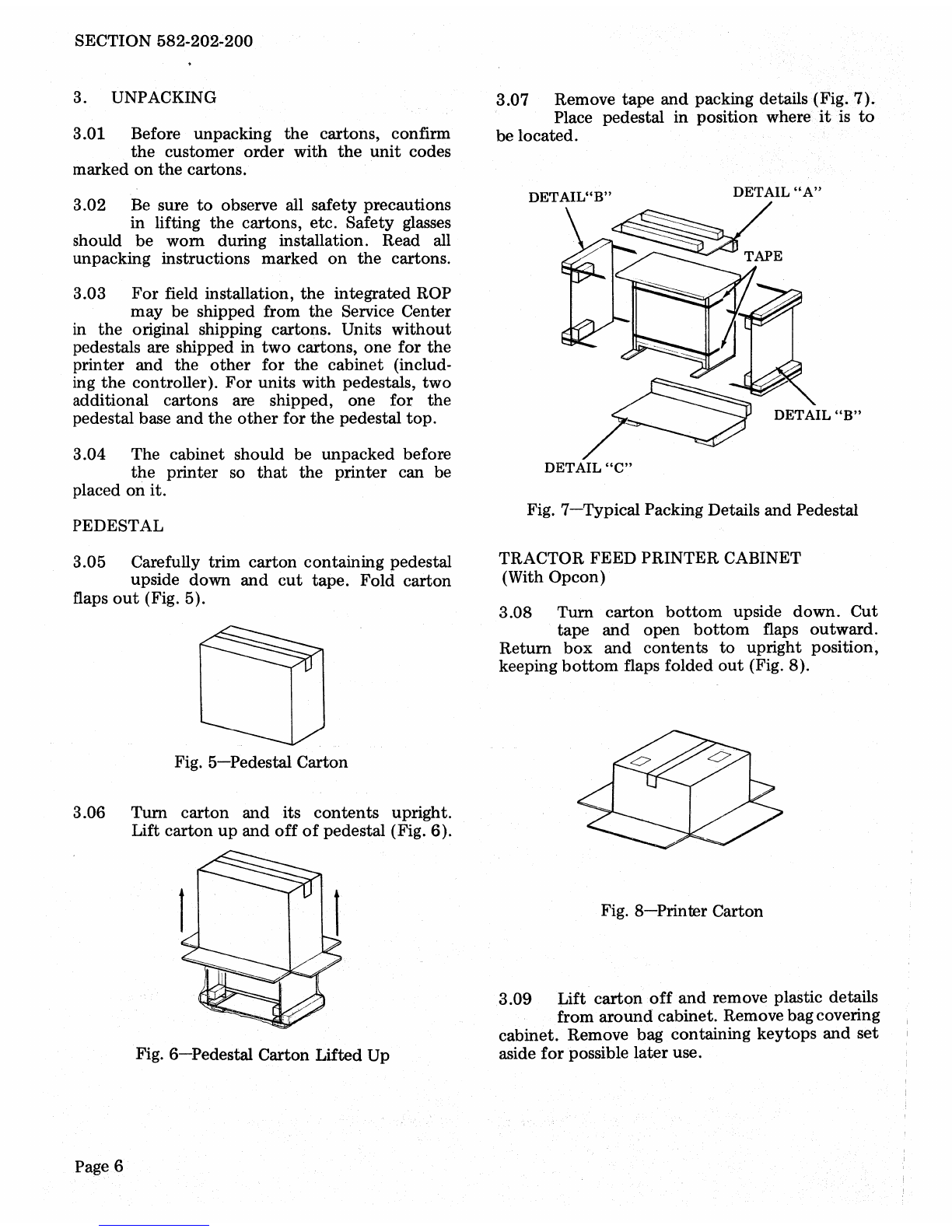

1.01 This section contains information

for

installing

the

Integrated Synchronous

DATASPEED

40

Receive-Only Printer (ROP)

Station. The Integrated Synchronous ROP

is

used in

the

following services: (2) Switched-

Network using

Data

Set 201C, 208B

or

212A,

(2) Multipoint Private Line using Data Set 201C,

208A

or

209A;

and

(3) Two-Point Nonselective

Private Line (point-to-point private line) using

Data Set 201C,

208A

or

209A.

1.02

This section

is

reissued

to

include

Option

179

(WACK/BUFFER Control)

and

information pertaining

to

Data

Set 212

and

forms

access arrangements. Since thisis a generalrevision,

no revision arrows have been used

to

denote

significant changes.

Note: When ordering tools

or

replaceable com-

ponents, unless otherwise specified, prefix each

part

number

with

the

letters

"TP"

(ie,

TP406173).

1.03

Circuit Card Handling Procedures:

Warning: To avoid possible internal damage

to the MOS devices,

or

card with MOS devices,

due to electrical static discharge by service per-

sonnel, the following should be observed.

All

personnel handling MOS devices, or circuit

cards with MOS devices,

must

wear a

346392

static discharge strap adjusted to make firm

contact with the skin at all

timest(Fig.

1).

t Service personnel are never

to

be

connected

directly

to

ground

but

rather

through a high

resistance discharge

path

of

a minimum

of

one

megohm where

115

V ac

is

present. This resis-

tance

is

built

into

the

346392

static discharge

strap.

Prepared for American Telephone

and

Telegraph Company

by

Teletype Corporation

©

1978

and

1980

by

Teletype Corporation

All rights reserved

Printed in U.S.A. Pagel