7Printed in Italy - EE167/0105

11- Maintenance

To maintain a good performance of the system, almost

once a year, an inspection of the valve is recommended.

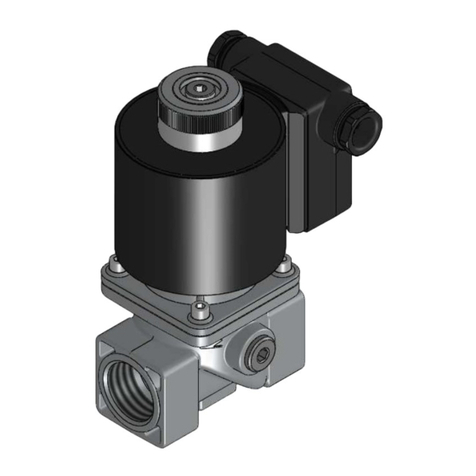

External inspection

Turn off all power before servicing any part of the

system.

Check the conditions of the DIN plug gasket. If gasket is

deteriorated, replace it with a new one.

Check the electrical connections are clean, dry and

correctly tightened.

Check the conditions of pipe connections: cover them

with a soap solution and check for leakages.

Check the proper operation of the valve: power the coil

and verify the valve closing.

Internal inspection

If the valve does not work properly, do not dismount

the resetting mechanism, but replace it with a new

one.

Threaded models:

1. Close ball valve upstream the system.

2. Reset the valve (valve open).

3. Unscrew the knob, but do not remove the nut below.

This to avoid the accidental dismounting of the

resetting mechanism.

4. Remove the locking nut and the coil.

5. Using an Allen key, remove the screws on the upper

flange, in cross way. The gas in the valve will come

out during this step.

6. Check the main O-ring. If it’s necessary, replace it.

7. Blow the spring with compressed air and check it is

corrosion free.

8. Check the conditions of the sealing gasket. If gasket

is deteriorated, replace it with a new one.

9. Clean the sealing lip with a clean cloth. Do not use

tools, because a lip damage could result.

10. Remove the filter and blow it with compressed air.

11. Reassemble the valve following the inverse

sequence.

Flanged models:

1. Close ball valve upstream the system.

2. Unscrew the knob.

3. Using an Allen key, remove the screws on the upper

flange, in cross way. The gas in the valve will come

out during this step.

4. Check the main O-ring and the rod O-ring. If it’s

necessary, replace them.

5. Remove the spring and blow it with compressed air.

Check the spring is corrosion free.

6. Clean the disc assembly with a clean cloth and

compressed air. Grease the rod O-ring.

7. Check the conditions of the sealing gasket. If gasket

is deteriorated, replace it with a new one.

8. Clean the sealing lip with a clean cloth. Do not use

tools, because a lip damage could result.

9. Remove the filter and blow it with compressed air.

10. Reassemble the valve following the inverse

sequence.

To insert the rod inside the flange assembly, power the

coil and, using a screw driver, move the pin to allow the

rod inserting.

When the reassembly is finished, verify the correct

sealing between the upper flange and the valve body:

1. Open ball valve to restore pressure into the valve.

2. Apply a soap solution between the upper flange and

the valve body and check for leakages.

3. Remove the soap solution with a clean cloth and

compressed air.

WARNING

•When reassemble, use all gaskets properly.

•Perform functional test after mounting.

•All works must be executed by qualified

technicians only and in compliance with local

and national codes.