Temescal BJD-1800 Manual

Temescal BJD-1800 Ebeam Evaporator (1) Operation

Procedure

When you approach the system check that the cryo pump temperature is 20K or less

If the cryo temperature is above 20K, do not use. Notify Nano3 staff.

The system should be left in high vacuum when not in use. If the system was not left in high

vacuum by the previous user you may proceed with your deposition but note that depending on

how long the system was left in roughing, the pump-down time may be longer than usual due to

mechanical pump oil back streaming into the chamber. Always remember to leave the system in

high vacuum!

Before you begin the process you must start your log book entry. Please write down your name,

date and the material you intend to evaporate on the log sheet.

Sample Loading Instructions:

1. Close the “High vac” valve.

2. Open the “Vent” valve. It will take approximately three minutes for the chamber to

reach atmospheric pressure.

3. Open the chamber lid and close the “Vent” valve.

4. Check that the glass slide mounted over the view port is clear. If not, replace it with a

new one.

5. Remove the sample holder.

6. If you need to deposit a metal other than one of those that is already in the chamber,

remove one of the crucibles and replace it with the desired material. The name of the

material contained in each crucible is scribed on the bottom of the crucible.

7. If the metal is getting low add more pellets. If the gold is getting low notify Nano3

staff.

8. Check the thickness monitor crystal usage (See the “I/C5 Deposition Controller”

segment of this operation procedure) Replace the crystal if necessary.

9. Place the sample holder and samples back in the chamber.

10. Check the chamber O-ring, make sure it is seated properly.

11. Close the chamber lid.

12. Record the load time on the log sheet.

Pump-down:

1. Turn on the Mechanical Pump by switching the breaker to the on position.

2. Open the “Roughing” valve.

3. Wait till the pressure reaches 50mT or less.

4. Close the “Roughing” valve. Allow a few seconds to insure that the valve is

completely shut.

5. Open the “High Vac” valve.

6. Wait till the pressure reaches 1.0e-6T or less.

7. Allow enough pumping time to reach 2.0e-6T or less. Record the base pressure in the

log sheet before you begin the deposition process.

I/C5 Deposition Controller:

1. Check crystal usage:

a. Press “Sensors”.

b. Check the reading in the “ACT” column. This is a reading of the crystal’s ability

to conduct current. If this number is less than 300 the crystal needs to be

replaced. Your trainer will instruct you on how to change the crystal.

c. Check reading in the “Life” column. This is a reading of the age of the crystal. If

this number is greater than 10, replace the crystal.

d. To exit the “Sensors” screen, press the “Operate” button.

2. Select your process:

a. Press “Process Directory”.

3. Using the arrow keys, cursor to the desired material. Select the material by pressing

“Select Active Process”.

4. Press the F6 button until you reach the main screen.

5. Press “Zero Thickness”.

6. DO NOT CHANGE ANY OTHER SETTINGS ANY WHERE IN THE I/C5

CONTROLLER!!!

Deposition:

1. Turn on the “Main Power” switch on the power supply.

2. Turn the interlock key on the control panel to the on position.

3. Set the latitudinal and longitudinal beam sweep dials to zero (counterclockwise).

4. Set the latitudinal and longitudinal sweep frequencies to 1.

5. Press the red “HV On” button to turn the high voltage on.

6. Make sure the turret dial is set to the metal you intend to evaporate.

7. Make sure the emission control dial is at zero.

8. Press “Gun 1 Fil On” button to turn on the filament.

9. Slowly increase the emission control setting by increasing the emission control dial

from 0 to 0.4, wait 30 seconds, 0.4 to 0.6, wait 30 seconds, 0.6 to 0.8, wait 30

seconds. If the emission control is increased too quickly the filament will warp or

break.

10. Open the shutter.

11. As you increase the emission control setting keep looking through the view port.

When the emission control setting reaches ~0.8 you will begin to see the beam on the

metal in the crucible.

12. Stop increasing the emission control setting when you can clearly see the beam

hitting the metal in the crucible.

13. Before continuing to increase the emission control setting to begin the evaporation

you must adjust the beam position and sweep settings.

14. Go to the “Beam Position and Sweep Settings” segment of this operation

procedure.

15. When the beam is positioned and sweeping correctly, check the log book to see the

recent emission control settings and deposition rates used by other users for the metal

you are evaporating. This will give you an idea of how far you should turn the dial

before the evaporation starts.

16. You may choose to close the shutter for a short period so that the initial evaporated

material does not reach your samples.

17. Continue to SLOWLY (0.1 per minute) increase the emission control setting.

Approach the final emission control setting slowly. The metal will glow bright orange

as it approaches the point of evaporation.

PLEASE NOTE: Turning the emission control setting up too fast and/or too high

can cause the metal to splash out of the crucible. THIS MUST BE AVOIDED. The

small pieces of metal can get stuck between moving parts and/or short out high

voltage circuitry.

18. If you have closed the shutter, open it when you reach your desired emission control

setting.

19. The thickness monitor will begin to register a rate and accumulate a thickness reading

when the evaporated material reaches the thickness monitor crystal surface. This

indicates that the deposition has started.

20. You may adjust the emission control slightly to increase or decrease the deposition

rate. DO NOT adjust the emission control so that the rate is higher than 5nm/s!

21. Record the deposition rate on the log sheet.

22. For longer depositions you must keep watch over the deposition rate as it may change

over time. Adjust the emission control dial to maintain the desired deposition rate.

23. Periodically verify that the beam is still sweeping correctly.

24. Record the pressure during evaporation in the “Pressure During Evaporation” column

of the log sheet.

25. When you reach the desired thickness, close the shutter. Remember that after the

shutter is closed the thickness will continue to increase for several seconds. You

should anticipate this if your process requires a precise thickness.

26. Record the final film thickness on the log sheet.

27. Begin to decrease the emission control setting at a rate of 0.20 on the emission control

dial per 30 seconds.

28. When you reach zero on the emission control dial, press the “Gun 1 Fil Off” button to

turn off the filament.

29. If you need to evaporate another metal at this point, return to step 6 of this section.

30. Press the “HV Off” button to turn off the high voltage.

31. Turn the interlock key back to its initial position.

32. Decrease the longitudinal and latitudinal beam sweep frequency to 1.

33. Turn the beam sweep dial to zero (counterclockwise).

34. Turn off the “Main Power” switch on the power supply.

35. For longer depositions (>500nm) you should allow at least five minutes for the

chamber to cool before continuing to unload your samples.

36. Go to the “Sample Unloading Instructions” segment of this operation procedure.

Beam Position and Sweep Settings:

1. Turn the longitudinal and latitudinal beam sweep knobs to zero (counterclockwise).

2. Set the longitudinal and latitudinal sweep frequencies to 1.

3. Starting with the beam position as it was left by the last user, make sure that the beam

is hitting in the center of the crucible. Typically the beam is already in the correct

position and does not require significant adjustment.

4. If the beam is not hitting the center of the crucible slowly adjust the longitudinal and

latitudinal beam position knobs until the beam is centered.

5. Slowly increase the longitudinal sweep knob until the beam sweeps across the entire

surface of the metal melt in the crucible; the beam should not touch the crucible.

6. For the thick walled, reduced volume crucibles latitudinal sweep is not required and

the latitudinal sweep dial should be left at zero. The filament is approximately the

same width as the inner diameter of the crucible so if it were to sweep latitudinally

the beam would touch the graphite crucible. For the thin walled, normal volume

crucibles adjust the latitudinal sweep as necessary.

7. Once the beam is well centered and sweeping over the entire metal melt surface,

increase the sweep frequencies to 9.

8. Return to step 15 of the “Deposition” segment of this operation procedure.

Sample Unloading Instructions:

1. Record the sample unload time on the log sheet.

2. Close the “High Vac” valve. Allow a few seconds for the valve to shut completely.

3. Open the “Vent” valve. It will take approximately three minutes for the chamber to

reach atmospheric pressure.

4. Open the chamber.

5. Remove your samples.

6. Make sure the sign indicates that the correct materials are located in the correct

crucible positions.

7. Replace the glass slide that covers the view port. Put the used slide in the sharps

container.

8. Make sure the chamber O-ring is seated properly.

9. Close the chamber lid.

10. Open the “Roughing” valve.

11. Wait till the chamber reaches 50mT or less.

12. Close the “Roughing” valve. Wait till the valve closes completely.

13. Open the “High Vac” valve.

14. Confirm that the system is in high vac on the log sheet.

15. Turn off the mechanical pump by switching the breaker to the off position.

16. Note any comments or concerns in the “Comments” section of the log sheet.

17. End of process.

Table of contents

Other Temescal Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Tenco

Tenco Enolmaster Technical handbook

Little Tikes

Little Tikes 640216M Assembly instructions

Pfeiffer Vacuum

Pfeiffer Vacuum OME 25 HP operating instructions

Doka

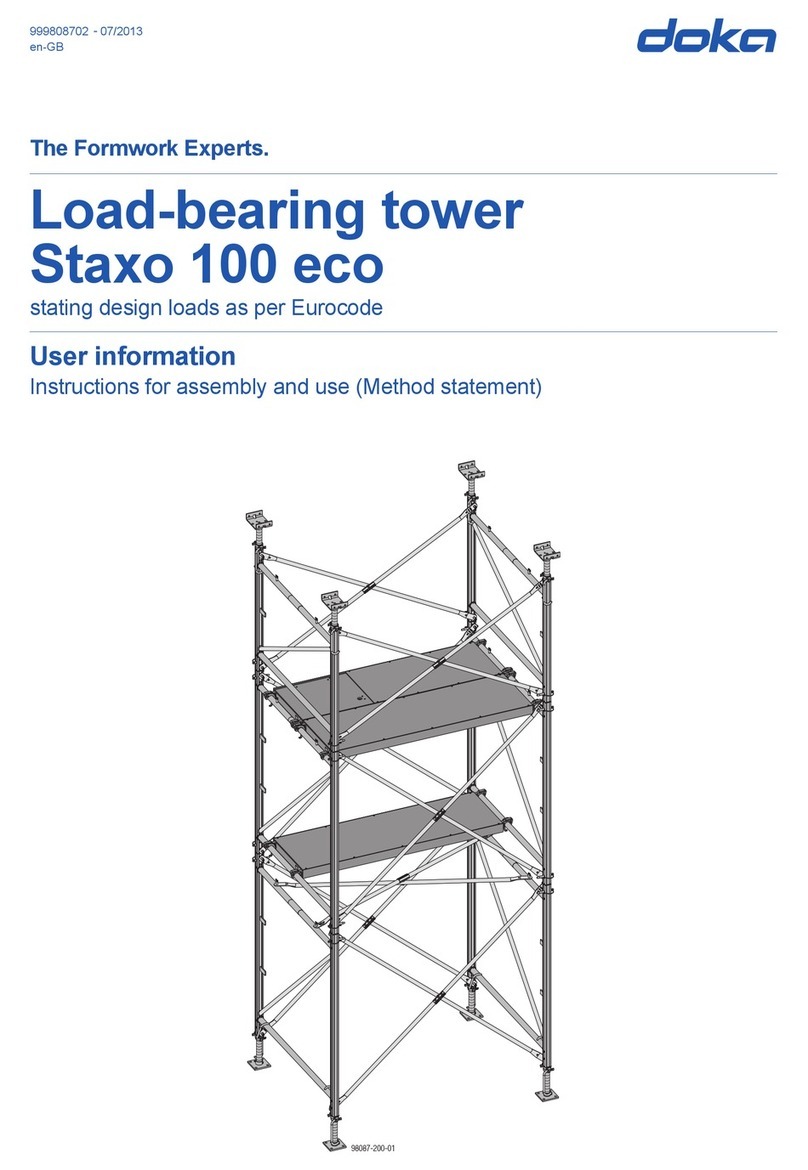

Doka Staxo 100 eco User information

HEIDENHAIN

HEIDENHAIN AE LS 4x7 Replacing Instructions

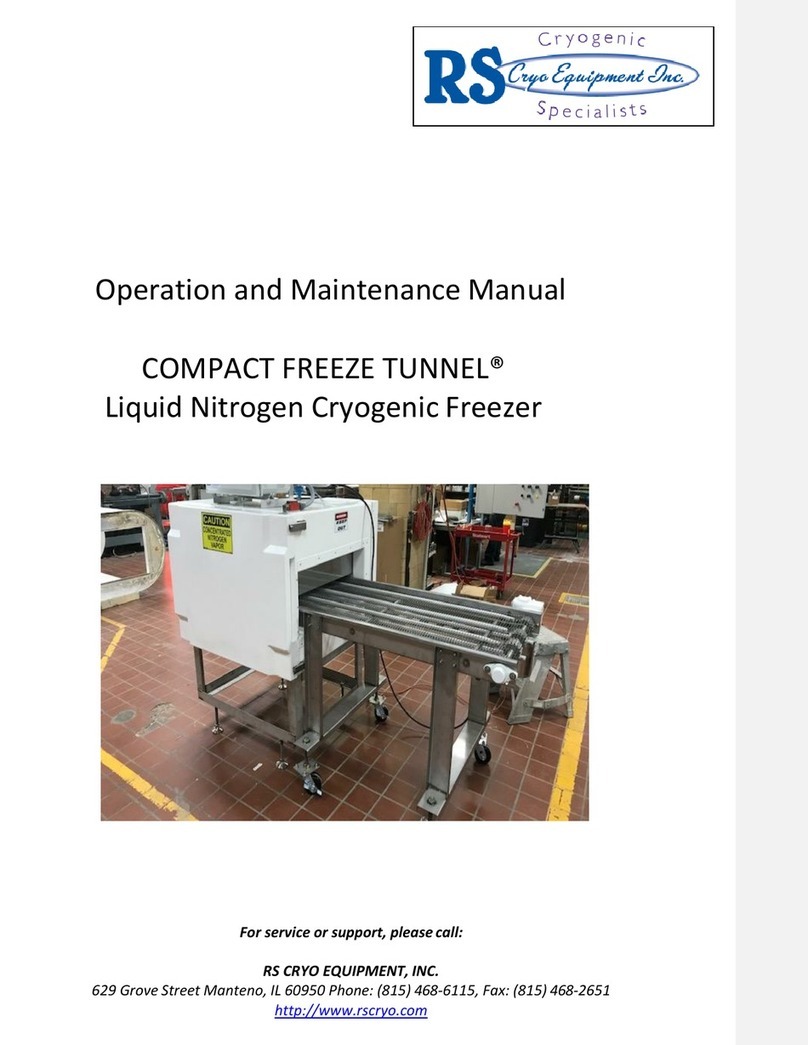

RS

RS COMPACT FREEZE TUNNEL Operation and maintenance manual