Telesis BenchMark 320 User manual

BenchMark 320/BM470 Marking System

34753A ©2020 Telesis Technologies, Inc. –All Rights Reserved 1of 10

Disclaimer: Printed or downloaded copies of this document are considered to be uncontrolled. Documentation is subject to change without

notice.

SYSTEM OVERVIEW

The Telesis®BenchMark®320 marking system

permanently prints messages into materials such as

steel, aluminum, and plastic. An electric solenoid

accelerates a hardened pin to indent dot matrix

characters into the item being marked. Character

shape, size, density, and location are determined by

the user through the marking system software.

Marking Head.The BenchMark 320 marking head

is an electromechanical marker. A thermoformed

cover houses the internal, mechanical components

that position the pin cartridge and fire the marking

pin. A spring returns the pin to its idle position

within the cartridge. The marking head moves the

pin cartridge through X- and Y-axis motions to

reach the correct position for each dot of the

characters to be marked. The system software

controls pin extension to mark the message.

The marker’s two stepper-motor drives rapidly and

accurately position the pin at coordinate-defined

locations in the marking window within 0.032 mm

(0.00125 inch). The marker accommodates the

rigorous dynamics of impacting, rebounding, and

rapid positioning of the marking pin through a

system of rigid rails and ball bearing saddles, timing

belts, and direct-drive, toothed pulleys.

The pin design permits high-quality, consistent

marks on irregular, slightly curved surfaces. It also

accommodates applications where marking surfaces

cannot be positioned at a consistent distance from

the marker.

The unique design of the BenchMark 320 provides

liberal access for securing and positioning parts for

printing. Using a gantry arm and a programmable

Park position, you can tuck the impact pin out of the

way when the marker finishes printing. Parts can be

easily secured and removed in front of the marking

head.

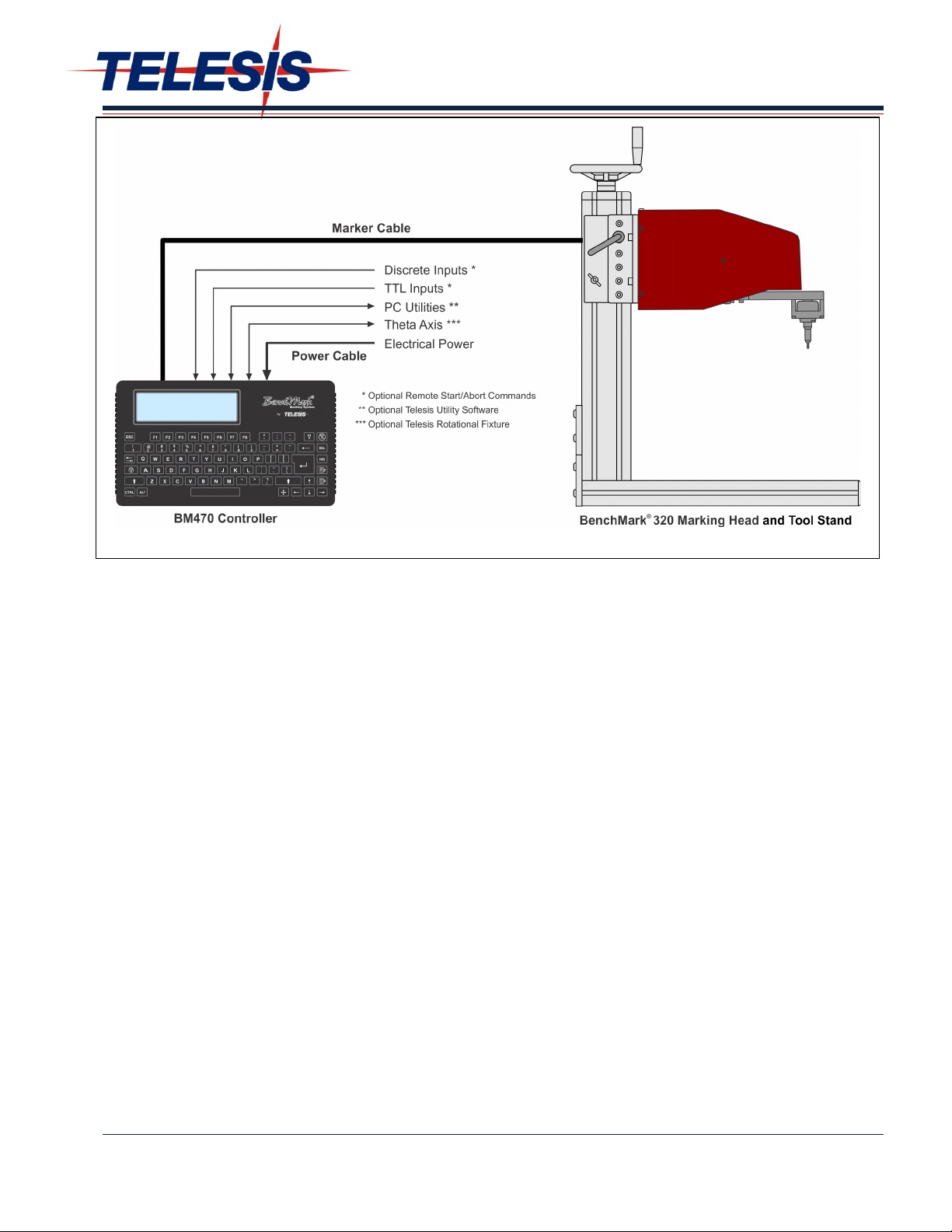

Marker Cable.The marker cable connects the

marker to the BM470 controller. The cable is 4 m

(13 feet) and is prewired to the marking head.

Pin Cartridge. The pin cartridge is machined from

engineered plastic materials and offers long life with

little maintenance. Screws attach the pin cartridge

to the marking head for easy removal, cleaning, and

pin replacement.

Marking Pins. The 25XLE-series marking pins are

made of tungsten carbide and are available in 30°

and 45° cone angles.

Controller. The BM470 controller allows full

operational control of the marking head. It contains

an integrated keyboard with an LCD display and

provides a text-only operator interface. The back

panel provides an electrical interface for connecting

optional remote I/O sources. Refer to BM470

Controller Specifications for details.

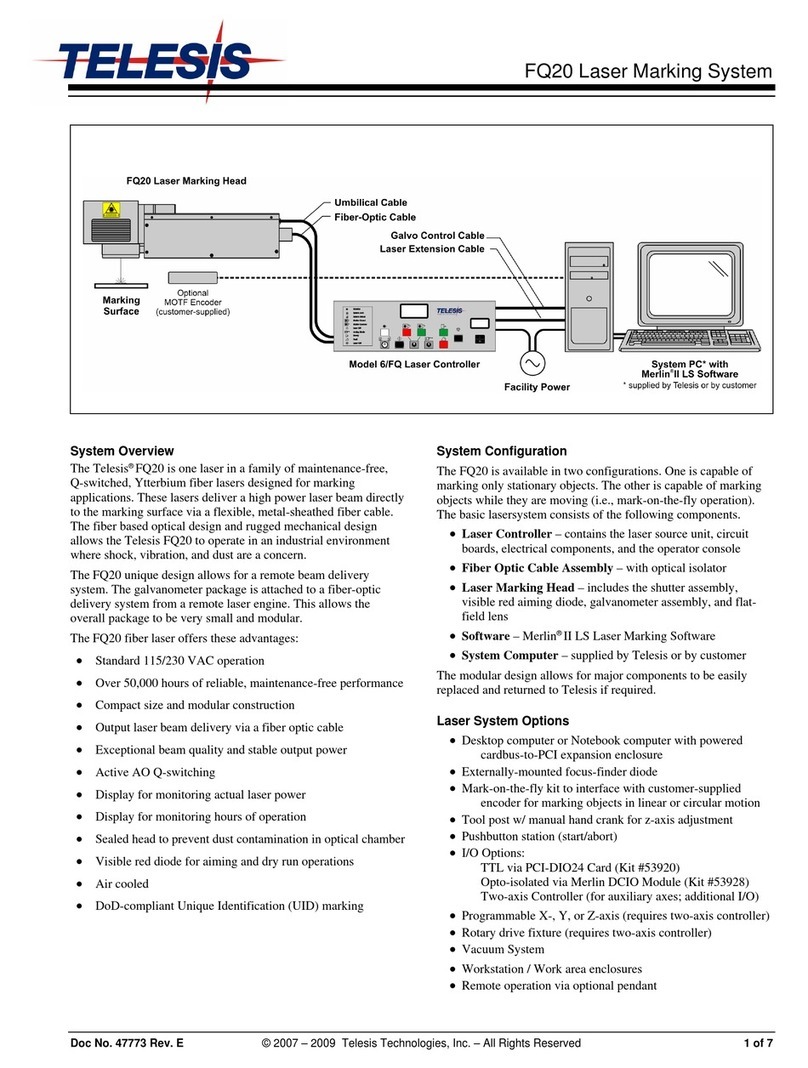

BenchMark320/BM470 Marking System – General Arrangement

BenchMark 320/BM470 Marking System

2of 10 34753A

Tool Stand. The tool stand holds the marking head

and provides a base for securing parts to be

marked. A screw jack with an adjustment wheel

positions the marker above the marking surface.

Adjustment locks secure it in place. The generous

vertical adjustment accommodates parts up to

298.4 mm (11.75 inches) high. The tool stand base

contains slots to accommodate part fixtures. The

tool stand comes with two 8 mm T-nuts to aid in

securing the parts for marking.

SYSTEM OPTIONS

·Auxiliary Axis Driver Board Kit

·Motorized Theta-Axis with Programmable

Rotary Drive Unit

·BM470 Controller Wall-Mounting Bracket Kit

·Barcode Scanner or Barcode Wand with Cable

·Foot Switch (Start Print) or Push Button

Station (Start/Abort)

·Backup Utility Software

·Upgrade Utility Software

·Logo/Font Generator Software

·BM470+ Enhanced Communications Software

SYSTEM SETUP

1. Position the tool stand assembly in the

appropriate location.

2. Mount the marking head to the tool stand

assembly using four M8-1.25 socket head cap

screws.The screws must extend at least 9

mm (0.375 inch) but not more than 12 mm

(0.5 inch) into the back plate. Refer to the

BenchMark 320 Marking Head Dimensions

drawing for details.

CAUTION

The BM470 controller is not a sealed unit.

Protect it from potentially damaging

conditions and contaminants. Do not

block the vents in the bottom of the case.

Ensure the marking system is electrically

isolated from devices that may generate

extreme electromagnetic interference

(EMI).

3. Locate the controller as close as practical to the

marking head. Standard marker cable length is

4 m (13 feet).

4. Ensure the controller power switch on the back

panel is OFF. Connect the power cable to the

controller.

5. Connect the marker cable from the marking

head to the controller, and securely tighten.

6. To start the marking system software, position

the controller power switch on the back panel to

ON.

7. Adjust the pin stroke for proper pin impact

depth.

BenchMark 320/BM470 Marking System

34753A 3of 10

BENCHMARK 320 MARKING HEAD

Specifications

The BenchMark 320 marking head specifications are

subject to change without notice.

Dimensions...................... see the BenchMark 320 Marking

Head Dimensions drawing

Weight

Marker ....................... 5.84 kg (12.865 lb)

Marker & Cable ........... 6.39 kg (14.055 lb)

Tool Stand.................. 16.0 kg (35.200 lb)

Noise (maximum)........... 65.4 dB

59.1 dB (LEQ)

see Marking Noise

Operating Temperature... 0° to 50°C

(32° to 122°F),

non-condensing

Marking Area.................. 150 x 100 mm

(6.0 x 4.0 inches)

Pin Types ....................... 25XLE-series

Pin Material.................... Tungsten Carbide

Marking Characteristics

The BenchMark 320 can accommodate character

sizes from .762 to 100 mm (.030 to 4.0 inches) in

.025 mm (.001-inch) increments. Characters can be

rotated in 1° increments with printing resolutions

from 4 dots/cm (10 dots/inch) to 32 dots/cm

(80 dots/inch) for an engraved look.

Marking Speeds

The system generally marks three characters per

second using 5 x 7 font, 3 mm (.118-inch) high, 2

mm (.080-inch) wide characters. Speeds vary

slightly depending on the selected character size,

style, and dot density. Specific times can be verified

by a Telesis representative.

Marking Noise

Although every attempt is made to reduce noise,

the material being marked significantly influences

the noise level. For example, marking a solid lead

block produces less noise than marking a thin-

walled steel pipe.

Marking Depth

The BenchMark 320 can obtain a marking depth of

.127 mm (.005 inch) in mild steel (Rb53) using a

25XLE carbide pin with a 45° cone angle. The depth

of mark can be adjusted over a significant range by

changing the impact force (via software parameter)

or by changing the impact distance (pin stroke).

Specific depths can be verified by a Telesis

representative.

Pin Life

Pin life depends largely on the type of material

being marked, how hard or abrasive it is, and the

required marking depth. On typical metals with a

hardness of Rockwell Rb47, marking at a depth of

.127 mm (.005 inch), carbide pins average

approximately 9 million impressions before needing

sharpened.

BenchMark 320/BM470 Marking System

4of 10 34753A

BenchMark 320 Marking Head Dimensions

BenchMark 320/BM470 Marking System

34753A 5of 10

BM470 CONTROLLER

Specifications

The BM470 controller specifications are subject to

change without notice.

Compliance .................. CE, RoHS

Rating ......................... NEMA 1 (I. P. 30)

Mounting Configuration.. Tabletop

Dimensions.................... see the BM470 Controller

Dimensions drawing

Weight ........................ 1.68 kg (3.69 lb) controller only

Power Requirements...... 95 to 250 VAC, 2 amps, 50-60

Hz, single phase

Operating Temperature ...0° to 50°C (32° to 122°F),

non-condensing

Operating Humidity ....... 10% to 80% non-condensing

Cooling.......................... Internal, thermostatically

controlled fan

Communications ........... TTL, RS232, and USB*

Input Signals** .............. Two available (Start Print,

Stop/Abort)

10 VDC (minimum voltage)

30 VDC (maximum voltage)

12 to 24 VDC (nominal voltage)

2.3 mA @ 12 VDC;

4.9 mA @ 24 VDC (nominal

current)

**USB for data backup and transfer

** Additional I/O signals available with the optional

BM470+ Enhanced Communications Software

Environmental Considerations

The following environmental considerations must be

taken into account when installing the BM470

controller.

Contaminants. The vented and fan-cooled

controller is rated NEMA 1 (I. P. 30). In

environments where solid or liquid contaminants are

present, the contaminants can be drawn into the

controller and cause the electronic components to

fail. For that reason, in these types of

environments, the controller must be located in a

sealed industrial enclosure.

EMI Susceptibility. Although the system has been

found to be in compliance with pertinent

susceptibility standards, care should be taken when

installing near welders and other extreme

generators of electromagnetic interference (EMI).

Particular care should be taken to ensure welder

currents are not injected through the marking head

chassis. The marking head chassis is connected to

the electrical service earth ground through the

marking head cable. The marking head should be

electrically isolated from all surfaces which could

become part of a welder current path.

Table of contents

Other Telesis Industrial Equipment manuals