Tenco Enolmaster Release Note

700-0007-000 Rev.0 Pag. 2

Tenco Srl

Via Arbora 1

16036 Avegno

(GE)

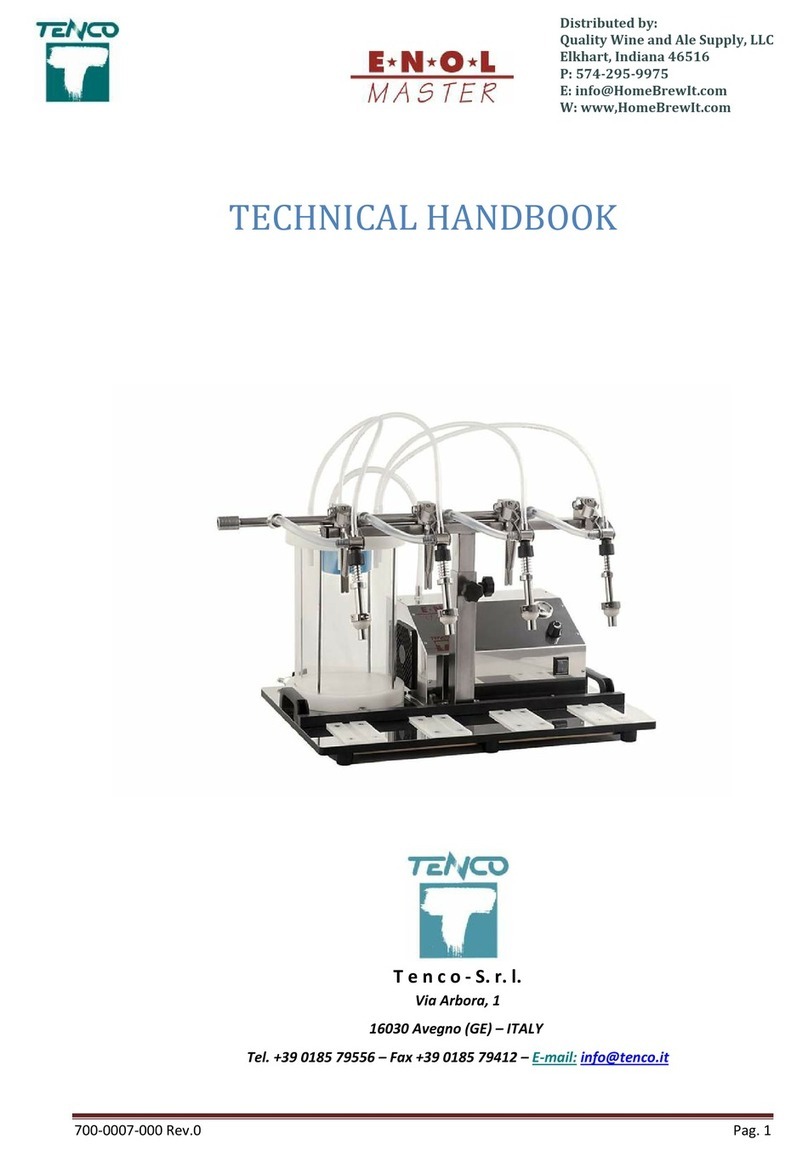

FOUR NOZZLES VACUUM FILLING MACHINE

CONTENTS

EC DECLARATION OF CONFORMITY ..................................................................... 3

CHAPTER 1 –GENERAL DIRECTIONS AND INSTRUCTIONS ....................................... 4

1.1 FOREWARD............................................................................................. 4

1.2 DESCRIPTION OF EQUIPMENT ................................................................... 4

1.3 USE ....................................................................................................... 4

1.4 TECHNICAL FEATURES ............................................................................. 4

1.5 CUSTOMER’S RESPONSIBILITY .................................................................. 4

1.6 CONNECTION AND START-UP.................................................................... 4

1.7 SAFETY INSTRUCTIONS............................................................................ 4

1.8 DIRECTIONS FOR USE.............................................................................. 4

CHAPTER 2 - INSTALLATION AND DIRECTIONS FOR USE ......................................... 5

CHAPTER 3 –CLEANING AND MAINTENANCE.......................................................... 7

CHAPTER 4 - DIAGNOSTICS................................................................................. 7

4.1 POSSIBLE TROUBLES WHILE ENOLMASTER IS RUNNING............................... 7

4.2 TROUBLESHOOTING ................................................................................ 8

CHAPTER 5 –REFERENCE STANDARDS.................................................................. 9

CHAPTER 6 - WARRANTY ..................................................................................... 9

700-0007-000 Rev.0 Pag. 3

Tenco Srl

Via Arbora 1

16036 Avegno

(GE)

FOUR NOZZLES VACUUM FILLING MACHINE

DICHIARAZIONE DI CONFORMITA’

EC DECLARATION OF COMFORMITY

Noi / We

Tenco s.r.l.-Unipersonale

VIA ARBORA, 1 - 16030 AVEGNO (GE) - ITALY

dichiariamo sotto la ns. responsabilità che: / declare under our own responsibility that:

La riempitrice a depressione

Riempitrice a depressione

Enolmaster

N. di serie

The vacuum filling machine

È conforme alla direttiva europea

2006/42/CE

2006/95/CE

2004/108/CE

Complies with the European directive

Data: / Date:

Firma / Signature

Il Direttore / The

Managing Director

700-0007-000 Rev.0 Pag. 4

Tenco Srl

Via Arbora 1

16036 Avegno

(GE)

FOUR NOZZLES VACUUM FILLING MACHINE

CHAPTER 1 – GENERAL DIRECTIONS AND

INSTRUCTIONS

1.1 FOREWARD

Before using Enolmaster, carefully read these directions for use.

1.2 DESCRIPTION OF EQUIPMENT

Enolmaster is a professional vacuum filling machine for the filling of approx. 600 bottles/hour.

1.3 USE

This equipment is to be used with wine, oil, spirits, fruit juices, perfumes, lotions, essential oils

NOTE: Products with more than 20% alcohol content could damage Enolmaster.

Therefore, in this case, we recommend to request the equipped equipped with pyrex recovery vessel.

In case the machine is used with the filter, please request TANDEM PROFESSIONAL (equipped with pyrex filter holder).

Also, if Enolmaster is employed to fill sugary liquors or products like balsamic vinegar, the air filtering unit must be

employed to avoid damage to the machine vacuum pump; this accessory is not part of the standard supply and, if

necessary, it must be ordered directly from the manufacturer.

Tenco srl. shall not be held responsible in case of malfunctioning of Enolmaster when the machine is operated to fill

products as those described above, without using the above specified accessories.

1.4 TECHNICAL FEATURES

Refer to the label on the machine.

1.5 CUSTOMER’S RESPONSIBILITY

Installation of filling machines in premises complying with all applicable sanitary regulations and fitted with certified

electrical systems shall be responsibility of the user.

1.6 CONNECTION AND START-UP

Place the equipment on a suitable surface. Connect the machine air treatment group to a compressor through a ø 8 mm

flexible hose. The machine is equipped with a quick connector for ø 8 mm hose.

1.7 SAFETY INSTRUCTIONS

Do not spill liquids into slots.

Do not open the machine, and, if so, only after power disconnection

1.8 DIRECTIONS FOR USE

1.8.1. Start-up: this equipment is started by acting on the relevant supply slide valve.

1.8.2. When the pump is working, in case the vacuum indicator is not moving, exert a small pressure on the

recovery vessel cover and check that the vacuum regulator is completely open (turned clockwise)

1.8.3. Stopping and emergency procedures: emergency stop is activated by sectioning the mains through the

slide valve (OFF position) or by pressing the red emergency button. To release, turn the button until it

returns to the normal position.

IMPORTANT: if you switch engine off while using Enolmaster, it’s absolutely necessary, before switching it on again, to

raise knob until there is no vacuum, (fig. 7). The same operation must be performed to remove the bowl cover.

700-0007-000 Rev.0 Pag. 5

Tenco Srl

Via Arbora 1

16036 Avegno

(GE)

FOUR NOZZLES VACUUM FILLING MACHINE

CHAPTER 2 - INSTALLATION AND DIRECTIONS FOR

USE

1. Before using Enolmaster, carefully read these directions for use.

2. Place Enolmaster on the work table.

3. Assemble the overflow float (fig. 1) by placing the knob with its gasket into the proper hole at the centre of the

vessel cover. Then place the float under the cover while slightly pressing the tapered plug of the knob into the

proper float housing.

4. Connect transparent hoses “A” to fittings on the cover of bowl and black hose “B” to fitting on bowl cover (fig. 2).

5. Connect the manifold from nozzles with the rigid suction pipe by using the 2 m transparent pipe supplied with the

unit. The end side (suction control) must be set to allow for fluid flow (fig. 3).

6. Connect the pipes of manifold to the nozzles.

7. Connect the supply hose to the quick connector and open the slide valve (fig.4). Make sure, by checking the

manometer on the LEFT, that the air pressure is 6 bar. If necessary act on the pressure regulator on the machine

right side for bringing the air pressure at such a value.

8. Place the suction pipe into the demijohn (or container). Be sure not to place the end in a way lees or sediments may

be sucked in.

9. Place the bottles on the proper base and one after the other into the nozzles. When the bottle is properly placed, the

lever should be in horizontal position (fig. 5). To properly adjust the lever, adjust the height of the nozzle-holding

shaft and lock it with the knob.

10. For adjusting the fill level it is necessary to adjust the cone position ring height. The maximum fill level is achieved by

moving the ring at the lower level (Fig.6-2), while the minimum fill level is achieved by moving the ring at the top

level (Fig.6-1). Intermediate levels can be achieved by positioning the ring and the silicone cone in a middle position.

For adjusting the ring position, loosen the 2 screws (A) and scroll it up / down until reaching the required position

(using the notches as a reference) then tighten the screws. Make sure the silicone cone (B) is completely adherent to

the ring. For obtaining precise and repetitive levels remove the filled bottles with a quick movement without lifting

them.

11. Filling speed may be adjusted by turning the vacuum knob (fig. 8). When using Enolmaster to fill thick fluids (oil,

liquors, a.s.o.) turn the knob to the maximum position. On the other side, when filling sparkling beverages: wine,

beer, a.s.o., turn the knob to minimum. Excessively high filling speed may cause too much foam.

12. In order to empty the recovery tank without removing it from its housing, lift the “S” knob of the float (fig. 7) until

you have no more vacuum inside. Then raise the lid and open the appropriate emptying tap.

Table of contents

Other Tenco Industrial Equipment manuals