Tempatron PID500 User manual

PID Temperature Controller

PID500 / 110 / 330

OPERATING INSTRUCTIONS

Tempatron Ltd.

Eltime House, Hall Road

Maldon, Essex CM9 4NF

Tel : +44 (0) 1621 859500

Fax : +44 (0) 1621 855335

Email : sales@tempatron.co.uk

www.tempatron.co.uk

Notes

44

Document name: Operating / 1104 / PID500/110/330 / VER3, OP104 -V03.

CONTENTS

Page no.

1. Features............................................................... 1

2. Ordering information............................................ 2

1. Safety Information................................................ 7

2. Terminal connections........................................... 9

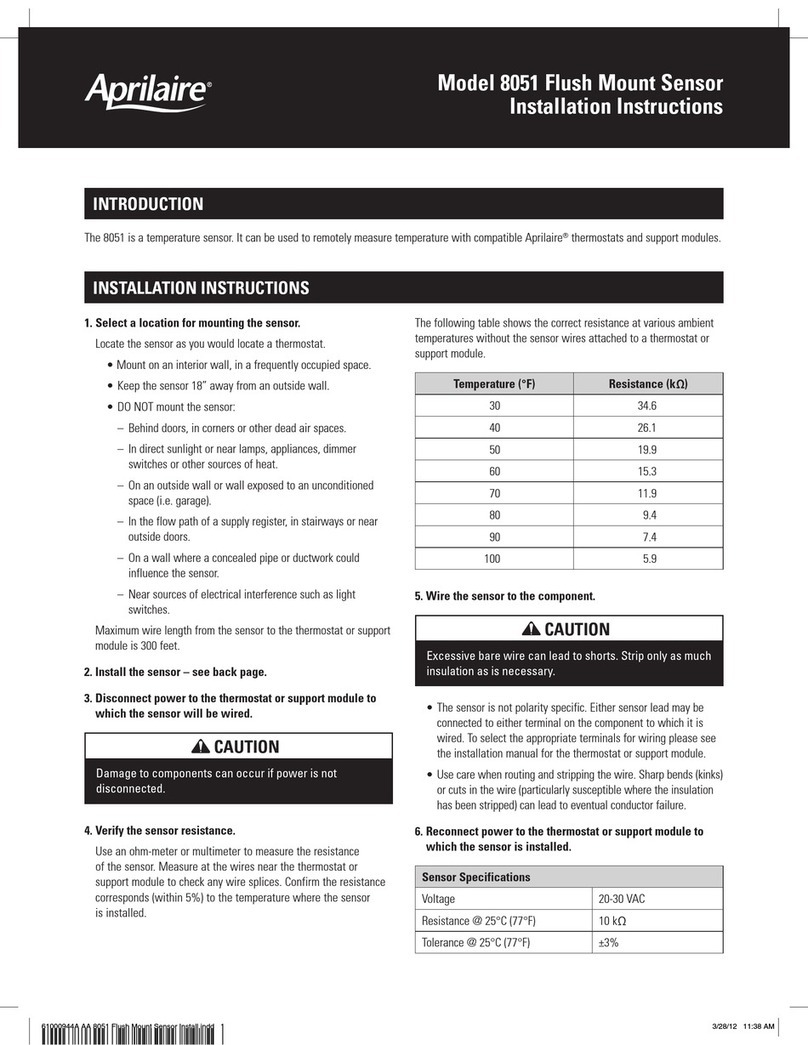

3. Sensor input wiring.............................................. 10

4. Control output wiring............................................ 10

1. Function menu..................................................... 13

2. Keys' description.................................................. 15

3. Level 0-Input parameters..................................... 16

4. Level 1-Output parameters.................................. 18

5. Level 2-Auxiliary output modes............................ 21

6. Level 3-Alarm 2 module....................................... 24

7. Level 4-Special functions..................................... 25

8. Level 5-Communication parameters.................... 28

9. Level 6-Lockout module....................................... 29

............................................................... 33

.......................... 38

A) OVERVIEW.

C) INSTALLATION.

D)

E) USER GUIDE

F) CONFIGURATION RECORD SHEET

B) SPECIFICATIONS

PROGRAMMING.

....................................................... 3

Notes

Notes

43

42

SALIENT FEATURES

?Universal Input

17 types including signal inputs.user selectable

?Selectable lower display

User selectable lower display options enable quick setting of different

parameters such as Set points, Alarms, PID values, Tuning etc.

?Zone PID

4 programmable control zones.

?Outputs

In signal output models output is selectable as control output or

retransmission output.

?Special Modes

User selectable special modes

- Heat-Cool PID

- Auto/Manual

- Single point ramp/soak.

- Soft start.

4Sensor break indication

4Sensor error compensation

4Programmable parameter lockouts

485 to 270 VAC/DC supply

4Compliance-

4IP66 front panel protection

Overview

1

Optional Features

4

4

4

4

4

4

4

4

Extra Alarm output

Heater current monitoring

Linear DC outputs (Factory set)

(0 to 10V, 0 to 5V, 0/4 to 20mA)

Remote set-point input

Motorised input

RS-485 MODBUS communication

12 VDC output to drive SSR.

24 VAC/DC supply voltage models

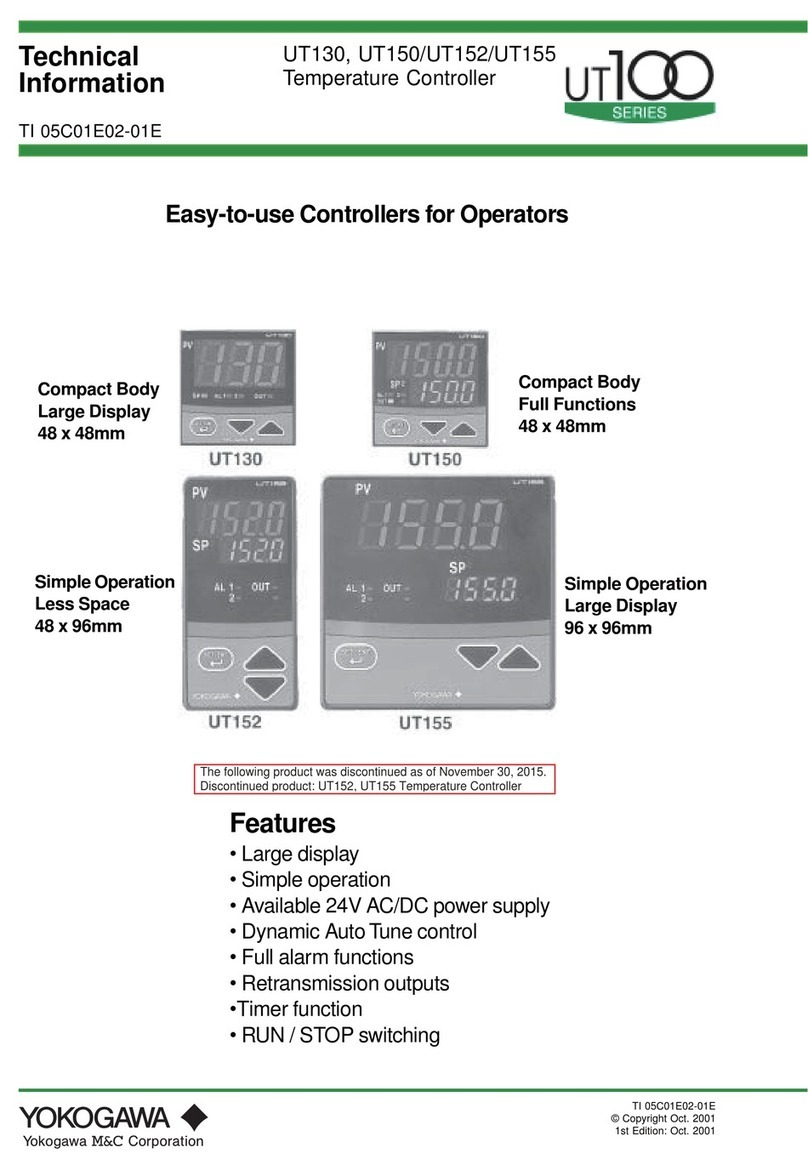

48 x 48

96 x 48

96 x 96

Configuration Record Sheet

Communication

Function Prompt Value or

Selection

Levels Factory

Setting

41

Special

Function

/

2. -ORDERING CODE

PID 110

PID 330

PID 500

A B

A : Output 1

0 - 10V

(Voltage)

Relay

12VDC

SSR drive

4 - 20mA

(Current)

0

1

2

3

XX

B : Output 2

Relay

**12V DC

SSR drive

0

1

Output 3 ( Relay )

Only Output 1 & Output 2

Output 3 (12 VDC SSR drive )

Communication RS485

Output 3 ( Relay ) +

Communication RS485

Output 3 (12 VDC SSR drive ) +

Communication RS485

CT Input

Output 3 ( Relay ) + CT Input

Output 3 (12 VDC SSR drive ) +

CT Input

CT Input + Communication RS485

*Second Analog Input ( valve positioner

type )

*Second Analog Input ( valve positioner

type ) + Communication Rs485

*Second Analog Input ( Remote set

point type )

*Second Analog Input ( Remote set

point type ) + Communication RS485

01

00

02

03

04

05

06

07

08

09

10

11

12

13

ORDERING EXAMPLE

Note: Input is user selectable.

Only Model name & output needs to be specified in the ordering code.

1. PID500 3 0 01

Output 3 ( Relay )

Output 2 ( Relay )

Output 1 ( Voltage ) 2

Overview

0 - 5V

(Voltage)

0 - 20mA

(Current)

4

5

-V 0-10V f/b input

*Second Analog input

Valve positioner type Remote Set point type

-P Potentiometric f/b input -C 4-20mA input

-C 4-20mA f/b input -V 0-10V input

Configuration Record Sheet

40

Function Prompt Value or

Selection

Levels Factory

Setting

Auxiliary

Output

Modes

Alarm 2

Module

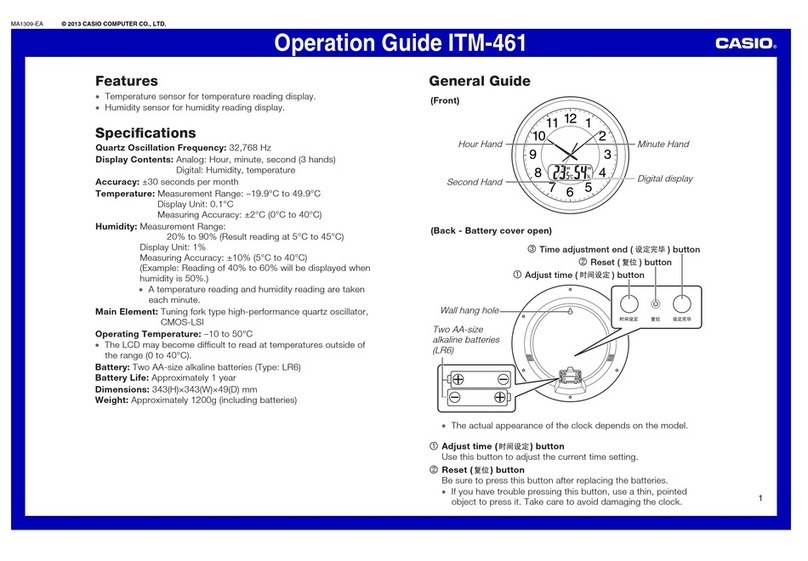

2. INPUT

Thermocouple:

RTD:

Signal inputs:

J,K,T,R,S,C,E,B,N,L,U,W,Platinel II.

PT100.

-5 to 56 mV, 0 to 10 VDC, 0 to 20 mA DC

(Programmable scale type)

200 ms.

1/0.1 for TC/RTD.

1/0.1/0.01/0.001 for Analog input.

(Decimal point position)

O

+

+

0.25% of span or 1 whichever is greater.

(20min of warmup time). Cold junction calibration

accuracy in TC mode 5 C.

O

o

OFF, 1 to 99 sec.

Led Status

Annunciators

Input

Sampling time

Resolution

Indication accuracy

Digital filtering

1. TECHNICAL SPECIFICATIONS

1. DISPLAY

Display

Main output (1)

Alarm output (

Manual output (M)

Tune (T)

2, 3)

3

Specifications

3. OUTPUT

3.1. Control Output

Rating: 5A @250 VAC or 30 VDC.

Life expectancy: 100000 cycles at maximum load rating.

18 VDC.

Range: 0 -20 mA DC, 4-20 mA DC (Factory set)

Action: Control.

Update rate: PID Update - Every Cycle time.

Analog Output - 100 msec.

Maximum output load resistance: 500E.

Range: 0-5 VDC .

Action: Control.

Minimum output load resistance: 10K.

, 0-10 VDC (Factory set)

Update rate: PID Update - Every Cycle time.

Analog Output - 100 ms.

Relay contact output

SSR drive voltage output

(optional)

Current output (Optional)

Voltage output (Optional)

PID500 - 48 X 48 - .

.

.

PID110 - 48x96 - .

.

.

PID330 - 96x96 - .

.

.

Dual 4 digit 7- segment LED

Upper display : 10mm high Red (process value)

Lower display : 7mm high Green (selectable)

Dual 4 digit 7- segment LED

Upper display : 10mm high Red (process value)

Lower display : 7mm high Green (selectable)

Dual 4 digit 7- segment LED

Upper display : 14mm high Red (process value)

Lower display : 10mm high Green (selectable)

** For PID110/PID330

18V DC SSR drive

3. FUNCTION

Control: PID or ON/OFF.

Output: Time proportioning or Linear DC.

Proportional band: 0 to 400

Integral time: 0 to 3600 sec

Derivative time: 0 to 200 sec

Cycle time: 0.1 to 100.0sec.

Auto tune.

Programmable % output.

O

4 programmable control zones.

Control: PID or ON/OFF

Output: Time proportioning.

Proportional gain: 0 to 400

Cycle time: 0.1 to 100.0sec.

Heat/Cool dead band overlap: Programmable

.

Range: 0 / 4-20mA.

Action: Retransmission

Update rate: 100 ms

Maximum output load resistance: 500E

Range: 0-5 / 10V.

Action: Retransmission

Update rate: 100msec

Minimum output load resistance: 10K

Main control

Zone PID

Heat-cool PID mode

Current output

Voltage output

3.3. Retransmission output (optional)

4

Specifications

Modes: Deviation high, Deviation low, Band,

Full scale high, Full scale low, Sensor break.

Operation: Absolute or Deviation mode

Hysteresis: Programmable

Hold/Standby mode: Programmable

Annunciator: Programmable

Reset action: Programmable - Automatic or latched

Probe break action: Upscale

Alarms

4. OPTIONAL

4.1. Remote set point input

0...20mA / 0...10V.

100 ohms.

-5% ... 105%.

-1999...9999 with fixed 1 C for TC/RTD and

as per resolution selected for Analog input.

O

Input type

Input Resistance

Over range

Scale range

Rating: 5A @250 VAC or 30 VDC.

Life expectancy: 100000 cycles at maximum load rating.

Relay contact output

(Relay 2, Relay 3 (optional)

3.2. Alarm Output

39

Function Prompt Value or

Selection

Factory

Setting

Levels

Configuration Record Sheet

Output

Parametrs

Zone

Settings

38

Function Prompt Value or

Selection

Factory

Setting

Input

Parametrs

Output

Parametrs

Enter the value or selection for each prompt on this sheet so you will have a

record of how your controller was configured.

As per input type

selected.

Levels

As per input type

selected.

Configuration Record Sheet

5

Specifications

Single phase, full wave monitoring of load currents

controlled by main output.

100mA AC output from current transformer.

0....999.9A.

47 ohms.

+ +0.5% of full scale 1 digit.

50...400Hz.

LA / HA / BAND.

105% Capacity.

150mA (continuous).

Type

Input

Display scale range

Input resistance

Accuracy

Frequency

Alarm mode

Over range

Over load

4.2. Heater current monitor input

RS 485.

0 .... 50 C.

o

85 .... 270 VAC/DC. (Optional 24 VAC/DC)

50/60Hz.

5 VA max.

-20 .... 75 C.

o

85% max. RH (non condensing) from 0 to 50 C.

o

1 .... 99, maximum of 32 units per line.

Half duplex.

MODBUS RTU.

500 m maximum.

9600, 4800, 2400, 1200, 600, 300 bits/sec.

None, Odd, Even, Mark, Space.

1 or 2.

100ms (max and independent of baud rate).

Interface standard

Operating range

Power supply

Frequency

Power consumption

Storage range

Storage humidity

Communication address

Transmission mode

Transmission protocol

Transmission distance

Transmission speed

Parity

Stop bits

Response time

4.3. Serial communication

5. ENVIRONMENTAL CONDITIONS

6. POWER SUPPLY

2000 volts.

2000 VAC.

AC line w.r.t. all inputs and outputs

All other inputs and outputs w.r.t. Relay contacts

7. ISOLATION BREAKDOWN RATINGS.

6

Sensor type Range Sensor type Range

J- 200 to 750 C

oE

K- 200 to 1350 C

oB

T- 200 to 400 C

oN

R0 to 1750 C

oL

S0 to 1750 C

oU

C0 to 2300 C

oW

Platinel II 0 to 1390 C

oPT100

- 200 to 750 C

o

+149 to 1820 C

o

- 200 to 1300 C

o

- 200 to C600o

- 200 to C900o

0 to 2300 C

o

- 100 to 850 C

o

Signal inputs: Input type

Linear mV

Voltage

Current

Range

-5 to 56mV

0 to 10 VDC

0 to 20mA

Specifications

CE.

As per BS EN 61010.

As per BS EN 61326.

IP66.

Compliance

LVD

EMC

Panel sealing

8. SAFETY AND EMC STANDARDS.

9. WEIGHT :

10. HOUSING :

11. INPUT SENSOR RANGES (for 1 C resolution):

PID500 : 195 gms ; PID110 : 250 gms ; PID330 : 295 gms

Flame retardant engineering plastic.

o

12. INPUT SELECTION JUMPER ASSIGNMENTS:

NOTE : Sensor selection to be done in Level 0 of programming also.

Short respective pins of JP3 & JP4 as per

the table given below for hardware selection

of input sensor types:

JP4

F E C D

JP3

X B A

4 - 20 mA (BA) (CD)

X B A F E C D

TC / RTD / LIN (mV)

Input type

0 - 10V

JP3

(XB)

(XB)

JP4

(FE)

(EC)

X B A

X B A F E C D

F E C D

User Guide

!

How to tune the Zones

To tune, say, Zone 1 program the following:

Zone PID:

There are 4 control Zones each having a set point and associated P, I and D values which

can be programmed as per the process requirements. A control Zone is selected

automatically and implemented as per the set value programmed, to accommodate

changing process requirements. The corresponding P, I,D values will be used to control

the process. The main advantage of Zone PID is in processes where there is a

requirement of frequent tuning, due to change in setpoint. Consider a case where the

process needs to be controlled at two different set points: 100 C and 400 C.

The Zone set points may be programmed as:

1. Zone setpoint 1 (Level1) : 150 C (This implies that for 0 < set1 < 150, Zone1 PID

values will be considered.)

2. Zone setpoint 2 (Level1) : 450 C (This implies that for 150 < set1 < 450, Zone2 PID

values will be considered.)

The P, I, D values for the respective Zones can be manually fed or can be tuned

automatically.

NOTE : Zone setpoint is not the tuning setpoint.

1. Set1 (Online) = 100 C (for eg.) (Zone 1 : 0 - 150 C)

• Set1 < Zone setpoint 1.

• The PID settings derived after tuning are stored in Zone 1.

• After tuning, for 0 < Set1 < 150 C, PID settings of Zone 1 are applicable.

2. Program Tune = ON (in Level 1 or Online)

3. After tuning the controller is automatically loaded with the new PID values.

Now to tune the next Zone, Zone 2, program the following:

1. Set 1 (Online) = 400 C (Zone 2 :150 - 450 C)

• Zone Setpoint 1 < Set 1 < Zone setpoint 2.

• The PID settings derived after tuning are stored in Zone 2.

• After tuning, for 150 < Set1 < 450 C, PID settings of Zone 2 are applicable.

Similarly, the four different Zones can be programmed.

O O

O

O

O O

O

O O

O

Note:

Note:

37

!

1.

Full scale High Alarm:

Refer Fig: d.

Full scale Low Alarm:

Refer Fig: e.

2.

Deviation High Alarm:

Refer Fig: a.

Deviation Low Alarm:

Refer Fig: b.

Deviation Band Alarm:

Refer Fig: c.

3.

ALARM MODES:

Absolute alarms (Independent Alarm) :

Deviation alarms (Error alarm):

BREAK ALARM:

Absolute alarm is a self-existent alarm independent of the main set point.For eg. If the

main set point is 100 C and absolute alarm is set as 110 C, the alarm will be activated at

110 C.

There are two absolute alarms-

sets off alarm signal when temperature rises above set point to a

pre-set temperature above scale minimum.

sets off alarm signal when temperature falls below setpoint to a

pre-set temperature above scale minimum.

This alarm is activated at an error on the main set point. For eg. If the main set point is

100 C and deviation alarm is set to +5 C then the alarm will be activated at 100+5=105

C. Incase of deviation band alarm the alarm will be activated on both sides of set point i.e.

At 95 and 105.

There are three deviation alarms -

sets off alarm signal when temperature rises above a pre-set

temperature above the set point.

sets off alarm signal when temperature falls below a pre-set

temperature below the set point.

sets off alarm signal when temperature rises above or falls below

a pre-set temperature above or below the set point.

Break Alarm: sets off alarm signal when sensor break / under range occurs.

O O

O

O O

O

User Guide

Deviation low alarm Deviation band alarm Full scale high alarm Full scale low alarmDeviation high alarm

SP2

SP2

SP2

SP2 SP2

SP2

SP

setpoint

SP

setpoint

SP

setpoint

SP

setpoint

SP

setpoint

Alarm

state

Fig: a. Fig: b. Fig: c. Fig: d. Fig: e.

36

!

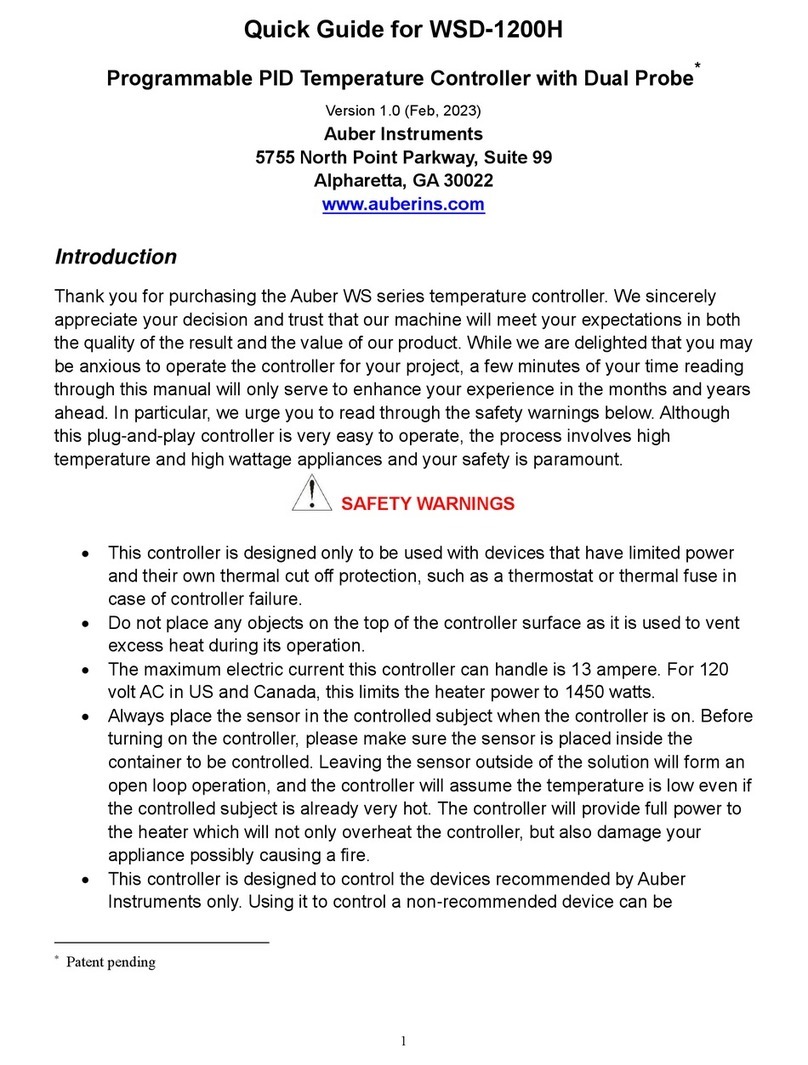

SAFETY SUMMARY

This manual is meant for the personnel involved in wiring, installation, operation, and

routine maintenance of the equipment. All safety related codifications; symbols and

instructions that appear in this operating manual or on the equipment must be strictly

followed to ensure the safety of the operating personnel as well as the instrument.

If the equipment is not handled in a manner specified by the manufacturer it might

impair the protection provided by the equipment.

Read complete instructions prior to installation and operation of the unit.

Risk of electric shock.

CAUTION:

CAUTION:

1. SAFETY INFORMATION

INSTALLATION INSTRUCTIONS

CAUTION:

CAUTION:

1.This equipment, being built-in-type,normally becomes a part of the main control

panel and in such case the terminals do not remain accessible to the end user

after installation and internal wiring.

2.Conductors must not come in contact with the internal circuitry of the equipment

or else it may lead to a safety hazard that may in turn endanger life or cause

electrical shock to the operator.

3.Circuit breaker or mains switch must be installed between power source and

supply terminals to facilitate power 'ON' or 'OFF' function. However this switch or

breaker must be installed in a convenient position normally accessible to an

operator.

1.The equipment shall not be installed in environmental conditions other than those

specified in this manual.

2.Fuse Protection - The equipment does not contain built-in fuse. Installation of

external fuse for electrical circuitry is highly recommended. Recommended rating

of such fuse shall be 275VAC/1Amp.

3.Since this is a built-in type equipment (finds place in main control panel), its

output terminals get connected to host equipment. Such equipment shall also

comply with basic EMI/EMC and safety requirements like BS EN 61326-1 and

BS EN 61010 respectively.

4.Thermal dissipation of equipment is met through ventilation holes provided on

chassis of equipment. Such ventilation holes shall not be obstructed else it can

lead to a safety hazard.

5.The output terminals shall be strictly loaded to the manufacturer specified

values/range.

!

!

7

Installation

MAINTENANCE

1.The equipment should be cleaned regularly to avoid blockage of ventilating parts.

2.Use soft cloth for cleaning. Do not use isopropyl alcohol or any other organic

cleaning agent.

WIRING INSTRUCTIONS

CAUTION:

1.To prevent the risk of electric shock power supply to the equipment must be

kept OFF while doing the wiring arrangement.

2.Terminals and electrically charged parts must not be touched when the power

is ON.

3.Wiring shall be done strictly according to the terminal layout with shortest

connections. Confirm that all connections are correct.

4.Use lugged terminals to meet M3.5 screws.

5.To eliminate electromagnetic interference use of short wire with adequate

ratings and twists of the same in equal size shall be made.

6.Cable used for connection to power source, must have a cross section of 1 or

greater. These wires shall have insulation capacity made of at least 1.5KV.

INSTALLATION GUIDELINES

Mechanical Installation:

For installing the controller

1.Prepare the panel cutout with proper dimensions as shown.

2.Remove the clamp from the controller.

3.Push the controller into the panel cutout. Secure the controller in its

place by pushing the clamp from the rear side.

CAUTION:

The equipment in its installed state must not come in close proximity to any

heating sources, caustic vapors, oils, steam, or other unwanted process by-

products.

!

8

Installation

ELECTRICAL PRECAUTIONS DURING USE

Electrical noise generated by switching of inductive loads can create momentary

disruption, erratic display, latch up, data loss or permanent damage to the instrument.

To reduce noise:

A) Use of MOV across supply of temperature controller & snubber circuits

across loads are recommended. Part numbers are as follows:

1. Snubber: APRC-01.

B) Use separate shielded wires for inputs.

C) The unit should preferably be shielded from the contactor.

EMC Guidelines:

1.Use proper input power cables with shortest connections and twisted type.

2.Layout of connecting cables shall be away from any internal EMI source.

OVERALL DIMENSIONS (All dimensions in mm)

E

A

Panel Cutout

F

D

BCG

AB C D E F G

PID500

48 48 100 45 7 45 45

96 96 74.5 90 10 92 92

PID330

96 48 74.5 90 10 92 45

PID110

MODELS

DIM

!DERIVATIVE APPROACH CONTROL:

AUTO-TUNE OF HEAT/COOL SYSTEMS:

ANALOG OUTPUT-RETRANSMISSION:

Derivative approach control (DAC) helps in reducing overshoot at startup. The control

output cutoff point is derived as DAC x Proportional band. Note that the DAC value is

automatically calculated and fed after autotuning (if tuning is initiated at startup).

During Autotune of heat/cool systems, the controller switches the cooling output (O2) ON

and OFF in addition to the heat output (O1). The heat/cool overlap deadband parameter

(db in Level 2) determines the amount of overlap or deadband between the two outputs

during Autotune.

For most applications, set this parameter to 0.0 prior to starting Autotune. After the

completion of Autotune, this parameter may need to be reset. It is important that external

load disturbances be minimized, and if present, other zone controllers idled as these may

have an effect on the PID constant determination.

Some water cooled processes exhibit an extreme non-linear gain characteristic. That is,

the process cooling gain starts very high and flattens out deeper into the cooling region.

This effect may result in regular oscillations at setpoint as the controller applies heat to

counteract the effect. These processes may benefit from a lower cooling fan setting and/or

reduced water flow in the jacket or manifold. The process heat and cool gains should be

balanced as much as possible, and the controller gains adjusted to the process.

1. The analog retransmission output feature allows the retransmission of the control

output to an external device.

2. The output is scaled by use of Analog low and high scaling points in level 2 of the

programming menu. The analog output will be proportional to PV (derived from

Analog Low and High scaling.)

3. A-LO : Displays the value that corresponds to 0V, 0/4mA as selected.

A-HI : Displays the value that corresponds to 10V or 20mA as selected.

4. Note that the main output selection in level 4 has to be relay 2.

!

!

User Guide

35

!

!

!

“antireset wind-up”

PROPORTIONAL BAND:

MANUAL RESET:

INTEGRAL TIME:

DERIVATIVE TIME

Proportional band is the area around the set point where the controller is actually

controlling the process; the output is at some level other than 100% or 0%.

Proportional band is expressed in terms of degree centigrade.

If the proportional band is too narrow an oscillation around the setpoint will result. If the

proportional band is too wide the control will respond in a sluggish manner, could take a

long time to settle at set point and may not respond adequately to upsets.

Virtually no process requires precisely 50% output on single output controls or 0% output

on two output controls. The adjustment called manual reset allows the user to redefine the

output requirement at the setpoint. A proportioning control without manual or automatic

reset will settle out somewhere within the proportioning band but likely not on the setpoint.

Integral time is defined as the time, in seconds, which corrects for any offset (between

setpoint and process variable) automatically over time by shifting the proportioning band.

Integral action (also known as “automatic reset”) changes the output power to bring the

process to setpoint. Integral times that are too fast (small times) do not allow the process

to respond to the new output value. This causes over-compensation and leads to an

unstable process with excessive overshoot. Integral times that are too slow (large times)

cause a slow response to steady state errors. Integral action may be disabled by setting

the time to zero. If time is set to zero, the previous integral output power value is

maintained. If integral action is disabled, manual reset is available by modifying the output

power offset (“MNL.r” initially set to zero) to eliminate steady state errors. The controller

has the feature to prevent integral action when operating outside the proportional band.

This feature is called .

Derivative action is used to shorten the process response time and helps to stabilize the

process by providing an output based on the rate of change of the process. In effect,

derivative action anticipates where the process is headed and changes the output before

it actually “arrives”. The derivative time is calculated in seconds. Increasing the derivative

time helps to stabilize the response, but too much derivative time coupled with noisy

signal processes, may cause the output to fluctuate too greatly, yielding poor control.

None or too little derivative action usually results in decreased stability with higher

overshoots. No derivative action usually requires a wider proportional and slower integral

times to maintain the same degree of stability as with derivative action. Derivative action is

disabled by setting the time to zero.

!

34

2. TERMINAL CONNECTIONS

9

Installation

PID500

+

SSR1 /

ANA OP

COM1

COM2

COM3

NO1

NO2

NO3

+

+

+

+

-

-

-

-

SSR2

SSR3

N

L

-

11

12

13

14

15

16

17

18

19

20

RS485

RTD3

mV

TC /RTD1

+

+

mV

TC /RTD2

-

-

1

2

3

4

5

6

7

8

9

10

+

V

+

+

MI /

CT/

R-SP

PID110

PID330

1689 10

5

4

3

2

16 17 18 19 20

15

14

13

1211

7

+

SSR1/

ANA OP

COM1 COM2 COM3NO1 NO2 NO3

+

+

++

+

+

SSR2 SSR3 LN

RS485

V

RTD3

mV

TC /RTD1

+

+

mV

TC /RTD2

-

-

-

MI / CT / R-SP

+

RTD3

ANA IP

TC /RTD1

+

+

+

-

ANA IP

TC /RTD2

-

-

RS485

12 7

13 8

14 9

15 10

COM2

SSR1/ 0-5 V/

0 -10 V/4 -20mA

SSR2

NO1

COM1

NO2 2

1

3

4

5

+

-

+

-

L (+) 6

11 (-) N

COM3

NO3

+

-

SSR3

NOTE: Terminals 11 to 15 are optional NOTE: Valid for optional configuration.

RTD3

ANA IP

TC /RTD1

+

+

ANA IP

TC /RTD2

-

-

7

13 8

14 9

15 10

COM2

SSR1/ 0-5 V/

0 -10 V/4 -20mA

SSR2

NO1

COM1

NO2 2

1

3

4

5

+

-

+

-

L (+) 6

12

11 (-) N

+

-

+

-

RS485

CT / MI / R-SP

User Guide

User Guide

ADJUST MENT SEQUENCE SYMPTOM SOLUTION

Slow Response Decrease PB

(1) Proportional Band (PB) High overshoot or

Oscillations Increase PB

Slow Response Decrease IT

(2) Integral Time (IT) Instability or

Oscillations Increase IT

Slow Response or

Oscillations Decrease TD

(3) Derivative Time (TD)

High Overshoot Increase TD

33

USER GUIDE

nAUTO TUNING:

Auto tuning is a function whereby the controller

learns the process characteristics by itself and

automatically sets the required P,I and D values.

The auto-tuning function can be activated at any

time during the process after power ON , while

temperature is rising or when control has

stabilized. Autotune is indicated by T LED blinking

After the auto tuning procedures are completed,

the T LED will stop flashing and the unit will

revert to PID control by using its new PID values.

The PID values obtained are stored in the nonvolatile memory.

Initial setup for a new process

The set point is changed substanitally from the previous auto-tuning value.

The control result in unsatisfactory.

The following controller parameters are automatically adjusted by Auto- tune

according to the characteristics of the process:

Proportional Band (Pb-1)

Integral Time (It-1)

Derivative Time (dt-1)

Input Filter (FtC)

The auto-tuning is applied in cases of:

=

=

=

If the control performance by using auto-tuning is still unsatisfactory, the following rules

can be applied for further adjustment of PID values:

set point

Temp.

Proportional band

PID - time proportioning

with auto reset & rate

Reduced overshoot

Time

3. SENSOR INPUT WIRING

TC - Thermocouple (J, K, T, R, S, C, E, B, N, L, U, W, Platinel II).

V - Voltage Input (0 to 10 V DC).

mA- Current Input (0 to 20mA DC)

RTD - PT100.

NOTE : 1) Refer input type selection in level 0 of programming menu.

2) For PID500 refer input jumper selection as in point no. 12 on page 6.

3) For 2 wire RTD short terminals 8 & 9 (for PID500) and terminals 3 & 4

(for PID110 & PID330) .

4. CONTROL OUTPUT WIRING

4

5

LOAD

230VAC

SUPPLY

NO

COM

10

Installation

RTD2

7

8

9

TC

+

-

V

+

-

+

-

mAV

RTD3

RTD1

PID500 PID110 & 330

PID500 PID110 & 330

11

12

LOAD

230VAC

SUPPLY

NO

COM

Fig1. Output 1 - Relay to drive load (resistive load less than 1A).

5

6

7

V

+

-

mA

V

RTD2

2

3

4

TC

+

-

RTD3

RTD1

+

-

N

L

N

L

32

DISPLAY CONDITIONDISPLAY DESCRIPTION

Output percentage

Elapsed soak time

Temperature unit

Alarm acknowledge 1

Alarm acknowledge 2

Blank

Programming

This parameter is read only

and cannot be altered.

Note: This parameter is

prompted only if Ramp is ON /

Hold. This parameter is read

only and cannot be altered.

Note: This parameter is not

prompted for 0-10 V / 4-20mA.

This parameter is read only

and cannot be altered.

Note: This parameter is

prompted only if Alarm1 is ON

and Latch is ON.

Note: This parameter is

prompted only if Alarm2 is ON

and Latch is ON.

/

PID500 PID110 & 330

4

5

NO Snubber(Optional)

(Part No: APRC-01)

230VAC

SUPPLY

COM

L

LOAD Contactor

N

Fig3. Output 1 - Pulsed voltage to drive SSR.

NOTE: Use snubber as shown above to increase life of internal relay of

temperature controller.

11

Installation

4

5

LOAD

230VAC

SUPPLY

SSR

11

12

NO Snubber(Optional)

(Part No: APRC-01)

230VAC

SUPPLY

COM

L

LOAD Contactor

N

Fig2. Output 1 - Relay / SSR to drive contactor(For single phase).

PID500 PID110 & 330

11

12

LOAD

230VAC

SUPPLY

SSR

Fig4. Output 1 - Linear current.

Fig5. Output 1 - Linear voltage.

4

5

LOAD

0-5V

OR

0-10V

Minimum

Load 10K

Ohms

NO

COM

Maximum

Load 500

Ohms

4

5

LOAD

4-20mA

NO

COM

12

Installation

PID500 PID110 & 330

Maximum

Load 500

Ohms

11

12

LOAD

4-20mA

NO

COM

PID500 PID110 & 330

11

12

LOAD

0-5V

OR

0-10V

Minimum

Load 10K

Ohms

NO

COM

NOTE:

For output 2 and output 3:

1) Configuration is same.

2) Terminal nos -

Output 2 : 2 - 3.

Output 3 : 14 - 15.

PID500 - ; PID110 & 330 -

PID500 - ; PID110 & 330 -

13 - 14

15 - 16

ONLINE DISPLAY OPTION

This function allows user to view online display options.

NOTE:

The parameters shown below are not prompted if they are locked in level 6.

Programming

DISPLAY DESCRIPTION

Set point 1

Set point 2

Set point 3

Proportional band - heat

Integral time

Derivative time

Auto tune

Hand output percentage

Manual reset

Proportional band - cool

DISPLAY CONDITION

Ramp set point

Online access for Set 2 not

valid if Auxillary output =

Sensor Break / OFF /

Retransmission

Online access for Set 3 not

valid if Alarm mode = Sensor

Break / OFF.

Online access for Auto tune

is not valid if PB-Heat=0 and

HC=no or PB-Cool=0.

This parameter is not

prompted if Pb- H = 0

Integral time is not

prompted if PB = 0

Derivative time is not

prompted if PB = 0

Manual reset is prompted

only if Integral-main=0 and

PB-heat>0.

This parameter is prompted

only if HC = yes.

This parameter is prompted

only if Ramp is ON / Hold.

This parameter is read only

and cannot be altered.

/

31

Lock Level 0

Lock Level 1

Lock Level 2

Lock Level 3

Lock Level 4

/

/

/

/

/

/

/

/

/

/

Display Name & Description Range Display

condition

Default

value

# If LOCK selection is LEVL, the following parameters will be prompted.

Change password

New password

/

NEW = Id-Y

Programming

Insert jumper to reset the lock - id.

NOTE:

UNLK - Full access to the particular level / parameter.

READ - Particular level / parameter can be read but not edited.

LOCK - No access to the particular level / parameter.

30

PR500

P

V

S

V

M

T1

2

3

Lock code

position

TO CHANGE LEVELS PRESS + OR + TOGETHER

Input type

Resolution

Temp unit

Display scaling

low

Input scaling

low

Display scaling

high

Input scaling

high

Reverse

scaling

Set2 mode

Set2 type

Set2 value

P B - cool

Cycle time - cool

Hysteresis

Hysteresis bias

Alarm mode

Alarm mode

Latch alarm

Hold alarm

Alarm status

Annunciator

Set point 3

Alarm Hysteresis

Hysteresis

bias

User ID

Program access

+

+

Online

Set 1

Set 2

Set 3

Auto tune

Appearance of all shaded menus dependent on selection of other parameters.

Refer programming for futher details

* - Applicable only if Alarm2 is available.

Programming

1. FUNCTIONS MENU

13

On/Off Hysteresis

Hysteresis

bias

Tune %age

Autotune

Relay 1 mode

O/P power low

limit

O/P power upper

limit

Set mode

Zone number

Zone set point

Proportional

band

Integral time

Derivative time

Heat - cool

Main output

SSR Output

Soft start time

Hand O/P %

Ramp mode

Ramp rate

Zone

SET = ZONE

Lock level 0

Lock level 1

Lock level 2

Lock level 3

Lock level 4

S.P.High limit

S.P. Low limit

Change password

New password

Hand O/P

%age

P.B - main

Integral

time

Derivative

time

Manual

reset

P.B - cool

Change

password

New

password

INPUT

PARAMETERS

OUTPUT

PARAMETERS

(main output)

*ALARM 2 MODULE

(output 3) (optional)

LOCK MODULE

(online

parameters)

LOCK MODULE

(levels)

NOTE:- LEVEL 5

LEVEL 9

LEVEL 10

- Communications Module.

- Heater current monitor input.

- Motorised input / Remote set point input.

Detailed description of the above levels will be provided as an addendum with the

respective models.

SPECIAL

FUNCTIONS

AUXILIARY OUTPUT

MODES (output 2)

Latch alarm

Hold alarm

Alarm status

Annunciator

Analog Low

Scale

Analog High

Scale

Sensor error

level

14

Programming

Integral time

Derivative time

Derivative approach

control

Cycle time

Cycle time (user)

Anti reset windup

ARW percentage

Manual reset

Proportional

band - heat

Timer

Sensor open

selection

Sensor fail

power level

P V bias

Filter time

constant

Rounding

increment

Standby mode

Reset all

Soak time

O/P power

dampening

User ID

Program access settings #

to

/

Display Name & Description Range Display

condition

Default

value

8. - PROGRAMMABLE PARAMETER

LOCKOUT MODULE

LEVEL 6

Lock Set 1

Lock Set 2

Lock Set 3

Lock tune parameter

Lock Hand parameter

/

/

/

/

/

/

/

/

/

/

Display Name & Description Range Display

condition

Default

value

# If LOCK selection is ONL, the following parameters will be prompted.

Lock proportional band

Lock integral time

Lock derivative time

Lock Manual reset parameter

Lock proportional band-cool

/

/

/

/

/

/

/

/

/

/

Programming

29

8. - COMMUNICATION PARAMETERS (OPTIONAL)LEVEL 5

Programming

RS232C 485

CONVERTER

11 1

66 6

77 7

88 8

9 9 9

10 10 1015 15

14 14 14

13 13 13

12 12 12

11 11 11

33 3

44 4

55 5

22 2

+

15

+

+

Terminating resistor

(100 ohm, ½ watt)

RS485 RS485 RS485

SLAVE 1 SLAVE 2 SLAVE 32

CONNECTION DIAGRAM

Note:

1. Maximum 32 slave controllers can be connected to the master.

2. The total cable length should not exceed 500 meters.

3. Use shielded twisted -pair cables for RS485 connections.

4. Use terminators having a resistance of 100ohm (½ watt).

28

Master

Baud Rate

Communication station No.

Display Name & Description Range Display

condition

Default

value

Parity

Stop bit

/ /

/

to

/

/

/

RS485-RS232 Converter

Part no.- AC-RS485-RS232-01

5

4

3

6

7

1

2

INDICATIONS AND DISPLAY

2

5

6

7

1Process-value (PV)

Set-value (SV)

3Relay 1 (1)

4Relay 2 (2)

Relay 3 (3)

M

T

Display the process temperature value.

Displays the value of the lower display option

selected. By default display is set1 value.

Indicates the status of Main output (relay 1).

Indicates the status of Alarm output (relay 2).

Indicates the status of relay 3).Alarm output (

Indication for Fixed Manual output.

Indication for Tuning in progress.

15

Programming

Key press

Functions

To enter or exit program mode

To change levels

To view function on the same level and

to display the current option.

To increase or decrease the value of a

particular function.

To view and change parameters online

+ together for 3 seconds

or till Level is displayed. + /

to increase or decrease the level number.

or key once to view the

next/previous function.

+ to increase and + to

decrease the function value.

key to view the parameter and + /

to scroll through the parameters. Press

+ / to change parameter value.

NOTE: The unit will autoexit program mode after 60 seconds of inactivity.

2. KEYS DESCRIPTION

16

3. - INPUT PARAMETERSLEVEL 0

Display Name & Description Range Display

condition

Default

value

Input type

Select input type as

Thermocouples: J,K,T,R,S,C,E,

B,N,L,U,W. Platinel II.

RTD: PT100

Signal Inputs: Linear mV (-5 to

56mV), Voltage (0 to 10V),

Current (4 to 20mA).

Refer table on page 6 for input

ranges.

Resolution

Temperature unit

Display value scaling point1 #1

Feed the value of the display

required at the lower value of

analog input

Input value scaling point1

Feed the lower value of the

analog input signal.

Display value scaling point2 #1

Feed the value of display

required at the higher value of

analog input

/ / /

/ / /

/ / /

/ / /

/

/ /

/

TC * / RTD:

Analog

input: /

/ /

/

/

to

Display

value

scaling

point2

mA /

mV

/ Vto

Input value

scaling

point2

Display

value

scaling

point1 to

Not prompted

for R, S, and

B type

thermocouple

.

TC/RTD

inputs.

Analog input.

Analog input. As per

input type

selected.

Analog input.

Programming

PROGRAMMING OF LEVELS

* - Fixed 1 C resolution for R, S, B type thermocouple.

o

27

Programming

PARAMETER EXPLANATIONS :

!

!

!

!

MAIN OUTPUT:

SOFT START TIME:

HAND OUTPUT PERCENTAGE:

RAMP - SOAK:

The main control output is selectable between Relay1 / Analog output (available across

terminals 4 and 5) and Relay2 (available across terminals 2 and 3). If main output is selected

as Relay 2, all the control parameters will be applicable to the output connected to Relay 2 but

the setpoint applicable will be Set 1 (main set point). For analog retransmission, the main

output must be set to Relay 2 and the analog output (across 4 and 5) will be used for

retransmission.

Soft start time can be programmed in situations where full output is not required at power ON.

The time duration for the output to rise from 0% to 100% is programmed as soft start time.

This parameter can be used when a fixed percentage of output is desired. For example: If 4-

20mA analog output is being used and the desired output is 12mA, the hand percentage can

be programmed as 50%. This will ensure that the analog output available is fixed 12 mA i.e.

50%. In case of relay output models, the relay ON time and OFF time will be according to the

programmed Hand output percentage i.e. For 50% hand o/p percentage and cycle time

15sec, relay will be ON for 7.5sec and OFF for 7.5 sec.

The setpoint ramp feature can reduce thermal shock to the process, reduce temperature

overshoot on start-up or set point changes, or ramp the process at a controlled rate. The soak

feature can be used to hold the process at a preset temperature for a preset time.

:

Ramp OFF: Controller will be simple PID/ ON-OFF controller with P, I, D

settings/hysteresis setting by user or default.

Ramp HOLD: Suspends the ramp at the last value.

Ramp ON: Initiates the ramp. Ramp rate and soak time settings as programmed by

the user or default.

Ramp modes

a

Rounding increment

Standby mode

Reset all

to

for TC/RTD

Display as

per decimal

point

selected for

analog

input.

/

/

Display Name & Description Range Display

condition

Default

value

TC / RTD with

resolution =

1 C or Analog

input.

O

26

Programming

Output power dampening , to

seconds

Analog output

model.

Filter time constant , to

seconds

17

Display Name & Description Range Display

condition

Default

value

Input value scaling point2

Feed the higher value of the

analog input signal.

Reverse scaling

Display scaling points can be

reversed.

Set point high limit #1

Set point low limit #1

Input value

scaling

point1 to

mA

/ mV

/ V

/

Set point low

limit to max.

sensor range

value. Set

point low

limit to

for

analog input.

Min. range

of sensor to

.

- to

Set point

high limit

Set

point high

limit for

analog input.

Analog input. As per

input type

selected.

Analog input.

Programming

18

ISC.L = 0.00

DSC.L = 0.0

RSCL = no

ISC.H = 20.00

DSC.H = 9999

INPUT

9999

0.0

0.00mA 20.00mA

DISPLAY

Programming

Display Name & Description Range Display

condition

Default

value

Auto tune /PID control

4. - OUTPUT PARAMETERSLEVEL 1

Display Name & Description Range Display

condition

Default

value

Set Mode

Tune percentage

/Zone PID =

YES in level 4.

Tune = ON

P.AU , 75 to

100

Main Output Mode / Heat-cool =

NO.

Heat-cool mode

The controller can be operated

in heat-cool mode if this

selection is YES.

Zone PID

Main Output

SSR Output

/

/

( /

) /

/ SSR output

model

Display Name & Description Range Display

condition

Default

value

7. - SPECIAL FUNCTIONSLEVEL 4

/

Soft start time

Hand output percentage

Ramp mode

Ramp rate

Soak time

Sensor open condition

Sensor fail power level

PV bias (Display Offset)

, to

minutes.

,O/P

power low

limit to O/P

power high

limit.

/

/

to

degree/hour.

to

minutes

/

to %;

- to %

in case of

heat-cool

mode.

to

+ for TC

(RTD) &

to

+ for AIN

models

decimal point

as per

selected.

PID control

PID control

Ramp mode

=ON/HOLD.

Ramp mode

=ON/HOLD.

PID control

Sensor open

condition =

MANL.

25

Programming

Display Name & Description Range Display

condition

Default

value

6. - ALARM 2 MODULE (OPTIONAL)LEVEL 3

Alarm2 mode

Alarm latch

/

/ /

/ /

/ .

/

Alarm 2

should be

available.

These

parameters

are not

prompted if

Alarm 2

mode is OFF.

Hold Alarm

Relay status for Alarm1

Alarm Annunciator

/

/

/

Set 3 Value to

These

parameters

are not

prompted if

Alarm 2

mode is

OFF/brk.

Alarm Hysteresis

Hysteresis bias

to

C

C

O

O

for

TC/RTD;

to

for analog

input.

to

(for

TC/RTD);

to

for AIN

models

decimal

point as per

selected

OC

PARAMETER EXPLANATIONS:

For parameter explanations refer Level 2.

24

Programming

Output power lower limit

Output power upper limit

% to o/p

power high

limit; %

to o/p

power

upper limit

(in heatcool

mode)

O/p power

low limit to

%

PID control

19

Programming

ON-OFF control hysteresis to ON-OFF

control*

PID control

Display Name & Description Range Display

condition

Default

value

Hysteresis bias

Timer

Integral time

Derivative time

Derivative approach control

TC/RTD:

Analog input:

to

as per

decimal point

selected.

to O

to

minutes

to

sec.

to

seconds.

to ( x

band)

ON-OFF

control*

Main= Fd

and control is

ON-OFF.*

Proportional band- heat to o

*NOTE : For operating in ON-OFF mode make Proportional band = 0

(-

for heat

- cool

mode)

PID control

PID control

PID control

Display Name & Description Range Display

condition

Default

value

Anti-reset windup

Anti-reset windup %

Manual Reset

/

to

%

to

(for 0.1

resolution)

to

(for 1 )

to

(for analog

input)

o

o

ARW = MAnL

Proportional

band > 0 and

Integral time

= 0.

20

Programming.

Cycle time

Cycle time-user

/

/

to

sec

Cycle time =

USEr

Display Name & Description Range Display

condition

Default

value

Zone number to Zone PID=

YES(in level4)

Zone set point to

Proportional band

Integral time

Derivative time

to

sec.

to

sec.

to o

Pb - n > 0

Pb - n > 0

*NOTE: For Proportional band, Integral time and Derivative time n = 1 to 4

*

*

*

If Set Mode = Zone and Zone PID = YES, the following parameters will

be prompted.

If Set Mode = All and Zone PID = YES, The parameters except the

shaded ones (i.e. Pb-1, It-1, dt-1) will be prompted.

PID control

PID control

Display Name & Description Range Display

condition

Default

value

/

NOTE:

HC mode

SET 2 MODE:

SET 2 TYPE:

ALARM MODES:

ALARM LATCH:

HOLD ALARM:

ALARM ANNUNCIATOR:

SENSOR ERROR LEVEL :

In only the following parameter will be prompted :-

In case of analog retransmission only the following parameters will be prompted:

1. Set 2 value - this parameter will be prompted as db (dead band)

2. Proportional band - cool (Pb-C)

3. Cycle time - cool (cyc.t)

1. A-LO : Analog low scaling.

2. A-HI : Analog high scaling.

3. S.ERR : Sensor error level.

Display is with fixed 1 resolution for TC/RTD and as per decimal point selected for analog

input.

AlrM: Set2 can be programmed as alarm.

NonE: If set2 is not required it can be programmed as none.

Fd: Set2 programmed in cooling mode.(output ON when above the setpoint).

rE: Set2 programmed in heating mode.(output ON when below the setpoint)

AbS: Absolute alarm is a self-existent alarm independent of the main set point.

DEV: The alarm is activated at an error on the main set point.

(Refer for detailed explanation).

When Latch is ON, the alarm once activated remains activated even when the error is

removed. To deactivate the alarm, it has to be acknowledged by selecting AL-NO from the

front online options and pressing + .

When HOLD is ON, in any alarm mode, it prevents an alarm signal on power-up. The alarm is

enabled only if the process temperature is within the alarm range.

When alarm annunciator is ON, during alarm condition, visual annunciation is given by the

upper display altering between AL-NO and process temperature where NO is the alarm

number. The annunciator may be disabled by selecting function ANN as OFF.

This parameter determines the analog retransmission output level in case of sensor failure.

For eg : In case of 4-20mA retransmission output, if the sensor error level is set to High, 20mA

will be available at the output at all times incase of input sensor failure.

O

PARAMETER EXPLANATIONS :

•

•

•

•

•

•

•

USER GUIDE

23

Programming.

For Analog

output if

Main output

= Relay2

Display Name & Description Range Display

condition

Default

value

Hysteresis to OC1. Set2

mode=Fd/rEV/

ALrM (not

sensor break);

2. Heat cool

mode (Pb-C=0)

Hysteresis bias

Alarm1 mode

Alarm latch

TC/RTD:

C

Analog input:

to

as per

decimal

point

selected.

to O

/

/ /

/ /

/

/

1. Set2

mode=Fd/rEV

/ALrM (not

sensor break);

2. Heat-cool

mode (Pb-C=0)

Set2

mode=ALrM

These

parameters

are not

prompted if

Alarm1 mode

is OFF.

Hold Alarm /

Relay status for Alarm1

Alarm Annunciator

/

/

Analog low scaling

Analog high scaling

to

to For Analog

output if

Main output

= Relay2

22

Programming.

For Analog

retransmission

if Main output

= Relay2 in

Level 4

Display Name & Description Range Display

condition

Default

value

Set 2 Mode *

Set 2 Type

/

/ /

/

Not for Heat-

cool mode.

Set2 mode =

Fd / rEV.

5. - AUXILIARY OUTPUT MODESLEVEL 2

PARAMETER EXPLANATIONS :

!

!

!

!

!

AUTO TUNING:

OUTPUT POWER LIMITS:

TIMER:

CYCLE TIME:

ANTIRESET WINDUP:

Auto tuning is a function whereby the controller learns the process characteristics by itself

and automatically sets the required P,I and D values. The new P,I,D parameters will be

stored in non-volatile memory automatically. TUNE ON is indicated by ‘T’LED blinking.

(For detailed explanations of PID parameters refer USER GUIDE).

These parameters are used to limit the minimum and maximum controller output power.

The output power lower limit will ensure that a minimum percentage of output (as per

requirement) is available in case any process disturbances or setpoint changes occur.

The output power high limit ensures that in case any process disturbance or set point

changes occur, the maximum value of output is limited to a value as per requirement.

TIMER is main output restart time. In this main output once turned OFF will turn ON only

after set time even if the temperature has increased and is more than the set temperature.

This is needed to prevent the compressor from restarting in a short time (less than the set

time).

There are 3 selectable modes for programming cycle time:

USEr: User can program the cycle time. The mode will be altered to AutO when put to

autotune.

Usr.F: User can fix the cycle time. This has the highest priority.

AutO: This is recommended. The cycle time value is calculated automatically during

autotune.

The anti-reset windup (ARW) inhibits the integral action until the PV is within the

proportional band thus reducing overshoot on start-up. If the selection is -

1. AutO: The value will be calculated automatically during autotune (Recommended).

2. ManL: The value can be fed manually by the user.

Set 2 Value

Proportional band-Cool

to

to

Not prompted

if Set2 mode =

alarm & alarm

mode = S. Brk.

Heat-cool mode

Cycle time-Cool to sec Pb-C>0

21

Programming.

NOTE: * - If set2 mode = none, no other parameters will be prompted.

This manual suits for next models

2

Table of contents

Other Tempatron Temperature Controllers manuals