TemperZone ISD 380KBY Maintenance and service guide

Other TemperZone Air Conditioner manuals

TemperZone

TemperZone OSA 175RKTHG Maintenance and service guide

TemperZone

TemperZone OPA RKTG-P Series Maintenance and service guide

TemperZone

TemperZone OPA 1410 RLTM1FPQ Maintenance and service guide

TemperZone

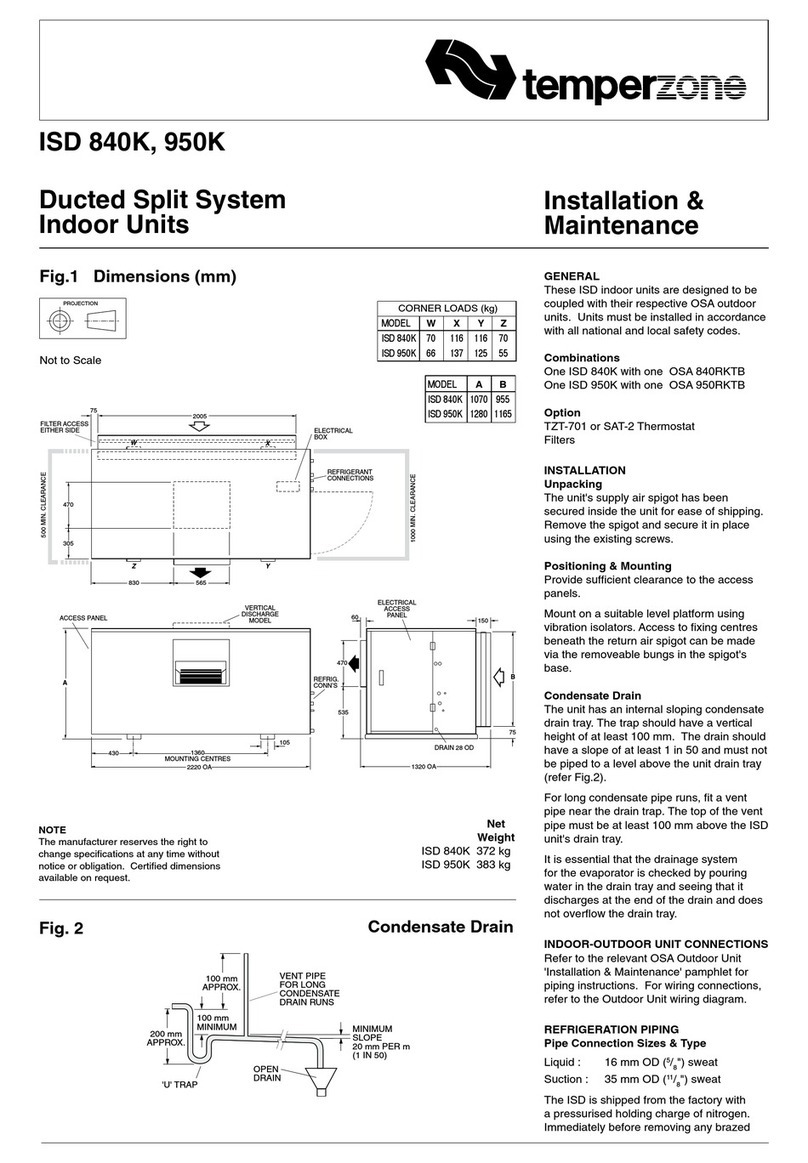

TemperZone ISD 840K Maintenance and service guide

TemperZone

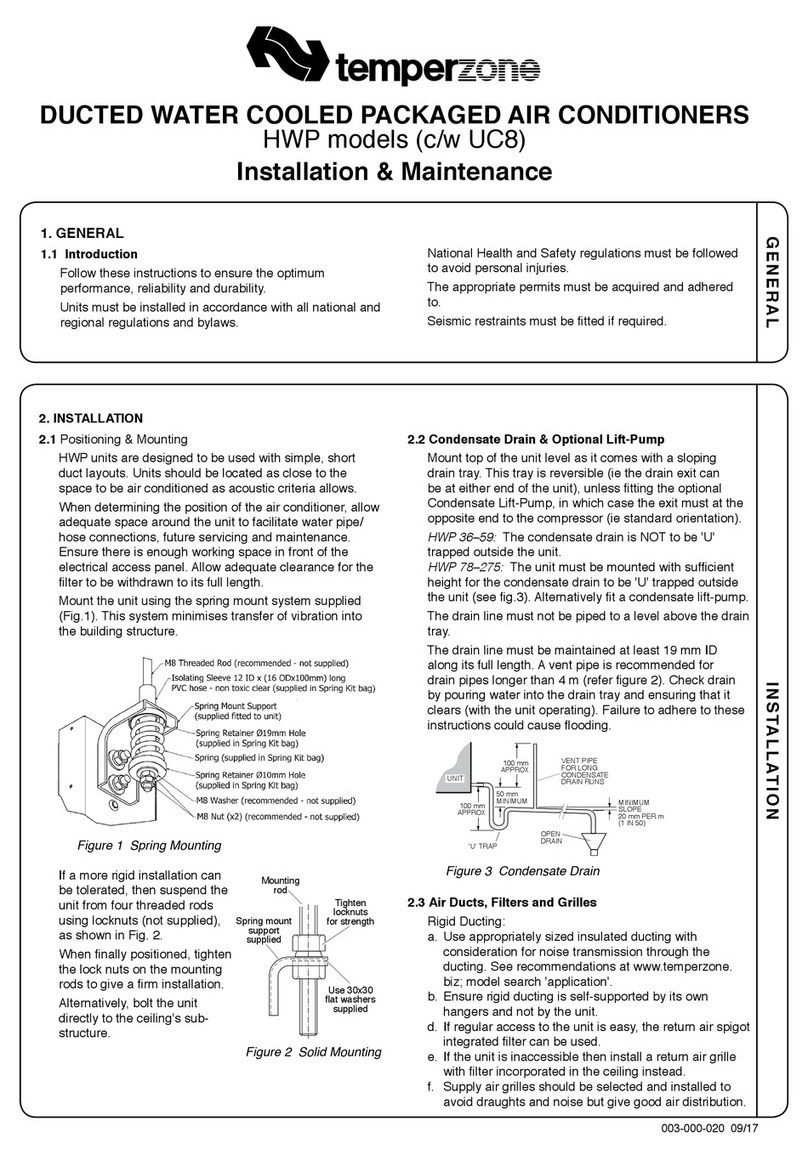

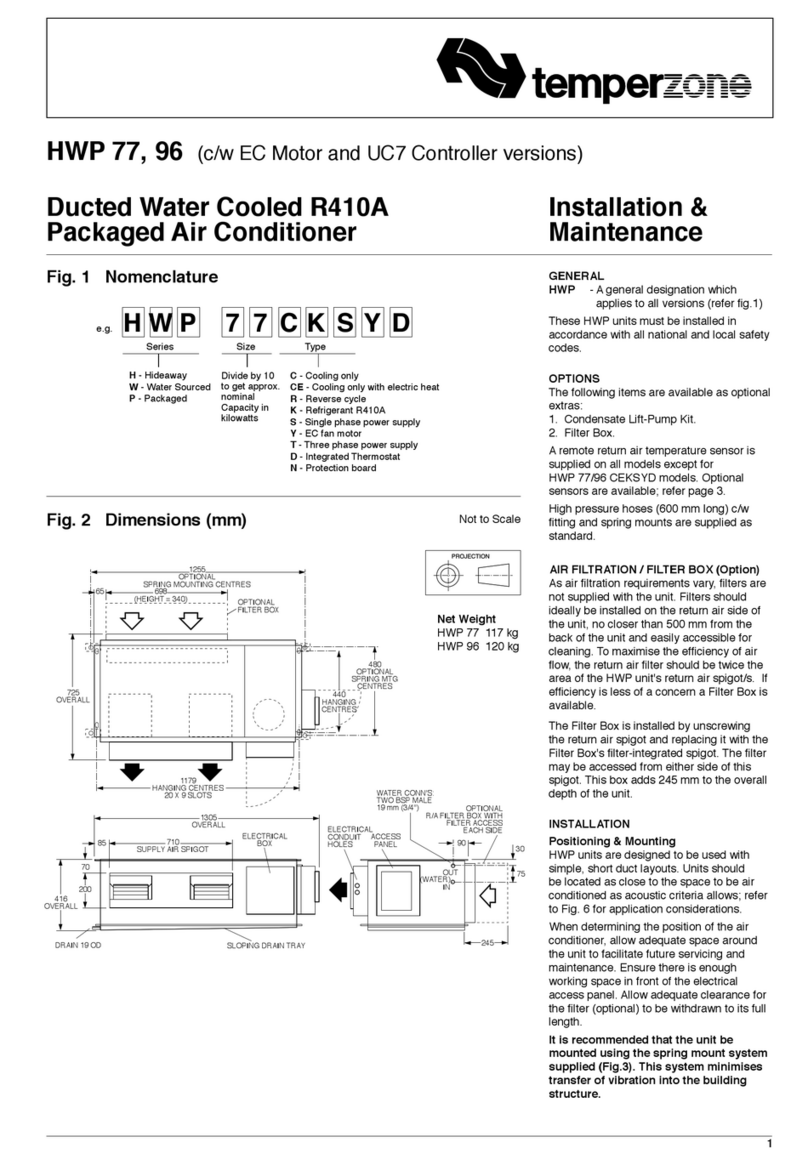

TemperZone HWP Series Maintenance and service guide

TemperZone

TemperZone OPA 201RKTY Maintenance and service guide

TemperZone

TemperZone OPA 1370RKTMG01-PZ Maintenance and service guide

TemperZone

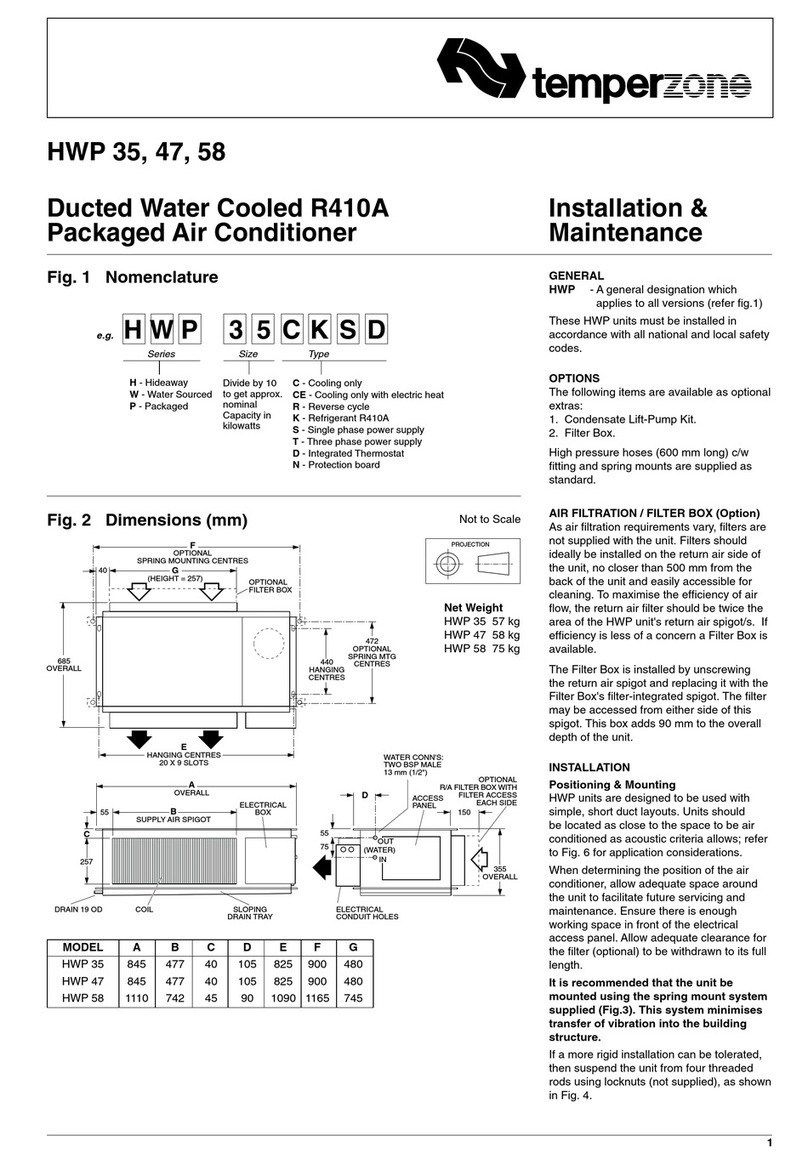

TemperZone HWP 35 Maintenance and service guide

TemperZone

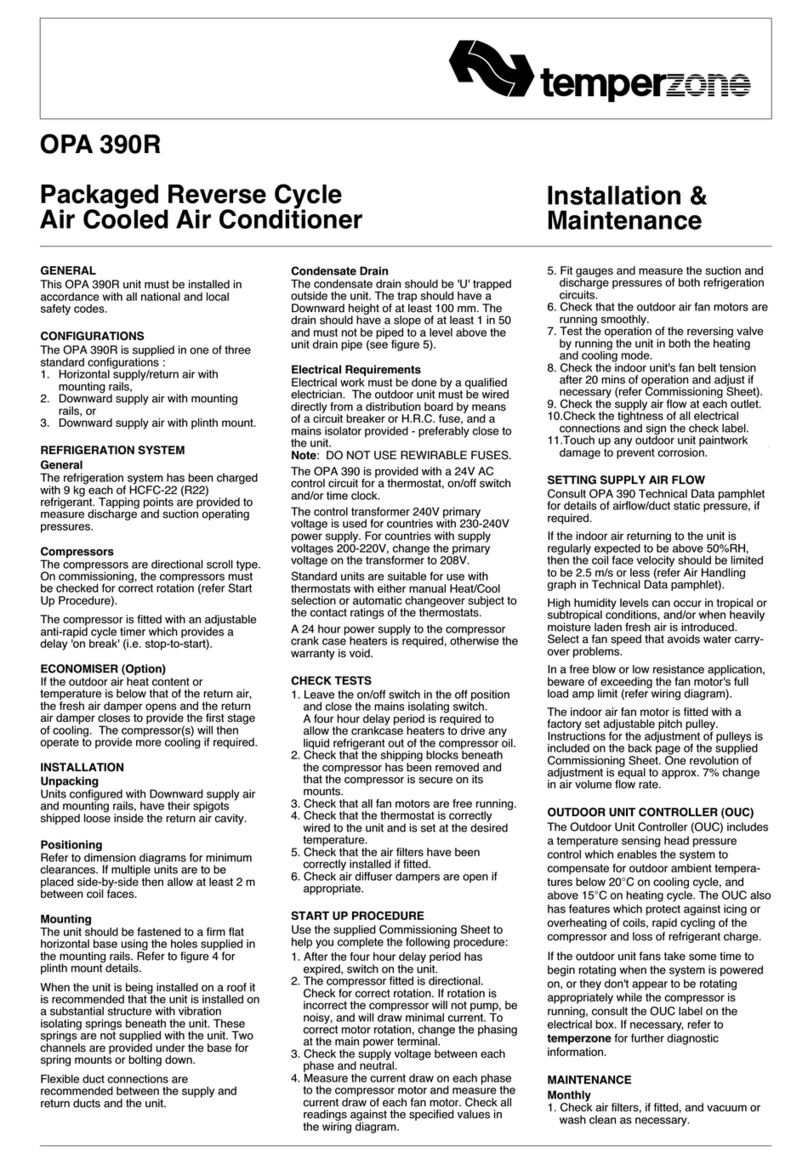

TemperZone OPA 390R Maintenance and service guide

TemperZone

TemperZone HWP 96 Series Maintenance and service guide

TemperZone

TemperZone OPA 186RKTYG Maintenance and service guide

TemperZone

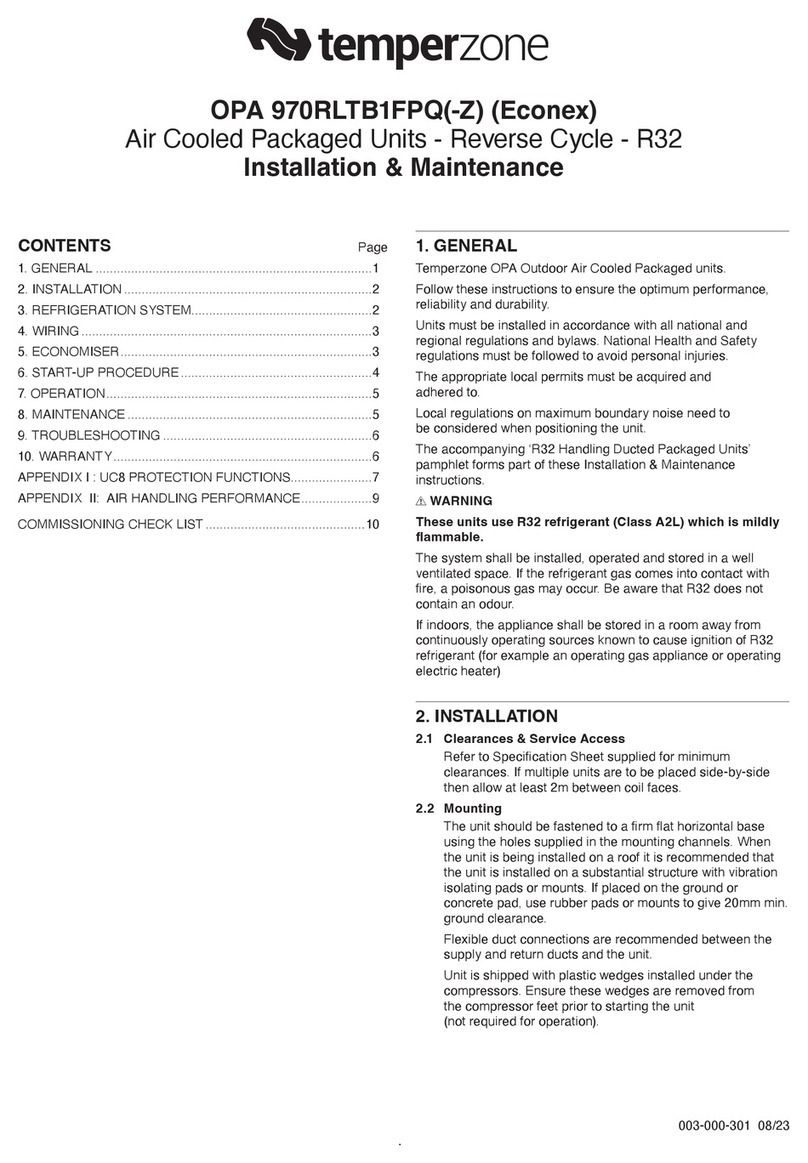

TemperZone OPA 970RLTB1FPQ Maintenance and service guide

TemperZone

TemperZone OPA 550RKTB Maintenance and service guide

TemperZone

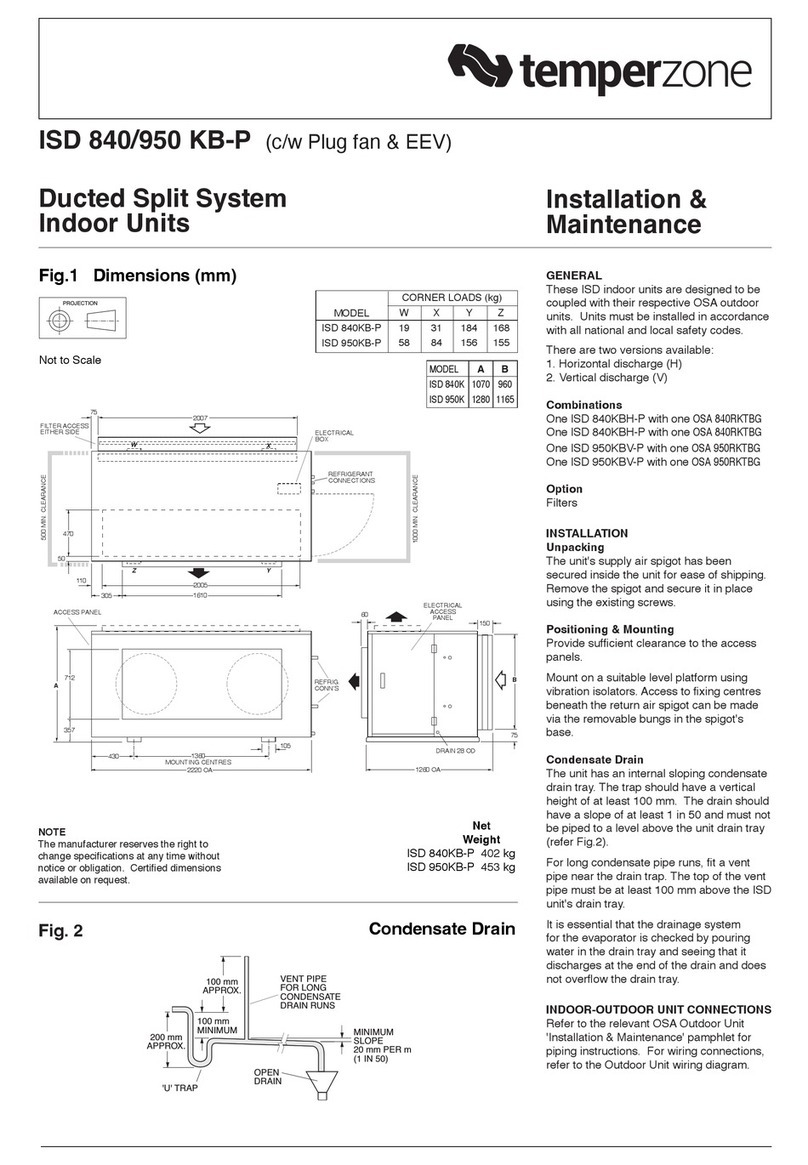

TemperZone ISD 840KB-P Maintenance and service guide

TemperZone

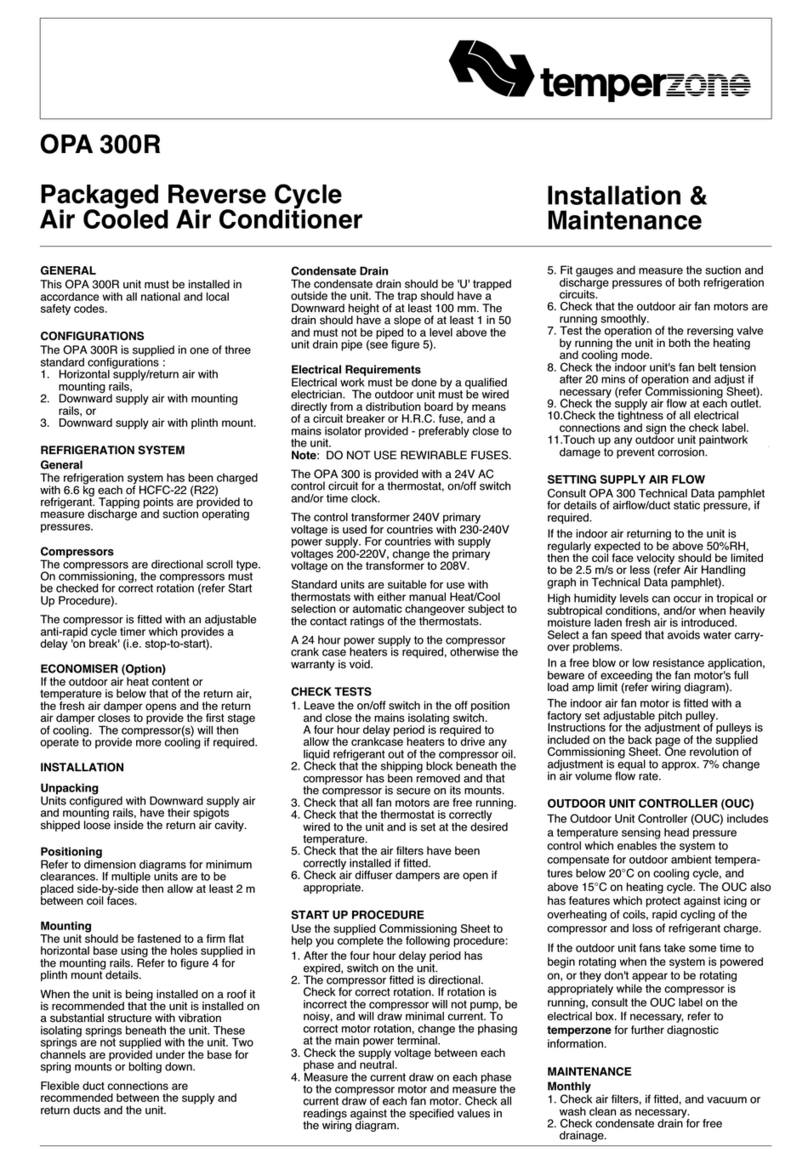

TemperZone OPA 300R Maintenance and service guide

TemperZone

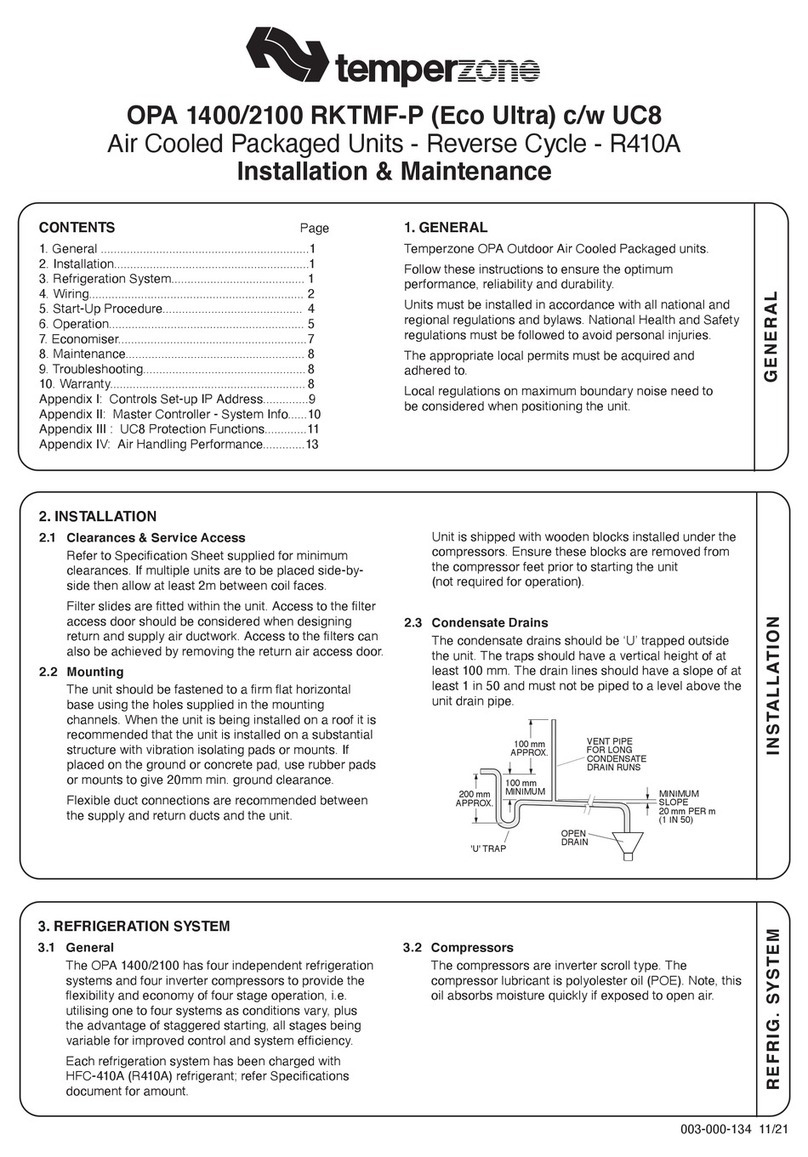

TemperZone EcoULTRA OPA 2100RKTM-P Maintenance and service guide

TemperZone

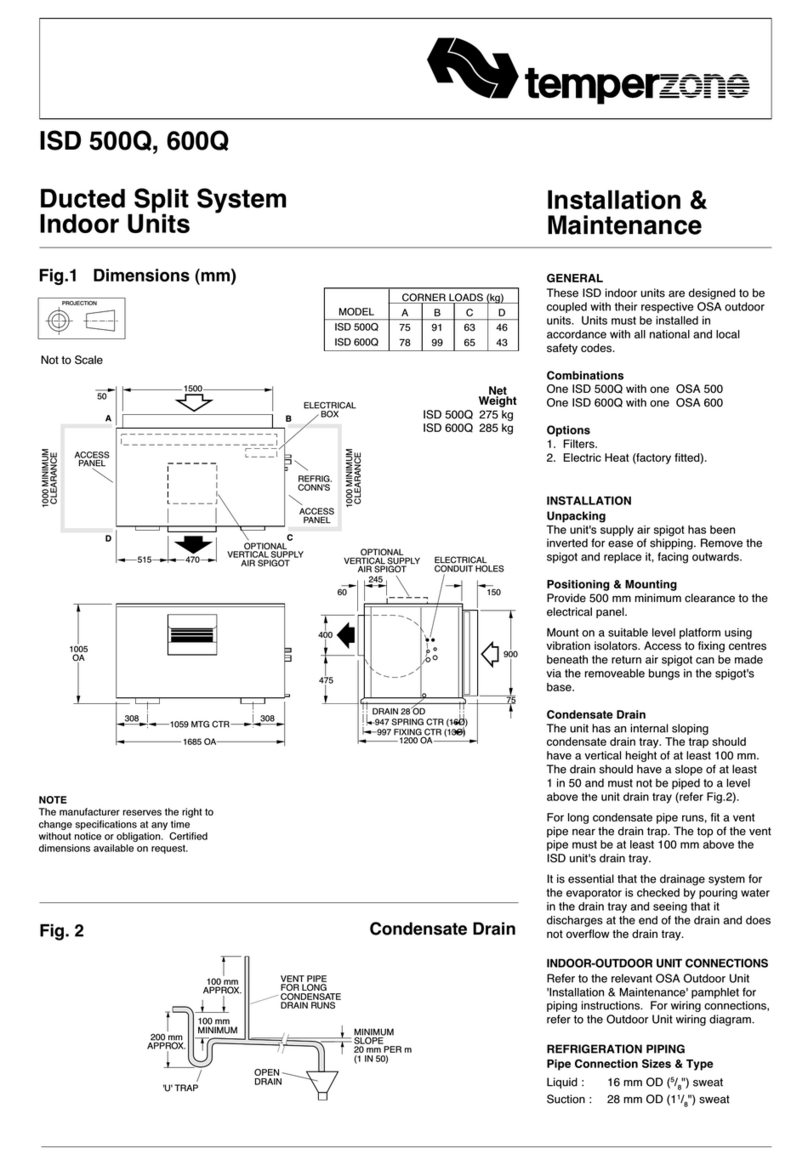

TemperZone ISD 500Q Maintenance and service guide

TemperZone

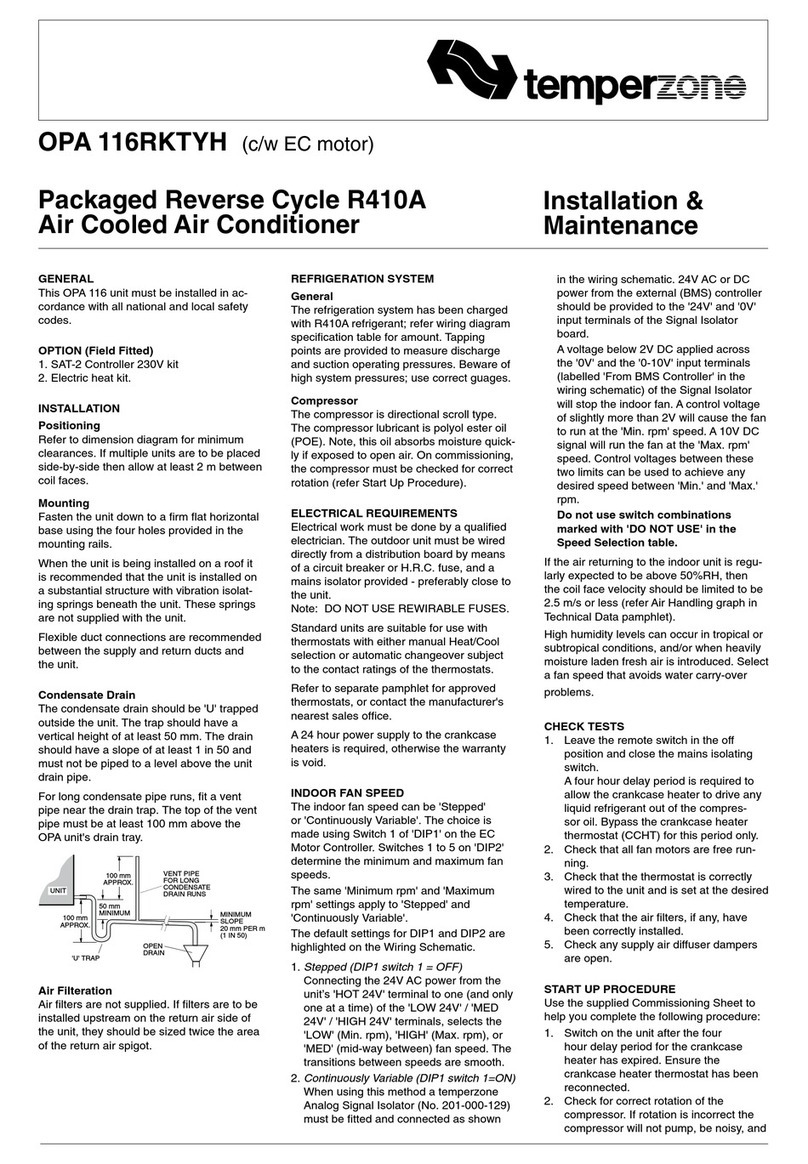

TemperZone OPA 116RKTYH Maintenance and service guide

TemperZone

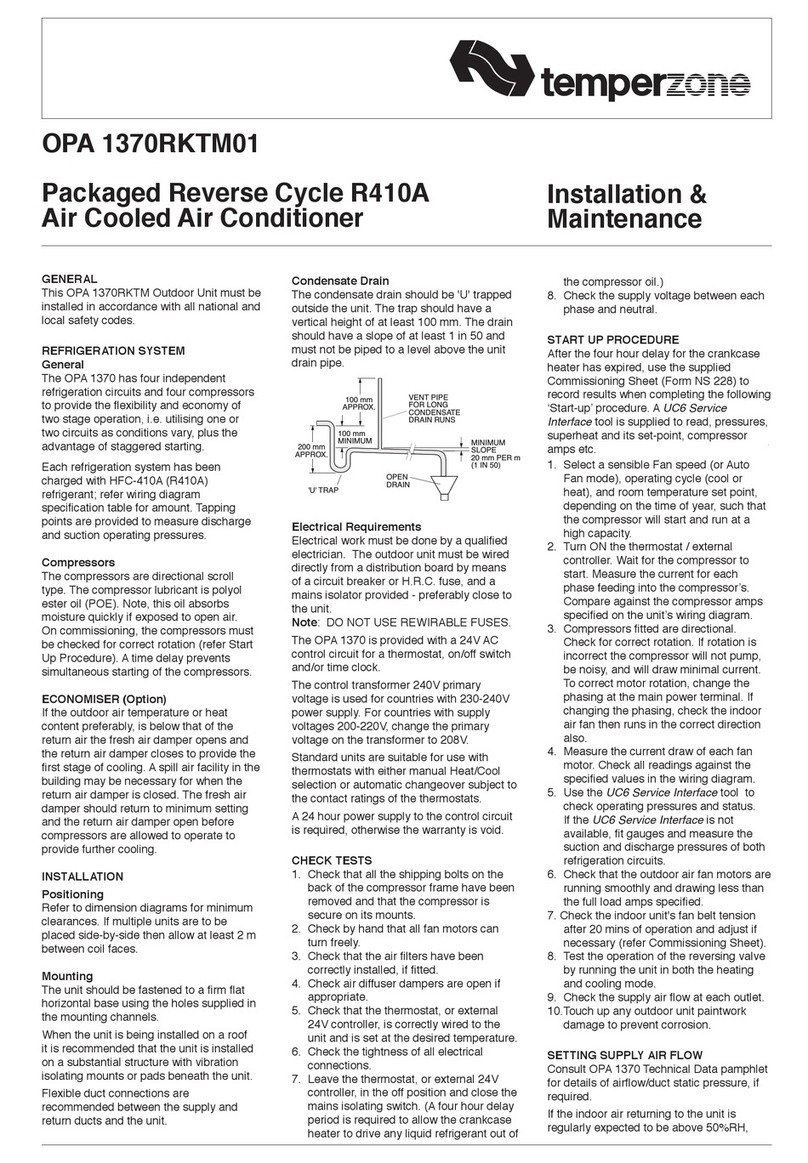

TemperZone OPA 1370RKTM01 Maintenance and service guide

TemperZone

TemperZone OSA 160RKTGH Maintenance and service guide

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions

McQuay

McQuay MCK020A Technical manual

Webasto

Webasto Frigo Top 25 DS Instructions for use

Frigidaire

Frigidaire FAZ12ES2A installation instructions

Mitsubishi Electric

Mitsubishi Electric MSC-GE20VB operating instructions

Mitsubishi Electric

Mitsubishi Electric PLA-M100EA installation manual

Daikin

Daikin Split Sensira R32 Service manual