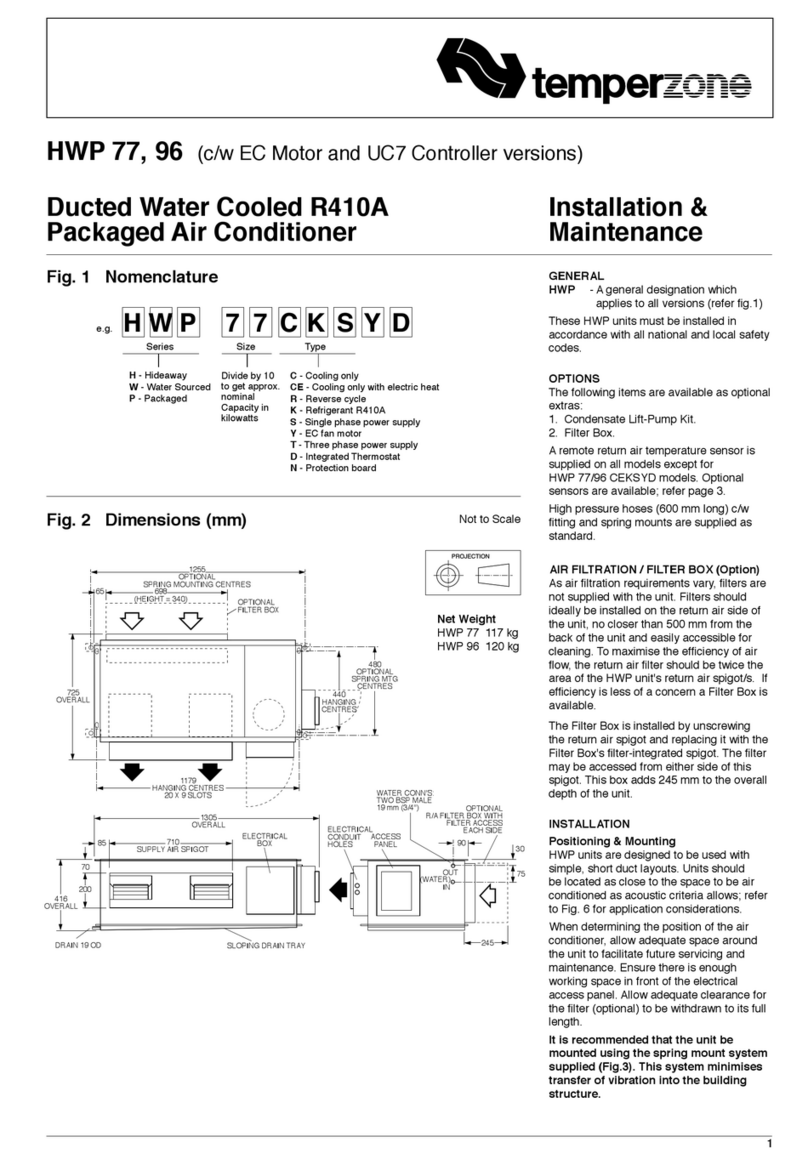

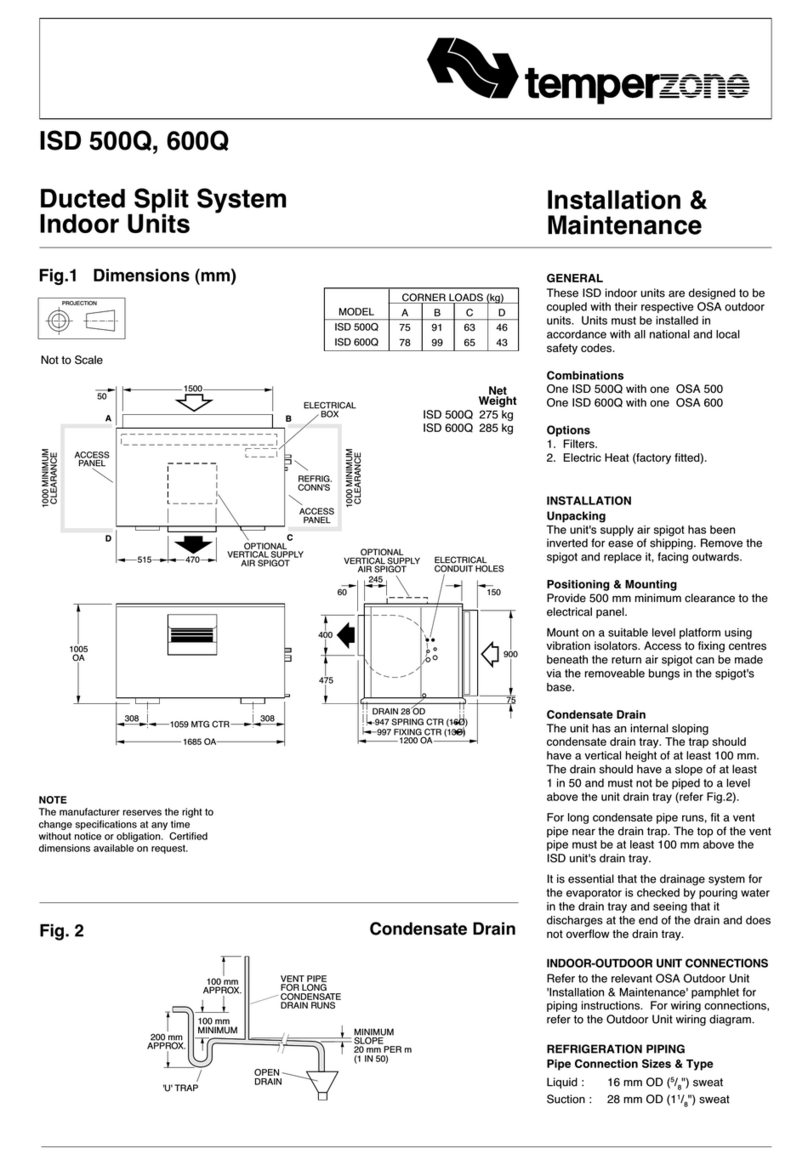

2

Mount the unit level as it comes with a

sloping drain tray. This tray is reversible

– but not if using the optional condensate

lift-pump; then the drain exit can only be at

the opposite end to the compressor.

The drain line must have a slope of at least

1 in 50 and must not be piped to a level

above the drain tray. Where required a

condensate lift-pump should be used

(optional extra).

When finally positioned, tighten the lock

nuts on the mounting rods to give a firm

installation (see Fig. 4).

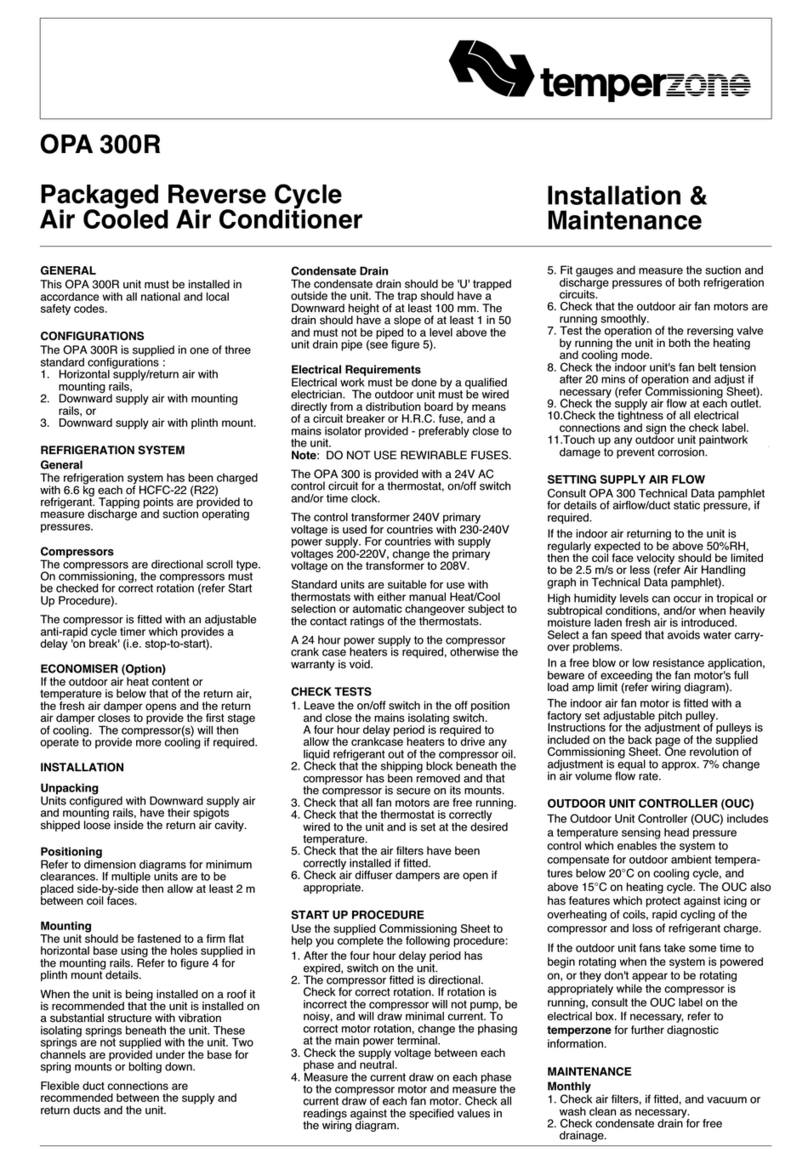

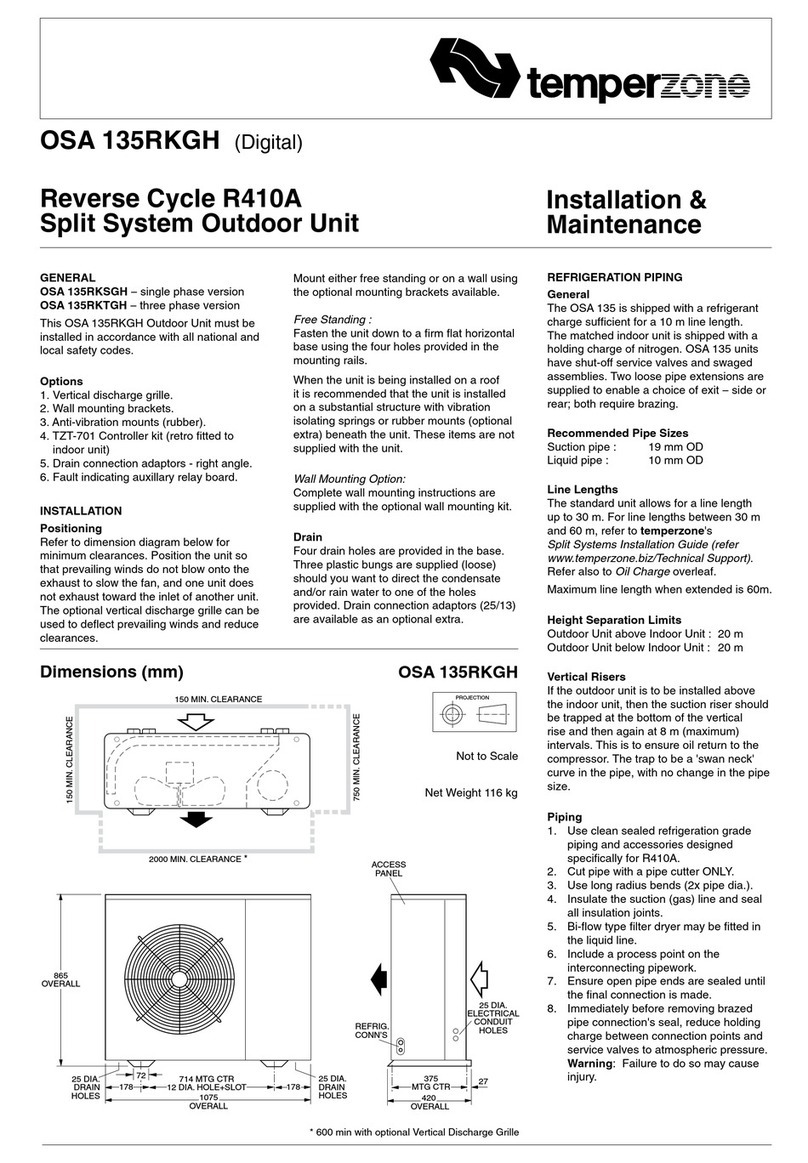

Condensate Drain

The condensate drain is not to be trapped

outside the unit. The drain line must be

maintained at least 19 mm ID along its

full length. Fit a vent pipe within 500 mm

of the unit, 300 mm high and 10 mm

ID (minimum); see Fig. 5. Check drain

by pouring water into the drain tray and

ensuring that it clears. Failure to adhere to

these instructions could cause flooding.

Water Supply & Return

The HWP unit's IN and OUT water

connections are male pipe threaded (refer

Fig. 1). The two temperzone 600 mm

flexible high pressure water hoses supplied

have female pipe threaded connections at

each end. Maximum water pressure for

each hose is 1720 kPa (250 psi). The HWP

unit alone, excluding hoses, will withstand

4480 kPa (650 psi).

Poor quality water supply must be pre-

filtered and it is essential that adequate

water treatment is maintained, particularly

where open cooling towers are used.

Note: It is required that the water supply

system be fitted with a water flow switch and

water pump safety interlock. These items

prevent the HWP units from going into fail

safe lockout status due to a loss of water

flow. Failure to install the above items would

require the resetting of all HWP units in the

system - either by breaking the power supply

to each unit or breaking the thermostat

control circuit.

HWPSR units require a minimum water

supply temperature of 17°C.

Circuit Balancing Valve

It is recommended that a circuit balancing

valve be fitted to maintain water flow at a

constant rate. The minimum water flow rates

in litres per second (l/s) are as follows:

HWP: 35 47 58

Minimium 0.17 0.27 0.36

Electrical

The air conditioner should be connected

to the appropriate power supply for each

model, as specified in the wiring diagram,

with neutral and adequate earth. The supply

to have an accessible switch to allow

isolation of the unit. Wire the heating and

cooling room thermostat to the electrical

terminals adhering to the wiring diagram

supplied with the unit. All wiring to the air

conditioner must comply with the wiring

regulations of the local electrical authority.

Air / Water Flow

Refer to HWP 35–58 Data Sheet pamphlets

for detailed information on air handling

performance and water flow rates.

Unit Protection

Unit protection is incorporated in either:

a.) HWP Protection Board, or

b.) SAT-2 Controller,

depending on which HWP model is being

installed.

A pump verification relay ensures that water

is flowing before the compressor will start.

A high pressure lockout protects the unit

from low water flow in cooling mode, or fan

failure in heating mode. Sensors protect

against low air coil temperature and loss of

refrigerant. Units include an anti rapid cycle

device for compressor protection.

HWPSR units also have a low refrigerant

temp. safety thermostat to protect against

icing up of the water within the unit's tube-in-

tube heat exchanger.

A non-specific fault LED/ output signal is

also included for remote fault indication to

building management systems (refer wiring).

Note: Lockout protection can be reset by

switching unit's power supply off and on.

Lockout protection will also reset when the

thermostat switches, or is switched to the

dead zone.

Units Supplied With SAT-2 Thermostat

Any faults detected are displayed on the

SAT-2 Wall plaque (refer Table 1). A non-

specific fault output signal is also included on

SAT-2 Controllers for remote fault indication

to building management systems.

Units Supplied With Electric Heat

HWPSCEKS models supplied with electric

heat include both auto (90°C) and manual

(120°C) high temp. safety thermostats. If the

manual safety t/stat requires resetting, then

the auto safety t/stat has failed and needs to

be replaced.

Room Thermostat

(Reverse Cycle Models)

The thermostat should be set within the

recommended operating range of between

19°C and 30°C. The thermostat should

not be used as an on-off switch. Refer to

temperzone for a list of other approved

thermostats.

If your unit is supplied with temperzone's

SAT-2 Thermostat, refer to page 3 for

installation instructions.

COMMISSIONING

1. Check that the thermostat is correctly

wired and set at the desired temperature.

2. Check that the air filter (if fitted) is clean.

3. Check that the fan runs freely without

vibration.

4. Check condensate drain and safety drain

tray for free drainage.

Demonstrate the SAT-2 Wall Control (if

supplied) to the owner/user, after having

first thoroughly familiarised yourself with the

User's Operating Instructions. This page is to

remain with the owner/user.

MAINTENANCE

Quarterly

1. Remove lint and dust accumulation from

heat exchange air coil. (Note: failure to

do this may affect efficiency).

2. Check air filters and vacuum or wash

clean as necessary.

3. Check condensate drain for free

drainage.

4. Check compressor compartment for oil

stains indicating refrigerant leaks.

5. Check quality of water supply.

Six Monthly

Check tightness of electrical connections.

Yearly

1. Remove lint and dust accumulation from

heat exchange air coil. (Note: failure to

do this may affect efficiency).

2. Replace air filter if damaged to maintain

adequate air flow and efficiency.

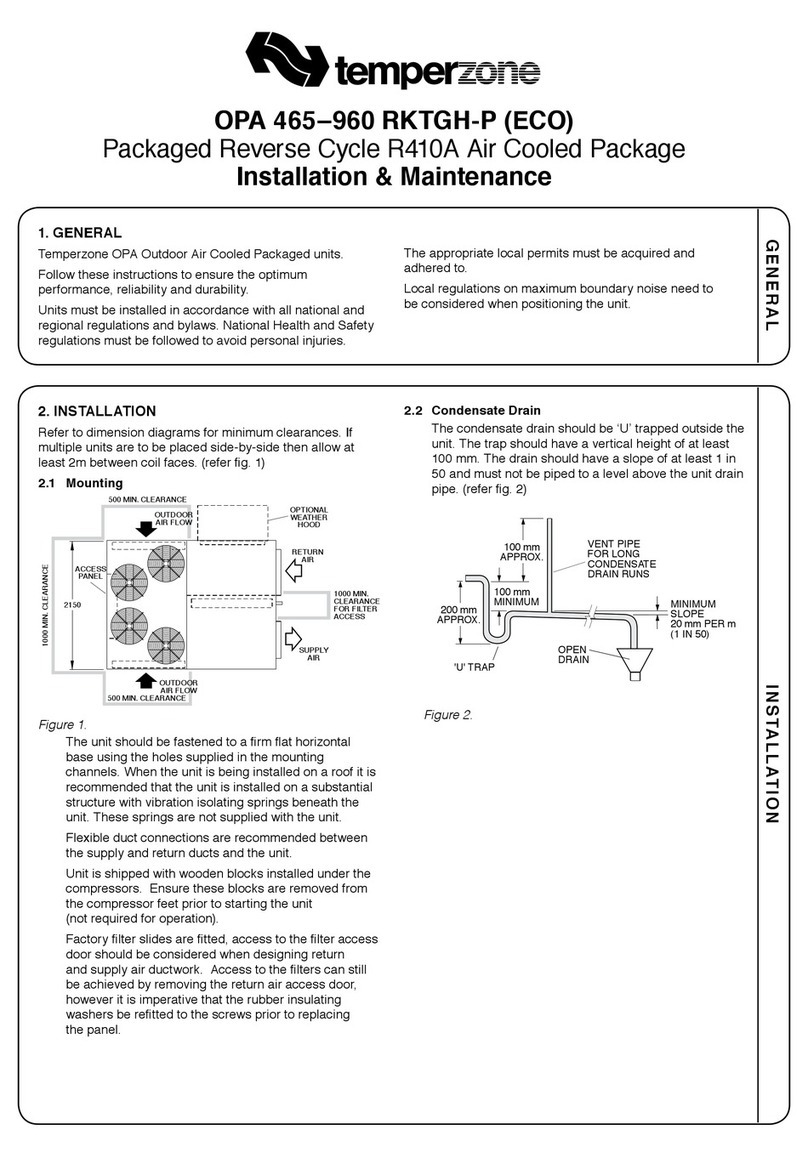

Fig. 3 Spring Mounting Fig. 4 Solid Mounting

MOUNTING

ROD TIGHTEN

LOCKNUTS

FOR

STRENGTH

PREFERRED

MOUNTING

SYSTEM

(SUPPLIED)

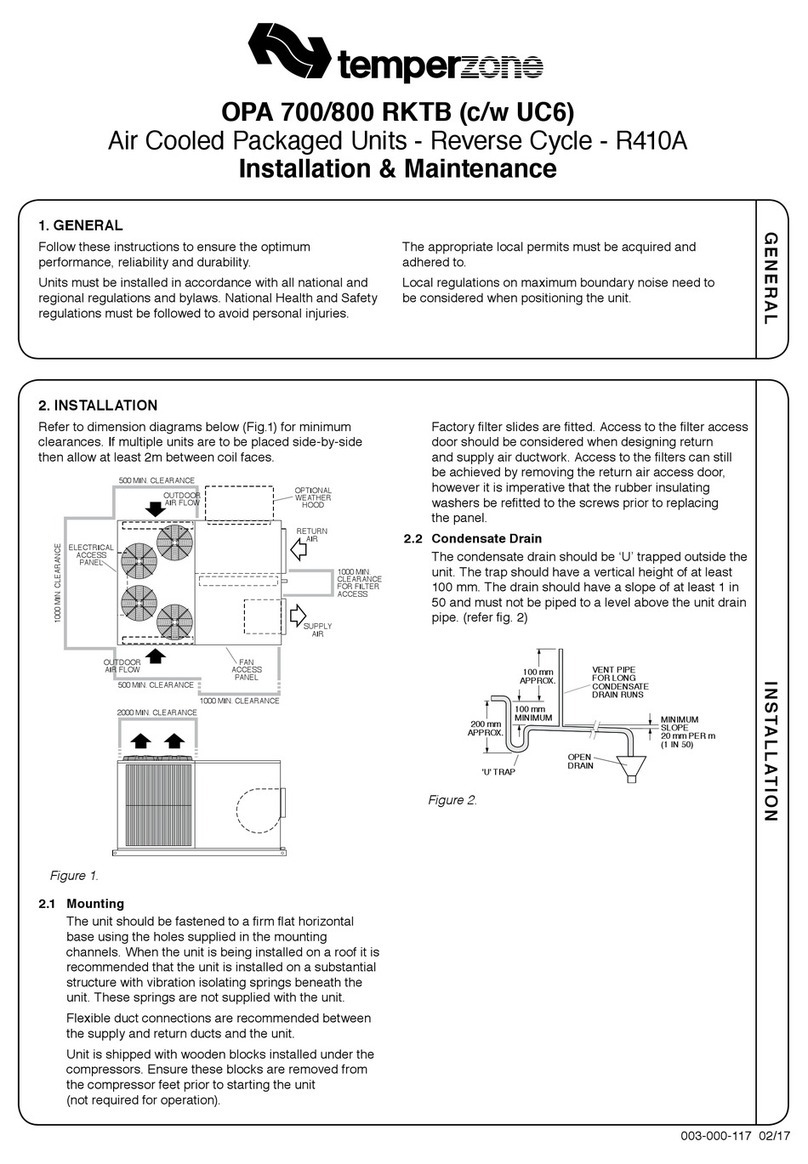

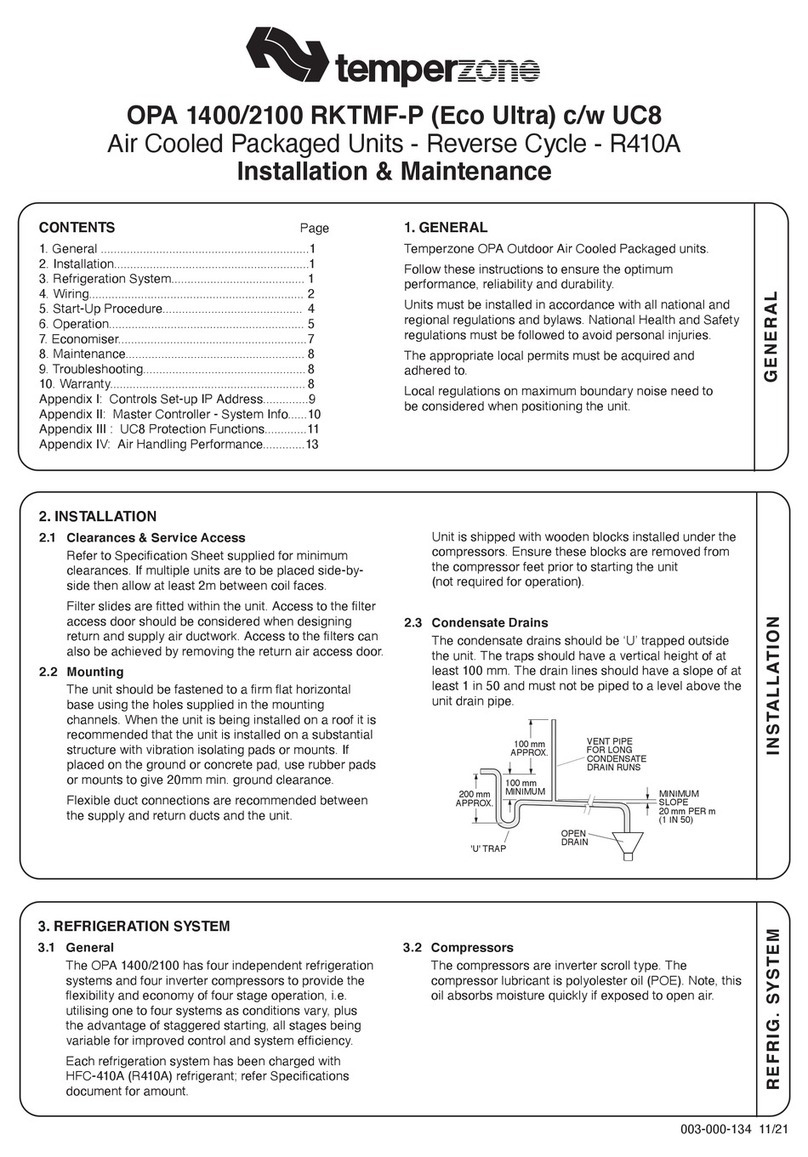

Fig. 5 Condensate Drain

OPEN

DRAIN

MINIMUM

SLOPE

20 mm PER m

(1 IN 50)

300 mm

APPROX.

VENT PIPE (10 ID)

FOR LONG

CONDENSATE

DRAIN RUNS

500 mm MAX.

FROM UNIT

NO TRAP

REQUIRED