TemperZone ISD 840KB-P Maintenance and service guide

Other TemperZone Air Conditioner manuals

TemperZone

TemperZone ISD 220Q Maintenance and service guide

TemperZone

TemperZone OPA 970RLTB1FPQ Maintenance and service guide

TemperZone

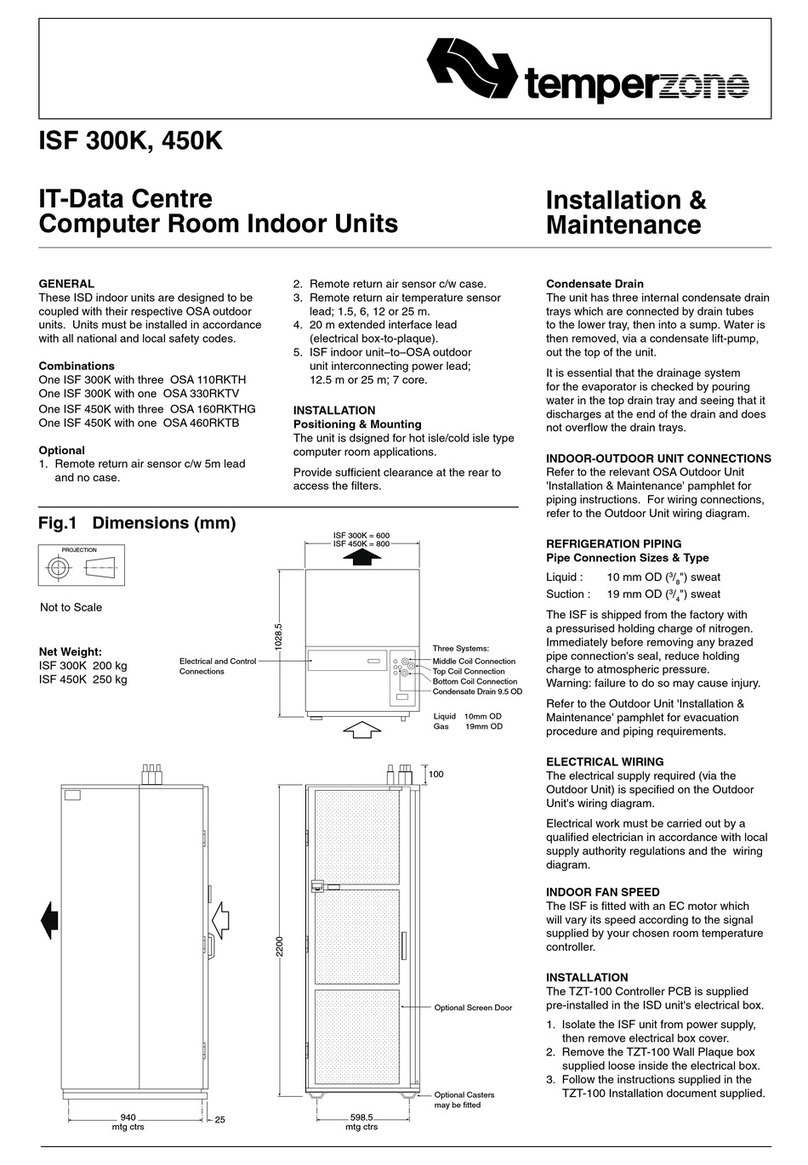

TemperZone ISF 300K Maintenance and service guide

TemperZone

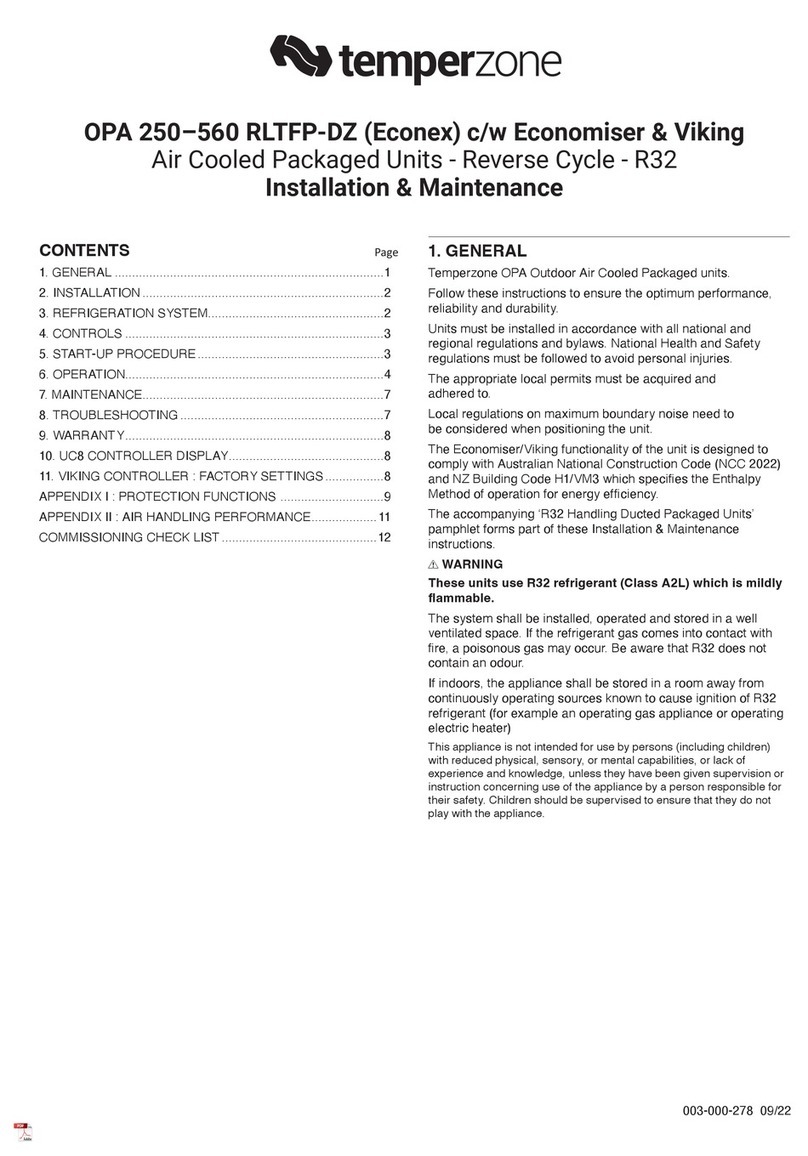

TemperZone OPA 250RLTFP-DZ Maintenance and service guide

TemperZone

TemperZone OPA 250 RLTFP-DZ Maintenance and service guide

TemperZone

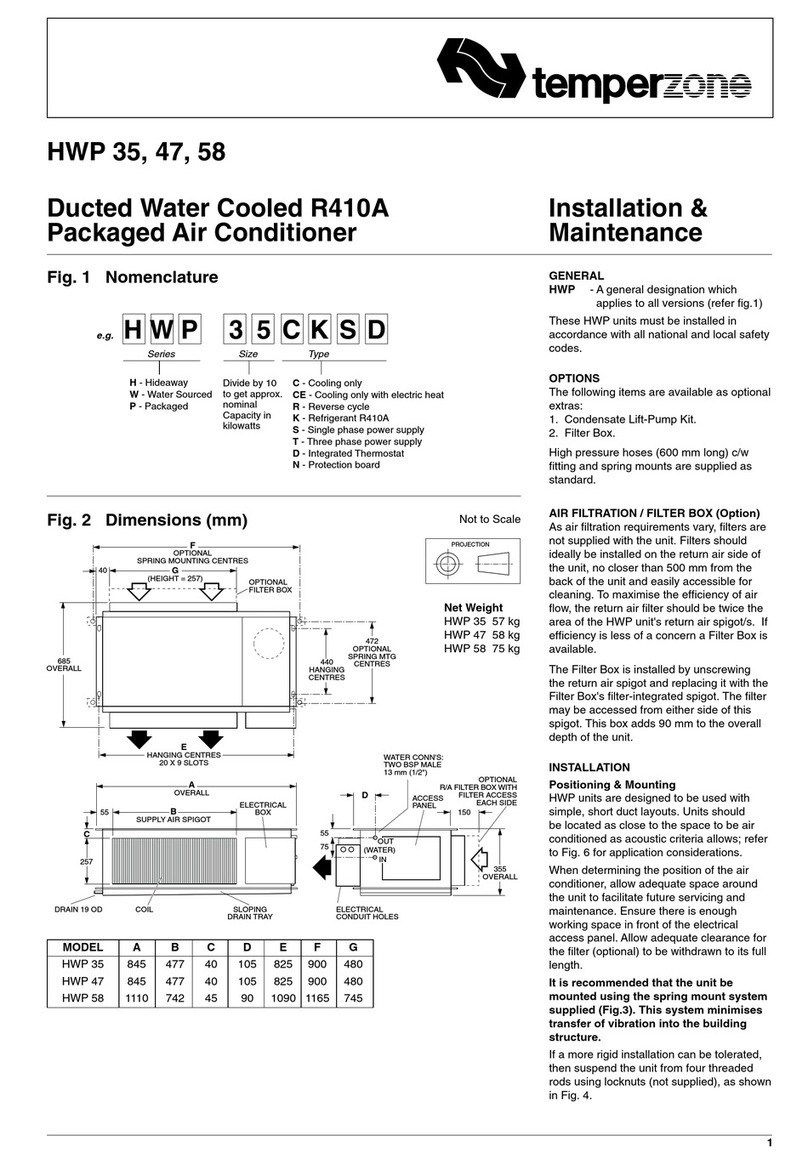

TemperZone HWP 35 Maintenance and service guide

TemperZone

TemperZone EcoULTRA OPA 2100RKTM-P Maintenance and service guide

TemperZone

TemperZone OPA 300R Maintenance and service guide

TemperZone

TemperZone OSA 160RKTGH Maintenance and service guide

TemperZone

TemperZone GME Series Maintenance and service guide

TemperZone

TemperZone OPA 201RKTY Maintenance and service guide

TemperZone

TemperZone OPA 116RKTYH Maintenance and service guide

TemperZone

TemperZone Econex Pro Maintenance and service guide

TemperZone

TemperZone ISD 480Q Maintenance and service guide

TemperZone

TemperZone OSA 300 Maintenance and service guide

TemperZone

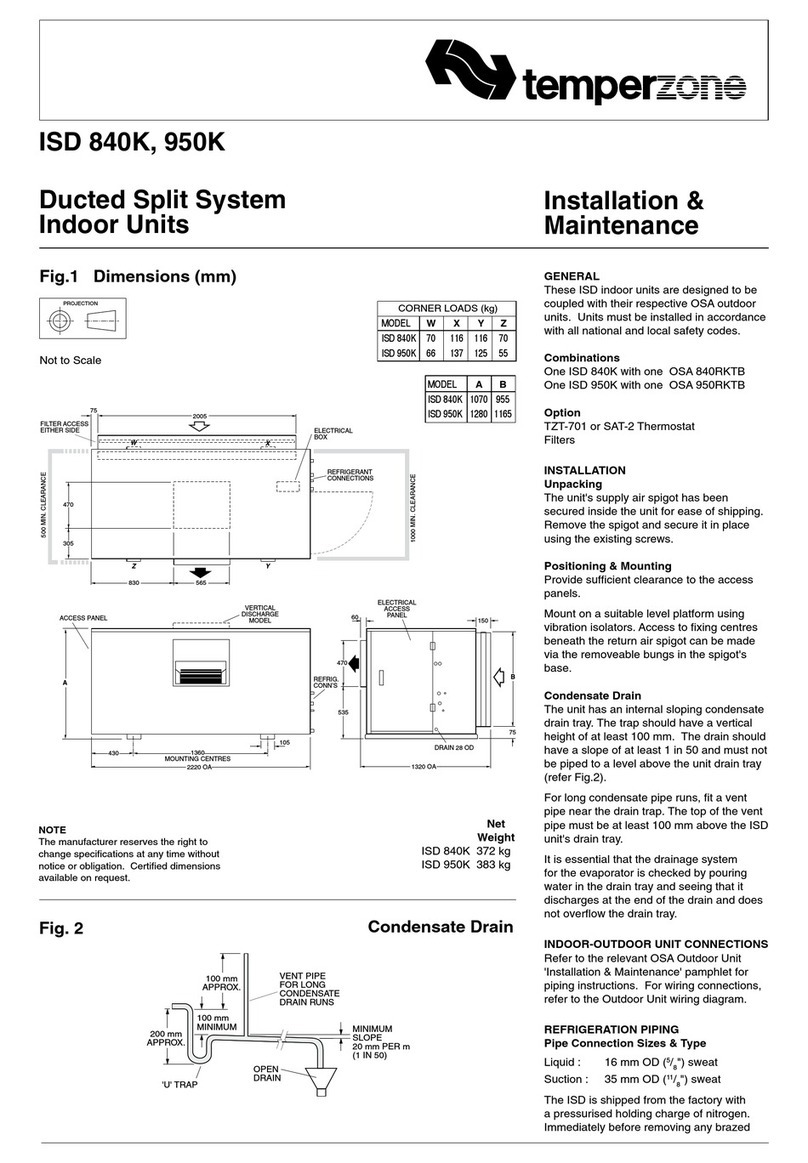

TemperZone ISD 840K Maintenance and service guide

TemperZone

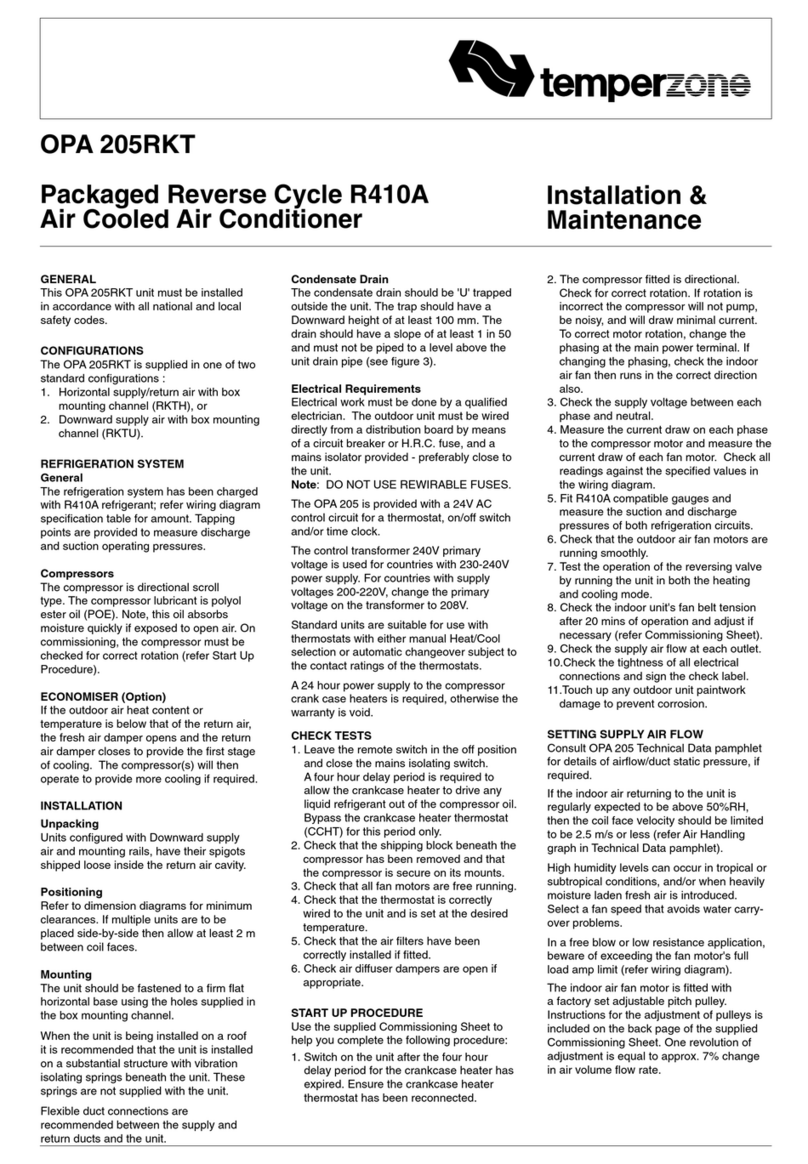

TemperZone OPA 205RKT Maintenance and service guide

TemperZone

TemperZone ISD 250Q Maintenance and service guide

TemperZone

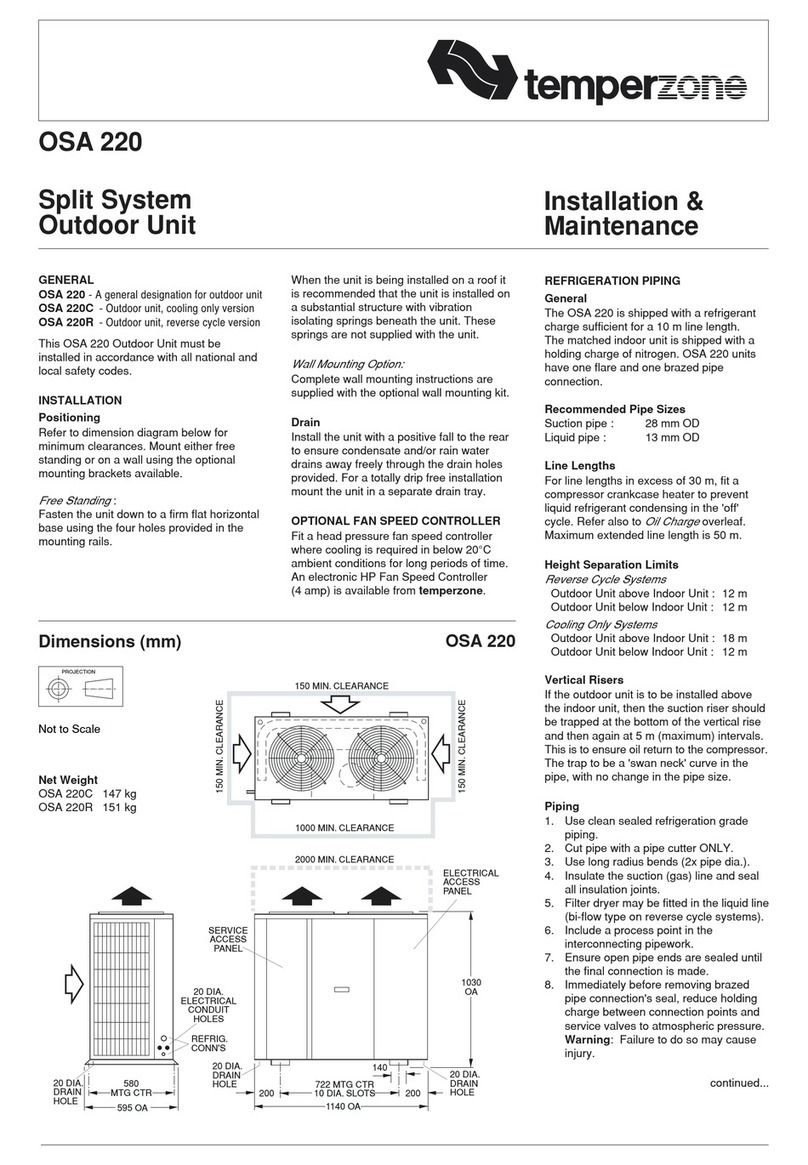

TemperZone OSA 220 Maintenance and service guide

TemperZone

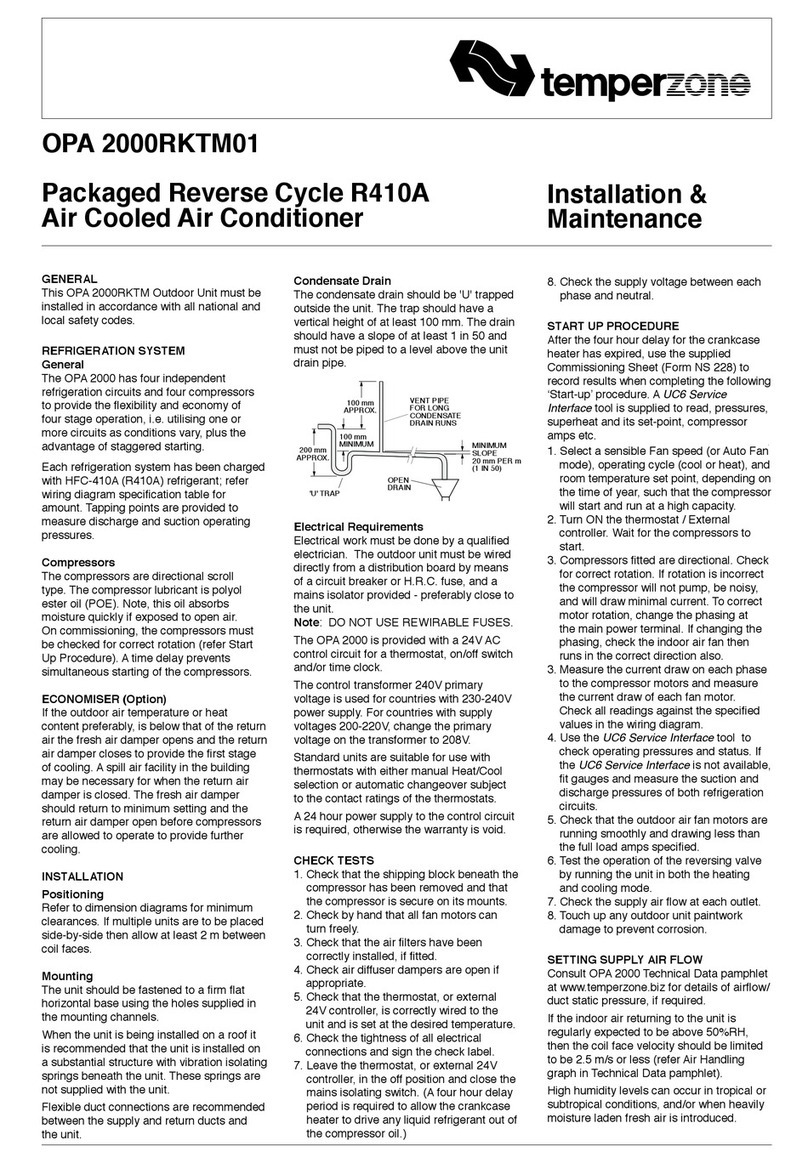

TemperZone OPA 2000RKTM01 Maintenance and service guide

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions

McQuay

McQuay MCK020A Technical manual

Webasto

Webasto Frigo Top 25 DS Instructions for use

Frigidaire

Frigidaire FAZ12ES2A installation instructions

Mitsubishi Electric

Mitsubishi Electric MSC-GE20VB operating instructions

Mitsubishi Electric

Mitsubishi Electric PLA-M100EA installation manual

Daikin

Daikin Split Sensira R32 Service manual