This OPA 550RKTB Outdoor Unit must be

installed in accordance with all national and

local safety codes.

The OPA 550RKTB is supplied in one of

two standard congurations :

1. Horizontal supply/return air with box

mounting channel (RKTBH), or

2. Downward supply/return air with box

mounting channel (RKTBU).

The OPA 550 has two independent

refrigeration circuits and two compressors

to provide the exibility and economy of

two stage operation, i.e. utilising one or

two circuits as conditions vary, plus the

advantage of staggered starting.

Each refrigeration system has been

charged with HFC-410A (R410A)

refrigerant; refer wiring diagram

specication table for amount. Tapping

points are provided to measure discharge

and suction operating pressures.

The compressors are directional scroll

type. The compressor lubricant is polyol

ester oil (POE). Note, this oil absorbs

moisture quickly if exposed to open air.

On commissioning, the compressors must

be checked for correct rotation (refer Start

Up Procedure). A time delay prevents

simultaneous starting of the compressors.

If the outdoor air temperature or heat

content preferably, is below that of the

return air the fresh air damper opens and

the return air damper closes to provide the

rst stage of cooling. A spill air facility in

the building may be necessary for when

the return air damper is closed. The fresh

air damper should return to minimum

setting and the return air damper open

before compressors are allowed to operate

to provide further cooling. A low limit

thermostat is tted to prevent compressors

operating with a mixed air-on coil

temperature below 18°C; resets at 20°C.

This is by-passed during heating mode.

Refer to dimension diagrams for minimum

clearances. If multiple units are to be

placed side-by-side then allow at least 2 m

between coil faces.

The unit should be fastened to a rm at

horizontal base using the holes supplied in

the mounting channels.

When the unit is being installed on a roof it is

recommended that the unit is installed on a

substantial structure with vibration isolating

springs beneath the unit. These springs are

not supplied with the unit.

Flexible duct connections are recommended

between the supply and return ducts and

the unit.

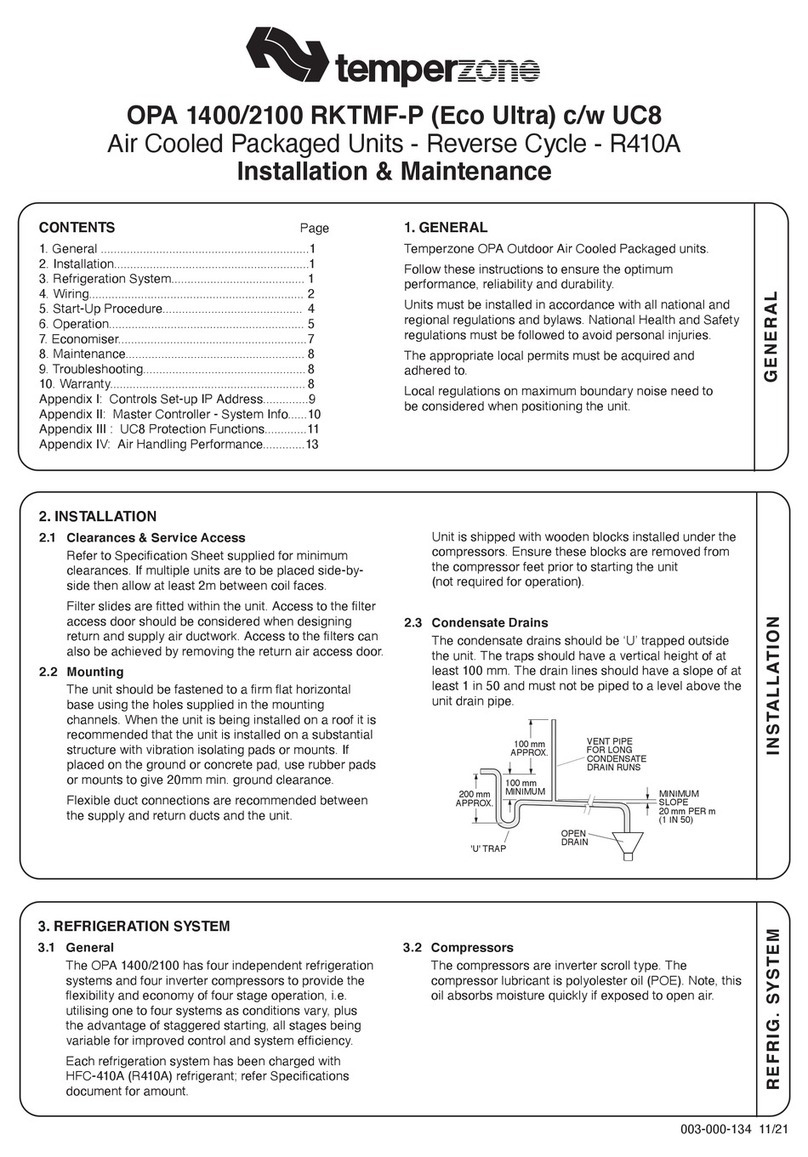

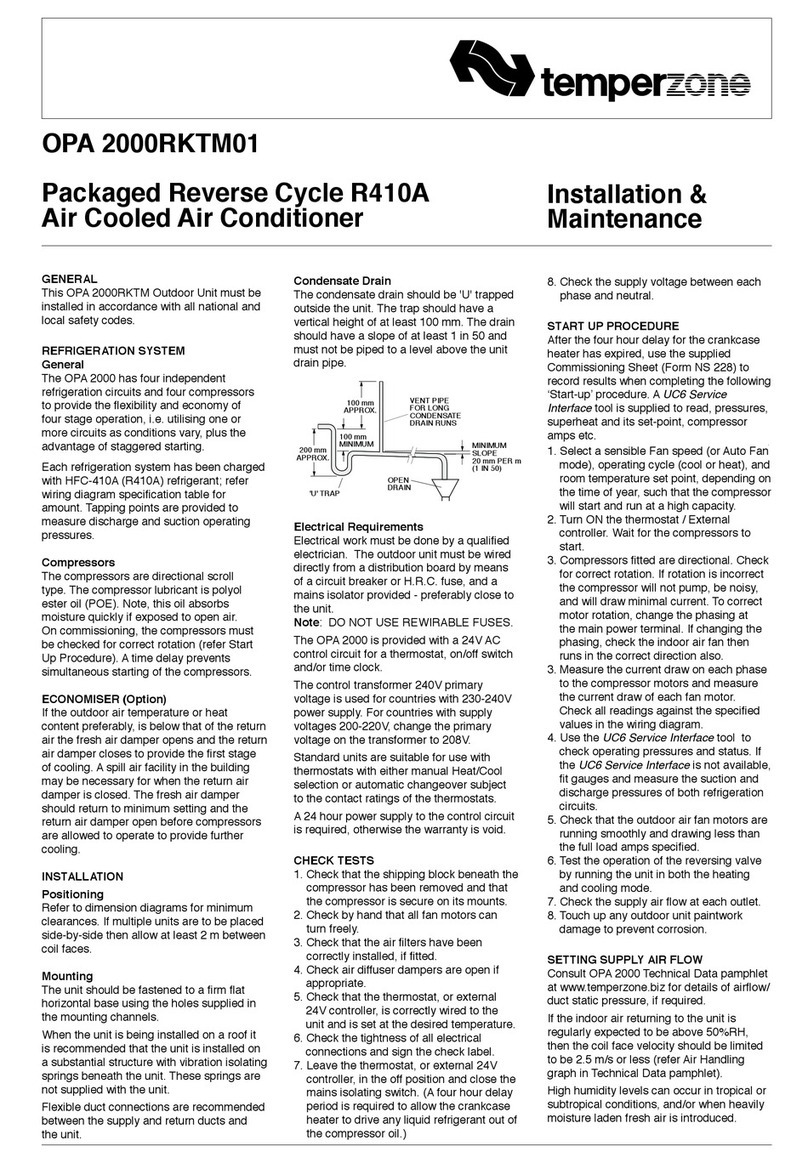

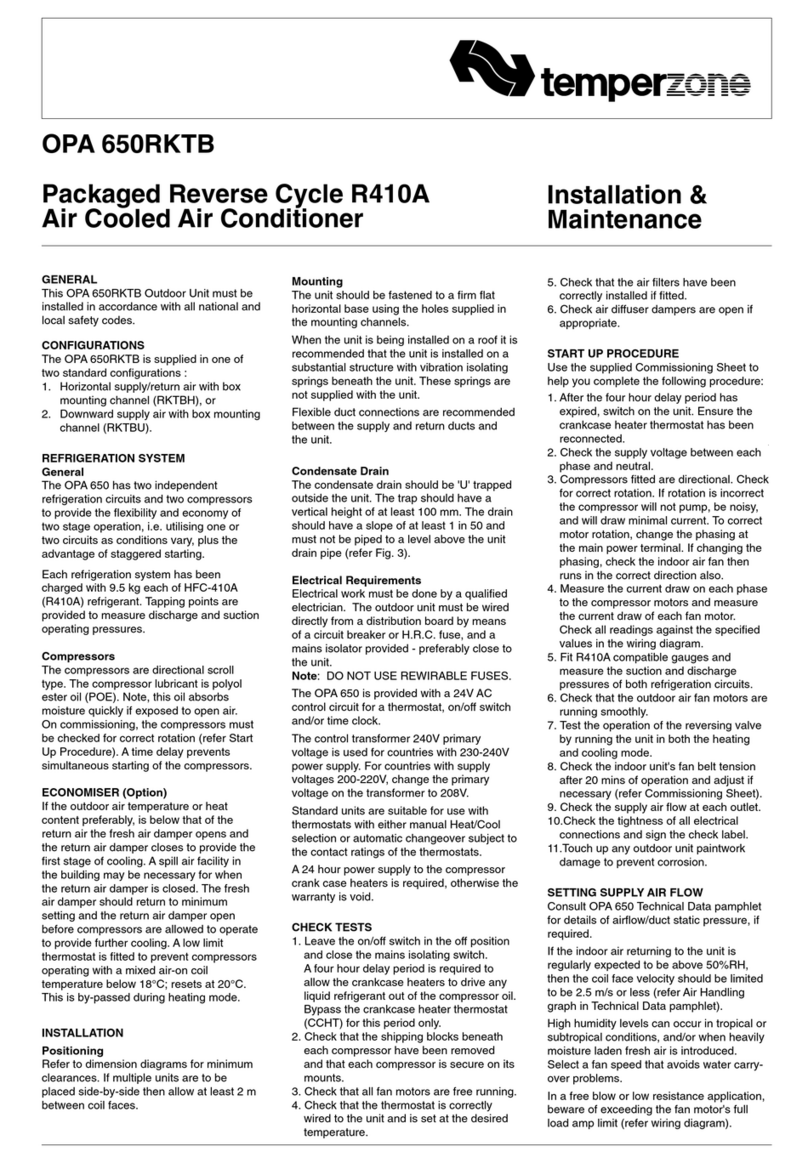

The condensate drain should be 'U' trapped

outside the unit. The trap should have a

vertical height of at least 100 mm. The drain

should have a slope of at least 1 in 50 and

must not be piped to a level above the unit

drain pipe (refer Fig. 3).

Electrical work must be done by a qualied

electrician. The outdoor unit must be wired

directly from a distribution board by means

of a circuit breaker or H.R.C. fuse, and a

mains isolator provided - preferably close to

the unit.

: DO NOT USE REWIRABLE FUSES.

The OPA 550 is provided with a 24V AC

control circuit for a thermostat, on/off switch

and/or time clock.

The control transformer 240V primary

voltage is used for countries with 230-240V

power supply. For countries with supply

voltages 200-220V, change the primary

voltage on the transformer to 208V.

Standard units are suitable for use with

thermostats with either manual Heat/Cool

selection or automatic changeover subject to

the contact ratings of the thermostats.

A 24 hour power supply to the compressor

crank case heaters is required, otherwise the

warranty is void.

1. Leave the on/off switch in the off position

and close the mains isolating switch.

A four hour delay period is required to

allow the crankcase heaters to drive any

liquid refrigerant out of the compressor oil.

Bypass the crankcase heater thermostat

(CCHT) for this period only

2. Check that the shipping blocks beneath

each compressor have been removed

and that each compressor is secure on its

mounts.

3. Check that all fan motors are free running.

4. Check that the thermostat is correctly

wired to the unit and is set at the desired

temperature.

5. Check that the air lters have been

correctly installed if tted.

6. Check air diffuser dampers are open if

appropriate.

Use the supplied Commissioning Sheet to

help you complete the following procedure:

1. After the four hour delay period has

expired, switch on the unit. Ensure the

crankcase heater thermostat has been

reconnected.

2. Check the supply voltage between each

phase and neutral.

3. Compressors tted are directional. Check

for correct rotation. If rotation is incorrect

the compressor will not pump, be noisy,

and will draw minimal current. To correct

motor rotation, change the phasing at

the main power terminal. If changing the

phasing, check the indoor air fan then

runs in the correct direction also.

4. Measure the current draw on each phase

to the compressor motors and measure

the current draw of each fan motor.

Check all readings against the specied

values in the wiring diagram.

5. Fit R410A compatible gauges and

measure the suction and discharge

pressures of both refrigeration circuits.

6. Check that the outdoor air fan motors are

running smoothly.

7. Test the operation of the reversing valve

by running the unit in both the heating

and cooling mode.

8. Check the indoor unit's fan belt tension

after 20 mins of operation and adjust if

necessary (refer Commissioning Sheet).

9. Check the supply air ow at each outlet.

10.Check the tightness of all electrical

connections and sign the check label.

11.Touch up any outdoor unit paintwork

damage to prevent corrosion.

Consult OPA 550 Technical Data pamphlet

for details of airow/duct static pressure, if

required.

If the indoor air returning to the unit is

regularly expected to be above 50%RH,

then the coil face velocity should be limited

to be 2.5 m/s or less (refer Air Handling

graph in Technical Data pamphlet).

High humidity levels can occur in tropical or

subtropical conditions, and/or when heavily

moisture laden fresh air is introduced.

Select a fan speed that avoids water carry-

over problems.

In a free blow or low resistance application,

beware of exceeding the fan motor's full

load amp limit (refer wiring diagram).